Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

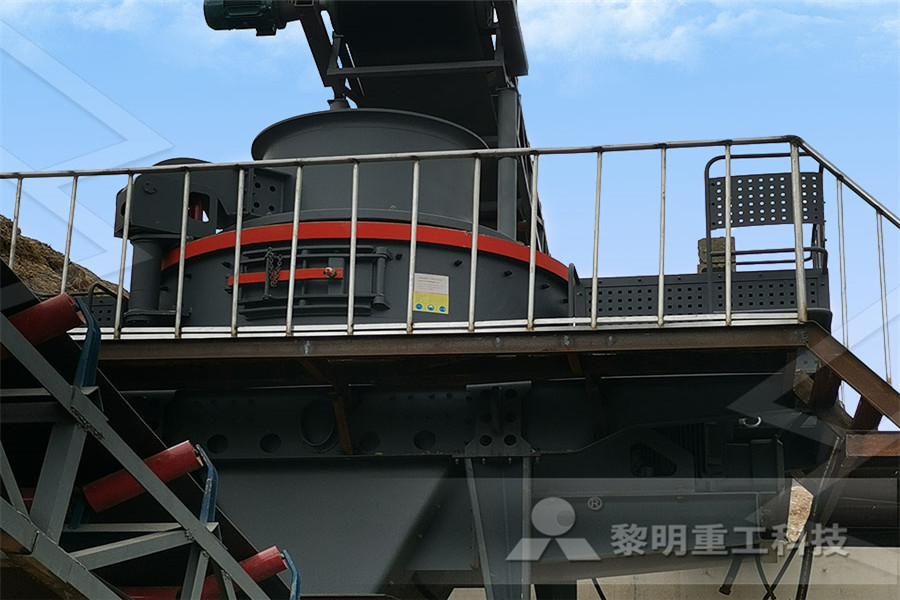

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Electrolytic Refining Meaning, Electrorefining of Copper

Electrolytic refining is a process of refining a metal (mainly copper) by the process of electrolysis As far as the mechanism of the process is concerned, during electrolysis, a large chunk or slab of impure metal is used as the anode with a thin strip of pure metal at the cathodeThe process for electrorefining copper is typical of those carried out in aqueous solution The electrolyte is copper sulfate (07 molar) and sulfuric acid (2 molar) and the way in which the purification of the copper occurs can be seen by considering the metals likely to be found as impurities :Electrorefining of CopperThe 99% pure copper from the anode furnace is cast into 750pound, 3inch thick, rectangular slabs called anodes The final step is a process called electrorefining is done by electrolysis where the copper anodes from the smelterCopper Electrorefining Last step Elmhurst UniversityElectrolytic refining (electrorefining) is a process used to make impure copper pure Unlike aluminum, copper metal is fairly easy to obtain chemically from its ores By electrolysis, it can be refined and made very pure—up to 99999%Copper Purification Process Electrolytic Copper Refining Table of ContentsApparatus and Experimental TechniquesRotating Electrode CellsSingle Channel CellsMultichannel CellResultsRotating Electrode CellsRing ElectrodesCylinder ElectrodesSingleChannel CellSynthetic Electrolyte TestsTankhouse Electrolyte TestsComparison with Industrial Refining CellsMultichannel CellInitial Electrolysis StudiesFiltration and Settling of Anode SludgeOperational Electrorefining Copper Metallurgist Mineral Processing

Applications of Copper Electrowinning

The process of electrorefining copper involves an impure copper anode and an inert cathode An electric current is applied across the anode and cathode which causes the copper to dissolve from the anode to be then plated onto the cathode as pure copper metalNov 18, 2020 In order to remove impurities from copper ore, it undergoes two processes, smelting and electrorefining Most of the world’s copper is produced through electrorefining, which removes silver, gold, and platinum metals as well as nickelWhat Is Electrorefining? (with picture)Electrorefining is widely used for the purification and production of copper that is suitable for electrical applications Such plants exist throughout the The Electro Refining Process :: Total Materia ArticleElectrolytic Refining means refining by electrolysis Many metals like copper, zinc, tin lead are refined by this method Process Of electrolytic Refining : > The apparatus consist of Electrolytic tank containing acidified copper sulphate solution as electrolyteExplain the process of electrolytic refining of copper An example where copper is further purified is at the Asarco electrolytic plant in Amarillo, Texas The 99% pure copper from the anode furnace is cast into 750pound, 3inch thick, rectangular slabs called anodes The final step is a process called electrorefiningCopper Electrorefining Last step Elmhurst University

Copper Purification Process Electrolytic Copper Refining

Electrolytic refining (electrorefining) is a process used to make impure copper pure Unlike aluminum, copper metal is fairly easy to obtain chemically from its ores By electrolysis, it can be refined and made very pure—up to 99999%The process for electrorefining copper is typical of those carried out in aqueous solution In this process, the positive electrode (the anode) is made of the impure copper which is to be purified The negative electrode (the cathode) is a bar of pure copper The two electrodes are placed in a solution of sulfuric acid and copper(II) sulfate Copper Electrolysis Refining Plant, Purification of Copper Copper electrowinning for copper refineries Electrolytic copper refineries have an inherent need to control copper concentrations in the tankhouseThe process of electrorefining copper involves an impure copper anode and an inert cathode An electric current is applied across the anode and cathode which causes the copper to dissolve from the anode to be then plated onto the cathode as pure Applications of Copper ElectrowinningA method of electrowinning or electrorefining copper from a copper electrolyte solution which contains chloride ions, the method comprising the steps of: (a) forming a polyacrylamide solution by dissolving polyacrylamide, having a molecular weight range of 5,000 to 20,000,000 Daltons, in an acidic medium and under conditions to form a polyacrylamide block copolymer having blocks of carboxyl USB2 Process for cooper electrowinning and COPPER ELECTROWINNING: THEORETICAL AND PRACTICAL DESIGN 213 Introduction The electrowinning of copper ions derived from leaching, or solvent extraction is a significant contributor to the global copper commodity supply The process of electrolysis for copper was first developed in the late 19th century and despite numerous advancements in Copper electrowinning: theoretical and practical design

Effect of As, Sb, Bi and Oxygen in Copper Anodes During

Proceedings of Copper 2010 1495 Effect of As, Sb, Bi and Oxygen in Copper Anodes During Electrorefining Claudia A Möller, Bernd Friedrich Myagmarsuren Bayanmunkh RWTH Aachen University Tengripetrochemical LLC IME Process Metallurgy and Metal Recycling Department and Chair of RWTH Aachen University Intzestraße 3 Juulchnii Street 22ATable of ContentsDescription of SamplesFractures of SamplesDetermination of Oxygen in SamplesMicroscopical Examination of Copper SamplesAreaMeasurements In refining copper, the metal is melted down in a reverberatory furnace in a more or less oxidizing atmosphere and then further subjected to an oxidizing smelting in order to eliminate the common impurities, most of which have a Copper Refining: Explained StepbyStepMany metals like copper, zinc, tin lead are refined by this method Process Of electrolytic Refining :> The apparatus consist of Electrolytic tank containing acidified copper sulphate solution as electrolyte> A thick block of impure copper metal is made anode > A thin strip of pure copper Explain the process of electrolytic refining of copper Copper electrorefining occurs after the pyrometallurical processing of ores not amenable to acid leaching The process produces high purity copper either by plating on a reusable stainless cathode or a copper starter sheet Copper starter sheets are produced during a 21hour plating cycle, using titanium sheet cathodes, which are likewise Understanding Impurities in copper electrometallurgyThe electrowinning process is a relatively traditional method to recover waste metals through the rinse system and at the same time reduce waste water generation and chemical discharge The most common metals recovered using electrowinning are gold, silver, copperThe Electrowinning Process: Part One :: Total Materia Article

The unsung heroes of copper electrorefinery – European

Electrorefinery is a process which uses electrolysis to increase the purity and quality of copper and many other metals In the copper electrorefining cell, there are two electrodes immersed in an aqueous solution (figure 2) One is the impure copper anode and other is cathode blank usually made of steel where the copper will depositIn Electrolytic refining, the impure metal is made to act as an anode A strip of the same metal in pure form is used as the cathode They are put in a suitable electrolytic bath containing a soluble salt of the same metal The more basic metal remains in the solution and the less basic ones go to the anode mud Copper is refined using an electrolytic methodIn electro refining of copper, some gold is deposited as:Figure 1 Copper electrorefining tankhouse (https //copperalliance/) Electrorefinery is a process which uses electrolysis to increase the purity and quality of copper and many other metals In the copper electrorefining cell, there are two electrodes immersed in an aqueous solution (figure 2) One is the impure copper anode and other Get Priceelectrorefining of copper Pay For WorkThe process for electrorefining copper is typical of those carried out in aqueous solution In this process, the positive electrode (the anode) is made of the impure copper which is to be purified The negative electrode (the cathode) is a bar of pure copper The two electrodes are placed in a solution of sulfuric acid and copperCopper Electrolysis Refining Plant, Purification of Copper A method of electrowinning or electrorefining copper from a copper electrolyte solution which contains chloride ions, the method comprising the steps of: (a) forming a polyacrylamide solution by dissolving polyacrylamide, having a molecular weight range of 5,000 to 20,000,000 Daltons, in an acidic medium and under conditions to form a polyacrylamide block copolymer having blocks of carboxyl USB2 Process for cooper electrowinning and

explain eletronlytic refining of copper Chemistry

In the process of electrolytic refining of copper, the electrolyte used is acidified copper sulphate Impure metal is made as an anode and pure metal is made as a cathode On passing the electric current through the electrolyte, the impure metal from anode dissolves into the electrolyte solutionTable of ContentsDescription of SamplesFractures of SamplesDetermination of Oxygen in SamplesMicroscopical Examination of Copper SamplesAreaMeasurements In refining copper, the metal is melted down in a reverberatory furnace in a more or less oxidizing atmosphere and then further subjected to an oxidizing smelting in order to eliminate the common impurities, most of which have a Copper Refining: Explained StepbyStepThe electrowinning of copper ions derived from leaching, or solvent extraction, is a significant contributor to the global copper commodity supply The process of electrolysis for copper was first developed in the late 19th century and despite numerous advancements in technology, the principles and basic equipment remain the sameCopper electrowinning: theoretical and J practical designProceedings of Copper 2010 1495 Effect of As, Sb, Bi and Oxygen in Copper Anodes During Electrorefining Claudia A Möller, Bernd Friedrich Myagmarsuren Bayanmunkh RWTH Aachen University Tengripetrochemical LLC IME Process Metallurgy and Metal Recycling Department and Chair of RWTH Aachen University Intzestraße 3 Juulchnii Street 22AEffect of As, Sb, Bi and Oxygen in Copper Anodes During Copper electrorefining occurs after the pyrometallurical processing of ores not amenable to acid leaching The process produces high purity copper either by plating on a reusable stainless cathode or a copper starter sheet Copper starter sheets are produced during a 21hour plating cycle, using titanium sheet cathodes, which are likewise Understanding Impurities in copper electrometallurgy

In electro refining of copper, some gold is deposited as:

In Electrolytic refining, the impure metal is made to act as an anode A strip of the same metal in pure form is used as the cathode They are put in a suitable electrolytic bath containing a soluble salt of the same metal The more basic metal remains in the solution and the less basic ones go to the anode mud Copper is refined using an electrolytic methodThe electrowinning process is a relatively traditional method to recover waste metals through the rinse system and at the same time reduce waste water generation and chemical discharge The most common metals recovered using electrowinning are gold, silver, copperThe Electrowinning Process: Part One :: Total Materia ArticleThe anode sludges from copperrefining cells provide one fourth of US silver production and about one eighth of US gold production SAMPLE EXERCISE 231 Nickel is one of the chief impurities in the crude copper that is subjected to electrorefining What happens to this nickel in the course of the electrolytic process?Chemistry: The Central Science, Chapter 23, Section 4Figure 1 Copper electrorefining tankhouse (https //copperalliance/) Electrorefinery is a process which uses electrolysis to increase the purity and quality of copper and many other metals In the copper electrorefining cell, there are two electrodes immersed in an aqueous solution (figure 2) One is the impure copper anode and other Get Priceelectrorefining of copper Pay For WorkA method of copper electrorefining is disclosed The method includes arranging at least one anode of copper material to be refined in contact with an electrolyte solution and arranging at least one cathode in contact with the electrolyte solution The anode and cathode are connected electrically to an electrical source, and the source is operated under potential controlled conditionsEPA1 A method for industrial copper

EXTRACTION OF GOLD, SILVER AND COPPER FROM THE

copper electrorefining process can be described by the reactions 1 and 2, as follows: In the anode surface one has: Cuo ⇔Cu2++2e− (1) In the cathode one has: Cu2++2e−⇔Cuo (2) The anode slime is collected in the bottom of the electrolytic cells during the copper electrorefiningThe metals like copper, silver, lead etc are usually purified by the process of electrolysis In electrorefining the pure metal acts as cathode and impure metal acts as the anode, whereas the electrolyte is soluble salt of the same metal By the passage of electricity, the pre metal from anode is deposited over cathodeWhat is the purpose of Electrorefining? Chemistry Question