Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

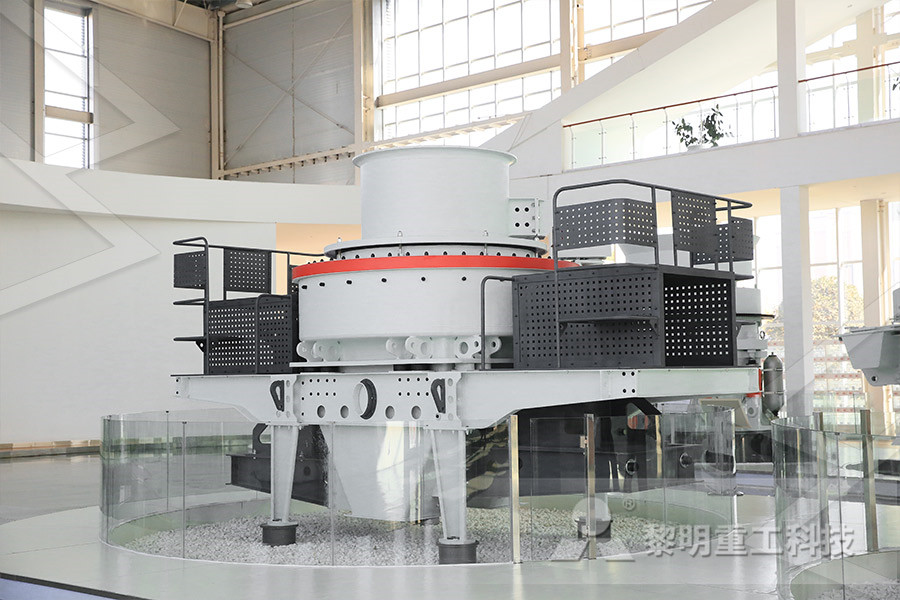

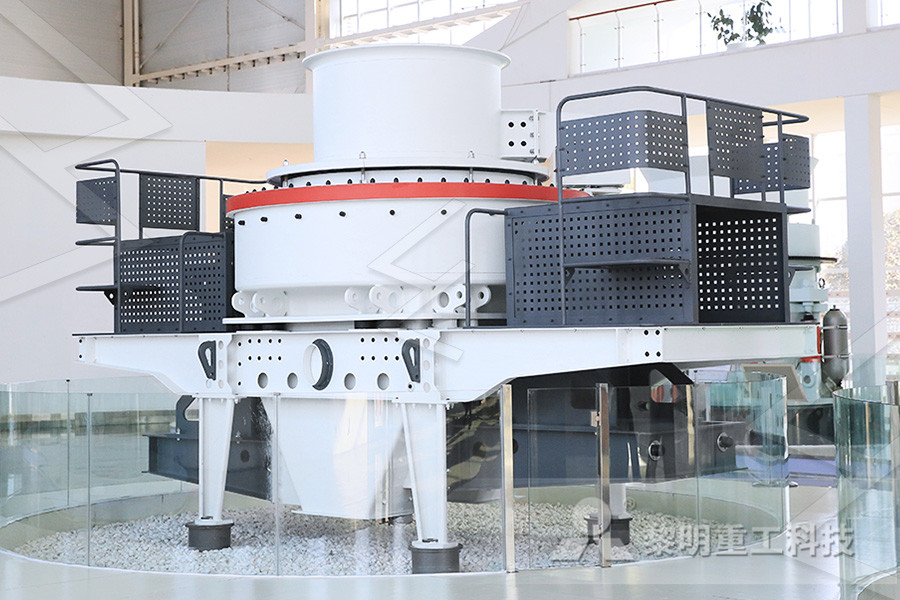

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

What is a Jaw Crusher and Selecting the Right One Gilson Co

The Working Principles Of A Jaw Crusher All jaw crushers operate on the same straightforward principle; two hardfaced heavy plates or jaws crush large particles between them One powered jaw reciprocates in an elliptical motion opposite a stationary jaw mounted in the frameWhat is a Jaw Crusher? A jaw crusher is a compression type crusher, comprised of a fixed jaw and moving jaw positioned in a (V) The movable jaw compresses material against the fixed jaw, crushing the material to the desired size The material exits the jaw through the bottom of the crusher otherwise, known as the discharge openingWhat is a Jaw Crusher? TelsmithSandvik jaw crushers are of the singletoggle type with advanced features for optimized performance, easy maintenance, long life and a low cost per tonJaw crushers, Stationary Jaw crusher series — Sandvik Jaw crushers are generally defined by their opening size For example, a 900x650 mm crusher refers to a crusher with an inlet measuring 900 mm by 650 mm The main parts and main technical parameters of a jaw crusher are presented below 1What is a Jaw Crusher? – MEKA Crushing EquipmentIntroduction: The jaw crusher is used in the first process of crushing various minerals and rocks It can process various ores with a compressive strength not higher than 320MPa to a Crusher Jaw Buy Crusher Jaw,High Efficiency Jaw Mobile

Jaw Crushers for Sale Metallurgist Mineral Processing

A critical point in the operation of large jaw crushers is the arrangement of swing jaw and its supporting shaft While in most crushers the jaw is pressed on the shaft and the latter swings in frame, in the jaw crusher the opposite principle is used—shaft is clamped in frame and jaw swings on shaft! Another point has been lubricationFor laboratories that require frequent removal of jaw and cheek plates for cleaning or for changing the jaw material among the three jaw types, we offer a QuickChange Jaw Option With this quickchange design the jaw and cheek plates can be removed and replaced in 2 – 3 minutesASC Scientific Laboratory Jaw Crusher ASC ScientificThe core of ® C Series™ jaw crusher is a pinned and bolted, nonwelded frame construction that provides excellent fatigue strength All the frame components are casted using an alloy developed inhouse especially for jaw crushersJaw crushers When the jaw stone crusher working, the motor drives the belt and Pulley, moves the movable jaw up and down through the eccentric shaft The angle between the bracing plate and movable jaw gets bigger when the jaw rising Then pushing the jaw close to the fixed jawcrusher plate, achieve the crushing aim when the materials were crushedJaw Crusher Handbook Stone Crusher PDF JXSC MineAug 09, 2016 update of the crusher with build picshomemade jaw crusher update and build pics YouTube

What is a Jaw Crusher? Telsmith

Jaw crushers are often designated by the size of the top opening where material enters The openings tend to be either rectangular or square and are referenced in inches For example, a 3244 or 32×44 jaw crusher has a 32” by 44” opening, 32” being the gap at the top between the jaw 1) Jaw crusher is the crushing equipment that uses two jaw plates to squeeze and bend materials to crush various hardness materials The crushing mechanism is composed of fixed jaw and movable jaw The material is crushed when the two jaws are close to each other, and the material smaller than the discharge gate are discharged from the bottom Impact Crusher VS Jaw Crusher:What Are the Differences?Jaw Crushers are sized by the top opening of the crushing chamber For example, a 32 x 54 Jaw Crusher measures 32" from jaw die to jaw die at the top opening or gape opening and 54” across the width of the two jaw dies The narrower bottom opening of the crushing chamber is used to size the discharge materialJaw Crushers McLanahanDec 12, 2020 A jaw crusher refers to a type of crusher A crusher is a machine that breaks material, usually rocks, into smaller pieces Jaw crushers are most often seen in mining or disposal, where they are used to break objects into smaller piecesWhat is a Jaw Crusher? (with pictures) jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying, and recycling industries These crushers are amongst the most advanced and reliable in the market and are highly productive in a variety of applicationsJaw Crusher

Jaw Crushers Mt Baker Mining and Metals

Jaw crushers are the workhorse of the crushing industry for mining, construction, and demolition recycling Mt Baker Mining and Metals’ jaw crushers are industrial grade, continuous duty machines They take large pieces of rock, ore, concrete, or other materials, 3260 Eagle Portable Jaw Crusher: Additional Features Hydraulic toggle system operates at much lower pressures than similar systems, allowing easier maintenance Hydraulically adjustable wedges allow changes to closed side setting quickly Includes removable electrical control panel featuring prewired receptacles for radial stackers3260 Eagle Portable Jaw Crusher mobile jaw crushers from Brandt deliver maximum productivity when precrushing natural rock As material enters these crushers, an extralarge screening surface separates the fine material to maximize the crusher’s capacity These long, articulated jaws further optimize the flow of material and reduce blockages, increasing both Brandt Mobile Jaw CrushersJaw Crusher is often used as the coarse crushing equipment of aggregate production line, followed by impact crusher or cone crusher, and then added sand making machine (shaping machine) for shaping 7 Which is Better, Hammer Crusher or Jaw Crusher The main advantage of hammer crusher is that the ore with low hardness can be formed in one timeHammer Crusher VS Jaw Crusher Which Is Better (7 Tips) MCAll Jaw crushers incorporate a fixed jaw die configuration with a wraparound design that protects the crusher frame Nanjing Manganese Manufacturing Co,Ltd is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts and Crusher spare parts for Trio jaw crusherWe supply wear parts to the USA Premium Replacement Trio Jaw Crusher Parts

Crusher Wikipedia

A jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker The volume or cavity between the two jaws is called the crushing chamberJaw crushers have been around for nearly 200 years at this point and are one of the most “historic” crusher types Because of this, jaw crushers have advanced technologically through the years to make them more durable and to improve their movement to reduce choking and increase operational speedHow Does a Jaw Crusher Work Jaw Crusher Kemper EquipmentFeb 01, 2014 “Successful jaw crusher maintenance requires the right resources, the right tools and the right approach,” says Bill Macini, a Telsmith service technician Certainly when an operation is down, whether for preventive maintenance or component failure, there is always the pressure to get the plant up and running as soon as possibleJaw crusher maintenance : Pit QuarryJAW CRUSHERS Jaw Crushers use jaw plates to compress and shear product into coarse intermediate particles Sturtevant’s models offer material reduction up to Used Jaw Crushers for sale equipment more MachinioJaw crushers have been around for nearly 200 years at this point and are one of the most “historic” crusher types Because of this, jaw crushers have advanced technologically through the years to make them more durable and to improve their How Does a Jaw Crusher Work Jaw Crusher Kemper Equipment

Minerals Processing Systems JW SERIES JAW CRUSHERS

® JW Series Jaw Crushers Why It Matters Full hydraulic closed side setting adjustment Fast, easy, safe adjustment Wedge jawface locking arrangement Easy maintenance access and fast jawface changeout Tight crushing chamber nip angle To aggressively grip rock for increased crusher throughput and jaw life Large crushing strokeA jaw or toggle crusher consists of a set of vertical jaws, one jaw is kept stationary and is called a fixed jaw while the other jaw called a swing jaw, moves back and forth relative to it, by a cam or pitman mechanism, acting like a class II lever or a nutcracker The volume or cavity between the two jaws is called the crushing chamberCrusher WikipediaA Jaw Crusher reduces large size rocks or ore by placing the rock into compression A fixed jaw, mounted in a "V" alignment is the stationary breaking surface, while the movable jaw exerts force on the rock by forcing it against the stationary plate The space at the bottom of the "V" aligned jaw plates is the crusher product size gap, or the how a jaw crusher works and what it is used for jaw crushers are designed to exceed the primary crushing needs of customers in the mining, quarrying, and recycling industries These crushers are amongst the most advanced and reliable in the market and are highly productive in a variety of applicationsJaw Crusher Jaw crushers are the workhorse of the crushing industry for mining, construction, and demolition recycling Mt Baker Mining and Metals’ jaw crushers are industrial grade, continuous duty machines They take large pieces of rock, ore, concrete, or other materials, Jaw Crushers Mt Baker Mining and Metals

Jaw Crushers For Sale MyLittleSalesman

Dec 17, 2020 Shop Jaw Crushers For Sale by owners dealers near you Browse 52 new and used Jaw Crushers by FABO, , Gator, Kolberg, Cedarapids, and moreJAW CRUSHERS Jaw Crushers use jaw plates to compress and shear product into coarse intermediate particles Sturtevant’s models offer material reduction up to Used Jaw Crushers for sale equipment more Machinio3260 Eagle Portable Jaw Crusher: Additional Features Hydraulic toggle system operates at much lower pressures than similar systems, allowing easier maintenance Hydraulically adjustable wedges allow changes to closed side setting quickly Includes removable electrical control panel featuring prewired receptacles for radial stackers3260 Eagle Portable Jaw CrusherJaw Crusher is often used as the coarse crushing equipment of aggregate production line, followed by impact crusher or cone crusher, and then added sand making machine (shaping machine) for shaping 7 Which is Better, Hammer Crusher or Jaw Crusher The main advantage of hammer crusher is that the ore with low hardness can be formed in one timeHammer Crusher VS Jaw Crusher Which Is Better (7 Tips) MCThe J50’s jaw speed leads to better reduction and material being processed faster through the crushing chamber McCloskey International has a proven reputation for designing quality, bestinclass equipment and the J50 Crusher brings even more power and productivity together in one machineJ50 Jaw Crusher McCloskey Equipment

Jaw Crusher Eastman Rock Crusher

Jaw crusher is a compression style rock crusher, useful in crushing the mediumhard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit Applications mining, quarry, construction waste recycling, aggregate making, etc Materials Limestone, cobblestone, cobblestone, quartz, basalt, iron ore, granite, shale, sandstone, gypsum, and a variety of oresJaw Crusher  is widely used in industrial and mining enterprises , this is because the aircraft structure is relatively simple , and has a large range of models Jaw Crusher  is mainly used as the primary crusher It can be used with mineral processing equipment, gravel ancillary equipment, it also can be used alone Structure of Jaw Crusher  is mainly include frame, eccentric shaft, big Jaw Crusher – Conmix CrusherAll Jaw crushers incorporate a fixed jaw die configuration with a wraparound design that protects the crusher frame Nanjing Manganese Manufacturing Co,Ltd is a dynamically growing company with many years of experiences in production and supply of Crusher wear parts and Crusher spare parts for Trio jaw crusherWe supply wear parts to the USA Premium Replacement Trio Jaw Crusher Parts