Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

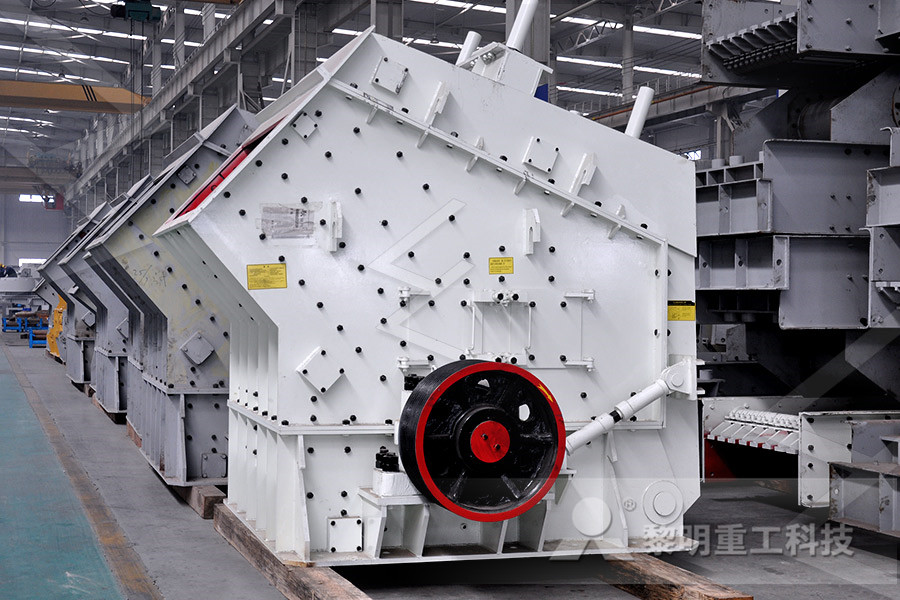

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Impact Crusher Parts Columbia Steel Casting Co, Inc

Impact Crushers Home → Products → Crusher Wear Parts → Impact Crushers Longlasting wear parts for horizontal and vertical shaft impactors Call Columbia Steel for your standard and heavy duty impeller bars, curtain liners and liner plates We also Impact crushers, or impactors as they are also called, are generally divided into two main technologies The conventional type has horizontal shaft configuration, and for that reason it is known as a horizontal shaft impact crusher or shorter as HSI crusher The other type has a centrifugal crusher with vertical shaft, and it is called a Impact crushers highquality impactors The impact crusher parts are available for both horizontal shaft impact (HSI) crushers and vertical shaft impact (VSI) crushers Discover impact crusher parts > Jaw crusher parts Known for cost efficiency and reduced downtime, 's jaw crusher parts are the best choise for long lasting, high quality productionCrusher parts spares and wears for cone, impact, jaw Nov 25, 2020 Minyu Impact Crushers are designed with an extra large feed opening, hydraulic hood opening, and automatic adjustment control Due to simple structure, low power consumption, high crushing ratio, and even grain distribution, our Impact Crushers have a Impact Crushers Crushing Equipment Minyu Machinery CorpUnique tooth type impact lining board crusher parts, especially suitable for crushing hard rock, high efficiency, and energysavingDifference between jaw crusher and impact crusherDifferent structure the structure of jaw crushers is simple so that it is easy to manufactureBut its performance is reliable, and the maintain not complicatedImpact Crusher And Its Parts logopedialogospl

Impact Crusher And Its Parts

Impact crusher and its spare parts blow bar exported application impact crusher is suitable for primary and secondary crushing low abrasion materials it is widely used in quarrying and gravel pit industries cement industry concrete and asphalt recycling and slag recycling impact crusher and its Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them Impact crushing can be of two variations: gravity and dynamic An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill) Dynamic impact could be described as material dropping Impact Crusher Working PrincipleDec 20, 2020 Shop Impact Crushers For Sale by owners dealers near you Browse 30 new and used Impact Crushers by FABO, EvoQuip, JCI, Pegson, Texas Crusher, and moreImpact Crushers For Sale MyLittleSalesmanImpact crushers and its parts impact crushers and its parts tourdesignersco new and used impact crushers for sale savona equipment is an impact crusher supplier worldwideeach crusher is designed to work with a certain maximum size of raw material and Get Priceimpact crusher and its partsImpact Crushers And Its Parts Angola Kavin Mining Impact crusher and its spare parts blow bar exported to wheel mobile primary impact crusher in cameroon application impact crusher is suitable for primary and secondary crushing low abrasion materials it is widely used in quarrying and gravel pit industries cement industry concrete and asphalt recycling and slag recyclingimpact crushers and its parts

Impact Crusher Working Principle

Starting from the base working principle that compression is the forcing of two surfaces towards one another to crush the material caught between them Impact crushing can be of two variations: gravity and dynamic An example of gravity impact would be dropping a rock onto a steel plate (similar to what goes on into an Autogenous Mill) Dynamic impact could be described as material dropping Impact crushing is a crushing method where comminution is by impact rather than by compression Sharp blows are applied at high speed to freefalling rock The moving parts are beaters, which transfer some of their kinetic energy to the ore particles on contacting themImpact Crushers SolidsWikiStedman Machine Impact Crushers As a trusted impact crusher manufacturer, every Stedman crusher is engineered for a maximum feed size, target output size, and total capacity, but selecting a crusher on these criteria alone is merely half the task These can be used as a cement crusher, mineral crusher, and many moreImpact Crusher Cement Crusher Manufacturer Stedman Impact Crushers offer more crushing force with a high pivot point and large crushing stroke for better end product shape and high production of salable material These are the result of extensive that has been manufacturing Impact crushers for over 30 yearsimpact crusher for sale,small impact crushers design,parts 13 hours ago The vertical shaft impact crusher has high production efficiency, but after a period of use, pay attention to the wear of the equipment Vertical shaft impact crusher has longterm contact with sand and gravel materials The wear of the internal parts of the vertical shaft impact crusher is mainly caused by the friction with the materialWhat are the reasons for the wear of the vertical shaft

Impact Crushers And Its Parts ePedicabs

Impact Crushers And Its Parts Production capacity : 12725t/h Max Feeding Size : 2550mm Environmental Friendly Sand makers are also called sand making machines Sand maker is made primary equipment of sand production line The machine Home Impact Crushers And Its Parts In Mozambi Copper Ore Processing Equipment Capacity:0187 (m ³/min) Suitable Materials:Copper, zinc, lead, nickel, gold and other nonferrous metals, ferrous and nonmetal View Details Send Enquiry Ceramsite Production Line Impact Crushers And Its Parts In MozambiThere are two main categories of VSI crushers – machines with impact wear parts around the body and machines that use a layer of accumulated material The first type is in many respects similar to the conventional impactor with horizontal shaft and rotor The second type became quite popular in the past decade and is known as the Barmac crusherCrushers All crusher types for your reduction needs Aug 01, 2019 Generally, the impact crusher, the fine crushing jaw crusher or the cone crusher is used as the secondary crushing to crush the material to less than 2 cm, and the selected granularity can be basically achieved Long life of wear parts: wear parts have a long service life, and the frequency of maintenance is greatly reduced2 Types of Concrete Crushers Fuel efficiency and electric power Traditionally, mobile impact crushers have used a dieselhydraulic engine for the trackdrive and power to the crusherThe advent of electricdrive and hybrid systems is one of the main advancements that has occurred over the last decade, and its development is seen by many as one of the most significant trends going forward, especially considering the The rise of mobile impact crushers for recycling

Impact Crushers Primary McLanahan

McLanahan offers a wide selection of Impact Crushers for quarried limestone and semiabrasive minerals McLanahan draws from the 75 years of field experience with the Universal line of Impactors, which includes impact breakers and Andreasstyle impactors At present, we offer the New Hollandstyle primary impact breaker and the MaxCap XSeries Primary, providing a means to reduce quarry shot Application Impact Crusher is suitable for primary and secondary crushing low abrasion materials It is widely used in quarrying and gravel pit industries, cement industry, concrete and asphalt recycling, and slag recycling PF1315 impact crusher and its spare parts blow bar: Client::Impact Crusher and its Spare Parts Blow Bar exported to New or additional parts attached to the crusher can enhance its performance and increase its lifespan You can figure out more about what parts or crusher models are right for you by doing an online search or discussing the matter with other members of your industrial project teamCrushers For Sale Equipment TraderDec 19, 2020 Impact crusher Impact crusher When the impact crusher is working, the rotor rotates at high speed under the driving of the motorAfter the ores enter the action area of the hammer, it collides with the hammer on the rotor and is thrown to the impact device to crush again, and then rebound from the impact lining to the hammer action zone to continuous crush4 Types of Stone Crushers' Maintenance and Efficient There are two main categories of VSI crushers – machines with impact wear parts around the body and machines that use a layer of accumulated material The first type is in many respects similar to the conventional impactor with horizontal shaft and rotor The second type became quite popular in the past decade and is known as the Barmac crusherCrushers All crusher types for your reduction needs

Impact Crushers SolidsWiki

Impact crushing is a crushing method where comminution is by impact rather than by compression Sharp blows are applied at high speed to freefalling rock The moving parts are beaters, which transfer some of their kinetic energy to the ore particles on contacting themStedman Machine Impact Crushers As a trusted impact crusher manufacturer, every Stedman crusher is engineered for a maximum feed size, target output size, and total capacity, but selecting a crusher on these criteria alone is merely half the task These can be used as a cement crusher, mineral crusher, and many moreImpact Crusher Cement Crusher Manufacturer Stedman Impact Crushers offer more crushing force with a high pivot point and large crushing stroke for better end product shape and high production of salable material These are the result of extensive that has been manufacturing Impact crushers for over 30 yearsimpact crusher for sale,small impact crushers design,parts Application Impact Crusher is suitable for primary and secondary crushing low abrasion materials It is widely used in quarrying and gravel pit industries, cement industry, concrete and asphalt recycling, and slag recycling PF1315 impact crusher and its spare parts blow bar: Client::Impact Crusher and its Spare Parts Blow Bar exported to Aug 01, 2019 Generally, the impact crusher, the fine crushing jaw crusher or the cone crusher is used as the secondary crushing to crush the material to less than 2 cm, and the selected granularity can be basically achieved Long life of wear parts: wear parts have a long service life, and the frequency of maintenance is greatly reduced2 Types of Concrete Crushers

Primary Impact Crushers Horizontal Impactor MegaSlam

A solid performer since its groundbreaking introduction, the Stedman MegaSlam horizontal impactor effectively handles large feed sizes beyond the range of secondary HSI crushers MegaSlam primary impact crushers are engineered for low maintenance and feature simplified interior access to breaker bars, primary and secondary aprons and side liners, maximizing production uptimeFuel efficiency and electric power Traditionally, mobile impact crushers have used a dieselhydraulic engine for the trackdrive and power to the crusherThe advent of electricdrive and hybrid systems is one of the main advancements that has occurred over the last decade, and its development is seen by many as one of the most significant trends going forward, especially considering the The rise of mobile impact crushers for recycling Mobile impact crushers The mobile impact crushers MOBIREX are used in soft to mediumhard natural rock and in recycling The capacity of the plants is enormous and the focus is not only on pure volume reduction Cost and environmental awareness, availability, versatility and, above all, the quality of the final product are important aspectsMobile impact crushers WIRTGEN GROUPDec 19, 2020 Impact crusher Impact crusher When the impact crusher is working, the rotor rotates at high speed under the driving of the motorAfter the ores enter the action area of the hammer, it collides with the hammer on the rotor and is thrown to the impact device to crush again, and then rebound from the impact lining to the hammer action zone to continuous crush4 Types of Stone Crushers' Maintenance and Efficient TC20 Mobile Impact Crusher (HSI) The TC20 track horizontal shaft impact (HSI) crusher has the largest hopper in its class and is built for big loads and even bigger production IROCK’s TC20 mobile unit produces a uniform, cubical product that will increase your bottom lineTC20 Mobile Impact Crusher (HSI) IROCK Crushers

The Models And Parameters Of Cone Crusher

However, impact crusher is generally used for crushing soft materials such as limestone because its crushing principle and wearresistant parts, and impact has a good performance in shaping When choosing crusher machines, a comparison should be conducted according to different situationsImpact crusher spare parts,crusher hammer,US $ 09 69 Piece, Anhui, China (Mainland), HDNM, C 2290Source from Maanshan Huadong Wear Resisting Alloy impact crusher parts for sale cn impact crusher parts and impact crusher parts manufacturers 21558 impact crusher parts wholesalers Suppliers from ChinaImpact Crusher Replacement PartsCrusher blow bars are the main impact crusher wear parts, which also called impact crusher liner, impact crusher hammer, and impact crusher break plate Crusher blow bars are thick slabs of metal, typically some mixture of chrome, that are forged for the purpose of effectively breaking apart material like asphalt, concrete, limestone, etcCrusher Blow Bars China Casting Foundry Qiming Machinery