Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

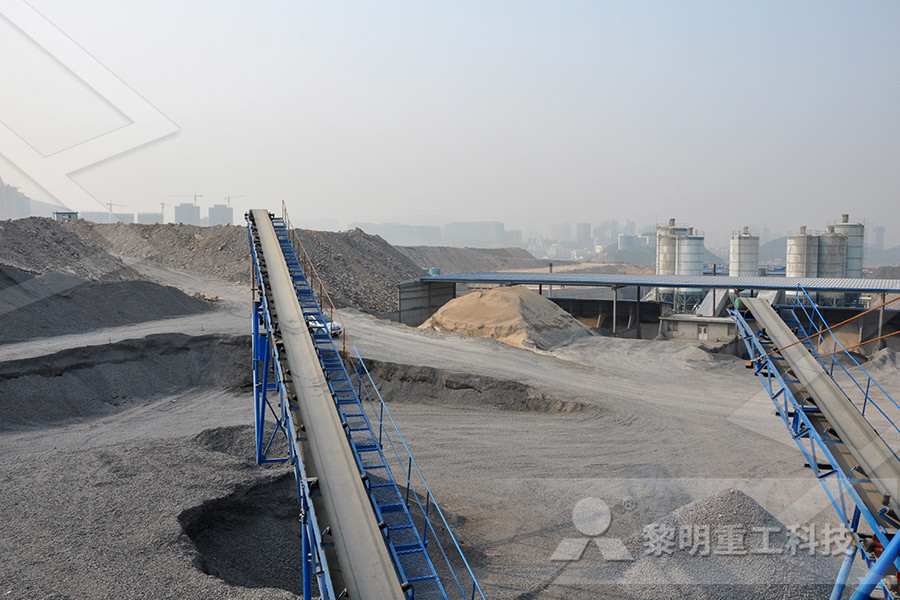

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Magnetic Separation an overview ScienceDirect Topics

Magnetic separation takes advantage of the fact that magnetite is strongly magnetic (ferromagnetic), hematite is weakly magnetic (paramagnetic), and most gangue minerals are not magnetic (diamagnetic) A simple magnetic separation circuit can be seen in Figure 125 [9]A slurry passes by a magnetized drum; the magnetic material sticks to the drum, while the nonmagnetic slurry keeps mercial magnetic separators are continuousprocess machines, and separation is carried out on a moving stream of particles passing into and through the magnetic field Close control of the speed of passage of the particles through the field is essential, which typically rules out Magnetic Separator an overview ScienceDirect TopicsAug 04, 2020 Payouts for magnetic separation systems are typically measured in months based on avoided use of filter elements (such as in deployments upstream of conventional filter systems) Drive higher product quality These systems are highly efficient (over 95%) at removing particulates all the way down below 01 microns Technical Brief: How a Magnetic Separator Can Reduce Magnetic Separation Products Permanent Magnets Eriez Permanent Magnetic Separators require no electric power With proper care, they can last a lifetime with very little loss of field strength The electromagnet is typically mounted or suspended over a conveyor belt to remove large pieces of tramp metal that represent a hazard to Magnetic Seperation Phenix Equipment IncMagnetic separation was typically limited and moderately effective Magnetic separators that used permanent magnets could generate fields of low intensity only These worked well in removing ferrous tramp but not fine paramagnetic particlesHighintensity magnetic separator Wikipedia

magnetic separation typically numismaticaleuvenbe

Magnetic Separation Know More Magnetic beads from iron oxide are typically used for biological separation The main properties of iron oxide are super paramagnetic properties (Meza, 1997)Additionally, rareearth dry magnetic separation circuits are typically lower in capital and ongoing maintenance costs, and are less complicated to operate than WHIMS Rareearth drum vs rareearth roll A RED is most often used to separate two or moreA discussion of magnetic separation techniques for The magnetic elements described above are axial elements The magnetic poles run across the width of the drum and are of alternating polarity Magnetic elements are typically assembled with a minimum of five magnetic poles that span an arc of 110 degrees (For all practical purposes, an arc of only 80 degrees is required to impart a separationWet Magnetic Drum Separator 911MetallurgistMagnetic separation is a versatile technique used in sample preparation for diagnostic purpose For such application, an external magnetic field is applied to drive the separation of target entity (eg bacteria, viruses, parasites and cancer cells) from a complex raw sample in order to ease the subsequent task(s) for disease diagnosisWorking principle and application of magnetic separation Finally, magnetic separators placed in the packaging / shipping area will insure customers receive products free of unwanted metals Add Magnet Selection to Your Operations Advanced Process Systems can connect you with the magnetic separation equipment and handling solutions your operation needs for improved efficiency and qualityMagnetic Separation

How magnetic separation optimizes sorting and process

Jun 18, 2020 View the magnetic separation webinar and white paper to dive deeper into this topic In the twostage, you typically have the weaker magnet at the top to separate your ferrous material and the stronger magnet at the bottom to separate your paramagnetic material We also use a wet magnetic separator in our plant to recover ferrosilicon (FeSi Magnetic Separation Products Permanent Magnets Eriez Permanent Magnetic Separators require no electric power With proper care, they can last a lifetime with very little loss of field strength The electromagnet is typically mounted or suspended over a conveyor belt to remove large pieces of tramp metal that represent a hazard to Magnetic Seperation Phenix Equipment IncAdditionally, rareearth dry magnetic separation circuits are typically lower in capital and ongoing maintenance costs, and are less complicated to operate than WHIMS Rareearth drum vs rareearth roll A RED is most often used to separate two or moreA discussion of magnetic separation techniques for The Magnetic Disc Separator is widely used to ensure an accurate separation of dry minerals that have varied magnetic susceptibilities The Design Typically, a Magnetic Disc Separator features up to three highintensity electromagnetic discs, each set at a different height from a feed conveyorVideo Explanation of the Magnetic Disc Separator Bunting Magnetic Separation Know More Magnetic beads from iron oxide are typically used for biological separation The main properties of iron oxide are super paramagnetic properties (Meza, 1997)magnetic separation typically numismaticaleuvenbe

Mineral processing Wikipedia

Magnetic separation is a process in which magnetically susceptible material is extracted from a mixture using a magnetic force This separation technique can be useful in mining iron as it is attracted to a magnet In mines where wolframite was mixed with cassiterite, such as South Crofty and East Pool mine in Cornwall or with bismuth such as Sep 13, 2012 On a commercial scale, the magnetic separation method could be used in conjunction with existing oil recovery techniques such as skimming, which would perform an initial separation The magnetic MIT researchers devise technique to clean up oil spills The magnetic elements described above are axial elements The magnetic poles run across the width of the drum and are of alternating polarity Magnetic elements are typically assembled with a minimum of five magnetic poles that span an arc of 110 degrees (For all practical purposes, an arc of only 80 degrees is required to impart a separationWet Magnetic Drum Separator 911MetallurgistInnovative Magnetic Technologies is a leading manufacturer supplier of industrial strength magnetic separation equipment Our product line consists of Suspended Plate Magnets, Cross Belt Separators, Magnetic Head Pulleys, Magnetic Plate Separators, Magnetic Conveyors, Drum Separators, Lifting Magnets and Magnetic SweepersOur equipment is available in Ceramic (Ferrite) or Rare Earth Specializing in Industrial Magnetic SeparationMagnetic Separation Head Pulleys Our comprehensive line of powerful permanent Magnetic Separation Pulleys are typically installed as magnetic head pulleys and occasionally as magnetic tail pulleys in conveyor system applications to improve product purity and protect equipment from metal damage They provide effective, automatic and continuous Industrial Magnetics, Inc Conveyor Line

(PDF) Variables and Applications on Dry Magnetic Separator

Nov 09, 2020 In mineral separation plant, typically magnetic roll separator for recove ring highvalue pro ducts and final cleaning, such as rutile and zircon, suitable separation if Magnetic rods and plugs generally need to be wiped clean only at each service interval Separation is not by Sizeexclusion Mechanics – As previously discussed, separation is based on physics considerably different from sizeexclusion – the method which defines the performance of conventional mechanical filters Instead, the capture Magnetic Filtration Applications and BenefitsInnovative Magnetic Technologies is a leading manufacturer supplier of industrial strength magnetic separation equipment Our product line consists of Suspended Plate Magnets, Cross Belt Separators, Magnetic Head Pulleys, Magnetic Plate Separators, Magnetic Conveyors, Drum Separators, Lifting Magnets and Magnetic Specializing in Industrial Magnetic SeparationMagnetic separation was typically limited and moderately effective Magnetic separators that used permanent magnets could generate fields of low intensity only These worked well in removing ferrous tramp but not fine paramagnetic particlesHighintensity magnetic separator WikipediaThe MagniSort™ Mouse CD45R (B220) Positive Selection Kit is designed for the magnetic separation of CD45R+ cells by positive selection It has been optimized for the isolation of CD45R+ cells from mouse spleens, bone marrow, or lymph nodes utilizing a biotinylated AntiMouse CD45R antibody and streptavidincoated magnetic beadsShop All Magnetic Affinity Separation Particles Thermo

magnetic separation typically numismaticaleuvenbe

Magnetic Separation Know More Magnetic beads from iron oxide are typically used for biological separation The main properties of iron oxide are super paramagnetic properties (Meza, 1997)For the primary separation, a Magnetic Separator (typically an Induced Magnetic Roll or Rare Earth Roll Separator) removes magneticallysusceptible para and ferro magnetic minerals (eg ilmenite, garnet, monazite) The secondary electrostatic separation focuses on separating the remaining minerals (eg zircon sand, silica and rutile)ElectroStatic Separation of Minerals Environmental XPRTMagnetic Separation in the Mining Industry Mainland Apr 29 2015 Magnetic separation is most commonly used in the mining industry to separate “tramp ore” or unwanted waste metals from the rest of the bulk material Tramp ore typically consists of the manmade byproducts created by the mining process itself such as wires from explosiveget priceApplication Of Magnetic Separation In Mining IndustrySep 13, 2012 On a commercial scale, the magnetic separation method could be used in conjunction with existing oil recovery techniques such as skimming, which would perform an initial separation The magnetic MIT researchers devise technique to clean up oil spills Magnetic Separator Used in Iron Sand Processing Magnetic separator is broadly used in iron sand processing, coal washing and chemical industry, for sorting the wet particle size of 6~10mm The strong magnetic minerals and magnetic minerals are divided into two kinds of material: nonmagnetic material and magnetic material Magnetic ore separator is appropriate for wet magnetic separation of magnetic separation in sand processing

Magnetic Filtration Applications and Benefits

Magnetic rods and plugs generally need to be wiped clean only at each service interval Separation is not by Sizeexclusion Mechanics – As previously discussed, separation is based on physics considerably different from sizeexclusion – the method which defines the performance of conventional mechanical filters Instead, the capture Nov 09, 2020 In mineral separation plant, typically magnetic roll separator for recove ring highvalue pro ducts and final cleaning, such as rutile and zircon, suitable separation if (PDF) Variables and Applications on Dry Magnetic SeparatorMagnetic Separation Products Permanent Magnets Eriez Permanent Magnetic Separators require no electric power With proper care, they can last a lifetime with very little loss of field strength The electromagnet is typically mounted or suspended over a conveyor belt to remove large pieces of tramp metal that represent a hazard to Magnetic Seperation Phenix Equipment IncAfter magnetic separation, the magnetic beads are washed to remove contaminants and salts using configuration of the instrument and the magnetic separation system used Typically, 96 samples can be purified in less than 30 minutes using the genesig Easy Extraction kits on the automation platformDNA/RNA Extraction Kit genesigThis is the strongest ferrite magnetic element utilized in a production wet drum magnetic separator Subsequent separation stages are typically conducted on magnetic concentrates after regrinding These separation stages are termed Cleaner or Finisher The cleaner and finisher magnetic separators are typically double or tripleMMPB470O Wet Drum Separators Eriez

Video Explanation of the Magnetic Disc Separator Bunting

The Magnetic Disc Separator is widely used to ensure an accurate separation of dry minerals that have varied magnetic susceptibilities The Design Typically, a Magnetic Disc Separator features up to three highintensity electromagnetic discs, each set at a different height from a feed conveyor