Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

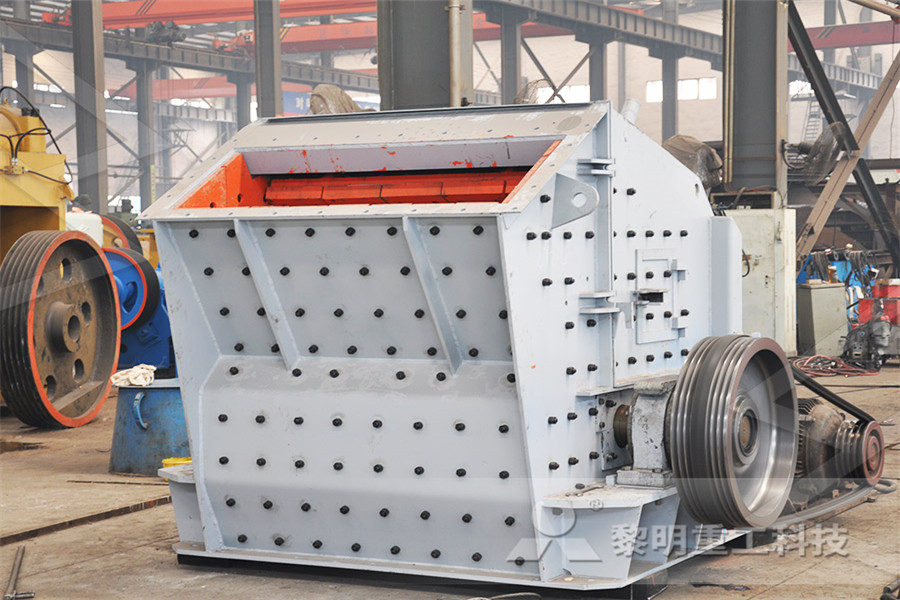

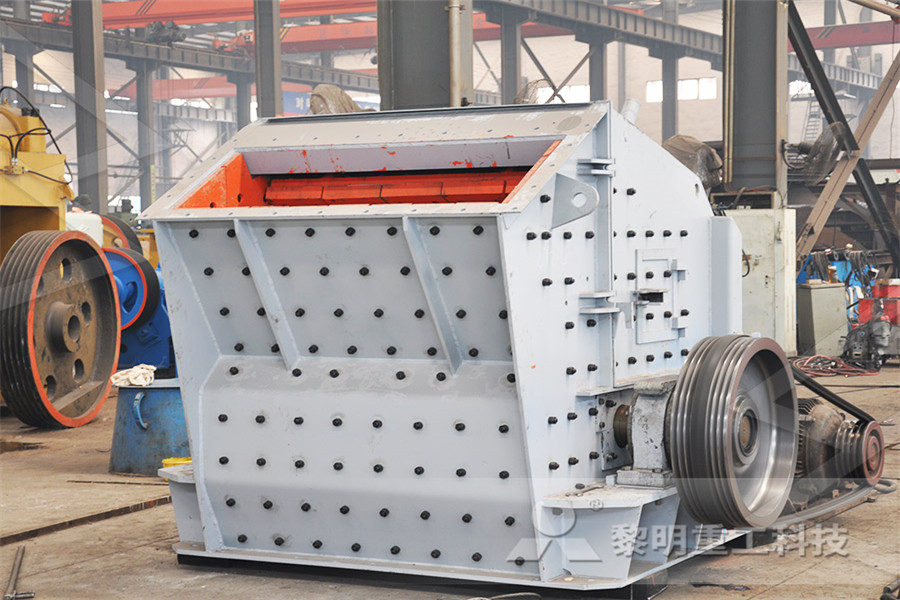

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Grinding aids for high performance cements

Cement Additives Division 1 Grinding aids for high performance cements MMagistri, PRecchi, Mapei SpA, Milan, Italy Introduction The interest in high performance cements has been growing in the last years, as a natural consequences of high performance concrete production Cement producers are requested to offerNov 12, 2019 Mapei also hosts an annual Cement Additives Seminar which is open to all cement producers and blenders; regardless of being a current customer or not Specialists and technical consultants from our CADD division in Milan come out to South Africa to interact, educate and present relevant content to the attendees about the Cement Additives industryAdvanced Additives from MAPEI are Improving the Quality of The effect of Grinding Additives is evident in all cases, especially in case of highBlaine CEM I and blended cements (CEM II as well as CEM III, CEM IV and CEM V cement types) The different grinding processes of vertical mills compared to tubular ball mills, have led to the development of a new generation of Cement Grinding AdditivesTechnical Notebook CEMENT ADDITIVES FOR VERTICAL MILLSCement grinding aid is designed to increase mill output and improve strength development in finished cement CGA (Cement Grinding Aid ) Description: HS CAG is a new generation cement grinding aid specially designed to increase mill output and obtain improved early strength development in finished cement As one admixture for cement product, it Cement Grinding Aid(cga) Buy Cement Grinding Aid(cga Dec 21, 2017 Grinding aids play a crucial role in the efficiency of the separator (the device that in modern cement grinding process allows obtaining a material with controlled fineness): and it is a useful method to study the interactions between cement additives and concrete admixtures Cement Additives Division, Mapei SpAThe cement industry and the most advanced analysis

Additives Made for Stronger Cement : PaintSquare News

Mapei says the additives promote sustainability in multiple ways The use of the additives reduces the energy needed in the grinding process, and reduces wear on grinding equipment The company also says the strengthening additives help achieve cement Cement Additives Division 1 “GREEN GRINDING: ENVIRONMENTAL PROTECTION AND COSTS SAVINGS THROUGH THE USE OF GRINDING AIDS IN THE CEMENT INDUSTRY” Matteo Magistri, Pietro Recchi, Mapei SpA, Milan, Italy Introduction Portland cement clinker is basically made by heating limestone and c lays to a 1450°C in a kiln“GREEN GRINDING: ENVIRONMENTAL PROTECTION AND CHRYSO is one of the world leaders in the development, manufacture and supply of chemical additives for concrete, cement and plaster Founded in 1942, CHRYSO is a technology leader who constantly develops innovative products, breaking technological barriers to add value to its customers’Additives for cementgrinding, and cement grinding is the most important process in the whole cement production However the fineness of cement grinding to a certain degree, there will be "reunion" phenomenon” this is because the cement produce electric charge in the process of grinding, the positive and negative charges on cement particle’s surface attract The Effect on the Performance of Cement Grinding Aid additives, a key issue to consider when evaluating the industrial application of ADITOR® M Stages in the ADITOR® M development project The work was structured in three main stages: Pilot plant scale trials: verification stage This involved the study of the performance of the new additives, as a grinding aid in a pilot plant cementLow Cost Grinding Aids for Cement

Advanced Additives from MAPEI are Improving the Quality of

Nov 12, 2019 Mapei also hosts an annual Cement Additives Seminar which is open to all cement producers and blenders; regardless of being a current customer or not Specialists and technical consultants from our CADD division in Milan come out to South Africa to interact, educate and present relevant content to the attendees about the Cement Additives industryCement grinding aid is designed to increase mill output and improve strength development in finished cement CGA (Cement Grinding Aid ) Description: HS CAG is a new generation cement grinding aid specially designed to increase mill output and obtain improved early strength development in finished cement As one admixture for cement product, it Cement Grinding Aid(cga) Buy Cement Grinding Aid(cga 3 Used as cement grinding aid early enhanced 3 ~ 5 mpa, the late 4 ~ 8 mpa 4 The molecular structure contains two kinds of alcohol and amine functional group at the same time, under some appropriate conditions can react with a variety of material generated ester, amide, salt, etcSpecifics of new generation cement grinding aid CGA raw additives, a key issue to consider when evaluating the industrial application of ADITOR® M Stages in the ADITOR® M development project The work was structured in three main stages: Pilot plant scale trials: verification stage This involved the study of the performance of the new additives, as a grinding aid in a pilot plant cementLow Cost Grinding Aids for CementProduct Description MYK Grind CAT 18 an aqueous solution of an amine salt withthe following Specification Specifications Specific Gravity1130 1160; Insoluble02% max; PH 8 10 @ 27 DegreeC Viscosity Maximum 30 Seconds using B4 Cup @ 27 DegreeC; Foaming Tendency None; MYK Grind CAT 18 is one of the most effective dispersants yet developed for use as a grinding aid for Portland cement Cement Grinding Aids Cement Grinding Additives

Cement Grinding Aids Penta Chem

Cement grinding aid adalah bahan tambahan dalam bentuk cair atau padat, yang ditambahkan/dicampur dalam jumlah kecil selama proses penggilingan klinker semen yang secara signifikan dapat meningkatkan efisiensi penggilingan dan mengurangi konsumsi energi, tanpa mengorbankan kualitas dari semenThe separate grinding of cement is a grinding technology that saves electricity (reduced electricity consumption) and reduces carbon consumption (reduced carbon emissions) In addition, it optimizes the performance of the cement and meets the different requirements of the user for cement performance (such as the water demand of cement)Grinding process and particle grading and water demand grinding, and cement grinding is the most important process in the whole cement production However the fineness of cement grinding to a certain degree, there will be "reunion" phenomenon” this is because the cement produce electric charge in the process of grinding, the positive and negative charges on cement particle’s surface attract The Effect on the Performance of Cement Grinding Aid We are distinctly reckoned in the Cement Additive for making available superior quality Cement Additive We have developed a new chemical Grinding Aid for Cement Additive Additive For Cement are an additive, which improve the quality of cement as increase the grinding efficiency It also increases the compressive strength of cementCement Additive Manufacturer,Cement Additive Supplier and The Commission Staff research found that the motivation for a cement company to intergrind 5% limestone (or in this case described as a blend of limestone, limestone dust and cement kiln dust — finished mill additives) is threefold: Replacing clinker with additives saves money since the additives are cheaper than the clinkerCement Industry Standard Practice to Add a Percentage of

Grinding Aids for Cement SlideShare

May 11, 2015 What are Grinding Aids? • Grinding mill grinds the hard clinker into fine cement powder • Additives used to improve the grinding efficiency of grinding mill • Improvement in grinding efficiency leads to reduction in electricity consumption 11052015 Indian Institute of Technology,Delhi 2 3 History of Grinding Aids • The history of Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 % It is somewhat surprising that the number of different grinding processes and mill types used by the Grinding trends in the cement industry Cement Lime Gypsum25 years in the cement industry supplying engineering and equipment for assembly and commissioning of clinker and slag Grinding Station, cement plants, metallic and concrete silos, vertical mills, horizontal mills, PLUGGRIND modular and portable grinding stations Modular and portable grinding station Plug and Grind The Cement Division of the Federation of Egyptian Industries is pursuing a variety of innovative measures to further reduce its carbon footprint, notably working with the Egyptian government, as well as regional and international institutions to create Egypt’s road map for CO2 reductionCement Industry Cement DivisionMAPEI Malaysia Sdn Bhd (MMSB) is a manufacturer and supplier of specialty chemicals for the building and construction industry MMSB was incorporated on 4 January 1992 and business activities started in the form of trading with 6 employeesMapei in Malaysia Mapei

Mapei in Malaysia

MAPEI Malaysia Sdn Bhd (MMSB) is a manufacturer and supplier of specialty chemicals for the building and construction industry MMSB was incorporated on 4 January 1992 and business activities started in the form of trading with 6 employeesWe first discuss cement production and special nomenclature used by cement industrialists in expressing the composition of their cement products We reveal different types of cement products, their compositions, properties, and typical uses Wherever possible, we tend to give reasons as to why a particular cement type is more suitable for a given purpose than other typesCement Types, Composition, Uses and Advantages of Grinding of cement clinker together with additives to control the properties of the cement (eg, fly ash, blast furnace slag, pozzolana, gypsum, and anhydrite) can be done in ball mills, roller mills, or roller presses Combinations of these milling techniques are often applied (see Table 2) Coarse material is separated in a classifier to be CARBON DIOXIDE EMISSIONS FROM THE GLOBAL CEMENT The cement manufacturing process involves three components: the mining and preparation of inputs; the chemical reactions that produce clinker; and the grinding of clinker with other additives to produce cement The feed for older kilns is a slurry of inputs, the wet kiln process, while large new plants mix dry materials for introduction to the Cement Industry an overview ScienceDirect TopicsJul 15, 2013 Cement industry has been always among the largest CO 2 emission sources Almost 5–7% of global CO 2 emissions are caused by cement plants, while 900 kg CO 2 is emitted to the atmosphere for producing one ton of cement In this work, global strategies and potentials toward mitigation of CO 2 emissions in cement plant have been discussed and the most promising Global strategies and potentials to curb CO2 emissions in

Port Kembla Grinding Mill ARA Electrical

The grinding mill itself was a joint venture between and Ecocem and Cement Australia ARA Electrical Engineering, in partnership with Mainteck Pty Ltd, provided a comprehensive electrical package for the grinding mill This included the installation of over 250 kilometres of Aug 30, 2012 Cement Manufacturing Process Phase II: Proportioning, Blending Grinding The raw materials from quarry are now routed in plant laboratory where, they are analyzed and proper proportioning of limestone and clay are making possible before the beginning of grinding Generally, limestone is 80% and remaining 20% is the clayCement Manufacturing Process Phases Flow Chart Nov 12, 2010 Cement begins as a powdery mix of grains made by grinding and then heating limestone with small amounts of other materials such as clay The Unraveling Cement's Molecular Mysteries Could Be Key to RD responsibility: to assist concrete business stakeholder (TMM Concrete/MiningCGA Manager/CEO) in daily RD activity of concrete admixture, mining/shotcrete cement grinding aid (CGA) including new product development, existing product improvement, implement new technology (instrumentation or techniques) and or find raw materials alternativeAchmad Fauzi RDQC Supervisor Concrete Admixture Sika Dec 01, 2011 1 Introduction Understanding the kinetic mechanisms of cement hydration intersects both academic and practical interests From an academic standpoint, the chemical and microstructural phenomena that characterize cement hydration are quite complex and interdependent, making it difficult to resolve the individual mechanisms or the parameters that determine their ratesMechanisms of cement hydration ScienceDirect

API SPEC 10A : Cements and Materials for Well Cementing

This specification is applicable to well cement classes A, B, C, and D, which are the products obtained by grinding Portland cement clinker and, if needed, calcium sulfate (CaSO 4) as an interground additive Processing additives can be used in the manufacture of cement of these classesSep 01, 1976 CEMENT and CONCRETE RESEARCH Vol 6, pp 623632, 1976 Pergamon Press, Inc Printed in the United States HYDRATION OF CEMENT ROLE OF TRIETHANOLAMINE VS Ramachandran Division of Building Research National Research Council of Canada, Ottawa (Communicated by F D Tamas) (Received Feb 24, 1976) ABSTRACT Following addition of 01, Hydration of cement — role of triethanolamine ScienceDirectSustainability has progressed handinhand with innovation: we were pioneers in developing waste management projects, controlling emissions into the air, developing new cement and concretebased products, and reducing CO 2 emissions to a minimum, being actively involved in both national and European innovation programmes over the last 20 yearsInterview with Elena Guede: 100 years of innovation and