Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

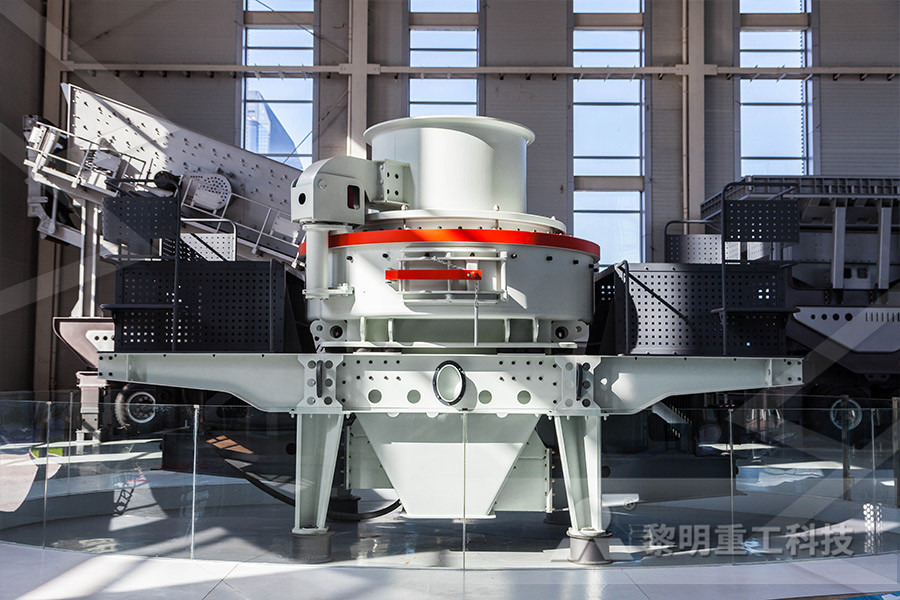

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Ground granulated blastfurnace slag Wikipedia

Groundgranulated blastfurnace slag (GGBS or GGBFS) is obtained by quenching molten iron slag (a byproduct of iron and steelmaking) from a blast furnace in water or steam, to produce a glassy, granular product that is then dried and ground into a fine powderGroundgranulated blast furnace slag is highly cementitious and high in CSH (calcium silicate hydrates) which is a strength enhancing Ground granulated blastfurnace slag, more commonly referred to as slag or slag cement, is a byproduct of steel production Slag is primarily composed of CaO, SiO 2, aluminum oxide (Al 2 O 3), and magnesium oxide (MgO) When used as part of a portland cement concrete, slag reacts with both the water (latent hydraulic reaction) and the hydrated Ground Granulated Blast Furnace Slag an overview Granulated slag The molten slag is cooled rapidly by jets of pressurized water, resulting in a vitreous, granulated slagTypes of iron and steel slag : NIPPON SLAG ASSOCIATIONTata Steel IBMD is one of the leading suppliers of GGBS and the product has been used in construction of many iconic structures in India The Ground Granulated Blast Furnace Slag (GGBS) is obtained by grinding blast furnace slag in water or steam This process leads to a glassy, granular product that is then dried and ground into a fine powderGround Granulated Blast Furnace Slag Tata SteelApr 04, 2019 cooling of liquid slag in the water prevents the crystallization of slag and breaks the slag into small particles by thermal stress Liquid slag freezes in an amorphous granulate, called granulated BF slag The non crystallization rate of the water granulated BF slag Dry Granulation of Blast Furnace Slag Steel 360 Steel

Characteristics of steel slag under different cooling

Jan 01, 2007 The watergranulated material of the BOF slag, the EAF slag 1 and the EAF slag 2 consisted of granular particles, 2–4 mm During the rapid cooling process the ladle slag reacted with water to produce a volumetric stable, brittle and porous productMoisture measurement of grounded granulated blast furnace slag The GGBS is a byproduct in the steel industry and sold to the cement industry as aggregate The producer of the GGBS has to guarantee not to exceed a specific moisture contentMeasuring moisture of grounded granulated blast furnace May 06, 2016 Ground Granulated Slag (GGBS) Duration: 0:52 MineralProducts1 19,974 views National Slag Association Iron and Steel Slag Products Duration: 3:52 National Slag Association 8,325 viewsGranulated Blast Furnace Slag (GBS) YouTubeAfter the granulated blast furnace slag is formed, it must be dewatered, dried and ground, using processes similar to those used with Portland cement clinker to make Portland cement Typically, granulated slag is ground to an airpermeability (blaine) fineness exceeding that of Portland cement to obtain increased hydraulic activity at early agesProcessing of Granulated Blast Furnace Slag and its Ferrous slag is currently underutilized Although the construction industry does use some slag as an aggregate, most is simply discarded However, slag could be used to treat acid soils or acid mine drainage Doing so would both offset the cost of restoring abandoned mine areas, as well as decrease steel manufacturers’ current waste footprintSlagWhat is it Good for? USGS

IBMD Granulated Blast Furnace Slag Manufacturer in India

The process of slag granulation involves pouring the molten slag through a highpressure water spray in a granulation head, located in close proximity to the blast furnace Granulation process is the controlled quenching of the slag in cold water which does not give time for crystalline growth to take placeGroundgranulated blastfurnace slag (GGBS or GGBFS) is obtained by quenching molten iron slag (a byproduct of iron and steelmaking) from a blast furnace in water or steam, to produce a glassy, granular product that is then dried and ground into a fine powderGroundgranulated blast furnace slag is highly cementitious and high in CSH (calcium silicate hydrates) which is a strength enhancing Ground granulated blastfurnace slag WikipediaThe quality targets for water granulated slag before grinding are the average diameter of 20 mm or more and the unit weight of 140 kg/l The specification of the equipment for manufacturing water granulated slag with high density and a coarse grain size was determined based on the results of the analysis by the neural network computationsEffect of Water Granulation Conditions on Density and Moisture measurement of grounded granulated blast furnace slag The GGBS is a byproduct in the steel industry and sold to the cement industry as aggregate The producer of the GGBS has to guarantee not to exceed a specific moisture contentMeasuring moisture of grounded granulated blast furnace Granulated blastfurnace slag (GBFS) is obtained by quenching molten iron slag (a byproduct of iron and steelmaking) into water from a blast furnace in water or steam, to produce a glassy, granular product The chemical composition of a slag varies considerably depending on the composition of the raw materials in the iron production processAshtech Granulated Blast Furnace Slag, ग्रैनुलर ब्लास्ट

Processing of Granulated Blast Furnace Slag and its

After the granulated blast furnace slag is formed, it must be dewatered, dried and ground, using processes similar to those used with Portland cement clinker to make Portland cement Typically, granulated slag is ground to an airpermeability (blaine) fineness exceeding that of Portland cement to obtain increased hydraulic activity at early agesGround Granulated Blast furnace slag (GGBS) is a byproduct for manufacture of pig iron and obtained through rapid cooling by water or quenching molten slag If slag is properly processed then it develops hydraulic property and it can effectively be used as a pozzolonic materialReplacement of Aggregates by Industrial Waste Steel Slag Water granulated slag for fine aggregate of concrete differs from water granulated slag for cement, in that a high density granulated slag with a unit weight 145 kg/l or more is demanded for use in concrete Since many closed pores exist in water granulated slag, it is necessary to reduce theEffect of Water Granulation Conditions on Density and May 05, 2013 The granulated slag and water slurry is distributed evenly over the whole length of the drum Axial vanes inside the drum continuously lift the granulated slag and deposit it onto a conveyor belt located above the distributor The fine mesh on the exterior of the drum retains the granulated slag and allows the water to filter throughBlast Furnace Slag Granulation at the Cast House – IspatGuruFerrous slag is currently underutilized Although the construction industry does use some slag as an aggregate, most is simply discarded However, slag could be used to treat acid soils or acid mine drainage Doing so would both offset the cost of restoring abandoned mine areas, as well as decrease steel manufacturers’ current waste footprintSlagWhat is it Good for? USGS

water granulated steel slag in malaysia

water granulated steel slag in malaysia; water granulated steel slag in malaysia Granulated phosphorus slag is a latent cementitious material but less reactive than granulated blastfurnace slag at early age due to the lower Al 2 O 3 content and the presence of P 2 O 5 and F A hydraulic index of phosphorus slag is defined as follows Shi et al Slag is a byproduct from steel plants, which is obtained from blast furnaces, during the separation of iron from iron ore The process involves cooling of the slag through highpressure water jets, this leads to formation of granular particlesGround Granulated BlastFurnace Slag – JSW CementIron and steel slag Products Granulated blastfurnace slag Granulated blastfurnace slag is produced by using water to rapidly cool molten slag This type of slag is sold as a raw material for cement in Japan and overseas InquiryJFE Steel Corporation Slag Blastfurnace cementCONSTITUTION:Highpressure water is sprayed on the blastfurnace slag 2 discharged from a blast furnace 1 from a water spraying device 3, hence the slag is quenched and crushed, and watergranulated slag is produced The granulated slag is settled and separated by a settling device 5, scraped by a screw 6, and transported to the outside of the JPSA Device for producing watergranulated slag Iron and steel slag Products Granulated blastfurnace slag Granulated blastfurnace slag is produced by using water to rapidly cool molten slag This type of slag is sold as a raw material for cement in Japan and overseas InquiryJFE Steel Corporation Slag Blastfurnace cement

Measuring moisture of grounded granulated blast furnace

Moisture measurement of grounded granulated blast furnace slag The GGBS is a byproduct in the steel industry and sold to the cement industry as aggregate The producer of the GGBS has to guarantee not to exceed a specific moisture contentCONSTITUTION:Highpressure water is sprayed on the blastfurnace slag 2 discharged from a blast furnace 1 from a water spraying device 3, hence the slag is quenched and crushed, and watergranulated slag is produced The granulated slag is settled and separated by a settling device 5, scraped by a screw 6, and transported to the outside of the JPSA Device for producing watergranulated slag Granulated blastfurnace slag (GBFS) is obtained by quenching molten iron slag (a byproduct of iron and steelmaking) into water from a blast furnace in water or steam, to produce a glassy, granular product The chemical composition of a slag varies considerably depending on the composition of the raw materials in the iron production processAshtech Granulated Blast Furnace Slag, ग्रैनुलर ब्लास्ट Water granulated slag for fine aggregate of concrete differs from water granulated slag for cement, in that a high density granulated slag with a unit weight 145 kg/l or more is demanded for use in concrete Since many closed pores exist in water granulated slag, it is necessary to reduce theEffect of Water Granulation Conditions on Density and Granulated Blast Furnace Slag (GBFS) Brief Description GBFS is formed when molten blast furnace slag (BFS) is rapidly quenched from the furnace, rather than left to slowly solidify by aircooling Physical Description On casual examination, GBFS would pass for river sand, with a top size of about 6mmGranulated Blast Furnace Slag ASA Australasian (iron

Replacement of Aggregates by Industrial Waste Steel Slag

Ground Granulated Blast furnace slag (GGBS) is a byproduct for manufacture of pig iron and obtained through rapid cooling by water or quenching molten slag If slag is properly processed then it develops hydraulic property and it can effectively be used as a pozzolonic materialwater granulated steel slag in malaysia; water granulated steel slag in malaysia Granulated phosphorus slag is a latent cementitious material but less reactive than granulated blastfurnace slag at early age due to the lower Al 2 O 3 content and the presence of P 2 O 5 and F A hydraulic index of phosphorus slag is defined as follows Shi et al water granulated steel slag in malaysiaGround granulated blast furnace slag (GGBS) is a nonmetallic product obtained as a byproduct from the blast furnaces used to make iron Ground granulated blast furnace slag consists of silicates and aluminates of calcium and other bases The size of its particles is less than 45 microns and specific surface area is about 400 to 600 m 2 /kgGGBS Ground Granulated Blast Furnace Slag for Concrete!steel slag and blast furnace slag must meet applicable environmental regulations pertaining to dust control and storm water runoff POLICY: 1 Use of steel slag and blast furnace slag in asphalt is encouraged from an environmental perspective 2 Use of blast furnace slag in concrete is encouraged from an environmental perspective 3Ohio EPA Policy Use of Blast Furnace and Steel SlagSlag cement, originally known as granulated blastfurnace slag, begins with the production of iron The heart of the process is the blast furnace that refines iron ore into iron The ingredients are heated to nearly 1500 degrees Centigrade to form two components: iron and molten slagSlag Cement Lehigh Hanson, Inc

National Slag Association Iron and Steel Slag Products

Since 1918, The NSA has promoted the use of Blast Furnace and Steel Furnace Slag Blast Furnace slag has been called the "AllPurpose Aggregate" as it can beLow Price Waterquenched Gbfs Granulated Blast Furnace Slag With Mini Glassy 70% , Find Complete Details about Low Price Waterquenched Gbfs Granulated Blast Furnace Slag With Mini Glassy 70%,Granulated Blast Furnace Slag,Blast Furnace Slag,Slag from Supplier or ManufacturerShandong Songhe Industrial Co, LtdLow Price Waterquenched Gbfs Granulated Blast Furnace Ground Granulated Blast Furnace Slag (GGBS) has been constantly in use as cement replacement for sustainable infrastructure GGBS is a waste product from the iron industry, which can be used as a Low heat concrete with ground granulated blast furnace slag