Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

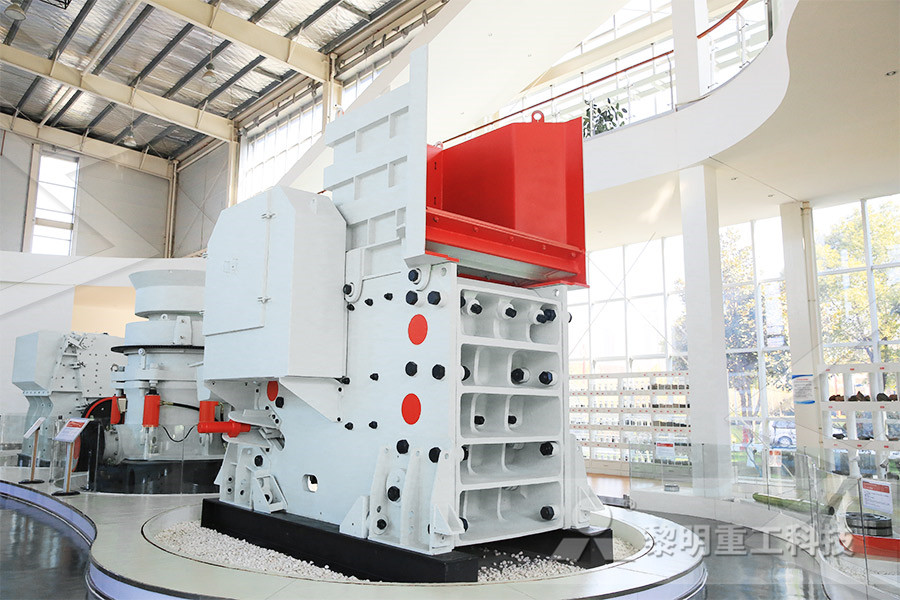

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

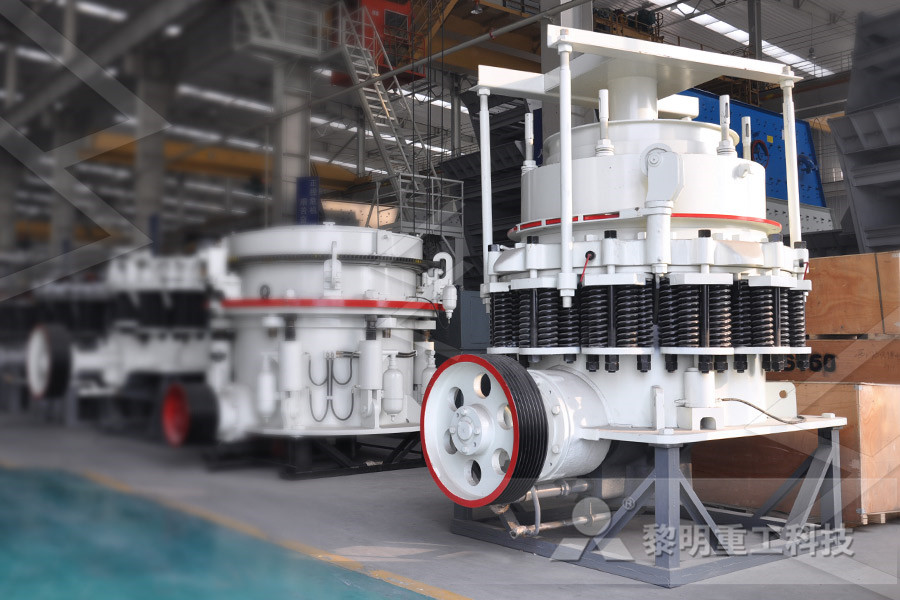

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Cement Grinding Mill Project YouTube

Dec 10, 2013 The perfect end for a successfully Project Story Cemengal shows here the last movie about the project for Cement Australia in Port Kembla Cemengal has accoMar 02, 2017 From the pioneer and pacemaker in grinding The intelligent concept of LOESCHE's CCG Plant enhances your flexibility during operation You can process all kiLOESCHE Compact Cement Grinding Plant (CCG Plant) YouTubeHow to diamond grind a concrete floor to the correct concrete surface profile required before installation of an epoxy or urethane coating https://foundHow To Diamond Grind A Concrete Floor YouTubeMar 13, 2013 for more how to concrete videos howtocement/HowToGrindConcreteGrindingCementhtmlthanks to OhioConcreteRepair for providinHow to grind a Concrete Trip Hazard, Fix Raised YouTubeMar 09, 2018 "Electronic ear" is not "electronic ear"! It is time to make clear that there are fundamental differences between electronic filllevel measurement systems fMillMaster + SmartFill for ball mills youtube

The OK™ mill YouTube

Jun 07, 2018 The OK mill has been ’s standard cement vertical roller mill (VRM) since 1993 In 2017, also introduced the OK raw mill for raw material griNov 23, 2020 These benefits of cement grinding aid use also contribute to lower energy costs on the part of industrial mills Grinding aid is a chemical agent used to make it easier to grind and mix cement The grinding aid began to gain popularity in the mid20th century as a reliable tool for cement What is a Grinding Aid? (with picture)The cement grinding is an energy intensive process The addition of grinding aid during the process of cement grinding, results in improvement of the specific surface and grindability of the material ground This is attributed to the additive’s ability to reduce resistance to comminution and to prevent agglomeration of the freshly ground Cement Grinding Aids Penta ChemHow to diamond grind a concrete floor to the correct concrete surface profile required before installation of an epoxy or urethane coating https://foundHow To Diamond Grind A Concrete Floor YouTubeThe use of a good Cement clinker grinding aid can be vital in today’s increasing material demands Along with the obligation to process increasingly larger quantities of ores containing finely disseminated minerals, our limited energy resources and the rising costs of energy present a challenge to the process engineer One research route that has been explored for about half a century is the Cement Clinker Grinding Aids

Concrete densifier and grinding aid PROSOCO First Cut

Grind and densify concrete in one consolidated, easy step with PROSOCO First Cut with Densifier, makes wetgrind and powertrowel polishing jobs 40% fasterGrinding aids are organic compounds that are added to the mill during cement grinding Their main purpose is to reduce the energy required to grind the clinker into a given fineness In addition, some products (usually referred to as performance enhancers) provide positive effect on cement hydration improving strength development [1]Grinding aids for high performance cementsThe increase will increase the fluidity of the cement (2) The amount of grinding aid The actual amount of grinding aid is generally low, depending on the type of grinding aid and the grinding aid efficiency, which is about 001% to 010%, which is less than the standard limit of 05% Each grinding aid has its optimum dosage rangeCement grinding aids for cement production and grinding aidMay 11, 2015 a grinding mill which consumes 6070% of the total electricity consumption of the cement plant[12] A grinding mill (Ball Mill) is used to grind the cement clinker into fine cement powder Grinding Aids are used to improve the grinding efficiency and reduce power consumption This paper discusses the grinding aids mechanism andGrinding Aids for Cement SlideShareTo clean the mill from remaining grinding aid, the mill was run blank in between It took up to 90mins to come back to the base line The chemical structure of the added grinding aids was previously carefully selected, based on practical experiences in industrial VRMs, in combination with new moleculesProgress with grinding aids for VRMs Global Cement

(PDF) Effect of Grinding Aids in Cement Grinding

Jul 23, 2020 In the grinding of cement clinker, gypsum also acted as a very effective grinding aid The action of these additives has been attributed to their ability to prevent agglomeration and ball and mill cement grinding aid has become one of the mainstream of the cement industry Composite cement grinding aid is by a variety of single component and grinding aid distribution, and the interaction of different monomer component, to make composite grinding agent has good grinding effect, good stability, wide adaptability of multiple effect 2 The Effect on the Performance of Cement Grinding Aid Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 % It is somewhat surprising that the number of different grinding processes and mill types used by the Grinding trends in the cement industry Cement Lime GypsumJul 18, 2016 Operation and Elements of a Closed Circuit Ball Mill System Cement ball mills typically have two grinding chambers The first chamber is filled with larger diameter grinding media and lined with lifting liners The first chamber coarsegrinds the feed material and prepares it for the second chamber The second chamber is the fine grinding chamberOptimization of Cement Grinding Operation in Ball Mills grinding aid aid composition weight percent glycol cement Prior art date Legal status (The legal status is an assumption and is not a legal conclusion Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed) Abandoned Application number US14/410,316 Inventor Ritesh Gulabani USA1 Cement grinding aid composition Google

Cement grinding aids GCPAT

TAVERO® grinding aids make life easier for busy cement producers Our grinding aids are designed to increase mill output without increasing costs, while saving energy and reducing CO 2 emissions Improved cement flowability reduces the effort for handling and transporting cementCement grinding aid Description: Our cement grinding aids is composed of various organic polymer main amines cement grinding aid raw materail It is nontoxic, noncorrosive, and could effective increase cement performance The product can increase efficiency of cement grinding system, increase hourly output of cement grinding mill, improve hydrating capacity of cement, increase cement Cement Grinding Aid Buy Cement Grinding Aid, Vertimal How to diamond grind a concrete floor to the correct concrete surface profile required before installation of an epoxy or urethane coating https://foundHow To Diamond Grind A Concrete Floor YouTubeGrinding aids are organic compounds that are added to the mill during cement grinding Their main purpose is to reduce the energy required to grind the clinker into a given fineness In addition, some products (usually referred to as performance enhancers) provide positive effect on cement hydration improving strength development [1]Grinding aids for high performance cementsTo clean the mill from remaining grinding aid, the mill was run blank in between It took up to 90mins to come back to the base line The chemical structure of the added grinding aids was previously carefully selected, based on practical experiences in industrial VRMs, in combination with new moleculesProgress with grinding aids for VRMs Global Cement

Cement grinding aids for cement production and grinding aid

The increase will increase the fluidity of the cement (2) The amount of grinding aid The actual amount of grinding aid is generally low, depending on the type of grinding aid and the grinding aid efficiency, which is about 001% to 010%, which is less than the standard limit of 05% Each grinding aid has its optimum dosage rangecement grinding aid has become one of the mainstream of the cement industry Composite cement grinding aid is by a variety of single component and grinding aid distribution, and the interaction of different monomer component, to make composite grinding agent has good grinding effect, good stability, wide adaptability of multiple effect 2 The Effect on the Performance of Cement Grinding Aid Feb 15, 2019 This research focuses on investigating the effects of the three different grinding aids, consisting of a mixture of amine, glycol and polyol in different ratios, on the model parameters of a twocompartment cement ball mill and an air classifierEffects of grinding aids on model parameters of a cement Cement grinding aid Description: Our cement grinding aids is composed of various organic polymer main amines cement grinding aid raw materail It is nontoxic, noncorrosive, and could effective increase cement performance The product can increase efficiency of cement grinding system, increase hourly output of cement grinding mill, improve hydrating capacity of cement, increase cement Cement Grinding Aid Buy Cement Grinding Aid, Vertimal grinding aid aid composition weight percent glycol cement Prior art date Legal status (The legal status is an assumption and is not a legal conclusion Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed) Abandoned Application number US14/410,316 Inventor Ritesh Gulabani USA1 Cement grinding aid composition Google

Cement grinding aid characteristics SHIJIAZHUANG CITY

Cement grinding aid characteristics A grinding aid is a surfactant that can improve the grinding environment The common grinding aid is to improve the grinding effect by improving the viscosity of the material in the mill, the dispersion of the particles and the flow state of the slurryJul 18, 2016 Operation and Elements of a Closed Circuit Ball Mill System Cement ball mills typically have two grinding chambers The first chamber is filled with larger diameter grinding media and lined with lifting liners The first chamber coarsegrinds the feed material and prepares it for the second chamber The second chamber is the fine grinding chamberOptimization of Cement Grinding Operation in Ball Mills For each experiment, 3000 g of clinker was weighed, and then the grinding aid + boron compound was added to give a total weight of 01% cement, and mixed well The laboratory type ball mill was loaded with clinker and grinding aid mixture and operated for 40 minutes Samples were taken from the stopped mill, and the SO 3 level was checkedEffects of Adding Boron Compounds to Glycol Based Grinding They work as a binder to insure the cohesion of pressed pellets, but also act as a grinding aid by minimizing the risk of sample sticking to the elements of the grinding vessel This grinding aid action also reduces the need for cleaning the grinding elements This Grinding and Pelletizing / Tabletting Aid XRF BinderNonball mill systems such as vertical mills also benefit from dry dispersion of cement additives Grinding additives assist with deaeration in front of the grinding roll, which allows for smoother operation (less vibration) as well as better dispersion at the nozzle ring and in the separator, resulting in less fines in the grinding bed on the Optimizing cement grinding with chemical additives

CEMENT GRINDING AID COMPOSITION Dow Global

Advantageously, the grinding aid composition minimizes the agglomeration of cement particles as well as their adherence to the surface of grinding media (eg, steel balls used in a grinding mill) thereby improving the energy and comminution efficiency of the grinding process