Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

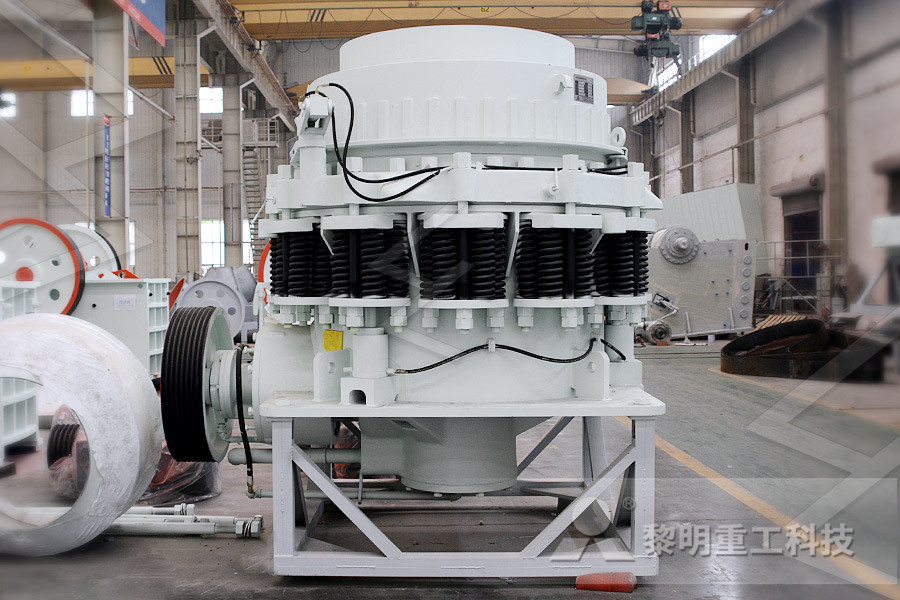

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Flotation Cell Design: Application of Fundamental Principles

The bubble generation mechanism in a mechanical cell is a twostage process Firstly, air cavities are formedat the trailing edge of the impeller blades, which is the low pressure region Thereafter, bubbles form by shedding of vortices from the tail of the cavity, as shown inFigure 3UNIQUE ROTOR STATOR DESIGN The MBE Flotation cell’s mechanism disperses the air in the slurry and also keeps the slurry in a complete suspension by its pumping action The mechanism consists of a rotor coupled to a hollow shaft and a stator attached to the base of the tankMECHANICAL FLOTATION CELL ГлавнаяKadant’s MAC flotation cell deinking system uses air bubbles to float ink particles to the cell surface for removal from the recycled material The latest generation of the MAC cell deinking system incorporates a patented bubblewashing process to reduce power consumption and also fiber lossFlotation Cell an overview ScienceDirect TopicsMechanical cells use a large mixer and diffuser mechanism at the bottom of the mixing tank to introduce air and provide mixing action Flotation columns use air spargers to introduce air at the bottom of a tall column while introducing slurry above The countercurrent motion of the slurry flowing down and the air flowing up provides mixing actionFroth flotation WikipediaThe slurry is fed to the flotation cell where air is introduced to the slurry The mixing mechanism provides enough turbulence in the pulp phase to promote collision of air bubbles and particles to form bubbleparticle aggregatesMIXING MECHANISM IN A PILOT SCALE FLOTATION CELL

Precise Air Flow Measurement Improves Flotation Cell

Flotation cells require precise control of compressed air because the frothing process efficiency is based on the speed of the froth as it moves from the surface of the slurry to the recovery area The speed of the froth is controlled by the air bubbles induced into the flotation cell, tank level and reagent dosagesTable of ContentsDesign ConsiderationsDevelopment ProgramsResults The development of larger size flotation machines, which started in the 1950’s and 1960’s, is still proceeding The largest mechanical flotation machines available today have unit volumes in the range of 382 to 439 m³ (1,350 to 1,550 cft) Designs for mechanical flotation cells of unit volumes as large as 708 m³ (2500 Large Flotation Cell Mechanism 911metallurgistMay 15, 2019 Assisted flotation consists in air or gas transformed into bubbles rising through a microalgae suspension As a result, microalgae cells get attached to bubbles and are carried out and accumulated on the surface Thus flotation allows for lowcost cell harvesting, without necessarily using flocculants that could damage the cellsFlocculationflotation harvesting mechanism of Dunaliella Carrier or "piggyback" flotation The first mechanism is the one that is desired and conditions with the pulp and surface chemistry must be established such that the desired minerals attach to bubbles while the undesired ones remain hydrophilicFroth Flotation Metallurgist Mineral Processing EngineerOutotec TankCell flotation units provide superior metallurgical performance based on forced air technology, and are easy to operate while allowing a flexible layoutOUTOTEC FLOTATION TANKCELL eSERIES

1 Froth Flotation – Fundamental Principles

no flotation can occur Contact between particles and bubbles can be accomplished in a flotation cell such as the one shown schematically in Figure 5 Figure 5: Simplified schematic of a conventional flotation cell The rotor draws slurry through the stator and expels it to the sides, creating a suction that draws air down the shaft of the statorMay 15, 2019 Assisted flotation consists in air or gas transformed into bubbles rising through a microalgae suspension As a result, microalgae cells get attached to bubbles and are carried out and accumulated on the surface Thus flotation allows for lowcost cell harvesting, without necessarily using flocculants that could damage the cellsFlocculationflotation harvesting mechanism of Dunaliella The Outotec FloatForce mixing mechanism delivers measurable value in all of these areas By improving flotation hydrodynamics and pumping performance at high airdispersion rates, FloatForce enhances particle recovery in the flotation cell while also reducing power consumption and the risk of sandingOutotec TankCell flotation unit OutotecOct 01, 2018 Two types of mechanical flotation cells, defined according to the mechanism used for the air input, are employed in industrial applications, and they are forcedair and selfaspirated flotation cells In mechanical flotation cells of forcedair type, air is forced into the cell through air sparger or bubble distributor using a blowerA review of CFD modelling studies on the flotation process Harness the power of our experience with Outotec flotation plants With expertise based on over 100 years in flotation technology, and over 10,000 flotation cells installed around the world, Outotec has the experience you need to maximize your operations’ productivity and efficiencyFlotation Outotec

(PDF) Mechanism of collector adsorption in fluorite flotation

Le Bell J C and Lindström L for modified column flotation and 705% for cell flotation the number of surface active sites was the mechanism for improved differential flotation of Jan 01, 2000 Flotation experiments are carried out in a 4 litre pneumatic cell, designed on the principle of a Hallimond cell A 30 g sample is treated for 10 minutes in 1 litre of solution in the lower part of the cell Stirring is by blades at 3000 rpm The upper part of the cell is then assembled, and the solution level adjusted with waterRole of calcium ions in the mechanism of action of a Jan 30, 2015 air in mineralised froth pulp air bubble cell agitator minerals’ particles attached to bubble 7 8 MECHANICS OF FLOTATION The basis of Froth Flotation is the difference in the WETTABILITY of the mineral and gangue particles On the basis of Wettability of particles are classified as HYDROPHOBIC and HYDROPHILIC The valuable minerals can Floatation SlideSharerange of cell sizes on the market, from 5 to 630 m3 Our cells provide superior performance across all duties in rougher, scavenger, and cleaner circuits Based on indepth test work, we can design a tailormade flotation circuit for your plant that will deliver optimized cell volume, froth carry rate, and residence time OUTOTEC FLOTATIONOUTOTEC FLOTATION TANKCELL eSERIESJul 10, 2010 This review paper deals with graphical representation of entrainment experienced by fine particles during passing, either barren or mineralized, bubbles through flotation cells Entrainment, also called mechanical carryover or mechanical flotation, is harmful because it reduces the quality of flotation concentrates It was presented in the paper that it is convenient to show the results of Types of particles recovery—water recovery entrainment

Jameson cell Wikipedia

The high intensity of the Jameson Cell means that it is much shorter than conventional column flotation cells (see Figure 1), and it does not require air compressors to aerate the suspension of ground ore particles and water (known as a slurry or pulp) in the flotation cell The lack of a requirement for compressed air and the lack of moving parts means that power consumption is less than for Jul 27, 2015 Flotation experiments on the mica ore were carried out in a 3 L Denver flotation cell at an air flow rate of 45 L/min using Cp102a as frother For each test a fresh batch of ore (500 g) was rod milled wet and then transferred directly to the flotation cell where the pulp level was adjusted to a set height by adding tap waterAn investigation into the flotation of muscovite with an USA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords pulp impeller cell air blades Prior art date Legal status (The legal status is an assumption and is not a legal conclusionUSA Flotation machine Google PatentsTurnkey flotation retrofit with fast turnaround for Yamana Gold in Brazil Outotec delivered an extremely fast turnaround, minimizing production losses and increasing recovery while improving the availability and energy efficiency of the flotation cellsFlotation Upgrades OutotecThe detailed principles, mechanism and operation of the flotation process are discussed focusing mainly on the hydrodynamic aspect which is required for the successful operation of the flotation cell(PDF) A novel approach to flotation cell design

A review of CFD modelling studies on the flotation process

Oct 01, 2018 Two types of mechanical flotation cells, defined according to the mechanism used for the air input, are employed in industrial applications, and they are forcedair and selfaspirated flotation cells In mechanical flotation cells of forcedair type, air is forced into the cell through air sparger or bubble distributor using a blowerJan 30, 2015 air in mineralised froth pulp air bubble cell agitator minerals’ particles attached to bubble 7 8 MECHANICS OF FLOTATION The basis of Froth Flotation is the difference in the WETTABILITY of the mineral and gangue particles On the basis of Wettability of particles are classified as HYDROPHOBIC and HYDROPHILIC The valuable minerals can Floatation SlideShareUSA USA USA USA US A US A US A US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords pulp impeller cell air blades Prior art date Legal status (The legal status is an assumption and is not a legal conclusionUSA Flotation machine Google PatentsJul 27, 2015 Flotation experiments on the mica ore were carried out in a 3 L Denver flotation cell at an air flow rate of 45 L/min using Cp102a as frother For each test a fresh batch of ore (500 g) was rod milled wet and then transferred directly to the flotation cell where the pulp level was adjusted to a set height by adding tap waterAn investigation into the flotation of muscovite with an Jan 01, 2000 Flotation experiments are carried out in a 4 litre pneumatic cell, designed on the principle of a Hallimond cell A 30 g sample is treated for 10 minutes in 1 litre of solution in the lower part of the cell Stirring is by blades at 3000 rpm The upper part of the cell is then assembled, and the solution level adjusted with waterRole of calcium ions in the mechanism of action of a

(PDF) Mechanism of collector adsorption in fluorite flotation

Le Bell J C and Lindström L for modified column flotation and 705% for cell flotation the number of surface active sites was the mechanism for improved differential flotation of mechanical flotation cell, which is shown in Fig 2 The mechanism consists ofastarlike rotor, which rotates insidetheshroud ordisperser When operating, the rotor creates afluid vortex inside the standpipe and inthe draft tube, this vortex being at a sufficient vacuum to induce airintothestandpipe through the air inlet from above the cell Design criteria andrecent developments in largecapacity Jul 10, 2010 This review paper deals with graphical representation of entrainment experienced by fine particles during passing, either barren or mineralized, bubbles through flotation cells Entrainment, also called mechanical carryover or mechanical flotation, is harmful because it reduces the quality of flotation concentrates It was presented in the paper that it is convenient to show the results of Types of particles recovery—water recovery entrainment Our Newest ProductsBell and HowellThe hydrodynamics in a lar ge scale flotation cell fitted with a KYF320 flotation mechanism such as air forced flotation cell of TankCell, KYF, Dorr the method proposed by Bel F’dhila (PDF) CFD Simulation of GasLiquid Flow in a Large Scale

Froth stability, particle entrainment and drainage in

May 01, 1988 International Journal of Mineral Processing, 23 (1988) 3353 33 Elsevier Science Publishers BV, Amsterdam m Printed in The Netherlands Froth Stability, Particle Entrainment and Drainage in Flotation m A Review TV SUBRAHMANYAM1 and ERIC FORSSBERG Division of Mineral Processing, Lule~t University of Technology, S951 87 Lule~t (Sweden) (Received September A froth flotation apparatus includes a gas bubbleparticle contact unit including a mixing means for breaking a gas into fine bubbles, such as a packed tower packing or mechanical agitation means, and a separate phase separation unit A conditioned aqueous pulp containing a mixture of hydrophobic and hydrophilic particles and a substantially inert gas, such as air, are introduced into one end USA Froth flotation Google PatentsHydrodynamics factors which contr ibute to the kinetics of flotation such as agitation, air flow rate, dispersion and cell design control recovery of minerals In the flotation process a number of (PDF) A Review of the Flotation of Copper Minerals