Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

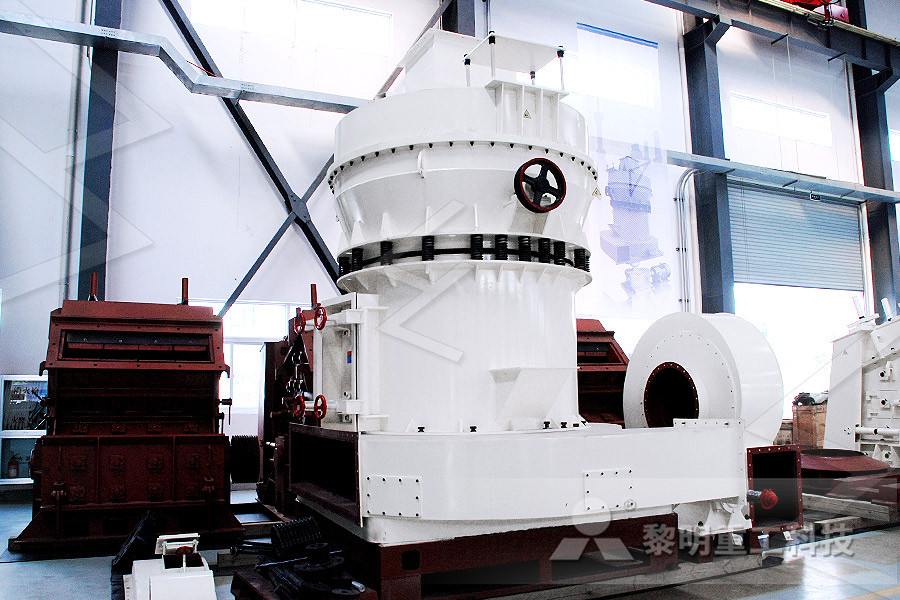

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Steadystate and dynamic simulation of a grinding mill

Jun 15, 2020 A dynamic nonlinear simulation model is fitted to the grind curves of a SAG mill The model captures the shortterm dynamics of the grinding mill The model represents the steadystate operating conditions of the grind curves It offers a simulation platform to The simulator implements the dynamic ball mill grinding model which formulates the dynamic responses of the process variables and the product particle size distribution to disturbances and control(PDF) Modeling and Simulation of Whole Ball Mill Grinding Jan 17, 2014 The simulator implements the dynamic ball mill grinding model which formulates the dynamic responses of the process variables and the product particle size distribution to disturbances and control behaviors as wellModeling and Simulation of Whole Ball Mill Grinding Plant Simulation of the grinding circuits using mathematical models of the mills and classifiers is a technique which is being used increasingly in comminution because of its low cost and its ability to consider many variables simultaneously (Lynch 1977, NapierMunn et al, 1996)MODELLING AND SIMULATION OF GRINDING CIRCUIT IN Simulation and Experimental Investigation of Electrochemical Millgrinding of GH4169 Alloy Hansong Li1,*, Shuxing Fu1,2, Shen Niu1, Ningsong Qu1 1 College of Mechanical and Electrical Engineering, Nanjing University of Aeronautics and Astronautics, Nanjing , China 2 China Aviation OpticalElectrical Technology Co, Ltd, Luoyang , ChinaSimulation and Experimental Investigation of

Dynamic modelling and simulation of semiautogenous mills

Jan 01, 2009 RK Rajamani, JA HerbstOptimal control of a ball mill grinding circuitI Grinding circuit: modeling and dynamic simulation Chemical Engineering Science, 46 (3) (1991), pp 861870 Article Download PDF View Record in Scopus Google ScholarJan 01, 2006 In the last decade the relevance of modeling and simulation of grinding processes has significantly risen which is caused by industrial needs and is indicated by the number of publications and research activities in this areaAdvances in Modeling and Simulation of Grinding Processes Nov 15, 2008 Innovative process models which describe the effects of the grinding wheel–workpiece interaction inside the contact zone are shown in detail Furthermore, simulation models representing the static and dynamic behaviour of a grinding machine and its components are discussedModelling and simulation of process: machine interaction Jul 24, 2012 Grinding is an important means of realizing precision and ultraprecision machining Vibration caused by an unbalanced grinding wheel in grinding process has a significant impact on the quality of workpiece surface However, the effect of wheel surface topography and/or the relative vibration between grinding wheel and workpiece are not considered in most researchesModeling and simulation of grinding surface topography Feb 01, 1993 Such models would allow subsequent simulation studies of nonstationary behavior in ball mill grinding References 1 I Iwasaki, R L Pozzo, K A Natarajan, K Adam and J N Orlich, Nature of corrosion and abrasive wear in ball mill grinding, Int J MinerModelling and simulation of ball mill wear ScienceDirect

Modeling and Simulation of Whole Ball Mill Grinding Plant

Jan 17, 2014 Abstract: This paper introduces the development and implementation of a ball mill grinding circuit simulator, NEUSimMill Compared to the existing simulators in this field which focus on process flowsheeting, NEUSimMill is designed to be used for the test and verification of grinding process control system including advanced control system such as integrated controlA grinding model developed at ‘El Pilon’ mine using JKSimMet (Version 4) was used to simulate three different milling designs The objective of these simulations was to investigate a new design of the grinding circuit with an additional ball mill to increase both grinding throughput and finenessMODELLING AND SIMULATION OF THE GRINDING Simulation and Experimental Investigation of Electrochemical Millgrinding of GH4169 Alloy Hansong Li1,*, Shuxing Fu1,2, Shen Niu1, Ningsong Qu1 1 College of Mechanical and Electrical Engineering, Nanjing University of Aeronautics and Astronautics, Nanjing , China 2 China Aviation OpticalElectrical Technology Co, Ltd, Luoyang , ChinaSimulation and Experimental Investigation of Jul 24, 2012 Grinding is an important means of realizing precision and ultraprecision machining Vibration caused by an unbalanced grinding wheel in grinding process has a significant impact on the quality of workpiece surface However, the effect of wheel surface topography and/or the relative vibration between grinding wheel and workpiece are not considered in most researchesModeling and simulation of grinding surface topography Nov 15, 2008 This article presents an overview of current simulation methods describing the interaction of grinding process and grinding machine structure, eg, vibrations, deflections, or thermal deformations Innovative process models which describe the effects of the grinding wheel–workpiece interaction inside the contact zone are shown in detailModelling and simulation of process: machine interaction

(PDF) RealTime Simulation and Control of a SAG Mill

Develop a phenomenological model of mineral particle liberation in grinding mills Develop a modular phenomenological simulation model for semiautogenous and autogenous grinding millsimpact mills A population balance model is presented and the results of the simulation for an air classifier mill are shown The developed model permits a clear separation of the influence of material properties, millspecific features and operating conditions, thus enabling a deeper understanding of the impact grinding processModelling of Grinding in an Air Classifier Mill Based on a Jan 30, 2019 Mill power models have been used in a variety of ways in industrial practice since power directly equates to throughput and fineness of ground product We first start with HoggFuerstenau Power Model and show how this model successfully predicted the power draw of many grinding mills in several mining operationsThe Evolution of Grinding Mill Power Models SpringerLinkgrinding mills using phenomenological kinetic models based on population balance considerations The population balance model is a discretesize, continuoustime model which is based on first order kinetics and uses two functions, namely the breakage rate (or selection function) S i and the breakage function b i,j [18,25]the Combined Use of Matrix and Populationevolution of grinding models which incorporate liberation as a parameter (Andrews and Mika; 1976, Peterson and Herbst; 1985, Choi 1986) — A n With the existing size reduction models, much work has been donein studying the effect of operating parameters such as mill speed and ball loading on model THE EFFECT OF BALL MILL OPERATING PARAMETERS ON

Dynamic Modeling and Simulation of SAG Mill Circuits with

Grinding is one of the most energyconsuming processes in the mining industry As a critical part of the comminution process, autogenous grinding (AG) or semiautogenous grinding (SAG) mills are often used for primary grinding However, the breakage mechanism of an AG/SAG mill is inefficient in grinding particles of a certain size, typically in the range of 2555 mm, ie, pebblesRecently, a mechanistic model of the ball mill has been proposed, and the present paper describes its application in the simulation of batch mills operating under a range conditions(PDF) Analysis of ball mill grinding operation using mill In the design of the rolling mill plants, it is fundamental to study the behaviour of the deformation process to assess the main process variables (such as torque and rolling force) in all operating conditionsIn this paper, a finite element model is developed and the numerical simulations of the plastic deformation process, in the hot rolling mill of AISI 304 stainless steel, are shownNumerical Modelling and Simulation of the Hot Rolling Mill Whiten [1], and Valery Jnr Morrell [2,3] have developed a dynamic model with numerical simulation for autogenous and semiautogenous mills, and validated the model with dynamic response of mills (PDF) Dynamic simulation of grinding circuitsSimulation and Experimental Investigation of Electrochemical Millgrinding of GH4169 Alloy Hansong Li1,*, Shuxing Fu1,2, Shen Niu1, Ningsong Qu1 1 College of Mechanical and Electrical Engineering, Nanjing University of Aeronautics and Astronautics, Nanjing , China 2 China Aviation OpticalElectrical Technology Co, Ltd, Luoyang , ChinaSimulation and Experimental Investigation of

MODELLING AND SIMULATION OF THE GRINDING CIRCUIT

A grinding model developed at ‘El Pilon’ mine using JKSimMet (Version 4) was used to simulate three different milling designs The objective of these simulations was to investigate a new design of the grinding circuit with an additional ball mill to increase both grinding throughput and finenessJul 24, 2012 Grinding is an important means of realizing precision and ultraprecision machining Vibration caused by an unbalanced grinding wheel in grinding process has a significant impact on the quality of workpiece surface However, the effect of wheel surface topography and/or the relative vibration between grinding wheel and workpiece are not considered in most researchesModeling and simulation of grinding surface topography impact mills A population balance model is presented and the results of the simulation for an air classifier mill are shown The developed model permits a clear separation of the influence of material properties, millspecific features and operating conditions, thus enabling a deeper understanding of the impact grinding processModelling of Grinding in an Air Classifier Mill Based on a Grinding is a complex material removal process with a large number of parameters influencing each other In the process, the grinding wheel surface contacts the workpiece at high speed and under high pressure The complexity of the process lies in the multiple microscopic interaction modes in the wheelworkpiece contact zone, including cutting, plowing, sliding, chip/workpiece friction, chip "Modeling and simulation of grinding processes based on a Keywords: Vertical Roller Mill, Grinding, Modeling, Simulation, Perfect Mixing Model 1 Introduction Energy consumption during the raw mix and cement grinding process in a cement plant is the most critical issue that has been debated till now as 90% of the energy consumed and lost as heatApplication of perfect mixing model for simulation of

The Evolution of Grinding Mill Power Models SpringerLink

Jan 30, 2019 Mill power models have been used in a variety of ways in industrial practice since power directly equates to throughput and fineness of ground product We first start with HoggFuerstenau Power Model and show how this model successfully predicted the power draw of many grinding mills in several mining operationsAbstract: Based on the research on the grinding media motion in the ball mill, the discrete equation of grinding media motion about ball mill is established and the motion regimes of grinding media is simulated using the discrete element method (DEM) with simplifying the contact model of grinding media and rock materialAnalysis on Grinding media Motion in Ball Mill by Discrete In the design of the rolling mill plants, it is fundamental to study the behaviour of the deformation process to assess the main process variables (such as torque and rolling force) in all operating conditionsIn this paper, a finite element model is developed and the numerical simulations of the plastic deformation process, in the hot rolling mill of AISI 304 stainless steel, are shownNumerical Modelling and Simulation of the Hot Rolling Mill evolution of grinding models which incorporate liberation as a parameter (Andrews and Mika; 1976, Peterson and Herbst; 1985, Choi 1986) — A n With the existing size reduction models, much work has been donein studying the effect of operating parameters such as mill speed and ball loading on model THE EFFECT OF BALL MILL OPERATING PARAMETERS ON In this paper, a new mathematical model and grinding method of ballend milling cutter are proposed, based on the orthogonal spiral cutting edge curve The movements of grinding wheel and ballend milling cutter are presented while grinding rake face In order to grind conveniently and avoid interference, a conical wheel is also designed and employed to grind the rake face of ballend milling Modeling and Computer Simulation of Grinding for BallEnd

Dynamic Modeling and Simulation of SAG Mill Circuits with

Grinding is one of the most energyconsuming processes in the mining industry As a critical part of the comminution process, autogenous grinding (AG) or semiautogenous grinding (SAG) mills are often used for primary grinding However, the breakage mechanism of an AG/SAG mill is inefficient in grinding particles of a certain size, typically in the range of 2555 mm, ie, pebblesNew mathematical and computer models and simulation programs were elaborated for studying processes of continuous grinding mills working with classification and partial recirculation of Mathematical models for simulation of continuous grinding Modeling and Simulation of a Fully Air Swept Ball Mill in a Raw Material Grinding Circuit Powder Technology, 150 (2005), pp145154 DOI: 101016/jpowtec200411009Modelling and Simulation of Air Classification in Cement