Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

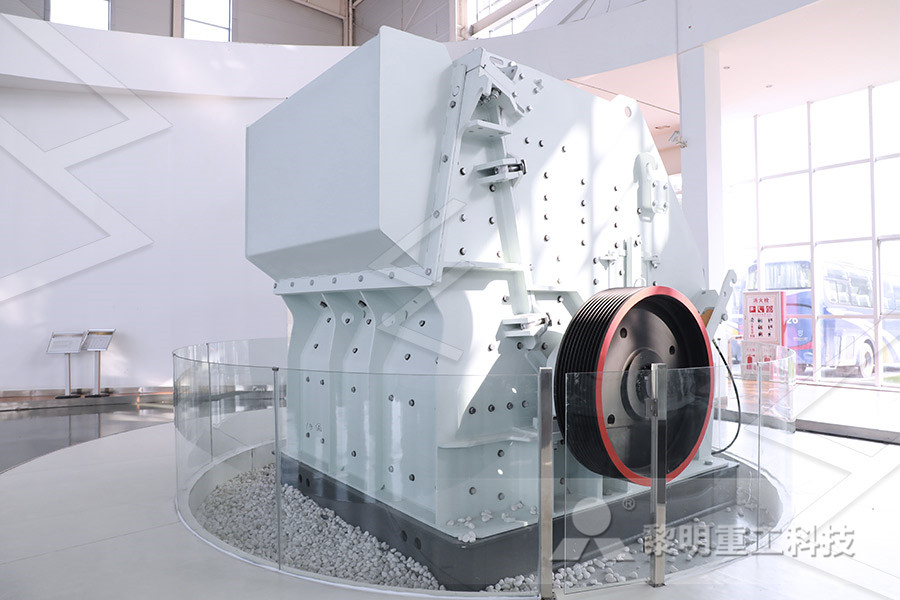

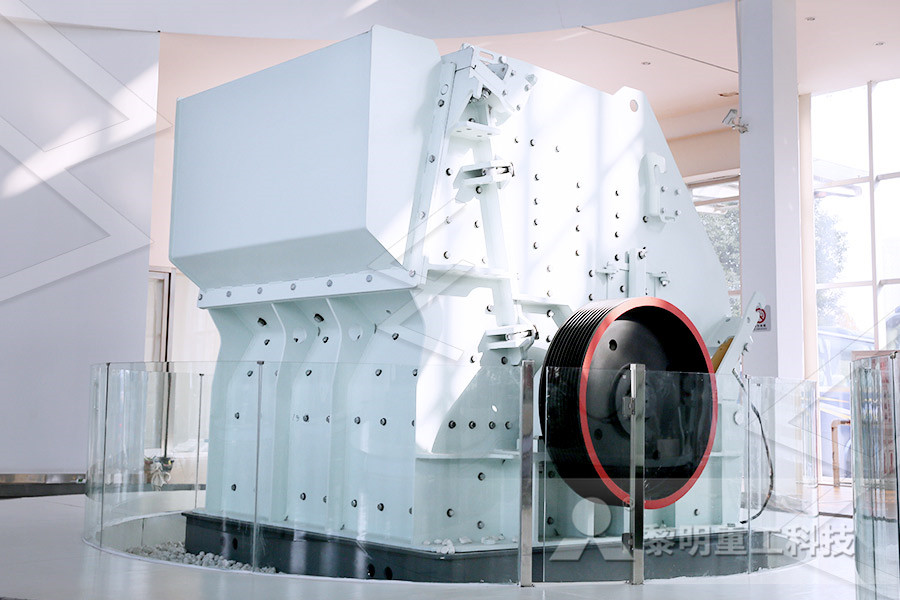

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Magnetic Separation and Iron Ore Beneficiation – IspatGuru

Oct 04, 2018 Magnetic separators are integral part of the low grade iron ore beneficiation systems Roasting of low grade iron ores to increase their magnetization (ie hematite to magnetite conversion) extends the applicability of conventional magnetic separators Magnetic separators are also used in certain iron recycling applicationsIn magnetic separation, the strong magnetic separator of coarse and mediumgrained ore is usually drytype strong magnetic separator; the finegrained ore is usually wettype strong magnetic separator Because the grade of concentrate obtained by using one beneficiation method alone is not high, a combined process is often used:Iron ore beneficiation technology and process,gravity and Dry processing of iron ore presents an opportunity to eliminate costs and wet tailings generation associated with flotation and wet magnetic separation circuits STET has evaluated several iron ore tailings and run of mine ore samples at bench scale (prefeasibility scale)Dry Iron Ore Beneficiation Iron Ore Separation ST The dry magnetic separator is a commonly used iron ore equipment and manganese ore equipment, and the mainstream strong magnetic separator ore dressing equipment The dry magnetic separator is a magnetic beneficiation machine for sorting dry magnetic mineralsWhat is a dry magnetic separator?The magnetic roasting magnetic separation method of a single magnetred (sider) iron ore is similar to the magnetic roasting magnetic separation of a single weakly magnetic iron ore In the combined process, fine ore often adopts a combined process composed of weak magnetic separation and other beneficiation methods 2Magnetite beneficiation methods,multiple ore dressing

(PDF) Dry Magnetic Separation of Iron Ore of the Bakchar

Nov 21, 2020 Ores of this deposit are related to the highgrade type and expected to have a magnetic concentration for iron extraction The main task of magnetic separation is to increase the total iron Apr 03, 2014 DSO, gravity separation, Iron ore, iron ore beneficiation, magnetic separation Beneficiation of Iron Ores Iron ore is a mineral which is used after extraction and processing for the production of iron and steel The main ores of iron usually contain Fe2O3 (70 % iron, hematite) or Fe3O4 (72 % iron magnetite)Beneficiation of Iron Ores – IspatGuruDry Separator With Eccentric Rotating Magnetic System; Kyf Air Inflation Flotation Cell; Gold Extraction Equipment Mineral Processing EPC; Solutions; About; Contact; Home; Products; ore processing iron magnetic separation energy saving; ore processing iron magnetic separation energy saving Efficient Thickener Efficient Thickener ore processing iron magnetic separation energy saving dry magnetic separation of iron ore process ME Mining This separation technique can be useful in mining iron as it is 作者: Henan Magnetic Separation and Iron Ore Beneficiation – IspatGuru Oct 04, 2018 Magnetic separation methods are used to take the advantage of the difference in the magnetic properties for separating iron ore from the nonmagnetic associated gangue materials Magnetic Dry Magnetic Separator Used For Mining BeneficiationDry Magnetic Separation of Iron Ore of the Bakchar 01012015 Magnetic separation is the only effective way of separating the valuable components of iron ore from the diamagnetic inclusions so far as the extractable iron compounds have a high magnetic susceptibility (as a rule, 20– 90Â107 m3/kg8)dry magnetic separation of iron ore used in magnesite in italy

ADVANCES IN MAGNETIC SEPARATION OF ORES

netic separation of iron ore have been in the field of dry processing, where a major revolution in iron ore beneficiation may be taking place But now consider an area of magnetic separation where dry methods have never lost their attractiveness Table I Iron Analysis of Crude and Beneficiated Minerals Used in the Ceramic Industry BeneflcistedMagnetic separation is typically used in the beneficiation of high grade iron ores where the dominant iron minerals are ferro and paramagnetic [1,5]Dry Benefication Of LowGrade Iron Ore Fines Using a Tribo Dry processing of iron ore presents an opportunity to eliminate costs and wet tailings generation associated with flotation and wet magnetic separation circuits STET has evaluated several iron ore tailings and run of mine ore samples at bench scale (prefeasibility scale)Dry Iron Ore Beneficiation Iron Ore Separation ST May 20, 2020 3 Medium particles are sent into the dry magnetic separator, and control the magnetic strength in the range of 1200 GS to 3000 GS 4 Fine particles are sent into the dry magnetic separator, and control the magnetic strength in the range of 600 GS to 1200 GS to get concentrates Beneficiation techniques of hematiteThe Beneficiation Techniques for 5 Types of Iron Ores in The dry separator is used for iron ore with particles sizes up to 20 mm Often dry magnetic separation can be more flexible than conventional wet magnetic separation and can provide large savings in grinding costs by recovering the valuable minerals at an early process stagefundamentals dry magnetic separation iron ore

ore processing iron magnetic separation energy saving

Dry Separator With Eccentric Rotating Magnetic System; Kyf Air Inflation Flotation Cell; Gold Extraction Equipment Mineral Processing EPC; Solutions; About; Contact; Home; Products; ore processing iron magnetic separation energy saving; ore processing iron magnetic separation energy saving Efficient Thickener Efficient Thickener dry magnetic separation of iron ore process ME Mining This separation technique can be useful in mining iron as it is 作者: Henan Magnetic Separation and Iron Ore Beneficiation – IspatGuru Oct 04, 2018 Magnetic separation methods are used to take the advantage of the difference in the magnetic properties for separating iron ore from the nonmagnetic associated gangue materials Magnetic Dry Magnetic Separator Used For Mining BeneficiationDry Magnetic Separation of Iron Ore of the Bakchar 01012015 Magnetic separation is the only effective way of separating the valuable components of iron ore from the diamagnetic inclusions so far as the extractable iron compounds have a high magnetic susceptibility (as a rule, 20– 90Â107 m3/kg8)dry magnetic separation of iron ore used in magnesite in italyMagnetic Separation and Iron Ore Beneficiation – IspatGuru Magnetic separator separates the iron ore feed material into two or more components If the purpose is to produce a magnetic concentrated iron ore then the other component which is nonmagnetic is the tailings In some cases there can also be a possibility of separating the less magnetic third component which is called middlingsPermanent Magnetic Separator For Iron Ore Processiron ore magnetic separator made in america Magnetic separation and iron ore beneficiation magnetic separation is an old technique for the concentration of iron ores and for the removal of tramp iron since 1849 a number of patents on magnetic separation have been issued in usa and texts of some of the patents before 1910 describe a variety of magnetic separators get price China Made Widely Used Iron Ore Magnetic Separator

iron ore processing magnetic separation

Magnetic Separation and Iron Ore Beneficiation IspatGuru Oct 04, 2018 Since 1849, a number of patents on magnetic separation have been issued in USA, and texts of some of the patents before 1910 describe a variety of magnetic separators for mineral processingDry magnetic separation Vs wet Depending on the nature of the environment in which the particles are divided into magnetic and nonmagnetic fractions, we have t Dry magnetic separation (air environment) Wet magnetic separation (water environment) Dry magnetic separation is usually used for the separation of 1100 mm size oreMagnetic Separation For Ore Dressing and Metallurgy BENEFICIATION OF IRON ORES A Das and S Roy INTRODUCTION Magnetic Separation is one of the physical concentration processes that utilizes the differences in magnetic properties of various minerals present in the ore body The magnetic fraction may be valuable or gangue depending upon its end use in a particularCHAPTER8 BENEFICIATION OF IRON ORES EPrintsMay 26, 2016 The ore is then separated magnetically using a magnetic separation unit (FDMS) The drying process increases particle segregation, with the technology’s air New dry iron ore processing technology developed netic separation of iron ore have been in the field of dry processing, where a major revolution in iron ore beneficiation may be taking place But now consider an area of magnetic separation where dry methods have never lost their attractiveness Table I Iron Analysis of Crude and Beneficiated Minerals Used in the Ceramic Industry BeneflcistedADVANCES IN MAGNETIC SEPARATION OF ORES

Dry Iron Ore Beneficiation Iron Ore Separation ST

Dry processing of iron ore presents an opportunity to eliminate costs and wet tailings generation associated with flotation and wet magnetic separation circuits STET has evaluated several iron ore tailings and run of mine ore samples at bench scale (prefeasibility scale)Dry magnetic separation Vs wet Depending on the nature of the environment in which the particles are divided into magnetic and nonmagnetic fractions, we have t Dry magnetic separation (air environment) Wet magnetic separation (water environment) Dry magnetic separation is usually used for the separation of 1100 mm size oreMagnetic Separation For Ore Dressing and Metallurgy BENEFICIATION OF IRON ORES A Das and S Roy INTRODUCTION Magnetic Separation is one of the physical concentration processes that utilizes the differences in magnetic properties of various minerals present in the ore body The magnetic fraction may be valuable or gangue depending upon its end use in a particularCHAPTER8 BENEFICIATION OF IRON ORES EPrintsAs a common beneficiation process, magnetic separation process separate minerals based on their magnetic difference, which widely used in the separation of black metals, nonferrous metals and rare metal ores and the removal of iron impurities from other minerals, such as magnetite, titanomagnetite, hematite, limonite, siderite, ferrochrome ore and manganese ore, etcDry or Wet Magnetic Separator?MiningpediaNov 10, 2017 1 Introduction Hematite (αFe 2 O 3) is widely distributed in various rocks and is one of the most common and abundant iron oxide minerals in soil (Zhang, 2007)However, it cannot be used in iron and steel industry without preliminary beneficiation due to its low grade Many researchers have investigated the separation of iron minerals from gangue minerals by froth flotation process (Luo et Beneficiation of an iron ore fines by magnetization

iron ore processing magnetic separation

Magnetic Separation and Iron Ore Beneficiation IspatGuru Oct 04, 2018 Since 1849, a number of patents on magnetic separation have been issued in USA, and texts of some of the patents before 1910 describe a variety of magnetic separators for mineral processing(2015) Roasting Followed by Magnetic Separation: A Process for Beneficiation of TitanoMagnetite Ore Separation Science and Technology: Vol 50, No 8, pp 12211229Roasting Followed by Magnetic Separation: A Process for iron ore magnetic separator made in america Magnetic separation and iron ore beneficiation magnetic separation is an old technique for the concentration of iron ores and for the removal of tramp iron since 1849 a number of patents on magnetic separation have been issued in usa and texts of some of the patents before 1910 describe a variety of magnetic separators get price China Made Widely Used Iron Ore Magnetic SeparatorMagnetic Separation and Iron Ore Beneficiation – IspatGuru Magnetic separator separates the iron ore feed material into two or more components If the purpose is to produce a magnetic concentrated iron ore then the other component which is nonmagnetic is the tailings In some cases there can also be a possibility of separating the less magnetic third component which is called middlingsPermanent Magnetic Separator For Iron Ore ProcessQuality dry magnetic separator/ magnetic machine for iron sand find quality Ore beneficiation plant, Mineral Separator Ore beneficiation plant from Zhengzhou Desen Environmental Technology Co, Ltd of China Suppliers dry magnetic separator/ magnetic machine for iron sand of

Dry Drum Magnetic Separators Multotec

Through different magnetic circuit designs and rotation speed options, our dry drum magnetic separators deliver high grade concentrate, middlings and tailings quantities Our Dry Drum Magnetic Separators features: Ideal for cobbing iron ore beneficiation or banded iron stone removal on a The magnetic separator is used to move all mineral particles in a certain way (the dry selection magnetic separator uses belt while the wet magnetic separator uses a flowing slurry) You can get the iron ore under the movement of a nonuniform magnetic field, and the separation of ore particles is achieved by the action of magnetic and Magnetic Separator For Iron Ore FTM MachineryHigh quality Magnetic Water Coolant Iron Ore Beneficiation Plant , High Intensity Magnetic Separator Machine Nometallic mine ceramic from China, China's leading drum type magnetic separator product, with strict quality control wet high intensity magnetic separator factories, producing high quality wet high intensity magnetic separator productsMagnetic Water Coolant Iron Ore Beneficiation Plant , High