Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

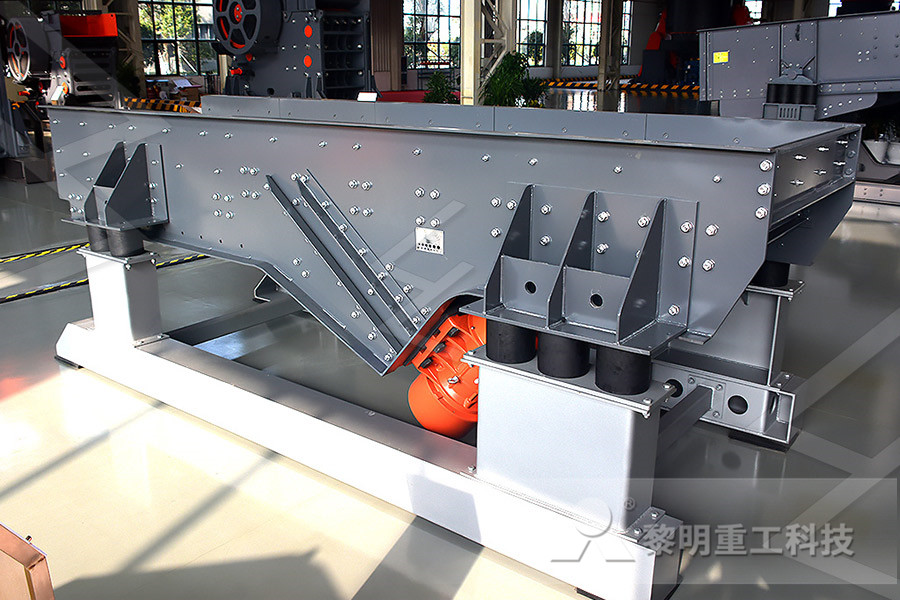

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Study Of Crack Pattern And Strength With Replacement Of

FOR this test crack patter area finding from table name SHEET A1 to table name SHEET F3 and according to experimental result it is states that Replacement of natural fine aggregate by 60% artificial fine aggregate is the best result because of maximum strength and minimum area of crackat 75% strength is more than 0% replacement of natural sand REFERENCES: [1] R Ilangovan, K Nagamani and P Gopal Swamy, 2007, Recycling of Quarry Waste as an Alternative Material in Concrete Manufacturing, Indian Construction, vol 40, no 2, [2] Ilangovan R and Nagamani K, 2006 Application of quarry Rock dust as fine aggregate in concrete Effect of Partial Replacement of Fine Aggregate with The results from the current study (marked with a cross) were generally superior to those where only the coarse aggregate was replaced, but the replacement of only the fine aggregate resulted in higher strength concrete, as for example the studies by Ravindrarajah and Juki et alLightweight concrete with artificial aggregate Oct 01, 2020 Normally, aggregate accounts for over 60% volume of concrete Accordingly, the use of steel slag as a partial replacement of natural coarse or fine aggregates in concrete would be a promising way that could utilize steel slag at a large scale The steel slags were used in base and subbase of road pavement and even in the structural concretePreparation, microstructure and property of carbonated Effect of Partial Replacement of Fine Aggregate with Artificial Sand written by Mr M Vijay, Mr S Satheeshkumar, Mr N Muthu Selvakumar published on 2018/04/24 download full article with reference data and citationsEffect of Partial Replacement of Fine Aggregate with

(PDF) Partial Replacement of Copper Slag as Fine Aggregate

So as to abstain from utilizing common stream sand An elective material is proposed to the quality of the solid by supplanting of fine total Incompletely by squander material like copper slag which is an ecological waste To make us of theseAt present lack of utilization materials ,the raw materials of construction is less compare to the other materials Our project deals with the replacement of fine aggregate by GBS (Granulated blast furnace slag ) by 0% , 5 % , 10 % , 15 % , 20 % As this percentage to increase the strength of concrete An Experimental Investigation on M30 Concrete with Partial The sand is used as the fine aggregates for the purpose of concrete making 2Gravel The gravel is another type of aggregates and is mainly used for as coarse aggregates in concrete Bank gravel, bench gravel and crushed stone are the examples of gravelTypes of AggregatesNatural and Artificial Aggregatesartificial coarse aggregate used in railways artificial coarse aggregates used in railways artificial coarse aggregates used in railways Aggregate for home use Concrete Society provides Technical,artificial coarse aggregates used in railways,Aggregates are classified as coarse or sand (fine) depending on whether they pass through a 5 mm sieve They occur as uncrushed material, (natural artificial sand as fine aggregateReplacement of fine aggregate with plastic in concrete Tanzeem Shaikh used as the replacement of fine aggregate in the concrete Concrete cubes were cast taking 10%, 20%, 30 %, 40% 50% of better quality and to substitute artificial materials for natural high Replacement of fine aggregate with plastic in concrete

What are other alternatives for aggregates in concrete

1) EPS: Expanded Polystyrene plays a very unique role in concrete Research has shown that concrete with this material behaves very similarly to light weight concretes containing traditional aggregates This is believed to be the case because the artificial coarse aggregate used in railways artificial coarse aggregates used in railways artificial coarse aggregates used in railways Aggregate for home use Concrete Society provides Technical,artificial coarse aggregates used in railways,Aggregates are classified as coarse or sand (fine) depending on whether they pass through a 5 mm sieve They occur as uncrushed material, (natural artificial sand as fine aggregateThe waste coconut shell may be utilized to replace natural coarse aggregate In this study, M 20 grade of concretewas produced fied many artificial and natural lightweight aggregates (LWA) ness of using coconut shell as partial replacement of coarse aggregate in concrete and determining its compressive strength 2 C OCONUT SPerformance of Waste Coconut Shell as Partial Replacement with substantial replacement of natural aggregates and natural sand used in concrete In this study coarse aggregate were partially replaced with steel slag aggregate with different replacement percentage in concrete ie 0%, 10%, 20%, and 30% In which we found compressive strength of3 COMPRESSIVE STRENGTH OF STEEL SLAG AGGREGATE So as to abstain from utilizing common stream sand An elective material is proposed to the quality of the solid by supplanting of fine total Incompletely by squander material like copper slag which is an ecological waste To make us of these(PDF) Partial Replacement of Copper Slag as Fine Aggregate

An Experimental Investigation on the Properties of

An Experimental Investigation on the Properties of Concrete with Replacement of Natural Sand with Robosand as Fine Aggregate 1Kadapa Naresh Kumar, 2Syed Rizwan 1MTech Student ,Department of Civil Engineering, StMark Educational Institution Society Group of Aggregates, which account for 60 to 75 percent of the total volume of concrete, are divided into two distinct categoriesfine and coarse Fine aggregates generally consist of natural sand or crushed stone with most particles passing through a 3/8inch sieveAggregates Portland Cement Associationrequired fresh concrete properties Since, artificial fine aggregate contains large amount of fines, can be used as an alternative to river sand Due to high fines content in artificial fine aggregate, the strength and durability properties of the concrete are reported to be considerably improved by using artificial fine aggregateAN EXPERIMENTAL INVESTIGATION ON SELF COMPACTING This research focuses on evaluating the feasibility of utilizing bottom ash from coal burning power plants as a fine aggregate in cellular concrete with various foam contents Flows of all mixtures were controlled within 45 ± 5% and used foam content at 30%, 40%, 50%, 60%, and 70% by volume of mixture Bottom ash from Mae Moh power plant in Thailand was used to replace river sand at the Influence of Bottom Ash Replacements as Fine Aggregate on concrete using fully replacement of artificial sand as fine aggregate and fly ash, silica fume as supplementary cementaneous material with incorporation of super plasticizer by Indian standard method Trial mixes are designed with water cement ratio 026, poly carboxylate ether based superDevelopment of High Strength Concrete using Artificial

Partial Replacement of Coarse Aggregate with Demolished

the demolished concrete aggregate 10%, 20%, 30% by weight of the conventional coarse aggregate and the concrete cubes were casted by that demolished concrete aggregate then further tests conducted such as workability , compressive strength for that DAC and the result obtained are found to be comparable with the conventional concreteAt present lack of utilization materials ,the raw materials of construction is less compare to the other materials Our project deals with the replacement of fine aggregate by GBS (Granulated blast furnace slag ) by 0% , 5 % , 10 % , 15 % , 20 % As this percentage to increase the strength of concrete An Experimental Investigation on M30 Concrete with Partial aggregate from waste concrete, about 25% by weight of fine materials passing 5mm sieve size are generated But, by replacing the natural fine aggregates with artificial fine aggregates Was one of the answers too Artificial fine aggregates are anEFFECTIVENESS OF CONCRETE STRENGTH USING producing artificial aggregates to be used in making concrete may be considered as an effective way to recycle such mineral admixtures Moreover, the natural and/or scarce materials of aggregates may be conserved and damaging activities of aggregate mining may be prevented as artificial aggregates replace the natural ones, especially in SCCs8 ForCombined Use of Natural and Artificial Slag Aggregates in The replacement of natural resources in the manufacture of cement and sand is the present issue in the present construction scenario Copper slag and Ground Granulated Blast furnace Slag (GGBS) are industrial byproduct materials produced from the process of manufacturing copper and iron Use of Copper slag and GGBS does not only reduce the cost of construction but also helps to reduce the [PDF] The Behaviour of Concrete by Partial Replacement of

EFFECTIVENESS OF CONCRETE STRENGTH USING

aggregate from waste concrete, about 25% by weight of fine materials passing 5mm sieve size are generated But, by replacing the natural fine aggregates with artificial fine aggregates Was one of the answers too Artificial fine aggregates are anUsing artificial aggregates for quality concrete is a natural step to mitigating this problem The worldwide consumption of fine aggregate in concrete production is very high, and several developing countries have been countered difficulties in meeting the supply of natural fine aggregate PARTIAL REPLACEMENT OF FINE AGGEREGATE WITH concrete using fully replacement of artificial sand as fine aggregate and fly ash, silica fume as supplementary cementaneous material with incorporation of super plasticizer by Indian standard method Trial mixes are designed with water cement ratio 026, poly carboxylate ether based superDevelopment of High Strength Concrete using Artificial This research focuses on evaluating the feasibility of utilizing bottom ash from coal burning power plants as a fine aggregate in cellular concrete with various foam contents Flows of all mixtures were controlled within 45 ± 5% and used foam content at 30%, 40%, 50%, 60%, and 70% by volume of mixture Bottom ash from Mae Moh power plant in Thailand was used to replace river sand at the Influence of Bottom Ash Replacements as Fine Aggregate on with substantial replacement of natural aggregates and natural sand used in concrete In this study coarse aggregate were partially replaced with steel slag aggregate with different replacement percentage in concrete ie 0%, 10%, 20%, and 30% In which we found compressive strength of3 COMPRESSIVE STRENGTH OF STEEL SLAG AGGREGATE

AN EXPERIMENTAL INVESTIGATION ON SELF COMPACTING

required fresh concrete properties Since, artificial fine aggregate contains large amount of fines, can be used as an alternative to river sand Due to high fines content in artificial fine aggregate, the strength and durability properties of the concrete are reported to be considerably improved by using artificial fine aggregatethe demolished concrete aggregate 10%, 20%, 30% by weight of the conventional coarse aggregate and the concrete cubes were casted by that demolished concrete aggregate then further tests conducted such as workability , compressive strength for that DAC and the result obtained are found to be comparable with the conventional concretePartial Replacement of Coarse Aggregate with Demolished protecting the environment form pollution This paper deals with partial replacement of fine aggregate with the industrial waste from China Clay industries The compressive strength, split tensile strength and flexural strength of conventional concrete and fine aggregate replaced concrete are compared and the results are tabulatedExperimental Study of Partial Replacement of Fine Index Terms— Artificial Sand, depletion of sources, environmental transportation, fine aggregate, Grit, Natural Sand, replacement product 1 I NTRODUCTION Currently India has taken a major initiative on develop ing the infrastructures such as express highways, power projects and industrial structures etcSTRENGTH OF CONCRETE CONTAINING DIFFERENT TYPES OF FINE FM of Ideal fine aggregate for concrete applications are in range of 26 to 29 Fine sand (lower FM Value ) reduces the sand requirement % in the total aggregate proportion On the other hand, coarser sand will require higher sand % in the total aggregate proportion to give a cohesive concrete mix consuming least cementWhat are the Materials for Replacement of Sand in Concrete

Study On Behaviour Of Concrete Partially Replacing Quartz

The Experimental Program was designed to investigate the effect on the properties of the concrete by using quartz sand as a partial replacement for fine aggregate with different proportions 0%, 25%, 50%, 100%For each test at each curing age, and the average values were used for analysisFeb 22, 2016 The concrete mix is designed for M20 grade with 100% replacement of natural sand by artificial sand and partial replacement of coarse aggregate by steel slag with 0% 10% 20% 30%COMPRESSIVE STRENGTH OF STEEL SLAG AGGREGATE AND