Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

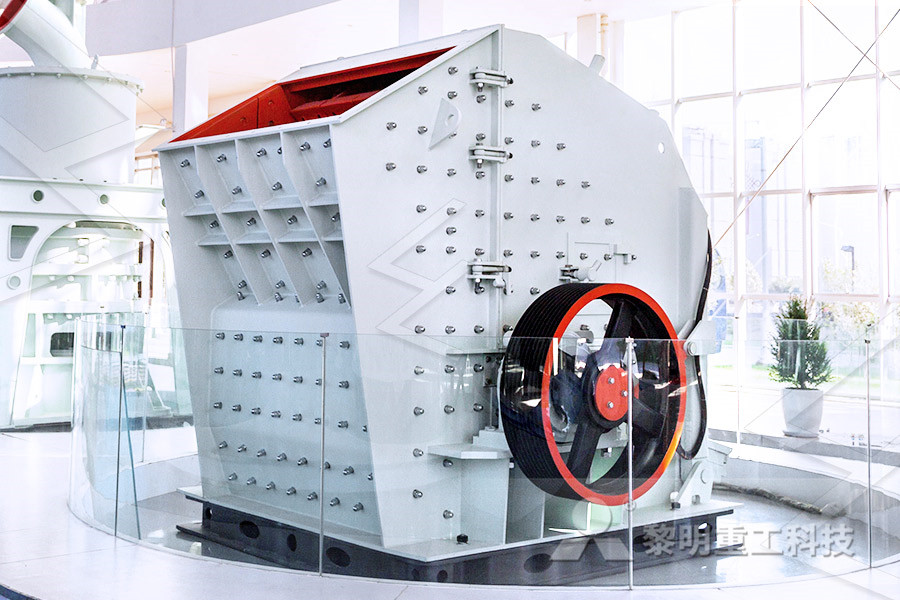

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Atmospheric oxidative and nonoxidative leaching of NiCu

and ammonia leaching has been based on local conditions or the composition of the matte Acid leaching has been used for mattes with substantial cobalt contents (above 3%), while ammonia leaching has been widely used for NiCu mattes with low cobalt contents (Pearce et al, 1960) However, with further developments in acid pressure leachingOct 06, 2020 Ammonia and ammonium salts have been recognized as effective leaching agents in hydrometallurgical processes due to low toxicity and cost, easy recovery and (PDF) Ammonia Leaching: A New Approach of Copper Industry Ammonia reacts rapidly in the atmosphere with both sulfuric and nitric acids to form fine particles(4) In most of the US the majority of aerosol ammonium is associated with sulfate ion(4) Once released into the atmosphere, ammonia is returned to the surface as either gaseous ammonia or Ammonia Environmental FateAtmospheric oxidative and nonoxidative leaching of NiCu and ammonia leaching has been based on local conditions or the composition of the matte Acid leaching has been used for mattes with substantial cobalt contents (above 3%), while ammonia leaching has been widely used for NiCu mattes with low cobalt contents (Pearce et al, 1960) However, with further developments in acid pressure leaching Atmospheric Ammonia Leach Matte guypaysagefrMar 01, 1978 Sherritt had considerable ex perience feeding a high grade nickel matte to their Fort Saskatchewan refinery on a regular basis for many years using the ammonia pressure leaching process [ !3 ] Sherritt had conducted several pilot plant campaigns treating mattes, including the acid pressure leaching of a nickelcobaltcopper matte in 1956 Recovery of nickel and copper from highgrade matte at

Ammonia/nitric Acid Leaching of Copper Cobalt Oxidized Ore

reported that, copper from Cu matte can Nieasily been leached by using ammonia at atmospheric condition Ammonia leaching is also selective in that it will not dissolve all available nonspecific metals, such as iron and manganese, along with the copper or cobalt, as sulphuric acid does More Ammonia leaching can be used in nonoxidative,Because the Outotec process is based on a calcium chloride solution, it enables easy acid and base regener ation Base metals are leached in oxidative conditions at atmospheric pressure, iron is precipitated with limestone, and base metals are purified by solvent extraction, using ammonia as the neutralization agentNICKEL MATTE CHLORIDE LEACHING OutotecMay 01, 2019 Leaching of the matte is performed in the presence of chloride compounds at temperatures close to the boiling point of solution Falconbridge (now Glencore) employed a nonoxidative chloride process using excess concentrated HCl under atmospheric Oxidative dissolution of nickel matte in dilute sulfuric The first one involves both atmospheric and pressure leaching in acidic copper–nickel sulphate solution, with oxygen being the oxidizing agent In this process the matte is first leached under atmospheric conditions followed by a pressure leach step, and in both steps O2/air is sparged into the leaching Atmospheric acid leaching of nickel copper matte from For many years, studies were conducted on the leaching of NiCu matte under atmospheric and pressure leaching in acidic coppernickel sulfate solution, with oxygen as the oxidizing agent (Forward (PDF) Leaching of IronContaining CopperNickel Matte at

Atmospheric oxidative and nonoxidative leaching of NiCu

and ammonia leaching has been based on local conditions or the composition of the matte Acid leaching has been used for mattes with substantial cobalt contents (above 3%), while ammonia leaching has been widely used for NiCu mattes with low cobalt contents (Pearce et al, 1960) However, with further developments in acid pressure leachingMethods for leaching ore at atmospheric pressure are well known to persons skilled in the art, and include heap leaching, vat leaching, tank leaching and dump leaching In preferred forms of the invention, the step of leaching the cured ore at atmospheric pressure through the application of an ammonium carbonate solution containing free ammonia US Patent Application for METHOD FOR AMMONIACAL LEACHING reported that, copper from Cu matte can Nieasily been leached by using ammonia at atmospheric condition Ammonia leaching is also selective in that it will not dissolve all available nonspecific metals, such as iron and manganese, along with the copper or cobalt, as sulphuric acid does More Ammonia leaching can be used in nonoxidative,Ammonia/nitric Acid Leaching of Copper Cobalt Oxidized Oreture, leaching time, ammonia concentration, and pH) on the leaching behavior of NiCu matte were investigated The temperature range studied was between 50 Cand70C, ammonia concentration was varied from 15, 20, 25, to 30M, while the leaching time ranged from 0 to 300min The stirring speed was kept constant at 410rpm, while theParametric Effects on Leaching Behavior of NickelCopper Copper (Cu) bearing matte from Impala Refinery (Pty) Ltd was used in the investigation The experiments were conducted in a leaching cell submerged in a water bath, with ammonia concentrations (leaching solution) of 30M, temperature of 50˚C, 60˚C and 70˚C, pH of 11 and for a time period of 130 minutesAn Investigation into the Effect of Temperature on the

Air Pollution: Ammonia and Hydrogen Sulfide and Ambient

Jan 26, 2017 Ammonia gas also impacts the environment through interaction in the atmosphere with other gases The primary products of these interactions are fine particulates (PM25) and ammonium (NH 4 + ) aerosols, which can negatively impact human health as respiratory irritants ( img source )There is disclosed a process for separating and recovering nickel and copper values from a nickelcopper matte which may contain iron and arsenic Finely divided nickelcopper matte undergoes one or more steps of sulphuric acid leaching at atmospheric pressure to produce a nickel sulphate solution and an iron and/or arsenic containing copperrich sulphide residueCAC Process for upgrading copper sulphide Atmospheric N is the major reservoir for N in the N cycle (air is 79 percent N2 gas) (H2) to form ammonia (NH3) Anhydrous ammonia is then used as a starting point in the manufacture of other nitrogen fertilizers Leaching is the loss of soluble NO 3N as it moves with soil water, generally excess water, below the root zone NitrateN Understanding nitrogen in soilsAtmospheric Leaching (AL) or Heap Leaching (HL) technologies These processes do not rely on autoclave technology and are therefore perceived to be less capital intensive and easier to operate However, they still require significant investment in terms of infrastructure Heap leaching is the optionMURDOCH RESEARCH REPOSITORYThe Finnish Environment 317 7 aaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaaa a a a a General Information 11 General Nickel is a silver white metal with typical metallic Marja RiekkolaVanhanen Finnish expert report on best

An Investigation into the Effect of Temperature on the

the temperature and the reaction involved on the leaching of coppermatte Copper (Cu) bearing matte from Impala Refinery (Pty) Ltd was used in the investigation The experiments were conducted in a leaching cell submerged in a water bath, with ammonia concentrations (leaching solution) of 30M, temperature of 50˚C,A sulfur dioxide free process for the production of high purity metallic copper from copper matte wherein copper matte (11) is leached under oxidizing conditions in a ferric ion containing acid copper sulfate electrolyte leach assembly (2) including one or more leach reactors to yield a copperrich electrolyte (13), and a copper cathode (41, 42, 43) is produced in an electrowinning assembly (4 WOA1 Process for electrowinning of copper Ammonia (NH 3) concentrations were continuously monitored at a moorland site in southern Scotland for 13 months from February 1995 to February 1996, providing about 13 500 half‐hourly average measurements (71% of the time)Concentrations were found to be log‐normally distributed (with a geometric mean of 043 μg m −3 and a geometric standard devation of 335), and were strongly Atmospheric ammonia at a moorland site I: The form of N, but is also highly susceptible to leaching losses Nitrification is most rapid when soil is warm (6786°F), moist and wellaerated, but is virtually halted below 41°F and above 122°F RNH 2 Æ NH 3 Æ NH 4 + organic N ammonia ammonium N 2 Æ NH 3 Æ RNH 2 nitrogen gas ammonia organic N NH 4 +Nitrogen Basics – The Nitrogen Cyclereported that, copper from Cu matte can Nieasily been leached by using ammonia at atmospheric condition Ammonia leaching is also selective in that it will not dissolve all available nonspecific metals, such as iron and manganese, along with the copper or cobalt, as sulphuric acid does More Ammonia leaching can be used in nonoxidative,Ammonia/nitric Acid Leaching of Copper Cobalt Oxidized Ore

Atmospheric ammonia at a moorland site I: The

Ammonia (NH 3) concentrations were continuously monitored at a moorland site in southern Scotland for 13 months from February 1995 to February 1996, providing about 13 500 half‐hourly average measurements (71% of the time)Concentrations were found to be log‐normally distributed (with a geometric mean of 043 μg m −3 and a geometric standard devation of 335), and were strongly the temperature and the reaction involved on the leaching of coppermatte Copper (Cu) bearing matte from Impala Refinery (Pty) Ltd was used in the investigation The experiments were conducted in a leaching cell submerged in a water bath, with ammonia concentrations (leaching solution) of 30M, temperature of 50˚C,An Investigation into the Effect of Temperature on the Jan 26, 2017 Ammonia gas also impacts the environment through interaction in the atmosphere with other gases The primary products of these interactions are fine particulates (PM25) and ammonium (NH 4 + ) aerosols, which can negatively impact human health as respiratory irritants ( img source )Air Pollution: Ammonia and Hydrogen Sulfide and Ambient Ammonia and GasPhase Chemistry • Most species in the atmosphere react with the hydroxyl radical (OH) • These reactions remove the primary species, but initiate a complicated chain of radical reactions leading to the formation of ozone and other secondary pollutantsAmmonia and Atmospheric ChemistryThe base metal recovery process consists of a matte repulping stage prior to a series of pressure leach stages Therefore, the repulping stage is basically an atmospheric leach stage in which the matte containing mostly Ni and Cu is leached in copperspent electrolyte from the tank house, resulting in dissolution of nickel and precipitation of Atmospheric acid leaching of nickelcopper matte from

COPPER(II) EXTRACTION FROM AMMONIA LEACH SOLUTION

Ammonia leaching of sulfide copper concentrates generate buffer type liquors (pH ranges from 9 to 10), because of the excess of ammonia and significant amount of ammonia sulfate as a leaching agent Metals such as Cu, Ni, Co and Zn occur in ammonia systems as a cationic amminacomplexes Alkalinity of the solution and freeAtmospheric N is the major reservoir for N in the N cycle (air is 79 percent N2 gas) (H2) to form ammonia (NH3) Anhydrous ammonia is then used as a starting point in the manufacture of other nitrogen fertilizers Leaching is the loss of soluble NO 3N as it moves with soil water, generally excess water, below the root zone NitrateN Understanding nitrogen in soilsThere is disclosed a process for separating and recovering nickel and copper values from a nickelcopper matte which may contain iron and arsenic Finely divided nickelcopper matte undergoes one or more steps of sulphuric acid leaching at atmospheric pressure to produce a nickel sulphate solution and an iron and/or arsenic containing copperrich sulphide residueCAC Process for upgrading copper sulphide Atmospheric Leaching (AL) or Heap Leaching (HL) technologies These processes do not rely on autoclave technology and are therefore perceived to be less capital intensive and easier to operate However, they still require significant investment in terms of infrastructure Heap leaching is the optionMURDOCH RESEARCH REPOSITORYform of N, but is also highly susceptible to leaching losses Nitrification is most rapid when soil is warm (6786°F), moist and wellaerated, but is virtually halted below 41°F and above 122°F RNH 2 Æ NH 3 Æ NH 4 + organic N ammonia ammonium N 2 Æ NH 3 Æ RNH 2 nitrogen gas ammonia organic N NH 4 +Nitrogen Basics – The Nitrogen Cycle

Uranium processing Leaching Britannica

Uranium processing Uranium processing Leaching: Roasted uranium ores are leached of their uranium values by both acidic and alkaline aqueous solutions For the successful operation of all leaching systems, uranium must either be initially present in the more stable hexavalent state or be oxidized to that state in the leaching process Acid leaching is commonly performed by agitating an Direct atmospheric leaching or pressure leaching as an alternative to the conventional 2006), and ammonia leaching (Babu et al, 2002; Goosh et al, 2002) Ferric ion, which is one of the most important oxidant used in leaching processes, in either sulphate or chloride media, can be used to leach zinc sulphide, according to theHydrometallurgical Treatment of a Zinc Concentrate by