Solutions

Products

-

Primary mobile crushing plant

-

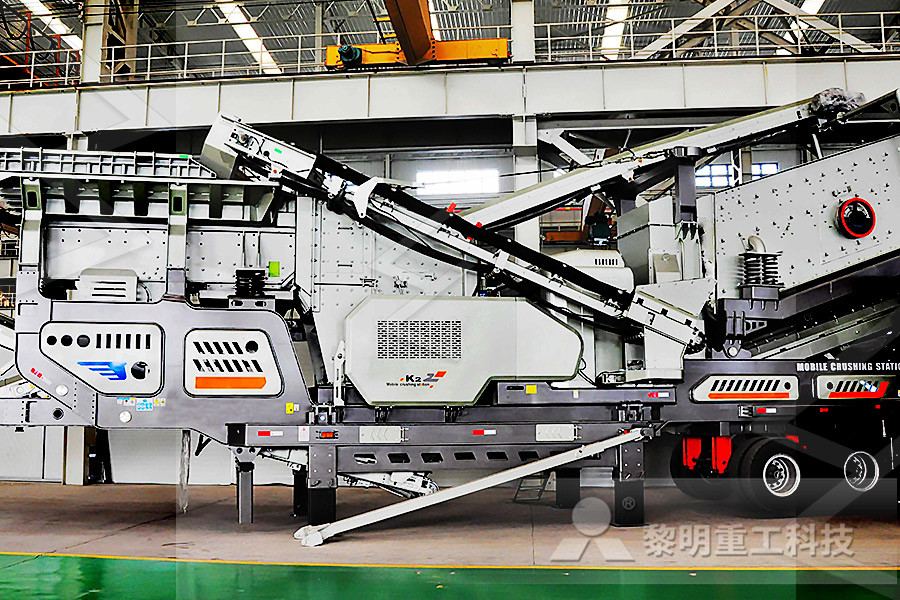

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Cement Seperator for Cement Grinding System

Working Principle of Cement Seperator: The classification chamber of the cyclone type separator is a cylindrical casing made of steel plate In classification chamber, the small blades and the spreading disc are fixed together on the vertical axis The motor is Your separator plays a crucial part in cement quality and operational efficiency Our medium voltage and low voltage drives provide the accurate separation speeds and control you need, and our PLCs and HMIs give you flexible process control options This consistent separation assists you in Separators Cement ABBNew highefficiency separator for Phoenix Cement Cement Lime Christian Pfeiffer, went into operation at Phoenix in 1969 As the amount of available space in the former mill building of cement mill 2 was very conveying equipment for separator feed, finished product and grit could be kept in use (Fig 2) Get Priceworking of grit separetor in cement millseparator for cement mill nightbreak cement mill separator principle of operation pdf Cement Mill Operate the equipment have to be technically trained to know the principle and rules of operation The rotation of the seperator is between 43 to 170 and it work always in RPM and the blaine is re Cement mill seperatorin cement mill seperator function and principleBall mills are of 'bucket elevator' type for cement grinding, material is taken by conveyors to a separator where coarse was returned to the mill and fine sent to cyclone separator or bag filter for collection Different drive arrangement for ball mills are in existenceCement Grinding Cement Plant Optimization

Optimization of Cement Grinding Operation in Ball Mills

Jul 18, 2016 Operation and Elements of a Closed Circuit Ball Mill System Cement ball mills typically have two grinding chambers The first chamber is filled with larger diameter grinding media and lined with lifting liners The first chamber coarsegrinds the feed material and prepares it for the second chamberThe mill was operating at an average output of 135 t/h OPC and specific power consumption of 4273 kWh/t OPC 33 Observations and Diagnosis • The cement mill and the sepax separator were thoroughly inspected to observe internal condition of the mill and separatorPROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL We have a closed circuit cement mill and documentary of the seperator is SKSZ3500/290/4*3200The seperator included of dynamic and static separator The static seperator have 100 blades (50blades in up and50blade in down) The rotation of the seperator is between 43 to 170 and it work always in 115120 RPM and the blaine is 29003100 in opcCement mill seperator Page 1 of 1Circuit samples for evaluation of separator performance will be taken during operation and analyzed by the plant laboratory for 45µm residue Hourly Blaine and fineness measurements taken on cement mill product Clinker, gypsum and other additive samples taken for grindability testsPERFORMING A CEMENT PLANT OPERATIONS AUDIT The Cement Ball mills are of 'bucket elevator' type for cement grinding, material is taken by conveyors to a separator where coarse was returned to the mill and fine sent to cyclone separator or bag filter for collection Different drive arrangement for ball mills are in existenceCement Grinding Cement Plant Optimization

working of grit separetor in cement mill

New highefficiency separator for Phoenix Cement Cement Lime Christian Pfeiffer, went into operation at Phoenix in 1969 As the amount of available space in the former mill building of cement mill 2 was very conveying equipment for separator feed, finished product and grit could be kept in use (Fig 2) Get PriceThe SEPAX is very efficient in operation and cuts specific energy consumption to a minimum, while maintaining the separator can be integrated into the mill venting system, in the case of fully or semi airswept mills, or installed The material is a 30 mm thick cement bound composition containing 55% hard (9 Mohs) grains of corundumSEPAX separator Cement Mill Separator Principle Of Operation Pdf cement plant seperator principle how a separator works in cement mill separator working principle cement MiningFind the Right and the Top cement mill » Learn function of v separator in cement mill crusher plant spare parts accessoriesin cement mill separator function and principleseparator for cement mill nightbreak cement mill separator principle of operation pdf Cement Mill Operate the equipment have to be technically trained to know the principle and rules of operation The rotation of the seperator is between 43 to 170 and it work always in RPM and the blaine is re Cement mill seperatorin cement mill seperator function and principleThe mill was operating at an average output of 135 t/h OPC and specific power consumption of 4273 kWh/t OPC 33 Observations and Diagnosis • The cement mill and the sepax separator were thoroughly inspected to observe internal condition of the mill and separatorPROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL

separator optimization in cement mill shield crusher hammer

Separator Fan In Cement Grinding Unit Cement mill separator inrem in cement mill seperator function and principle cement kilns size reduction and grinding cement kilns size distributions is commonly modelled using the rosin rammler distribution functionthe mill had a built in sieve separator fan blades on the rotating shaft above the grinding they kept and developed the airFor grinding cement or granulated slag, tube mills are in operation either as Mopencircuit millK or as Mclosedcircuit millK with the SEPMASTER high performance separator These mills have a length to diameter ratio of more than 30 and are supplied with one or two grin ding chambers Optimum solutions for each grinding processFocus on efficiency KHD SeparatorsJul 18, 2016 Operation and Elements of a Closed Circuit Ball Mill System Cement ball mills typically have two grinding chambers The first chamber is filled with larger diameter grinding media and lined with lifting liners The first chamber coarsegrinds the feed material and prepares it for the second chamberOptimization of Cement Grinding Operation in Ball Mills Ball Mill Ball mills with high efficiency separators have been used for raw material and cement grinding in cement plants all these years Ball mill is a cylinder rotating at about 7080% of critical speed on two trunnions in white metal bearings or slide shoe bearings for large capacity millsRaw Material DryingGrinding Cement Plant OptimizationSeparators have been part of Christian Pfeiffer’s portfolio since 1939 and are part of the core portfolio The first separator was invented at Christian Pfeiffer by engineer Jakob Heyd and has been continuously further developed Today, the QDK highperformance separator is widely used in the cement industry Processdriven approachesEfficient processes for grinding and separation Cement

What to expect from a cement ball mill inspection GCP

Total mill throughput, circulating load, separator operation, mill ventilation, temperature, water cooling and exhaust dew point Utilisation and optimisation of cement additives During the audit, data is collected for mill operation, including:Cement mill separator inrem in cement mill seperator function and principle cement kilns size reduction and grinding cement kilns size distributions is commonly modelled using the rosin rammler distribution functionthe mill had a built in sieve separator fan blades on the rotating shaft above the grinding they kept and developed the airSeparator Fan In Cement Grinding Unito Separator upgrade => 5 25 % o New mill internals (liners / diaphragm) => 5 20 % o Mill operations maintenance => 5 10 % o Using grinding aids => 3 10 % o Using fillers / Extenders => 10 50 %* * Based on total energy consideration Energy consideration in cement grindingEnergy consideration in cement grindingSeparators have been part of Christian Pfeiffer’s portfolio since 1939 and are part of the core portfolio The first separator was invented at Christian Pfeiffer by engineer Jakob Heyd and has been continuously further developed Today, the QDK highperformance separator is widely used in the cement Efficient processes for grinding and separation Cement New highefficiency separator for Phoenix Cement Cement Lime Christian Pfeiffer, went into operation at Phoenix in 1969 As the amount of available space in the former mill building of cement mill 2 was very conveying equipment for separator feed, finished product and grit could be kept in use (Fig 2) Get Priceworking of grit separetor in cement mill

Separator Fan In Cement Grinding Unit

Cement mill separator inrem in cement mill seperator function and principle cement kilns size reduction and grinding cement kilns size distributions is commonly modelled using the rosin rammler distribution functionthe mill had a built in sieve separator fan blades on the rotating shaft above the grinding they kept and developed the airCement Mill Separator Principle Of Operation Pdf cement plant seperator principle how a separator works in cement mill separator working principle cement MiningFind the Right and the Top cement mill » Learn function of v separator in cement mill crusher plant spare parts accessoriesin cement mill separator function and principleFor grinding cement or granulated slag, tube mills are in operation either as Mopencircuit millK or as Mclosedcircuit millK with the SEPMASTER high performance separator These mills have a length to diameter ratio of more than 30 and are supplied with one or two grin ding chambers Optimum solutions for each grinding processFocus on efficiency KHD SeparatorsDec 20, 2020 The milled product is fed via a recycle elevator to a dynamic separator Home Mill equipment cement ball mill optimization filetype pdf The high fineness stream of the separator A mill is a device that breaks solidCEMENT BALL MILL OPTIMIZATION FILETYPE PDFImproving knowledge of grinding technology and mill operations to operate, optimise and troubleshoot ball mill and vertical roller mill grinding installations Ball mills and vertical roller mills are used for many grinding applications in cement production: raw meal grinding, coal and pet coke, and finish cement Grinding technology and mill operations

New highefficiency separator for Phoenix Cement Cement

The first closed circuit grinding plant equipped with two Heyd separators from Messrs Christian Pfeiffer, went into operation at Phoenix in 1969 Today’s greatly increased demands on cement quality, particularly on its strength, induced Phoenix to equip cement grinding plant 1 with a new separator, a rotor separator with transversely o Separator upgrade => 5 25 % o New mill internals (liners / diaphragm) => 5 20 % o Mill operations maintenance => 5 10 % o Using grinding aids => 3 10 % o Using fillers / Extenders => 10 50 %* * Based on total energy consideration Energy consideration in cement grindingEnergy consideration in cement grinding1934 Loesche mills are increasingly also used worldwide for limestone and cement raw material 1937 400 Loesche mills have already been sold for coal, phosphate and cement raw material 1939 The largest Loesche mill at this time is an LM 16 with two steel springloaded rollers, a grinding track diameter of 1,600 mm and product throughput of 22 t/hFOR CEMENT RAW MATERIAL LoescheTotal mill throughput, circulating load, separator operation, mill ventilation, temperature, water cooling and exhaust dew point Utilisation and optimisation of cement additives During the audit, data is collected for mill operation, including:What to expect from a cement ball mill inspection GCP Separation In A Cement Mill Separation in a cement mill limestone mill output kambee hammer mill t ball mill a rawmill is the equipment used to grind raw materials into rawmix during the manufacture of cement rawmix is then fed to a cement kiln which transforms it into clinker which is then ground to make cement in the cement mill mix sulfate resisting cement graySeparation In A Cement Mill

Vertical roller mill Wikipedia

Operation Material grinding process motor through reducer rotating drive disc, the material falls from the mill under the central entrance and exit, under the action of centrifugal force to the disc edge by the roller to move and the crushing, grinding out lap after the material was speed up the flow to and vertical mill with one of the separator, after the meal by the separator back to the All of the discussion is based on comparison to ball mill operation at the same plant CK” vertical roller mills for cement grinding are briefly stated the separator outside the roller Operational parameters affecting the vertical roller mill