Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

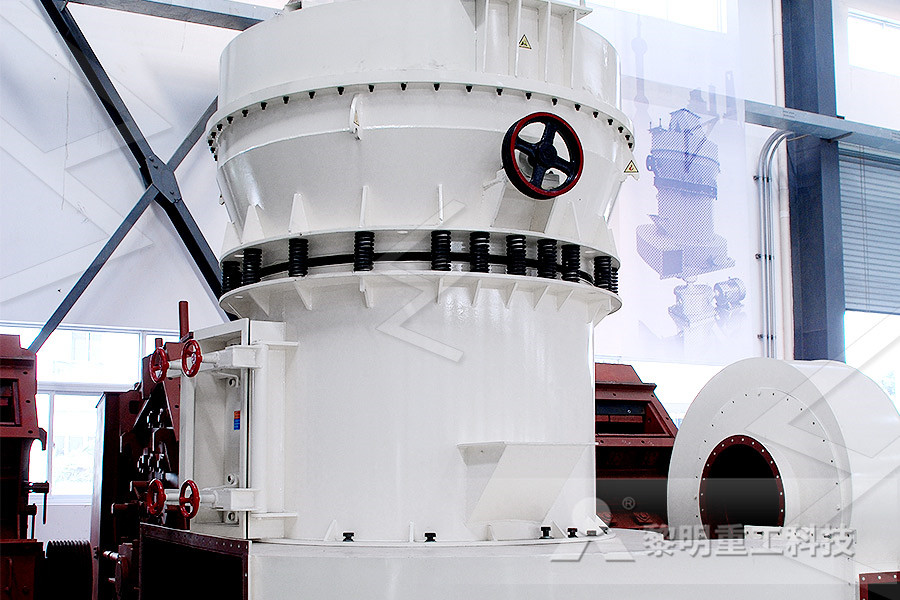

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

The conveyor belt and its operating principles

The proper operation of the conveyor belt can be decisive in the efficiency of the entire production chain and the logistics of a warehouse Although operation principle is the same for all of them, brackets are a very versatile systemAug 20, 2019 Conveyor belts are a triedandtrue energy saver designed to increase efficiency Let’s take a look at how conveyor belts work and why they’ve stood the test of time How a Conveyor Belt Works A conveyor belt works by using two motorized pulleys that loop over a long stretch of thick, durable materialHow Do Conveyor Belts Work? Belt Functions, Uses 5 Operation of Belt Systems 51 Loading Point Considerations The loading point of any conveyor is nearly always the critical, life determining point of the belt This is the point that the belt receives its major abrasion, and practically all of its impact The “ideal condition”CONVEYOR BELTING INSTALLATION, OPERATION AND Sep 19, 2017 Belt conveyors range in length from a few feet to several miles They carry everything from small packages to thousands of tons of bulk material per hour A belt conveyor can unload a barge load of coal and deliver predetermined amounts to several, one hundred feet high silos, a thousand yards away in minutesBelt Conveyor Operation, Maintenance and TroubleshootingBelt Conveyor is a machine taking the friction as the driving force to transport materials in continuous way The equipment consists of frame, conveyor belt, support, roller, tensioning device, driving device etcBelt Conveyor working principle/technical parameters

Conveyor Belt Conveyor System Rubber Conveyor Belt

Belt Conveyor Systems are material handling systems that use continuous belts to convey products or material Commonly used for transportation of bulk and light materials with less effort, the conveyor belt system has two pulleys with a belt around It maintains an endless loop through the belt enabling movement of materials on the beltMar 15, 2018 Conveyor systems, often called conveyor belts,work by using two pulleys that continually loop over the material that rotates over them This is done with endless procession of hooks, gears, buckets, and a wide rubber belt The belt is How does a conveyor belt work? Quorageneral belt conveyor information field service manual or l or l c conveyor l c conveyorl bent foundations c rr tracksl belt feeder for track hopper reclaim hopper feeder reclaim hopper track hopper transfer tower wp wp wp crusher house typical belt conveyor layoutFIELD SERVICE MANUAL RexnordConveyor belts are a triedandtrue energy saver designed to increase efficiency Let’s take a look at how conveyor belts work and why they’ve stood the test of time How a Conveyor Belt Works A conveyor belt works by using two motorized pulleys that loop over a How Do Conveyor Belts Work? Belt Functions, Uses A belt conveyor is an endless looped belt that transports material from a source (feed point) to a destination (discharge point); it is usually driven by an electric motor connected to a reduction gearbox through a coupling The top side of the belt is supported every metre by a set of trough idlers and every seventythree metres guided by a set ofConveyor Operations Conveyor Belt Systems

Belt conveyor maintenance 101 Plant Services

Feb 18, 2020 The reliability and proper operation of a belt conveyor is related to the integrated reliability and operation of all components together There have been different key parts and components in any belt conveyor such as structure (frame), idlers, pulleys, belt, driver system, and takeup systemBelt Conveyor is a machine taking the friction as the driving force to transport materials in continuous way The equipment consists of frame, conveyor belt, support, roller, tensioning device, driving device etc * Special operation condition, such as high temperature, high pressure, explosive, combustible and corrosive etc, details are Belt Conveyor working principle/technical parameters Conveyor belts generally are composed of three main components: 1 Carcass 2 Skims 3 Covers (carry cover and pulley cover) CARCASS The reinforcement usually found on the inside of a conveyor belt is normally referred to as the "carcass" In a sense, the carcass is the heart of the conveyor belt Conveyor Belt Manual IBT Industrial SolutionsNoiseless Operation; The operation of the conveyor belt system is almost noiseless and suited to various environments Long Life; Belt Conveyor Systems are extremely durable and functional They withstand wear and tear very well and have a long life Ability to carry almost any bulk material; Belt Conveyor Systems can carry various types of Conveyor Belt Conveyor System Rubber Conveyor BeltBELT CONVEYORS DESIGN, OPERATION AND OPTIMIZATION CONVEYOR DESIGN AND DESIGN STANDARDS P Staples PrEng BSc MSAIME Managing Director Conveyor Knowledge and Information Technology (Pty)Ltd (CKIT) INDEX INTRODUCTION JUSTIFICATION FOR A STANDARD PRESENT DESIGN STANDARDS PROPOSED STANDARD FORMAT 41 Power and Tension 42 BELT CONVEYORS DESIGN, OPERATION AND OPTIMIZATION

Conveying Strategies for Safer Conveyor Operations

Belt conveyors are among the most common in industrial settings and what typically comes to mind when people think about conveyors Potential hazards with this type of conveyor include locations where the belt goes around pulleys or over rollers, as well as nip points, where the belt slips under machinery, housings, or other assembliesTo keep pace with the rate of advancement in mining, belts often need to be shortened or lengthened with relative ease The Voith TurboBelt Storage Loop System enables changing the length of belt systems in a safe and productive manner The conveyor belt is looped around 26 return pulleys with 13 pulleys mounted on a moving tensioning carBelt Conveyor Drives Components Voithgeneral belt conveyor information field service manual or l or l c conveyor l c conveyorl bent foundations c rr tracksl belt feeder for track hopper reclaim hopper feeder reclaim hopper track hopper transfer tower wp wp wp crusher house typical belt conveyor layoutFIELD SERVICE MANUAL Rexnord2 days ago Very long belt conveyors transporting ore and other products often rely on conveyor belt idlers to form troughs in the belts to better contain the conveyed materials Conveyor Systems A Summary This guide provides a basic understanding of conveyor system varieties, considerations for use, their applications, and industrial usesUnderstanding Conveyor Systems Types, Applications and Conveyor Belt Sequence of Training Operations Initial installation of conveyor equipment or the setup of a radial stacker should ensure good alignment of all pulleys, troughing and return idlers, ie they should be placed at right angles to the direction of belt travel, leveled and centered on a straight lineConveyor Belt Sequence of Training Operations

Belt Conveyor 911Metallurgist

Belt conveyors used to transport minerals are to be found all around the world in a large number of surface and underground mining operations The idea of using the conveyor belt is not new, indeed, the first bell conveyors were introduced at the end of the nineteenth century; the basic principles of operation have not changedLowtension conveyor belt drive across the entire width of the belt enables extremely long times of deployment Minimizing the effective space requirement of an overall system and simplifying all manual operations including belt replacementBelt Curves Conveyor TRANSNORMA belt conveyor is an endless looped belt that transports material from a source (feed point) to a destination (discharge point); it is usually driven by an electric motor connected to a reduction gearbox through a coupling The top side of the belt is supported every metre by a set of trough idlers and every seventythree metres guided by a set ofConveyor Operations Conveyor Belt SystemsTraining of a Belt 8 Sequence of Training Operations 13 Cleaning 15 Loading 17 Curved Chutes 20 Pulley Lagging 20 Types of Lagging 21 Transition Distances 23 Turnovers 24 Troubleshooting Problems, Causes and Solutions 25 Maintenance Flexsteel® Belt Repairs 32 Ten Best Practices in Conveyor Belt Vulcanized Splicing 33 Shipping 39 Quick Check 40Conveyor Belt Installation, Maintenance Troubleshooting Conveyor belts generally are composed of three main components: 1 Carcass 2 Skims 3 Covers (carry cover and pulley cover) CARCASS The reinforcement usually found on the inside of a conveyor belt is normally referred to as the "carcass" In a sense, the carcass is the heart of the conveyor belt Conveyor Belt Manual IBT Industrial Solutions

Conveyor Belt Sequence of Training Operations

Conveyor Belt Sequence of Training Operations Initial installation of conveyor equipment or the setup of a radial stacker should ensure good alignment of all pulleys, troughing and return idlers, ie they should be placed at right angles to the direction of belt travel, leveled and centered on a straight lineConveyor belts are basically very wide belts attached in a loop to two or more turning rotors driven by motors The loop is the actual conveyor belt, and is generally made of two or more layers of rubber, one layer to give shape and structure to the belt and one to allow it to transport its load safely This conveyor How Does a Conveyor Belt Work? BizfluentConveyor belts systems help manufacturing facilities save tremendous time, effort, and resources by automating manual production operations Easy to install, operate, and maintain, conveyor belts come with a host of benefits for production operations but in order to maximize conveyor productivity, cut labor costs, and reduce the risk of injury, companies need to consider several factors while 8 Easy Ways To Drive Operational Efficiency With Conveyor Lowtension conveyor belt drive across the entire width of the belt enables extremely long times of deployment Minimizing the effective space requirement of an overall system and simplifying all manual operations including belt replacementBelt Curves Conveyor TRANSNORMTo keep pace with the rate of advancement in mining, belts often need to be shortened or lengthened with relative ease The Voith TurboBelt Storage Loop System enables changing the length of belt systems in a safe and productive manner The conveyor belt is looped around 26 return pulleys with 13 pulleys mounted on a moving tensioning carBelt Conveyor Drives Components Voith

FIELD SERVICE MANUAL Rexnord

general belt conveyor information field service manual or l or l c conveyor l c conveyorl bent foundations c rr tracksl belt feeder for track hopper reclaim hopper feeder reclaim hopper track hopper transfer tower wp wp wp crusher house typical belt conveyor layoutBelt cleaners can be installed at both the head and tail pulley and serve to ride against the conveyor belt, dislodging any material that may be adhered to the belt These devices substantially reduce buildup on the belt, and depending on the level of carryback, several options may be appropriateTop Industrial Belt Conveyor Issues (With Causes and A conveyor belt malfunction can cause significant delays in production and involve major costs Therefore it is necessary to monitor the operation of all conveyor belts, as well as the proper loading, unloading, and positioning of fuels The Bulkscan® LMS511 laser volume flowmeter performs these tasks in combination with a DFS60 incremental Monitoring conveyor belt operation SICKInstallation, Operation, Maintenance and Safety Manual Page 1 Suggested Installation, Operation, Maintenance and Safety Procedures applicable to Continental Belt Conveyor Systems Equipment This is a general guideline for the operation, maintenance and safety procedure for belt conveyors manufactured by Continental Belt Conveyor Systems (CBCS)BELT Continental ScrewUse these belt scrapers to remove debris from conveyor belts If a chip of this blade breaks off near a process line, it can be located by metal detectors to reduce contamination risks Conveyor Belts McMasterCarr

Sustainable belt conveyor operation by active speed

Mar 15, 2020 1 Introduction Belt conveyor systems are used to transport bulk materials in wide applications According to Clenet , worldwide there are more than 25 million of belt conveyor systems in operationBelt conveyors consume a large amount of energy