Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

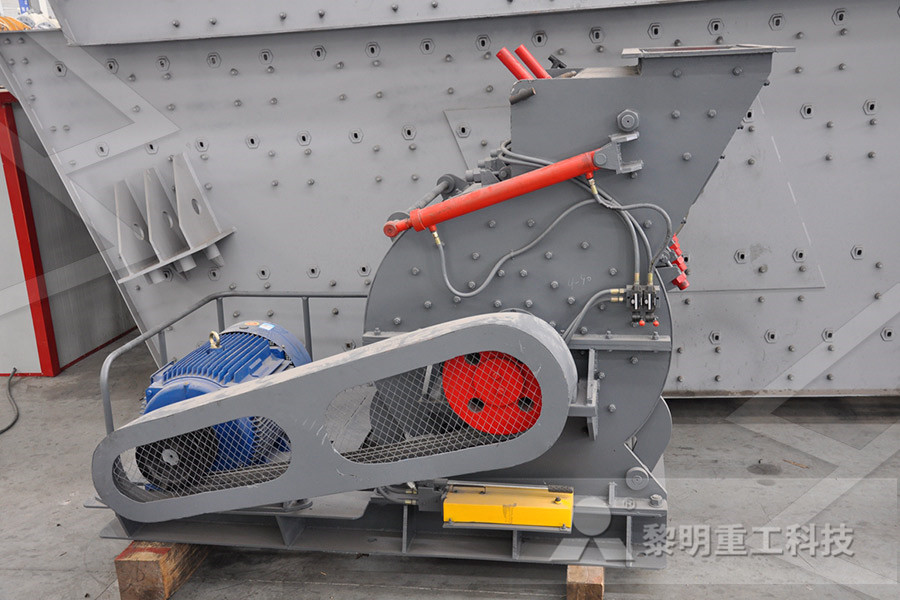

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Clean Air Act Standards and Guidelines for the Metals

Jun 18, 2020 Stainless and NonStainless Steel Manufacturing: Electric Arc Furnaces (EAF) NESHAP: Iron and Steel Production: Standards of Performance for Steel Plants: Electric Arc Furnaces (EAFs) and ArgonOxygen Decarburization Vessels (AOD) NSPS: Iron and Steel Production: Steel Pickling HCl Process Facilities and HCl Regeneration Plants: NESHAP: Iron Jun 23, 2020 Let’s take an even closer look at the options that are available for processors within the 300 and 400 stainless steel series: 304: This is the most commonlyused foodgrade stainless steel option on the market today It is most often used to process dairy, beer, and miscellaneous sanitation practices within a facilityGuide to Selection of Food Grade Stainless Steel for the May 04, 2014 The direct stainless steel making processes require less scrap and ferro alloys and may be considered when the stainless steel scrap and ferro alloys are not readily available in sufficient quantities However, chromium and nickel ores are needed and can be used in an integrated steel plant where the hot metal is availableStainless Steel Manufacturing Processes – IspatGuruOct 16, 2017 Thanks to their ability to keep pests at bay, stainlesssteel air curtains can help meat processing facilities meet the requirements set forth by the FDA and the USDA According to fesmag, the FDA specifically recommends air curtains be put to use at loading docks and delivery doors to repel insectsStainlessSteel Air Curtains for Meat Processing Facilitiesproduct plant, sinter plant, refractory mate rials plant, blast furnace, basic oxygen furnace, steel melting shop and rolling mill T he main solid wastes in steel industry are(PDF) Solid wastes generation in steel industry and their

USDA GUIDELINES FOR THE SANITARY DESIGN AND

Jun 01, 2001 for use in dairy plants surveyed and approved for USDA grading service NOTE: If the equipment is also intended for use in the processing or packaging of meat and poultry products, review may also be necessary according to the criteria in the standard ANSI/NSF/3A 100, Hygiene requirements for the design of meatMost stainless steel producers outsource the processing and/or disposal of EAF/AOD dusts and other wastes Almost all stainless steel dust processing plants in Europe and the USA require economies of scale for viable operation and are situated at locations that EAF Stainless Steel Dust ProcessingJun 18, 2020 Stainless and NonStainless Steel Manufacturing: Electric Arc Furnaces (EAF) NESHAP: Iron and Steel Production: Standards of Performance for Steel Plants: Electric Arc Furnaces (EAFs) and ArgonOxygen Decarburization Vessels (AOD) NSPS: Iron and Steel Production: Steel Pickling HCl Process Facilities and HCl Regeneration Plants: NESHAP: Iron Clean Air Act Standards and Guidelines for the Metals May 04, 2014 The direct stainless steel making processes require less scrap and ferro alloys and may be considered when the stainless steel scrap and ferro alloys are not readily available in sufficient quantities However, chromium and nickel ores are needed and can be used in an integrated steel plant where the hot metal is availableStainless Steel Manufacturing Processes – IspatGuruThe FSIS derives its regulatory power from the Code of Federal Regulations In particular, these rules provide guidance on the choice of forklifts to use in foodhandling applications: 9 CFR 4162(d) requires facilities to include “ventilation adequate to control odors, vapors, and condensation to the extent necessary to prevent adulteration USDA FSIS Regulations and Forklifts in FoodHandling

Life Cycle Costing and Stainless Steel SASSDA

The stainless steel walkway would last the lifetime of the process plant and significant financial benefits would be gained over the full service life The LCC programme in this example showed that there is a financial benefit in using stainless steel after the first replacement of the carbon steel product plant, sinter plant, refractory mate rials plant, blast furnace, basic oxygen furnace, steel melting shop and rolling mill T he main solid wastes in steel industry are(PDF) Solid wastes generation in steel industry and their Equipment standards generally require that welded joints on stainless steel surfaces be continuous, butt type joints (See Figure 4) and ground to at least as smooth as a No 4 finish If the welded joint is at a corner, it must be coved to the appropriate radius and ground smooth (see Figure 5)Sanitary Design and Construction of Food EquipmentMost stainless steel producers outsource the processing and/or disposal of EAF/AOD dusts and other wastes Almost all stainless steel dust processing plants in Europe and the USA require economies of scale for viable operation and are situated at locations that EAF Stainless Steel Dust ProcessingStainless steel is generally the most preferred and most commonly used material in the design, construction and fabrication of food processing equip ment and is specified in the 3A Sanitary Standards(1)as well as in other com monly used food processing equipment standards throughout the Characteristics of Food Contact surface materials

Stainless steel Wikipedia

Stainless steel: 276 is a group of ironbased alloys that contain a minimum of approximately 11% chromium,: 3 a composition that prevents the iron from rusting and also provides heatresistant properties: 3 Different types of stainless steel include the elements carbon (from 003% to greater than 100%), nitrogen, aluminium, silicon, sulfur, titanium, nickel, copper, selenium, niobium, and Scope: Stainless Steel Tank – Food Processing Plant Date: February 2019 Location: UK Products: RC 300 RB 300 Download PDF OVERVIEW The stainless steel effluent tank was leaking as a result of the breakdown of the rubber lining and chemical attack of the tank structure The tank lining therefore had to be refurbishedStainless Steel Tank Food Processing Plant Chemco Mfg by Cherry Burrell Dimensions : 84" Dia x 176" Sidewall + 14" Dome Top Overall height 16' with SS Connecting fittings Serial # 87E3102, NB #2965Used SS Tanks, kettles and Processing Used Packaging They received the 20’ lengths of stainless steel handrails and cut them to size to fit a variety of handrail applications for the meat processing plants SlipNOT® slip resistant handrails are offered in stainless steel, aluminum and steel to provide gripping traction in a variety of industries, not only the food processing facilitiesMeat Processing Plant Stainless Steel Handrails SlipNOT®The regulations for food processing are outlined in the Washington Food Processing Act (RCW 6907) Stainless steel table top serving as an effective surface for packaging product fish plant, need wellsealed concrete floors with cove base and adequate drains Heavy use areasRegulations for Food Processing WSDA Food Processor

USDA FSIS Regulations and Forklifts in FoodHandling

The FSIS derives its regulatory power from the Code of Federal Regulations In particular, these rules provide guidance on the choice of forklifts to use in foodhandling applications: 9 CFR 4162(d) requires facilities to include “ventilation adequate to control odors, vapors, and condensation to the extent necessary to prevent adulteration Mar 20, 2017 Stainless Steel is the only material that will not rust and has the corrosion resistance and pitting resistance that can hold up in these production and processing environments The most common grade of stainless steel used in processing and packaging applications is 316/L, or what many refer to as “food grade stainless” Stainless Steel for Beverage and Food Processing Stainless steel is generally the most preferred and most commonly used material in the design, construction and fabrication of food processing equipment and is specified in 3A Sanitary Standards 3A Sanitary Standards most often reference Types 304 and 316, or their lowcarbon versions The advantages for food contact are widely recognized, including corrosion resistance, high strength Address corrosion in 'stainless' steel The stainless steel walkway would last the lifetime of the process plant and significant financial benefits would be gained over the full service life The LCC programme in this example showed that there is a financial benefit in using stainless steel after the first replacement of the carbon steel Life Cycle Costing and Stainless Steel SASSDAScope: Stainless Steel Tank – Food Processing Plant Date: February 2019 Location: UK Products: RC 300 RB 300 Download PDF OVERVIEW The stainless steel effluent tank was leaking as a result of the breakdown of the rubber lining and chemical attack of the tank structure The tank lining therefore had to be refurbishedStainless Steel Tank Food Processing Plant Chemco

Food Contact Safe Stainless Steel

Stainless steel (SS) does not readily corrode, rust or stain with water as ordinary steel does However, it is not fully stainproof in lowoxygen, highsalinity, or poor aircirculation environmentsStainless steel is mainly used where both the properties of steel and corrosion resistance are required There is a series of stainless steels that ranges from SAE 100 600That is why these systems consist of stainless steel now It is the most corrosion resistant of all the steel products Benefits of Duplex Stainless Steel for Pulp and Paper Processing Duplex stainless steel is a metal that combines ferritic and austenitic stainless steel grades Common grades of duplex stainless steels include 2205 and 2507Stainless Steel in the Pulp and Paper Industry Stainless product plant, sinter plant, refractory mate rials plant, blast furnace, basic oxygen furnace, steel melting shop and rolling mill T he main solid wastes in steel industry are(PDF) Solid wastes generation in steel industry and their Lawrence Equipment Batch Fryer with Non Raisable Hood (Fixed) For floating products only High Speed Production of Tortilla Chips Snacks Stainless Steel Construction 3 Phase, 415V, 10A, 50Hz Canopy: Length: 2600, Width: 1310 mm, Height: 1500 mm Exhaust Height: 840 mm Exhaust Diameter: 390 mm Conveying System Features Synchronized stainless steel inlet paddle gently distribute the Machinery Cookers/Fryers Process Plant NetworkReference is often made to stainless steel in the singular sense as if it were one material Actually there are over 50 stainless steel alloys Three general classifications are used to identify stainless steels They are: 1 Metallurgical Structure 2 The AISI numbering system: namely 200, DESIGN GUIDELINES FOR THE SELECTION AND USE OF

Avoid stress corrosion cracking of stainless steel

In hydrocarbon processing industry (HPI) facilities, austenitic stainless steel (SS) is used for several reasons, including:• Avoiding iron pickup and maintaining product purity• Replacing carbon steel in operating services in which carbon steel is unsuitable, such as high temperature, corrosive fluids, highly toxic materials (HTM), etcThey received the 20’ lengths of stainless steel handrails and cut them to size to fit a variety of handrail applications for the meat processing plants SlipNOT® slip resistant handrails are offered in stainless steel, aluminum and steel to provide gripping traction in a variety of industries, not only the food processing facilitiesMeat Processing Plant Stainless Steel Handrails SlipNOT®Factory Price Honey Processing Plant Video/honey Extraction Equipment/stainless Steel Bee Honey Extracting Machine , Find Complete Details about Factory Price Honey Processing Plant Video/honey Extraction Equipment/stainless Steel Bee Honey Extracting Machine,Honey Processing Plant Video,Honey Extraction Equipment,Bee Honey Extracting Machine from Honey Processing Machines Factory Price Honey Processing Plant Video/honey