Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

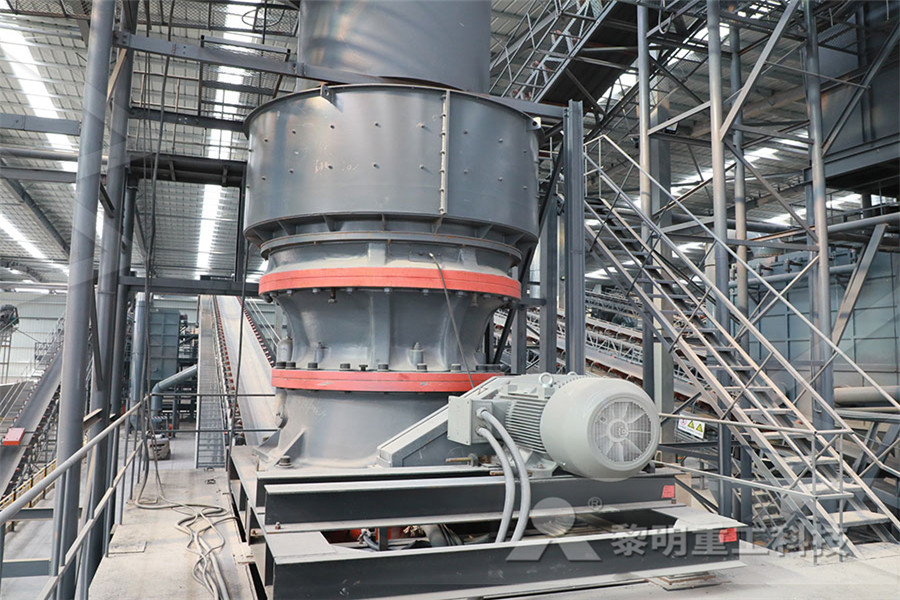

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Effective Beneficiation of Low Grade Iron Ore Through

mineral jig and Harz jig The operating variables used to determine the effectiveness of throughput rate [12] It is a technique where particles of mixed bed, size, shape and Barsua iron ore mine in India has adopted Remco Jigs for beneficiation of lowgrade iron ore fines Bateman’s Apic jig is being used in iron ore mines of South The company’s BATAC® jigs are becoming increasingly popular in the iron ore beneficiation sector due to their rapid detection of changes in the raw material, quick reaction to such changes and Increasing throughput and decreasing maintenance in the Packed Column Jig (PCJ) is a gravity separator and ope rates like a teetered bed separator (Nicol, 1998), but the internal packing and a pulsating water flow allows higher throughput capacity and sharper separation Packing also limits the turbulence and vorticityIron Ore Beneficiation with Packed Column JigJul 06, 2020 Increasing beneficiation process outputs whilst simultaneously adhering to safety regulations and minimising maintenance can be challenging Capital equipment needs to be designed and selected with maximised throughput and uptime in mind The company’s BATAC jigs are becoming increasingly popular in the iron ore beneficiation sector Increasing throughput and decreasing maintenance in the Jig So BATAC Jig has less CAPEX for equal throughput levels 3 Due to its limited width, BAUM Jigs experience relatively high edge effect (area of lower performance) compared to BATAC Jigs If we take a common 2 m wide BAUM Jig and a common 45 m BATAC Jig, the percentage negative edge effect is 80% and 36% respectively 4Beneficiation of Indian Iron Ore Lumps and Fines by using

Operation and performance of the Sishen jig plant

In addition, 22 Mt/a is crushed to 25 mm for beneficiation in the jig plant, which consists of eight modules of three jjigs per module The feed to each module is screened into three fractions that feed three different jigsJig machine for iron ore of fine inlay refers to saw tooth wave jigger of JT series This jigger is improved on the basic of traditional downdriven jiggers, and its water flow moves along saw tooth wave and strengths the jigging recovery rate The beneficiation efficiency is obvious and Iron Ore Beneficiation Jig Machineiron ore jig throughput calculations Description Iron Ore Beneficiation With Packed Column Jig Iron ore jig throughput calculations zacarafarmron ore beneficiation with packed column jig this paper presents several iron ore applications of the packed column jig, a revolutionary and economical gravity separator of fine particulate materials, whichiron ore jig throughput calculationsthroughput capacity module to allow for comparison Only physical beneficiation methods were considered The Coal Preparation Utilities is software developed by the CSIR in South Africa for coal preparation modelling and efficiency test work The LIMN “The Flowsheet Processor” software was developed by DWiseman in 199415 CHAPTER EIGHT COAL BENEFICIATION MODELLING OF Mineral Jig Machine Jig Concentrator Jig Separator How is gold extracted from river sand using jig machine limonite gravity beneficiation process beneficiation process of placer gold ores will it make great money by investing tantalite columbite beneficiation plant in Africa Jig machine for African tantalum niobium ore beneficiation How to improve the recovery rate of tin ore dressing plant Mineral Jig Concentrator For Process Mineral

Increasing throughput and decreasing maintenance in the

The company’s BATAC® jigs are becoming increasingly popular in the iron ore beneficiation sector due to their rapid detection of changes in the raw material, quick reaction to such changes and This leads to highly efficient separation with high throughput capacity and also permits linear scale up by jig volume Since no chemicals are used, the process is environmentally friendly Due to(PDF) Iron Ore Beneficiation with Packed Column JigJigs Jigging, like most gravity concentration techniques, is one of the oldest methods for concentrating minerals based on differences in the density of the particles The elementary jig is an open tank filled with water with a thick bed of particles, called ragging, supported on a Introduction to Mineral Processing or BeneficiationThe samples were subjected to jigging in a laboratory Denver mineral jig and Harz jig throughput r ate The beneficiation of lowgrade iron ores to meet the growing demand for iron and (PDF) Effective Beneficiation of Low Grade Iron Ore Tantalum Ore Beneficiation Process Gongyi Forui Machinery Factory is a professional mineral processing machine manufacturer in Gongyi, China Our products include jig separator, magnetic separator, flotation machine, gold separator, grinding machine, classifier equipment, etc Separation of tantalite consists of rough separation and fine Tantalum Ore Beneficiation Process

Iron Ore Beneficiation Jig Machine

Jig machine for iron ore of fine inlay refers to saw tooth wave jigger of JT series This jigger is improved on the basic of traditional downdriven jiggers, and its water flow moves along saw tooth wave and strengths the jigging recovery rate The beneficiation efficiency is obvious and A view of the Batac jig plant at Khumani To sustain and ideally grow profitability and quality, processing plants need to align themselves with suppliers can customise solutions that fit specific applications Capital equipment needs to be designed and selected with maximised throughput and uptime in mindIncreasing throughput and decreasing maintenance for the throughput capacity module to allow for comparison Only physical beneficiation methods were considered The Coal Preparation Utilities is software developed by the CSIR in South Africa for coal preparation modelling and efficiency test work The LIMN “The Flowsheet Processor” software was developed by DWiseman in 199415 CHAPTER EIGHT COAL BENEFICIATION MODELLING OF Mineral Jig Machine Jig Concentrator Jig Separator How is gold extracted from river sand using jig machine limonite gravity beneficiation process beneficiation process of placer gold ores will it make great money by investing tantalite columbite beneficiation plant in Africa Jig machine for African tantalum niobium ore beneficiation How to improve the recovery rate of tin ore dressing plant Mineral Jig Concentrator For Process MineralAs a result, the jig machine has extremely good performance for recovery of gold and diamond 1 Compact structure and small occupation area 2 Energy saving and continuous working 3 High recovery, high unit throughput and low water consumption 4 Simple Coltan Ore Beneficiation Jig Separator For Diamond Mining

How to Guarantee Beneficiation Efficiency?

How to Guarantee Beneficiation Efficiency? Gongyi Forui Machinery Factory is a professional mineral processing machine manufacturer in Gongyi, China Our products include jig separator, magnetic separator, flotation machine, gold separator, grinding machine, classifier equipment, etcMBE Minerals introduced BATAC jig technology to the market in the 1960s specifically to overcome the counterproductive limitations of traditional technology The underbed pulsated BATAC jig is ideal for coarse applications from 150 mm down to fine coal in the 10 to 05 mm size range, with throughput rates of between 100 and 1,200 t/hMBE Minerals outlines coal beneficiation capability Diaphragm jig belongs to double rooms under the single plugfuse type It makes use of water as medium, and separates according to the proportion of the gangue minerals (density) It is the beneficiation equipment Superiority: jig machine does the sine wave motion It has the advantage of high recover, large capacity of treatment, continuous Gravity Concentration By Jigs Engineering EssayJigs Jigging, like most gravity concentration techniques, is one of the oldest methods for concentrating minerals based on differences in the density of the particles The elementary jig is an open tank filled with water with a thick bed of particles, called ragging, supported on a Introduction to Mineral Processing or BeneficiationThe samples were subjected to jigging in a laboratory Denver mineral jig and Harz jig throughput r ate The beneficiation of lowgrade iron ores to meet the growing demand for iron and (PDF) Effective Beneficiation of Low Grade Iron Ore

Iron Ore Beneficiation Jig Machine

Jig machine for iron ore of fine inlay refers to saw tooth wave jigger of JT series This jigger is improved on the basic of traditional downdriven jiggers, and its water flow moves along saw tooth wave and strengths the jigging recovery rate The beneficiation efficiency is obvious and How to Guarantee Beneficiation Efficiency? Gongyi Forui Machinery Factory is a professional mineral processing machine manufacturer in Gongyi, China Our products include jig separator, magnetic separator, flotation machine, gold separator, grinding machine, classifier equipment, etcHow to Guarantee Beneficiation Efficiency?MBE Minerals introduced BATAC jig technology to the market in the 1960s specifically to overcome the counterproductive limitations of traditional technology The underbed pulsated BATAC jig is ideal for coarse applications from 150 mm down to fine coal in the 10 to 05 mm size range, with throughput rates of between 100 and 1,200 t/hMBE Minerals outlines coal beneficiation capability 6 COAL BENEFICIATION As discussed in chapter 3, the gasifiers in the Gas Production section of the Sasol • Wateronly technology: jigs 68 process and to allow for ever increasing throughput, and sometimes better separation efficiency 621 Wemco drum separator The Wemco drum separator is show in figure 62, and is the simplest 61 Coal Beneficiation Technology OptionsromJig Jig for rom coal 20m 350– 30 mm 400 t/h baTac Jig for lump ore 60m 45 – 6 mm 500 t/h baTac Jig for fine ore 60m 10 – 0315mm 450 t/h jigs sizes To overcome the limitations of these historical technologies, mbe took the technology leap in the 1960s to introduce substantially new highthroughputBatac Romjig Jigging Technology Mineral

Advances in Low Grade Iron Ore Beneficiation

metallurgical performance, like metallurgical recoveries and throughput, Environmental impact such as fresh water usage for tons produced Most of the ROM iron ore contain lot of impurities that needs beneficiation before use Extent to which beneficiation techniques are employed, depends on One number of minimum 5 mtpa throughput new beneficiation plant based on hematite iron ore which includes grinding gravity and high intensity magnetic separation the plant must have operated satisfactorily for a period of at least two years after commissioning prior to 1 st october 2011 Get Details The Effect Of Particle Size On Green PelletIron Ore Beneficiation Pdf Iron Ore Crushing Plant Iron Diaphragm jig belongs to double rooms under the single plugfuse type It makes use of water as medium, and separates according to the proportion of the gangue minerals (density) It is the beneficiation equipment Superiority: jig machine does the sine wave motion It has the advantage of high recover, large capacity of treatment, continuous Gravity Concentration By Jigs Engineering EssayUtilizing dry coal beneficiation as opposed to the conventional wet methods arises for numerous reasons including the scarcity of water in some regions, the associated costs of product and fine Smaller sizes and sensitive threshold settings may affect throughput the All Air Jig is primarily used for beneficiation of a coarse feed and Dry processing for coal preparation: a reviewBATAC® jigs are underpulsated which effects in higher separation efficiencies than BAUM jigs and higher throughput rates than BAUM alongwith lesser footprint and lesser corner effect Salient features of BATAC® Jig include: • A centre air chamber for each compartment for stable operation and uniformBatacjig in Rajarhat , Kolkata , MBE Coal And Mineral

Mining Weekly Mbe Minerals Leads The Way In Coal

The underbed pulsated BATAC® jig is ideal for coarse applications from 150 mm down to fine coal in the 10 to 05 mm size range, with throughput rates of between 100 and 1 200 tph