Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

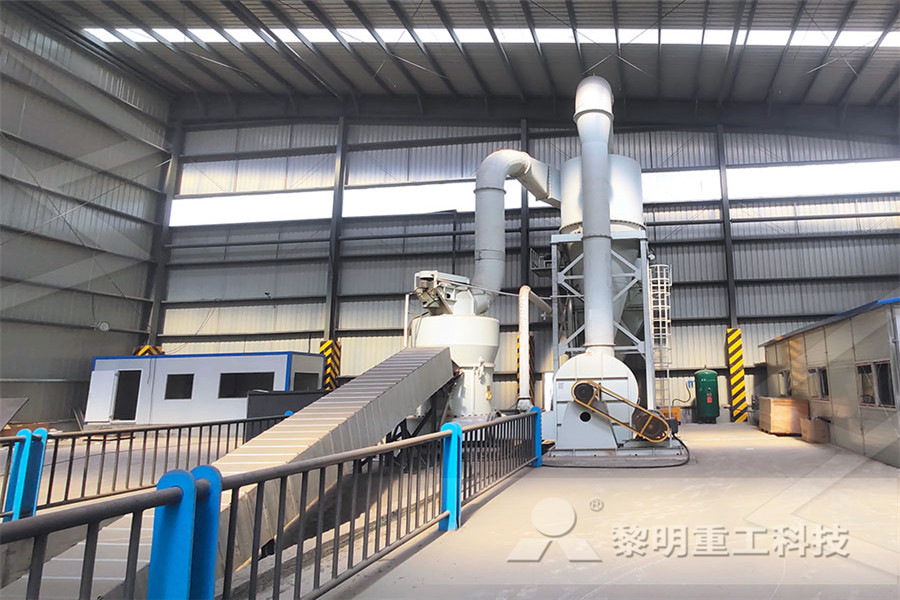

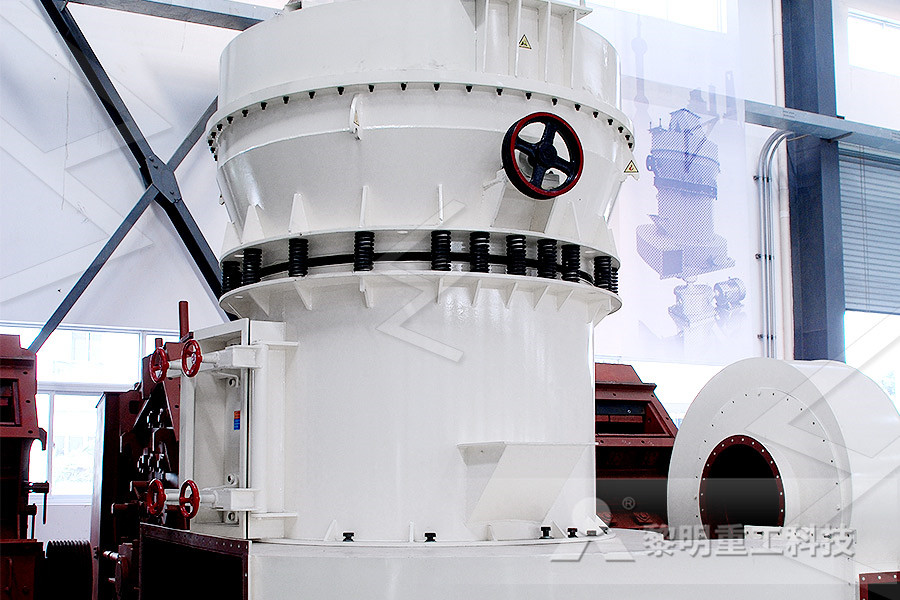

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Aggregate Production Process Cornerstone Aggregates Inc

Aggregate Production Process Our Crushing Plant is now considered the most reliable plant in CALABARZON, specifically Batangas The plant is located at Brgy Lucsuhin, Calatagan, Batangas, Philippines QUARRYING This is an essentials stage in the production process, because the quality of the aggregates produced depends on it This is our AGGREGATE PRODUCTION This chapter discusses the total process of aggregate production from extraction through processing Also discussed is the handling, stockpiling, and shipping of the product up to the point where the material leaves the Producer's 5 Aggregate Production INgovThe aggregate manufactured by RTAL of Tilbury in Essex, UK, is based on a mixture of pulverised fuel ash, clay and MIBA (Cresswell, 2007)The manufacturing process of this aggregate involves agglomeration in a slightly moist environment on an inclined rotating panManufactured Aggregate an overview ScienceDirect TopicsAggregate production plans facilitate matching of supply and demand while reducing costs Process of Aggregate production planning applies the upperlevel predictions to lowerlevel, productionfloor scheduling and is most successful when applied to periods 2 to 18 months in the futureAggregate Production Planning, Aggregate Planning Process Hydrated Lime Manufacturing Process Aggregate Crushing Hydrated Lime Manufacturing Process Quick lime raw material, by the loader to join in the bin and join the rest of the E crusher by vibrating feeder evenly broken from around 3050 mm, dust produced in the process of broken by induced draft fan through the upper E crusher dust hood to workshop external pulse bag dust collector, the The Process Of Manufacturing Aggregate Stone Crusher

1120 Lightweight Aggregate Manufacturing

11201 Process Description1,2 Lightweight aggregate is a type of coarse aggregate that is used in the production of lightweight concrete products such as concrete block, structural concrete, and pavement The Standard Industrial Classification (SIC) code for lightweight aggregate manufacturing is 3295; there currently is no Source Dec 22, 2009 Constant production rates can be met by using subcontractors to provide extra capacity Aggregate Planning Guidelines The following are the guidelines for aggregate planning: Determine corporate policy regarding controllable variables Use a good forecast as a basis for planning Plan in proper units of capacity Maintain the stable workforceAGGREGATE PLANNING IN OPERATIONS MANAGEMENT in A process for manufacturing aggregate from the ash residues resulting from incineration of municipal solid waste Fly ash residue is added to bottom ash residue and oversized material is removed The combined ash residue is mixed and ferrous metal is magnetically removed The combined ash residue is comminuted and heavy metal immobilizing and volumetric stabilizing agents are addedUSA Process for manufacturing aggregate from ash A process for manufacturing aggregate as recited in claim 23, wherein the resulting mixture of said Portland cement, said water and said combined ash residue is retained for approximately twelve hours to eighteen hours to allow the immobilizing and stabilizing reactions to Process for manufacturing aggregate from ash residue Aggregate production functions are reducedform relationships that emerge en uses an aggregate production function with capital and labor to model the process of economic growth The debate kicked off with Joan Robinson’s 1953 paper criticizing the aggregate proThe Microeconomic Foundations of Aggregate Production

the process of manufacturing aggregate

The Aggregate Manufacturing Process General Kinematics For more than 50 years, General Kinematics has provided innovative vibratory equipment that is essential in the mining and aggregate manufacturing process A World of Minerals Most of the products we use every day are made with feldspar, the most abundant group of minerals in the earth’s the aggregate production plan is generated, constraints are imposed on the detailed production scheduling process which decides the speciflc quantities to be produced of each individual item The plan must take into account the various ways a flrm can cope with demand °uctuations as1 Aggregate Production Planning Columbia UniversitySep 04, 2009 The appellate court clarified that a manufacturing process must be considered in the aggregate, but the components of the process may also be individually considered Moreover, in considering whether an entity took adequate steps to protect its secrets, the court must focus on the steps the entity took instead of those it did not takeWhether a Manufacturing Process is a Trade Secret Must Be Aggregate supply will decrease The government relaxes pollution regulations on all manufacturing firms The determinant causing the shift in this scenario is government intervention A new process for producing glass revolutionizes the industry The determinant causing the shift in this scenario isAP Macro module 3 Flashcards QuizletProduction Process The raw material is processed by heating in rotary kilns at temperatures in excess of 2000° F under carefully controlled conditions The result is a structural grade ceramic lightweight aggregate that is screened to produce precise gradings required for use in asphalt surface treatments, structural lightweight concrete Lightweight Aggregate Production Process

Aggregate Planning Definition, Importance, Strategies

Aug 24, 2020 Definition: Aggregate planning is a planning method in the production process which is also considered a marketing activity used to determine the required resource capacity to meet expected demandAggregate planning The aggregate planning is done in advance of 6 – 18 months and includes a combination of subcontracting, sourcing, outsourcing, employment, labor overtime, Mainly used in the construction of road surfaces, they are essential for the manufacture of concrete Today, Vicat produces and markets more than 24 million Aggregate: the essential for the manufacture of concrete A process for manufacturing aggregate from the ash residues resulting from incineration of municipal solid waste Fly ash residue is added to bottom ash residue and oversized material is removed The combined ash residue is mixed and ferrous metal is magnetically removed The combined ash residue is comminuted and heavy metal immobilizing and volumetric stabilizing agents are addedUSA Process for manufacturing aggregate from ash A process for manufacturing aggregate as recited in claim 23, wherein the resulting mixture of said Portland cement, said water and said combined ash residue is retained for approximately twelve hours to eighteen hours to allow the immobilizing and stabilizing reactions to Process for manufacturing aggregate from ash residue Constant production rates can be met by using subcontractors to provide extra capacity Aggregate Planning Guidelines The following are the guidelines for aggregate planning: Determine corporate policy regarding controllable variables Use a good forecast as a basis for planning Plan in proper units of capacity Maintain the stable workforceAGGREGATE PLANNING IN OPERATIONS MANAGEMENT in Production

Outline Chapter 8: Aggregate Planning in the Supply Chain

Aggregate planning: – Is the process by which a company determines levels of capacity, production, subcontracting, inventory, stockouts, and pricing over a specified time horizon – goal is to maximize profit Or, if demand is effectively fixed for all theThe Aggregate Manufacturing Process General Kinematics For more than 50 years, General Kinematics has provided innovative vibratory equipment that is essential in the mining and aggregate manufacturing process A World of Minerals Most of the products we use every day are made with feldspar, the most abundant group of minerals in the earth’s the process of manufacturing aggregatethe aggregate production plan is generated, constraints are imposed on the detailed production scheduling process which decides the speciflc quantities to be produced of each individual item The plan must take into account the various ways a flrm can cope with demand °uctuations as1 Aggregate Production Planning Columbia UniversityExtensive drilling as well as regional geologic relationships demonstrate the uniformity of the shale and its extreme thickness, estimated to exceed 3,000 feet The quarry is assured of a longterm supply of uniform quality raw material to maintain the feed for high quality lightweight aggregate:: Production Process :: Norlite Lightweight AggregateIn many applications, we want to understand how the aggregate production function responds to variations in the technology or other inputs This is illustrated in Figure 169 An increase in, say, technology means that for a given level of the capital stock, more output is produced: the production function shifts upward as technology increasesThe Aggregate Production Function lardbucket

How to Develop an Aggregate Plan for Your Operations

Aggregate planning is an ongoing process A plan usually provides details at the monthly level over the course of a year, and you should update it as conditions change For example, you need to account for changes in expected demand as well as unexpected events such as material shortages and production aggregate is highly absorptive, the aggregate continues to absorb asphalt, after initial mixing at the plant, until the mix cools down completely This process leaves less asphalt for bonding purposes; therefore, a more porous aggregate requires more asphalt than a less porous aggregate3 Aggregate Properties INgov[Manufacturing Equipment] Figure 1 shows the flow sheet of an artificial lightweight aggregate manufacturing plant This plant is comprised of silos, feeders, conveyors, a mixer, a pantype pelletizer, a sinterstrand, a dust collector, and fans Figure 1: Flow sheet of artificial lightweight aggregate manufacturing process [Manufacturing Process]Artificial Lightweight Aggregate Manufacturing Process