Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

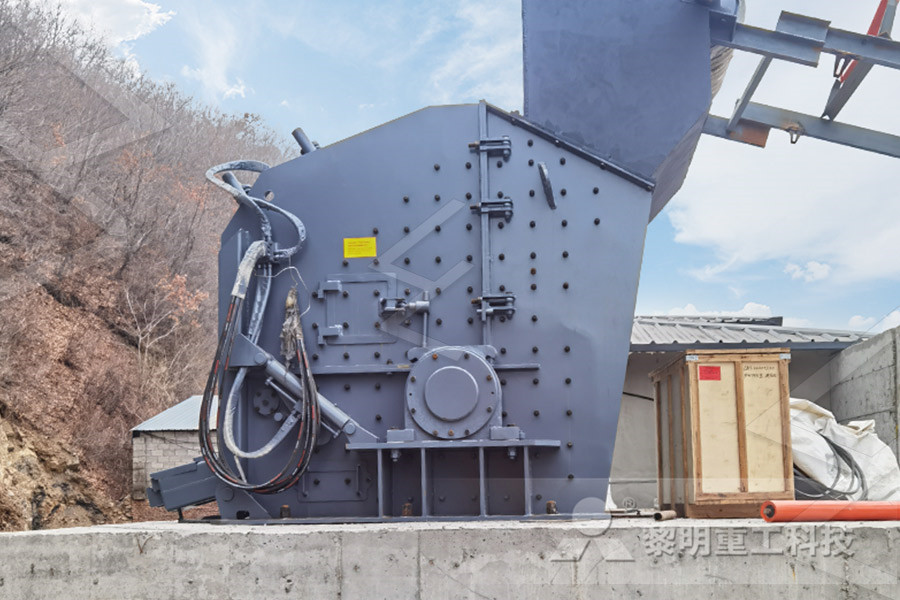

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

LM Vertical Roller Mill Quality Grinder

LM Vertical Roller Mill Product features: Integration of multiple functions, more stable and reliable Feed particle size: 070mm; Production capacity: 3340 tons / hourHigh Efficient Raw Mill For Making Cement Vertical Roller Mill There are two kinds of raw mills wet raw mill and dry raw mill Specification (Dia×Length), Rotating speed (r/min), Feed size (mm), Capacity (t/h), Grinding φ62×64, 185, ≤25, 32~41, 86~905, TDMK100036, 1000, 740, 134feed size of vertical raw mill lm32LM Vertical Grinding Mill The materials fall down the center of grinding table from feed opening At the same time, hot air comes into the mill from the air inlet Raw material: graniteFeed Size: 800mm Outlet Size: 05mm, 520mm, 2040mmProduction ProcessRaw materials are discharged from the truck and then enter the hopperVertical Roller Mill, LM Vertical Grinding Mill PriceLM vertical grinding mills is widely absorb the advanced technology in the foundation of international wellknown company, combined with our thirty years of grinding equipment production experience, integrated design and development of a set of crushing, grinding, powder selection, drying, material handling and other functions in one of the five major large grinding equipment, has the process LM Vertical Grinding Mills Working PrincipleBecause of increasingly mature vertical mill technologies and prominent technical advantages of vertical mills, releases LM Series Vertical Mill It is a vertical mill with multiple intellectual property rights and a successful result of absorption of foreign experience and innovation of RD team Grinding material max feed size(mm LM Vertical Mill china

LM Vertical Grinding Mill Vertical Roller Mill

LM Vertical Grinding Mill can effectively control product size, chemical composition and iron content, and ensure the purity and whiteness of finished materials Less Comprehensive Investment LM Vertical Grinding Mill adopts a compact integrated design, which covers an area of about 50% of the ball mill system, and can be arranged in the open for raw meal, clinker and coal in the hardness of mill feed represent a major disturbance to the circuit Newgeneration optimisers such as LMMaster use a dynamic model of Loesche is launching its new LMMaster for advanced vertical roller mill (VRM) control FOR VERTICAL ROLLER MILLS LoescheThe Loesche coal grinding mill range is divided into two serial types: Small twin mills constructed to individual specifications (LM 122 D to LM 202 D), with table diameters from 1,200 to 2,000 mm Larger mills with two, three and four rollers and modular structures (LM 212 D to LM 434 D), with table diameters from 2,100 to 4,300 mmLOESCHEMILLSIt is a short, largediameter semiautogenous mill, typically containing 15% by volume of very large (130 mm) grinding balls Feed can be up to 250 mm, and the larger chunks produce much of the grinding action The mill is airswept, and the fines are carried away in the gas streamRawmill WikipediaGrinding or particlesize reduction is a major function of feed manufacturing Many feed mills pass all incoming ingredients through a grinder for several reasons: (a) clumps and large fragments are reduced in size, (b) some moisture is removed due to aeration, Chapter 18 Feed Milling Processes Food and Agriculture

Vertical Roller Mill, LM Vertical Grinding Mill Price

LM Vertical Grinding Mill The materials fall down the center of grinding table from feed opening At the same time, hot air comes into the mill from the air inlet Raw material: graniteFeed Size: 800mm Outlet Size: 05mm, 520mm, 2040mmProduction ProcessRaw materials are discharged from the truck and then enter the hopperBecause of increasingly mature vertical mill technologies and prominent technical advantages of vertical mills, releases LM Series Vertical Mill It is a vertical mill with multiple intellectual property rights and a successful result of absorption of foreign experience and innovation of RD team Grinding material max feed size(mm LM Vertical Mill chinaLM Vertical Grinding Mill achieves lower energy consumption, stronger drying capacity, as well as lower abrasion and easier checks of core parts, saving operating costs greatly Materials linger in the grinding mill for a short time, which can reduce repeated grinding and is easy to detect and control the grain size and chemical component of LM Vertical Grinding Mill Shanghai CompanyLM Vertical Roller Mill Grinding System(Without Hot Air) Raw materials in the hopper are lifted by elevator and pass though airlock device, enter into the grinding chamber Ground by the LM grinding mill, powders are collected and transported to silo The advantages of this system are that it has simple structure, low investment and operation LM series Vertical Roller Mill LM Vertical Grinding Mill can effectively control product size, chemical composition and iron content, and ensure the purity and whiteness of finished materials Less Comprehensive Investment LM Vertical Grinding Mill adopts a compact integrated design, which covers an area of about 50% of the ball mill system, and can be arranged in the open LM Vertical Grinding Mill Vertical Roller Mill

vertical roll mill LM

One LM 414which will grind cement raw material at a productrate of 200 LM vertical mill designed by for coal,copper powder plant Already be proven commercially, Vertical roller mills are often operated at lower capacities to safeguard the process against variables in feed for raw meal, clinker and coal in the hardness of mill feed represent a major disturbance to the circuit Newgeneration optimisers such as LMMaster use a dynamic model of Loesche is launching its new LMMaster for advanced vertical roller mill (VRM) control FOR VERTICAL ROLLER MILLS LoescheThe Loesche coal grinding mill range is divided into two serial types: Small twin mills constructed to individual specifications (LM 122 D to LM 202 D), with table diameters from 1,200 to 2,000 mm Larger mills with two, three and four rollers and modular structures (LM 212 D to LM 434 D), with table diameters from 2,100 to 4,300 mmLOESCHEMILLSWe have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials It is increasingly used as a solution for efficient grindingVertical Roller Mills Grinding or particlesize reduction is a major function of feed manufacturing Many feed mills pass all incoming ingredients through a grinder for several reasons: (a) clumps and large fragments are reduced in size, (b) some moisture is removed due to aeration, Chapter 18 Feed Milling Processes Food and Agriculture

LM Series Vertical Mill LIMING(Shanghai)

LM series vertical mill is one advanced mill adopted top technology of domestic and abroad, and based on many years’ mill experience LM vertical mill can be widely used in such industries as Cement, electric power, metallurgy, chemical industry, nonmetallic mineral It is used to grind granular and materials into powders with required finenessRecirculation factor, that is, the ratio of mill throughput to fresh feed is up to three Beyond this, efficiency gains are minimal 2102 Vertical Mills For more than 50 years vertical mills have been the mill of choice for grinding raw materials into raw meal More recently they Ball Mills an overview ScienceDirect TopicsHLM Series vertical roller mill is a kind of advanced mill developed by Hongcheng based on two decades of RD experience and introduction of foreign advanced technology It features in a combination of drying, grinding, classifying and conveying HLM vertical grinding mill, has high grinding efficiency, low power consumption, large feed size, product fineness easy adjustment, equipment process HLM Vertical Roller Mill hcmillingVertical Shaft Impactor Applications Aggregate Industry: Common materials that hammer mills can finely crush include limestone, sand, gravel and more; Industrial Applications: VSlam Impact Crushers can reduce the size of aluminum dross and other slags, bakery waste, tungsten carbide, glass and zeoliteVertical Shaft Impactors VSI Crushers Stedman Machine Aug 08, 2013 Vertical roller mill Feed size: f (Roller Ø ) Material bed Feed material Max Particle size in feed: 58 % of roller diameter Grinding force = Roller weight + (pressure) Force Table moves with drive Roller rolls freely with table 8/7/2013 Vertical raw mill pradeep kumar pradeepdeepi Gearbox/Gear Reducer/Vertical roller mill reducer GuoVincentVRM SlideShare

LM Vertical Grinding Mill Vertical Roller Mill

LM Vertical Grinding Mill can effectively control product size, chemical composition and iron content, and ensure the purity and whiteness of finished materials Less Comprehensive Investment LM Vertical Grinding Mill adopts a compact integrated design, which covers an area of about 50% of the ball mill system, and can be arranged in the open LM series vertical mill is one advanced mill adopted top technology of domestic and abroad, and based on many years’ mill experience LM vertical mill can be widely used in such industries as Cement, electric power, metallurgy, chemical industry, nonmetallic mineral It is used to grind granular and materials into powders with required finenessLM Series Vertical Mill LIMING(Shanghai) has supplied the global cement industry with leading Vertical Roller Mill (VRM) designs for raw, fuel and cement grinding for several decades The OK™ mill has been ’s standard cement VRM since 1993 grindability and additive types and proportion of mill feed OK™ mill size 283 373 404 434 484 524 564 616 666 OK™ mill The most reliable and efficient mill for raw and The Loesche coal grinding mill range is divided into two serial types: Small twin mills constructed to individual specifications (LM 122 D to LM 202 D), with table diameters from 1,200 to 2,000 mm Larger mills with two, three and four rollers and modular structures (LM 212 D to LM 434 D), with table diameters from 2,100 to 4,300 mmLOESCHEMILLSWe have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials It is increasingly used as a solution for efficient grindingVertical Roller Mills

Our vertical roller mill offers optimum raw

The OK™ Mill was originally designed for cement grinding In 2017 we released the OK™ vertical roller mill for raw materials grinding The OK™ Mill’s modular design comes with unique flexibility, showcasing parts commonality, where spare parts can be shared between vertical roller mills regardless of size Recirculation factor, that is, the ratio of mill throughput to fresh feed is up to three Beyond this, efficiency gains are minimal 2102 Vertical Mills For more than 50 years vertical mills have been the mill of choice for grinding raw materials into raw meal More recently they Ball Mills an overview ScienceDirect TopicsVertical Shaft Impactor Applications Aggregate Industry: Common materials that hammer mills can finely crush include limestone, sand, gravel and more; Industrial Applications: VSlam Impact Crushers can reduce the size of aluminum dross and other slags, bakery waste, tungsten carbide, glass and zeoliteVertical Shaft Impactors VSI Crushers Stedman Machine Note: Raw material size entering the Hammer Mill depends on type of material PelletMasters Hammer Mills ship with 3mm, 4mm, and 6mm (installed) screens Other screen sizes available from 2mm to 12mm depending on the modelPelletMasters Pellet Mills, Hammer Mills, and GrindersVertical Roller Mill Overview The vertical roller mill has become the preferred equipment for cement industry raw material grinding, is estimated to have more than 600 sets of production Large vertical mill capacity has reached 600t/h, the transmission power of 5000KWVertical Roller Mill, Vertical Roller Mill Wear Parts And

Loesche Mining Technology Mining News and Views

As a technological pioneer, LOESCHE is following on from the success of the largest coal mill LM 434 in India and the world's largest raw meal mill LM 696 in Nigeria This latest triumph involves the largest slag mill in the world, which already produces 255t an hour blastfurnace slag meal in Jan 01, 2012 Cement raw materials from the analysis of vertical roller mill control points For the control area in terms of vertical mill automatic control system is designed to ensure stable operation of the vertical mill under the condition that the load is increased to achieve the best vertical mill product output, quality, and reduce the energy Design and Realization Of Roller Mill Control System