Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

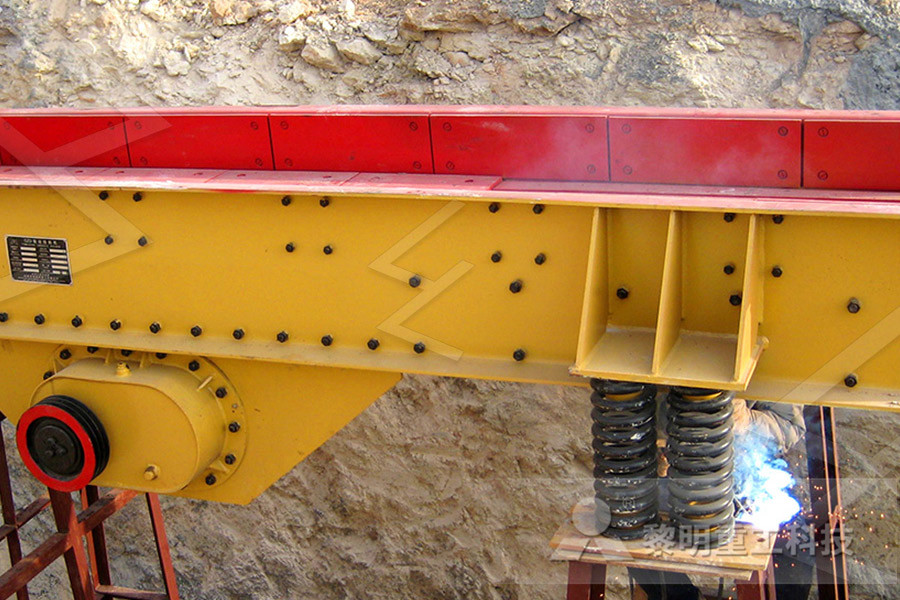

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Crushing Systems

single toggle jaw crusher is its kinematic design ’s chamber design enables the TST to efficiently crush hard material via a combination of shaft eccentricity, toggle angle and chamber layout The steep nip angle enables the units to easily crush the hardest rock at high production rates, while maintaining the necessary product sizeJW Series of single toggle jaw crushers, built for troublefree operation in heavy and continuous applications Designed to suit track, mobile or static plant installations these rugged machines are manufactured with heavyduty components for optimum operation and long life Typical applications for our single toggle jaw crushers are in Minerals Processing Systems JW SERIES JAW CRUSHERSSingle Toggle Jaw Crusher Part Book Buttons n Bows how much crusher,crusher price,cost of crushers for sale crushers mills the hammer mill (also called hm series coarse powder mill) is one kind of new [10/04/2014 ® XA400 Static Single Toggle Jaw Crushersingle toggle jaw crusher part bookThe upper arc is small, the lower arc is large, and the crushing efficiency is low The fragmentation ratio is generally 36 Because the movement track is simply socalled a single toggle jaw crusher The structure of the single – toggle jaw crusher is compact and simple, and the force of transmission parts such as eccentric shaft is smallJaw Stone Crusher Single Toggle vs Double Toggle JXSC MineMore information With 1270mm (50”) x 735mm (29”) single toggle jaw (the widest jaw in its class), the J50 places McCloskey International at the fore of portable crushing machinery Maximum productivity is delivered through the enhancements to the jaw box including heavier flywheels and optimization for all crushing applicationsJ50 Jaw Crusher McCloskey Equipment

Difference Between Single Double Toggle Jaw Crusher

A double toggle jaw crusher is much larger, heavier, more moving parts and lower throughput than modern single toggle jaw crushers The lower throughput statement is a bit misleading because it’s partially attributed to the type of bearings they have versus modern crushers, so if one was to upgrade the bearings, throughput could be closer to that of a modern jaw Anyway, double toggle jaw single toggle jaw crusher is its kinematic design ’s chamber design enables the TST to efficiently crush hard material via a combination of shaft eccentricity, toggle angle and chamber layout The steep nip angle enables the units to easily crush the hardest rock at high production rates, while maintaining the necessary product sizeCrushing Systems Single Toggle Jaw Crusher Construction Details Wear Parts Roller Bearings General Parts Main Frame JawHolder Hydraulic System Toggle Mechanism Tension Rod Assembly KEY Single Toggle Jaw Crusherdd 4 22/2/11 11:52:27 AMSingle Toggle Jaw Crusher TEREX JAQUES SINGLE TOGGLE “Computer Aided Design of Jaw crusher” A schematic diagram of a single toggle jaw crusher is shown in figure 21 single toggle jaw crusher design, IEEE pyb1200 cone crusher diagram with part Crushers Parts Scheme Crusher Mills, Cone Crusher, Jaw JW Series of single toggle jaw crushers, built for troublefree operation in heavy and continuous applications Designed to suit track, mobile or static plant installations these rugged machines are manufactured with heavyduty components for optimum operation and long life Typical applications for our single toggle jaw crushers are in Minerals Processing Systems JW SERIES JAW CRUSHERS

TST jaw crusher

proud to add their new line of single toggle jaw crushers, the TST, to the heritage the double toggle crushers established The TST jaw crushers are engineered for troublefree operation, characterized by safe and easy serviceability The most modern analysis techniques and features available to date ensure a strong and reliable crusher designMar 30, 2013 Portable 20×36 Jaw Crushing Plant (#) 20″ x 36″ singletoggle jaw crusher w/ new parts manual jaw crushers pionner 20×36 – Beneficiation Pioneer Crusher Manganese Wear Parts, Jaw Rock Crushing parts manual jaw crusher 20 x 36 worldcrushersSingle Toggle Jaw Crusher is ideally suitable for primary and secondary crusher for material with compression strength less than 320mpa Jaw crusher is of high crushing ratio, larger capacity, welldistributed final product size, simple structure, reliable performance, convenient maintenance, lower operation cost, etc it is widely used in mining, metallurgy, construction, highway, rail road Single Toggle Jaw Crusher at Rs /unit सिंगल टॉगल Jaw Crushers are designed to exceed the primary needs of customers in the mining, aggregates and recycling industries by Shree Conmix Engineers Pvt Ltd And it is also providing Indiaâ s best and highest selling wide range of  Single Toggle Jaw Crushers  , Jaw  Coal Jaw Crushers, Primary Jaw Crushers  with special highquality cast steel components and durable wear parts Jaw Crusher – Conmix CrusherWith 1270mm (50”) x 735mm (29”) single toggle jaw (the widest jaw in its class), the J50 places McCloskey International at the fore of portable crushing machinery Maximum productivity is delivered through the enhancements to the jaw box including heavier flywheels and J50 Jaw Crusher McCloskey Equipment

Jaw Crushers, Jaw Crusher, Hard Rock Processing, Materials

During the crushing operation, the toggle plate which acts as a pivot point for the jawstock, controls movement of the lower part of the swing jaw SINGLE TOGGLE The single toggle crusher is designed for a high capacity throughput due to the elliptical movement of the swing jaw which also assists in the discharge of the crushed materialA double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top of the crusher, while the other is an eccentric shaft that drives both toggle plates The chewing movement, which causes compression at both material intake and discharge, gives the single toggle jaw better capacity, compared to a double Crushers All crusher types for your reduction needs Singletoggle jaw crushers – design and operating principle Technical data Singletoggle jaw crusher Design Singletoggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plateIndustrial Solutions Jaw crushersThe preference of a company can be reflected by the quality of products/services it serves to clients For us, Maxwell Crushtech, our company's primary vision is to earn a prominent name in the industry through our innovative and modern products including 110KW Single Toggle Jaw Crusher, 37KW Single Toggle Jaw Crusher, 110KW Cone Crusher, etc, which are designed using advanced technologySingle Toggle Jaw Crusher Exporter,Vertical Shaft Impactor The ® Jaques Single Toggle jaw crushers feature large gape feed openings, high production and low operating costs These rugged machines are manufactured with heavy duty parts for constant operation and long life Typical applications for our singletoggle jaw ST47 Jaw Crusher MPS

Single Toggle Jaw Crusher TEREX JAQUES SINGLE TOGGLE

Single Toggle Jaw Crusher Construction Details Wear Parts Roller Bearings General Parts Main Frame JawHolder Hydraulic System Toggle Mechanism Tension Rod Assembly KEY Single Toggle Jaw Crusherdd 4 22/2/11 11:52:27 AMSingletoggle jaw crushers – design and operating principle Technical data Singletoggle jaw crusher Design Singletoggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being braced against the crusher frame by means of a toggle plateIndustrial Solutions Jaw crushersJW Series of single toggle jaw crushers, built for troublefree operation in heavy and continuous applications Designed to suit track, mobile or static plant installations these rugged machines are manufactured with heavyduty components for optimum operation and long life Typical applications for our single toggle jaw crushers are in Minerals Processing Systems JW SERIES JAW CRUSHERSproud to add their new line of single toggle jaw crushers, the TST, to the heritage the double toggle crushers established The TST jaw crushers are engineered for troublefree operation, characterized by safe and easy serviceability The most modern analysis techniques and features available to date ensure a strong and reliable crusher designTST jaw crusher Our Sandvik CJ412 singletoggle jaw crusher is engineered for even the toughest mining applications thanks to its heavyduty design Characterized by an attention to detail in its design and manufacture, this machine is an excellent choice when you need high production and low total costSandvik CJ412 SingleToggle Jaw Crusher For Low Total Cost

parts manual jaw crusher 20 x 36 worldcrushers

Mar 30, 2013 Portable 20×36 Jaw Crushing Plant (#) 20″ x 36″ singletoggle jaw crusher w/ new parts manual jaw crushers pionner 20×36 – Beneficiation Pioneer Crusher Manganese Wear Parts, Jaw Rock Crushing Single Toggle Jaw Crusher is ideally suitable for primary and secondary crusher for material with compression strength less than 320mpa Jaw crusher is of high crushing ratio, larger capacity, welldistributed final product size, simple structure, reliable performance, convenient maintenance, lower operation cost, etc it is widely used in mining, metallurgy, construction, highway, rail road Single Toggle Jaw Crusher at Rs /unit सिंगल टॉगल • Single toggle jaw crusher elemental parts of the system and consequently difficult to This book is about best practices for the design of mechanical products It is available from (PDF) Design of Impact stone crusher machineQJ241 JAW CRUSHER ENGINEERING IN MOTION QJ241 JAW CRUSHER KEY SPECIFICATIONS DATA Equipment Single toggle C10 jaw crusher Feed opening 1000 mm x 650 mm / 40” x 26” Optimum feed size 520 mm3 / 21 inch3 Engine C71 Acert 168 kW / 225 hp Transport dimensions 1390 m / 45’ 7 ⅜” (l) 264 m / 8’ 7 ⅞” (w) 322 m / 10’ 6 ⅝” (h)TECHNICAL SPECIFICATIONS QJ241 JAW CRUSHERJaw crushers are used mainly in first stage, primary crushing applications and are ideal for use in quarries and recycling demolition operations The two main types of jaw crusher produced by Parker are both single toggle designs with the upthrust toggle RockSizer / StoneSizer model and downthrust toggle RockSledger modelJaw Crushers Parker Plant

Jaw Crusher With Different Models

Application fields The jaw crusher is a kind of early crushing device With simple and firm structure, reliable operation, easy maintenance and service and relatively low costs in production and construction, jaw crusher is still widely used in coarse, medium and fine crushing for various ores and rocks with compressive strengths ranging from 147 to 245 MPa in metallurgy, chemistry, building Double toggle jaw crusher is heavier and lots of moving parts than the single toggle jaw crusher The main difference is the position of eccentric between both of them Jaw crusher available in three variant mobile, stationary, and portable design whatever customer suits and full fills there need may consider itShould know all about Stone Crusher Plant Machine ThugSandvik CJ411 singletoggle jaw crusher is engineered for even the toughest mining applications thanks to its heavyduty design Characterized by an attention to detail in its design and manufacture, this machine is an excellent choice when you need high production and low total costUJ310 Wheeled unit — Sandvik Mining and Rock TechnologyKueKen – 35200 Double Toggle Brown Lennox – Single Toggle All of our jaw plates are stocked in 18% manganese/Cr stock a wide range spare replacement parts for these machines, including pitmans, toggles front rear, toggle seats, eccentric shafts and diaphragmsManganese Parts Australian Crushing and Mining