Solutions

Products

-

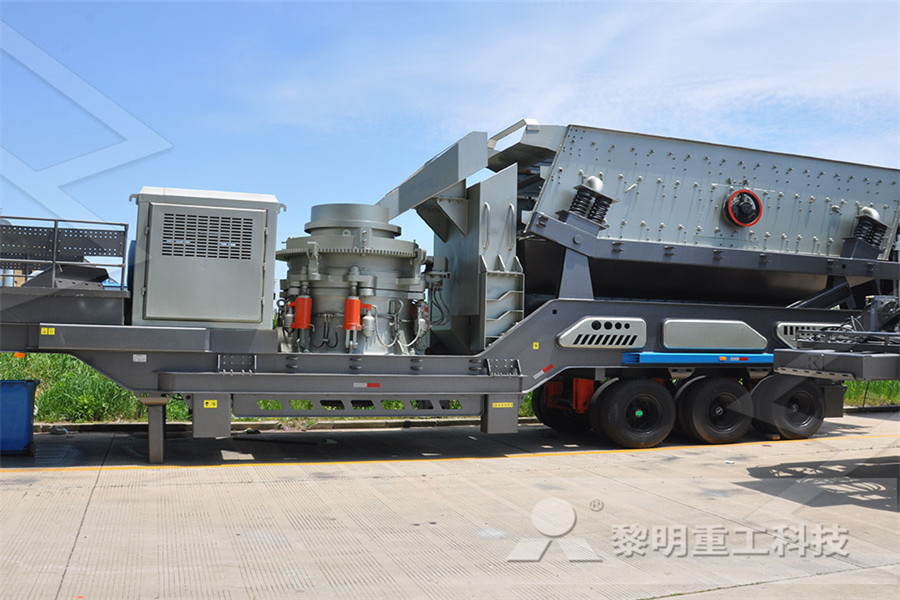

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

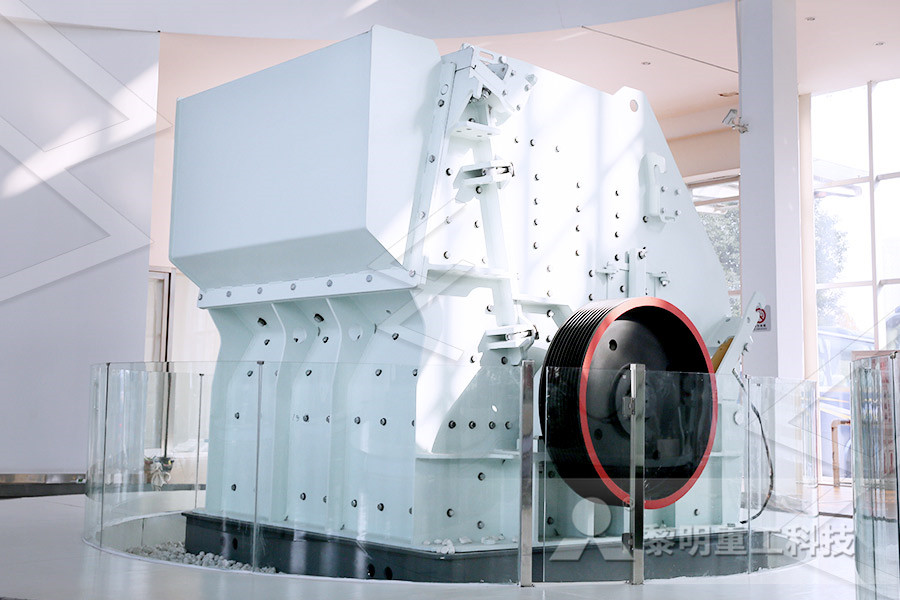

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Copper Electrolysis Refining Plant, Purification of Copper

The refining anodes taken out from the refining furnace is changed into electrolytic copper with purity of 9999% through an electrolysis process: During electrolysis, copper (II) ions leave the impure copper anode and since they are positive, migrating to the negative cathode From time to time, the pure copper Electrolytic Copper Refining Plant Copper electrorefining entails electrochemically dissolving copper from impure copper anodes into an electrolyte containing CuSO4 and H2SO4, and selectively electroplating pure copper from this electrolyte without the anode impuritiesElectrolytic Copper Refining Plant Italimpianti OrafiSemiconductor packaging uses copper electroplating in several important applications: dual damascene process, throughsilicon vias (TSV), copper pillars, and copper redistribution layers (RDL) In each case, feature geometry as well as plating time affect how additives behaveCopper electroplating fundamentals DuPontDec 16, 2012 copper ore electroplating plant Posted at:December 16, 2012[ 46 1359 Ratings] mini chrome ore crushing and plating plant in Haiti chrome plating plant chrome ore plant chrome ore plant types of applications like iron ore, copper, gold ore, manganese ore, chrome copper ore electroplating plant MiningA typical overall view of a tin plating plant with both rack and barrel plating capabilities Electroplating line for tin with barrels and process tank equipment visible Electroplating tanks and equipment for copper, nickel and chrome platingAutomated Electroplating and Coating Plants Galvatek

Copper recovery using leach/solvent extraction

Most copper SX plants built in the past 25 years are of the low profile design Typically, copper SX plants are designed so that the dispersion exits the mixer directly into the mixer end of the settler with the flow of the phases away from the mixerProfessional electroplating requires specialized chemicals and equipment to make a highquality coat, but in this project you can try your hand at a simple procedure that will transfer copper (a versatile, naturallyoccurring metal) to a brass keyElectroplating: CopperPlated Key Home Science ToolsNov 05, 2012 1996 A Hi, Miss Sae According to the Electroplating Engineering Handbook, commercial electropolishing of copper is done in phosphoric acid, or modified phosphoric acid (US Patent 2,366,714) or phosphoricchromic acid (US Patent 2,347,039) According to the Metals Handbook, phosphoricchromic acid is used at 18V and 3040 A/dm2 (much higher than you are Electropolishing of copper QA'sSep 06, 2018 Copper Plating Solution but real, robust, electroplating and electroforming isn't done from homebrews of kitchen or commodity chemicals Rather we let specialists carefully formulate electroplating solutions with the proper copper concentration and acid ratio, and which include that hocuspocus of levelers, brighteners, surfactantsHow to Electroplate small nonconductive items: Flowers Apr 14, 2020 Connect the copper to the positive terminal of the battery Using an alligator clip, attach the positive terminal of the battery to the piece of copper If you clip the copper piece to the wrong terminal, the electroplating will not work On a standard 6volt battery, the positive terminal is the male side of the batteryHow to Electroplate Household Metals (with Pictures) wikiHow

Electrolytic Copper Refining Plant Italimpianti Orafi

Electrolytic Copper Refining Plant Copper electrorefining entails electrochemically dissolving copper from impure copper anodes into an electrolyte containing CuSO4 and H2SO4, and selectively electroplating pure copper from this electrolyte without the Semiconductor packaging uses copper electroplating in several important applications: dual damascene process, throughsilicon vias (TSV), copper pillars, and copper redistribution layers (RDL) In each case, feature geometry as well as plating time affect how additives behaveCopper electroplating fundamentals DuPontApr 12, 2016 Welcome to science at home in this experiment we are exploring copper electroplating by coating a nail with copper Copper electroplating requires electrictyCopper Electroplating The Sci Guys: Science at Home Most copper SX plants built in the past 25 years are of the low profile design Typically, copper SX plants are designed so that the dispersion exits the mixer directly into the mixer end of the settler with the flow of the phases away from the mixerCopper recovery using leach/solvent extraction Professional electroplating requires specialized chemicals and equipment to make a highquality coat, but in this project you can try your hand at a simple procedure that will transfer copper (a versatile, Electroplating: CopperPlated Key Home Science Tools

Electroplating an overview ScienceDirect Topics

Major compositions of the (A) dehydrated copperbearing electroplating sludge and (B) 900°C sintered chromite ore processing residue (COPR) used in the study The elemental compositions of the sludge were analyzed by XRF and expressed as the basic oxide forms Fig 2 XRD pattern of the dehydrated copperbearing electroplating 68 Copper plating tank parameters 69 Air sampling results copper plating • 610 Nickel plating parameters • • 611 Air surveys of approximately 30 electroplating plants, and 9 indepth surveys at B electroplating plants Preliminary surveys were conducted to further identify control methods, select plant Control Technology Assessment: Metal Plating and the removal of copper and chromium present in the composite wastewater The study revealed that activated alumina performed very well as the adsorbing media for the removal of both chromium and copper IIELECTROPLATING UNIT UNDER THE PRESENT STUDY The Study was performed with the effluent from rinsing tank of electroplating plant Treatment of Electroplating Wastewater by Adsorption The former Copper Cliff iron ore recovery plant, located across the highway from Vale's current headquarters, is being demolished The company says the building will be gone by the end of 2018Demolition of Copper Cliff iron ore recovery plant The aim of this study was the recovery of copper from the oxide copper ore by froth flotation and agitating sulphuric acid (H 2 SO 4) leaching The ore with 421% copper grade used in this study was obtained from ÇorumDangaz region of Turkey Native copperRECOVERY OF COPPER FROM OXIDE COPPER ORE BY

From Ore to Finished Product Copper

Copper From Beginning to End Copper is a major metal and an essential element used by man It is found in ore deposits around the world It is also the oldest metal known to man and was first discovered and used about 10,000 years ago And as alloyed in bronze (copper Sep 11, 2019 The Ore Washing Plant is a machine added by IndustrialCraft 2, used to convert Crushed Ore into Purified Crushed Ore Each process takes about 20 seconds, and consumes 16 EU/t (about 6400 EU total) and 1000 mB of WaterThe Ore Washing Plant Ore Washing Plant (IndustrialCraft 2) Official Feed The Copper plating and copper sheathing were widely used to protect the underwater hulls of ships, a technique pioneered by the British Admiralty in the 18th century The Norddeutsche Affinerie in Hamburg was the first modern electroplating plantCopper WikipediaNov 25, 2019 However, Luigi Brugnatelli did write about electroplating in the Belgian Journal of Physics and Chemistry, "I have lately gilt in a complete manner two large silver medals, by bringing Electroplating: History and Timeline ThoughtCoconductivity of copper, and the ease of mechanical working and brazing Brass can be cast readily into intricate shapes and is used for many cast products having utilitarian or decorative applications The ease of chrome plating brass has diversified the use of copper Electrorefining of Copper

Copper Sulphate Crystallisation Plants at Remote Ore

Copper Sulphate Crystallisation Plants An alternative processing route ore that provides competitive advantage a to other conventional mineral processing is proposedtechnologies The processing facility produces copper sulphate maintaining favourable copper plating For plants with a daily flow of 38,000 liters (10,000 gallons) per day or more, the pretreatment standards specifically limit indirect discharges of cyanide and the following metals: lead, cadmium, copper, Electroplating Effluent Guidelines US EPARecovery of copper from CuSO4 as a science experiment 2001 Q To whom it may concern, I am a GNVQ intermediate science student I am doing an assignment, and the scenario for this assignment is: 'The chemical plant produces as a byproduct a solution of copper sulphate, I am required to investigate the recovery of the copper Recovery of copper from electroplating and etching solutions