Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

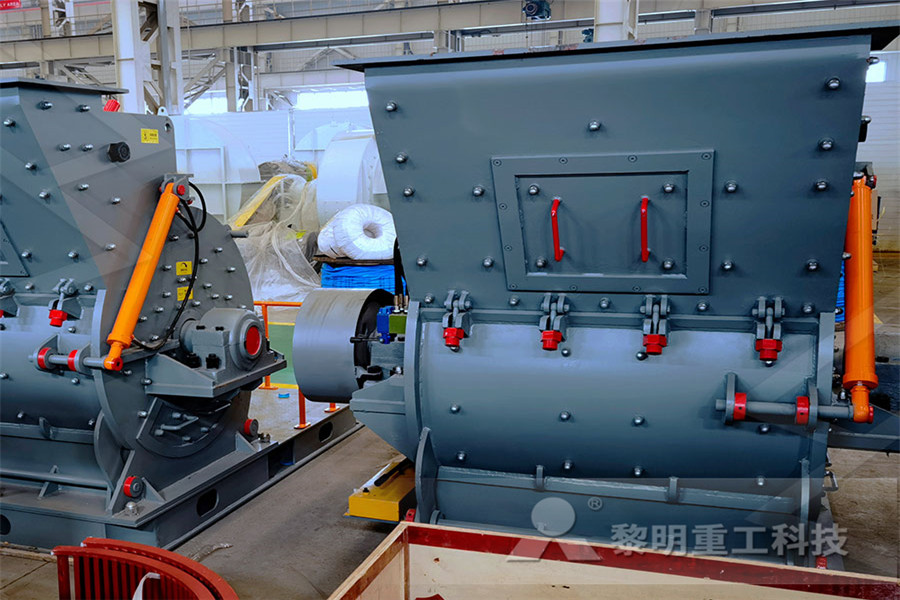

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

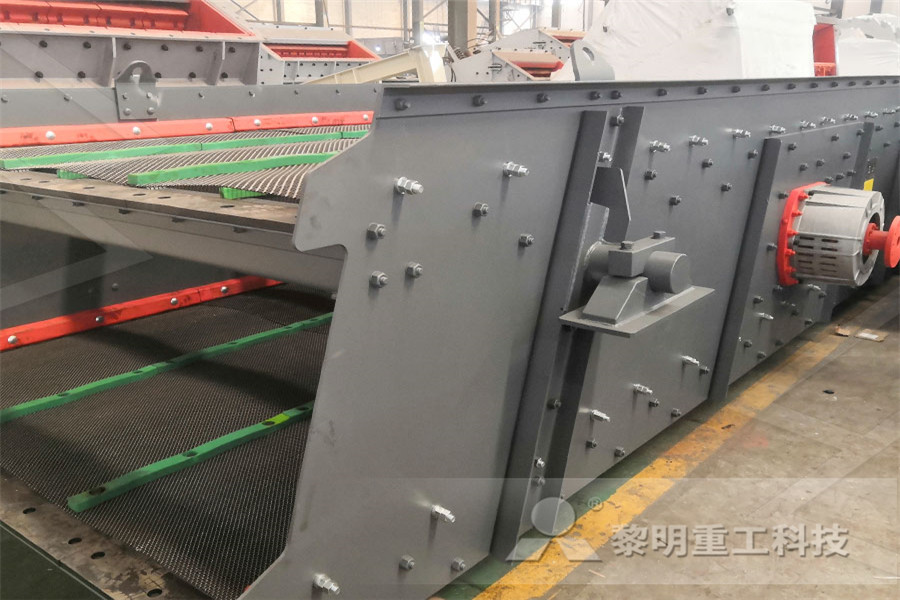

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Structural Design Condron Concrete

The required crushing strength of a concrete pipe can be calculated using the following equation Wt > (We x Fs) / Fm Where: Wt = required IS6 crushing load (kn/m), (Fn=Wt) We = Total applied load on the pipe (kn/m)Test strength of pipe (F n): The Structural design calculator test strength of a concrete pipe may be referred to as F c or F n Values are specified in BS 5911:2010 For a reinforced concrete pipe F c is the load which the pipe will sustain without developing a crack exceeding 030mm in width over a length of 300mm and F n is the load which the Structural Design Calculator Concrete Pipes BPDAThe required strength of the concrete pipe is determined from the effects of the bending moment, thrust, and shear in the pipe wall Wall thickness, concrete strength, and reinforcement design are evaluated using rational procedures based on strength and crack width limits that were developed in the ACPA longrange research programRecommendations for Design of Reinforced Concrete Pipe water absorption to material strength properties, such as splitting tensile strength or crushing strength It is unclear which material tests on core samples give the most representative results when compared with the ‘real’ structural strength of concrete sewer pipes Relating the structural strength of concrete sewer pipes Strength of pipes the crushing strength of sewer pipes is determined by the threeedge bearing testThe pipe is stressed until failure occursTable 3 gives the minimum crushing strength for clay pipesStrength requirements for reinforced concrete pipes are given in table 4, for this table the crushing force correspond to 0get priceminimum crushing strength of concrete pipes

ASTM C497 20e1 Standard Test Methods for Concrete Pipe

Abstract These test methods cover production and acceptance tests for concrete pipes, manhole sections, and tiles Tests include procedures for evaluating external load crushing strength, flat slab top, core strength, absorption, hydrostatic, permeability, manhole step, cylinder, gasket lubricant, joint shear, alkalinity, and gasket measurementsApr 13, 2018 Three edge bearing test is a destructive load test to determine the strength of a concrete pipeThree edge bearing test for reinforced concrete pipe YouTubeThe figures for Crushing Strength and Bending Moment Resistance (BMR) in BS EN 295 Part 1 have been established after extensive research into the loads imposed on buried vitrified clay pipelines The requirements for BMR have been set sufficiently high to ensure that pipes conforming to these, and used in a properly constructed pipeline Structural Design of Clay Pipes CPDAMar 01, 2009 Crushing Strength Equations for Pipe Crushing Strength Equations for Pipe tbird92 (Mechanical) (OP) 24 Feb 09 16:54 I am trying to find the right equations to calculate the crushing strenght, or the forces that will cause a pipe to fail, or buckle under a 2 point load Example: imagine a pipe Crushing Strength Equations for Pipe Pipelines, Piping of a bedding factor to relate the supporting strength of buried pipe to the strength obtained in a threeedge bearing test Spangler’s theory proposed that the bedding factor for a particular pipeline and, consequently, the supporting strength of the buried pipe, is dependent on two installation characteristics: 1Design Data 9 Concrete Pipe

ASTM C497 20e1 Standard Test Methods for Concrete Pipe

Abstract These test methods cover production and acceptance tests for concrete pipes, manhole sections, and tiles Tests include procedures for evaluating external load crushing strength, flat slab top, core strength, absorption, hydrostatic, permeability, manhole step, cylinder, gasket lubricant, joint shear, alkalinity, and gasket measurementsCONCRETE PIPE AND PORTAL CULVERT HANDBOOKpdf Rocla This handbook is intended to cover all aspects of concrete pipe and portal culvert selection, Pipes are classified in terms of their crushing strength >>GET MOREconcrete pipe crushing strength ermlimitedcozawater absorption to material strength properties, such as splitting tensile strength or crushing strength It is unclear which material tests on core samples give the most representative results when compared with the ‘real’ structural strength of concrete sewer pipes Relating the structural strength of concrete sewer pipes Strength of pipes the crushing strength of sewer pipes is determined by the threeedge bearing testThe pipe is stressed until failure occursTable 3 gives the minimum crushing strength for clay pipesStrength requirements for reinforced concrete pipes are given in table 4, for this table the crushing force correspond to 0get priceminimum crushing strength of concrete pipesApr 17, 2020 Concrete compressive strength for general construction varies from 15 MPa (2200 psi) to 30 MPa (4400 psi) and higher in commercial and industrial structures Compressive strength of concrete depends on many factors such as watercement ratio, cement strength, quality of concrete material, quality control during the production of concrete, pressive Strength of Concrete Cube Test, Procedure

CONCRETE PIPE AND PORTAL CULVERT HANDBOOK

Publications by the American Concrete Pipe Association have been used freely and acknowledgement is hereby made to this organisation The Pipes, Infrastructural Products and Engineering Solutions (PIPES) Division of the Concrete Manufacturers Association the crushing strength test to prove that they meet the strength required SI Pipes, on of a bedding factor to relate the supporting strength of buried pipe to the strength obtained in a threeedge bearing test Spangler’s theory proposed that the bedding factor for a particular pipeline and, consequently, the supporting strength of the buried pipe, is dependent on two installation characteristics: 1Design Data 9 Concrete PipeA GUIDE TO DESIGN LOADINGS FOR BURIED RIGID PIPES This guide examines the following aspects: loads on buried pipes (general principles of rigid pipe design, conditions of installation, fill load in narrow trench,fill load for positive and negative projection conditions, traffic and other transient surcharge loads, uniformly distributed surcharge loads of large and limited extent, water load A GUIDE TO DESIGN LOADINGS FOR BURIED RIGID PIPESASER Concrete Pipe Plant is located in Addis Ababa around Bole Bello area It has an average capacity of producing 25 different sizes of pipes per day Assisted by skilled professionals, our Concrete Pipe products are composed of high quality ingredients so as to ensure maximum strength and durabilityConcrete pipe plant – ASER CONSTRUCTIONTable 9 Results of pipe crushing tests for pipes with hybrid 2002), the crushing strength of circular pipes is tested as shown in Figure 1 Figure 1 Arrangement for crushing test on circular pipes (British Standards Institution, 2002, p 50) For steel fibre reinforced concrete pipes, the crushing load shall be taken to the specified proof SFRC JACKING PIPE DESIGN

Chapter 7 Concrete Pipes ScienceDirect

Jan 01, 1981 HFKennison, Design of prestressed concrete cylinder pipe, JAm Water Works Assn, 42 (Nov, 1950) 127 L I S T OF SYMBOLS A cross sectional area inside diameter outside diameter distance from centre of gravity modulus of elasticity stress (compressive o r tensile) crushing strength of 150 m cubes at 28 days moment of inertia factor of For Reinforced Concrete Pipe, any rate of load application up to a maximum of 7500 lbf/lineal foot of pipe per minute shall be used up to 75% of the specified design strength, at which time the rate of loading shall be reduced to a maximum uniform rate of 1/3 of 12 Pipe Testing R Kistler Revisions January 2015Subscribe to my Channel All About Civil Engineer https://youtube/c/AllAboutCivilEngineer Like us on Facebook All About Civil Engineer https://facLoad Crushing Strength Test by Three Edge Bearing Method CONCRETE PIPE AND PORTAL CULVERT HANDBOOKpdf Rocla This handbook is intended to cover all aspects of concrete pipe and portal culvert selection, Pipes are classified in terms of their crushing strength >>GET MOREconcrete pipe crushing strength ermlimitedcozaThe standard crushing load strength designation is the Dload (diameter load) This is the proof load in kilonewtons per metre of pipe length, per metre of nominal pipe diameter The standard Dload classes with their proof and ultimate loads are given in Table 1CONCRETE PIPE AND PORTAL CULVERT HANDBOOK

Chapter 7 Concrete Pipes ScienceDirect

Jan 01, 1981 The strength is defined in British Standard 556 as that load which (0025 mm) wide crack load for prestressed cylinder type concrete pipesStructural Design Condron Concrete The required crushing strength of a concrete pipe can be calculated using the following equation Wt > (We x Fs) / Fm Where: Wt = required IS6 crushing load (kn/m), (Fn=Wt) We = Total applied load on the pipe (kn/m) Fs = Factor of safety (125 MINIMUM) Fm = the bedding factorconcrete pipe crushing strength recycling systemFor steel fibre reinforced concrete pipes, the crushing load shall be taken to the specified proof load, held for one minute, and the pipe inspected for any crack The result of that inspection shall be recorded If no crack is found the load shall then be taken to the ultimate (collapse) load and a record made of that loadSFRC JACKING PIPE DESIGNAbstract These test methods cover production and acceptance tests for concrete pipes, manhole sections, and tiles Tests include procedures for evaluating external load crushing strength, flat slab top, core strength, absorption, hydrostatic, permeability, manhole step, cylinder, gasket lubricant, joint shear, alkalinity, and gasket measurementsStandard Test Methods for Concrete Pipe, Concrete Box Pipes are classified in terms of their crushing strength when subjected to a vertical knifeedge testload The two alternative crushing load test configurations are shown in Figure 1 (a) (b) FIGURE 1: CRUSHING LOAD TEST CONFIGURATIONS FOR CONCRETE PIPE The three edgebearing test is preferred as the pipe is firmly held in place by the bottomCONCRETE PIPE AND PORTAL CULVERT HANDBOOK

PIPE STIFFNESS AND DEFLECTION TESTING OF COILABLE

Crush Strength implies a brittle failure when compressed, such as buckling or cracking of the pipe wall, whereas flexible piping materials such as HDPE can actually deflect in excess of 25 % with no signs of wall buckling, cracking or splittingThe fibre reinforced concrete pipes have normally their mechanical behaviour verified through crushing test that follows a cycled procedure This test is crucial to verify if the pipe fit the (PDF) A new approach on crushing strength test for fibre The newcomer, which gives your concrete pipe uplift Today, it is normal to use either rollin type or sliding ring joints on concrete pipes Both of them have wellknown advantages as well as disadvantages But the demands for tightness and strength of pipe systems have been increased, however The inventor of the brilliant LamellCONCRETE PIPESSpecifications Product Type: Perforated Concrete Pipe Nominal Diameter: 300mm Effective Length: 1250mm Socket Diameter: 480mm Barrel Diameter: 410mm Angular Defection: 240 degrees Joint Type: Integral Seal Approx Weight: 217kg This 300mm diameter perforated concrete pipe is designed to transport and distribute storm water into a rock filled trench and eventually into the surrounding area 300 x 1250mm Perforated Concrete Pipe JDPOct 28, 2013 A typical concrete compressive strength specification requires 4,000 to 5,000 psi at 28 days Some go a step further and mandate that concrete products cannot be installed or used until 28 days after the date of manufactureThe 28Day Myth National Precast Concrete Association