Solutions

Products

-

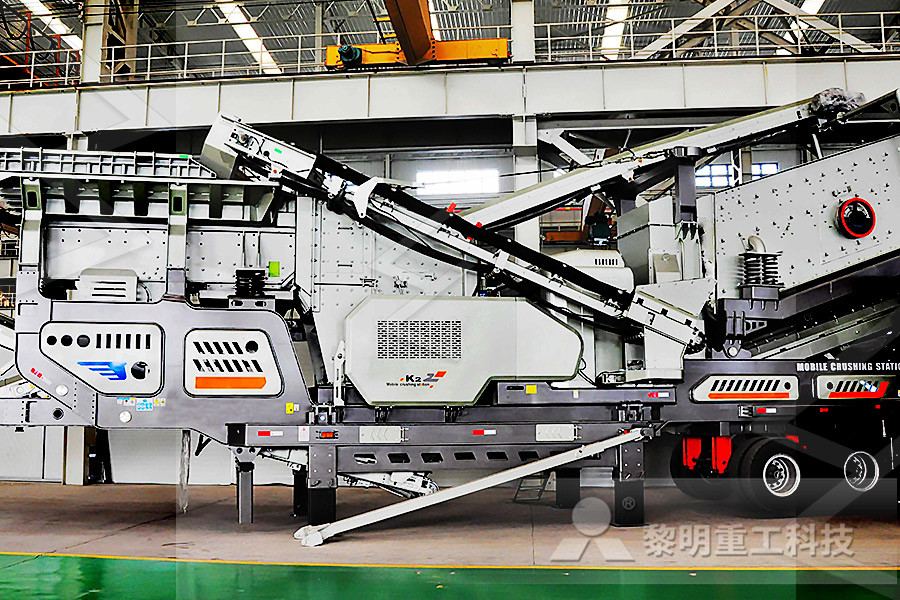

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

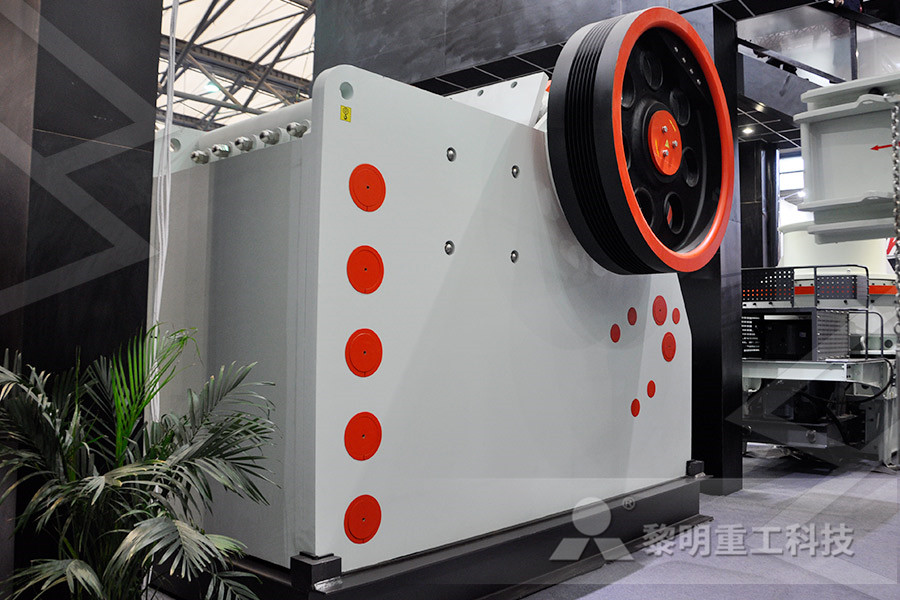

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

CLINKER GRINDING UNIT PROCESS Mechanical engineering

In clinker grinding, gypsum being the more readily grindable, tends to be concentrated in the finer particle size fraction of the product Strength development improves if cement is more closely graded, provided the specific surface of cement is not reduced Improvement in strength is due to faster rate of hydration Grindability Index of Clinkerclinker grinding processing: Clinker grinding is the stage in which the final product stage in cement production,it is independent of each other In this stage, the cement clinker is added with an appropriate amount of the mixed material,it is be ground to produce finished cementClinker Grinding Unit Great WallIt is the ideal grinding equipment for cement clinker, limestone, gypsum, slag, ore, and other grindable hardness materials In the process of cement production, cement raw meal is calcined in a rotary kiln to obtain cement clinker After the cement clinker is cooled, Use Cement Ball Mill Grinding Cement Clinker Cement Ball The cooled clinker is a kind of granular material with different particle sizes They will be ground in the grinding mill to reach the qualified fineness of cement products During the grinding, 23% gypsum powder is added as retarder so that when cement contacts with water, its Clinker Calcination Datis Export GroupClinker free lime (CaO f) should be as high as possible to avoid hard burning of clinker, but safely below value, inviting mortar expansion; normally, between 05% and 15% Free lime indicates incomplete clinker burning, therefore should be monitored regularly and maintained closely in the acceptable rangeClinkerization Cement Plant Optimization

Cement Clinker Grinding Process

Cement Clinker Grinding Process Clinker grinding process in cement in uae CLINKER Clinker Supplier CTC Dubai is a leading international clinker trading and cement trading company known across the world In the 30 Years since CTC Dubai’s inception the company has supplied over 50 million tonnes of Clinker to various destinations from Arabian Gulf Far East Indian subcontinent Europe Africa Clinker Grinding Unit Great Wall Machinery clinker grinding processing: Clinker grinding is the stage in which the final product stage in cement production ,it is independent of each other In this stage, the cement clinker is added with an appropriate amount of the mixed material ,it Clinker grinding appropriate ideenausstahlchIn clinker grinding, gypsum being the more readily grindable, tends to be concentrated in the finer particle size fraction of the product Strength development improves if cement is more closely graded, provided the specific surface of cement is not reduced Improvement in strength is due to faster rate of hydration Grindability Index of ClinkerCLINKER GRINDING UNIT PROCESS Mechanical engineering clinker grinding processing: Clinker grinding is the stage in which the final product stage in cement production,it is independent of each other In this stage, the cement clinker is added with an appropriate amount of the mixed material,it is be ground to produce finished cementClinker Grinding Unit Great WallThe cooled clinker is a kind of granular material with different particle sizes They will be ground in the grinding mill to reach the qualified fineness of cement products During the grinding, 23% gypsum powder is added as retarder so that when cement contacts with water, its Clinker Calcination Datis Export Group

Clinkerization Cement Plant Optimization

Clinker free lime (CaO f) should be as high as possible to avoid hard burning of clinker, but safely below value, inviting mortar expansion; normally, between 05% and 15% Free lime indicates incomplete clinker burning, therefore should be monitored regularly and maintained closely in the acceptable rangeThere are six grinding systems available for the grinding of clinker Conventional closed circuit system consisting of ball mill, bucket elevator and high efficiency separator Pre grinding with aroller press and subsequent finish grinding in a ball mill operating in either open or close circuit Hybrid grinding in a roller press operating in closed circuit with separator and subsequent linker grinding process MiningCement Clinker Grinding Process Clinker grinding process in cement in uae CLINKER Clinker Supplier CTC Dubai is a leading international clinker trading and cement trading company known across the world In the 30 Years since CTC Dubai’s inception the company has supplied over 50 million tonnes of Clinker to various destinations from Arabian Gulf Far East Indian subcontinent Europe Africa Cement Clinker Grinding ProcessClinker Grinding Unit Great Wall Machinery clinker grinding processing: Clinker grinding is the stage in which the final product stage in cement production ,it is independent of each other In this stage, the cement clinker is added with an appropriate amount of the mixed material ,it Clinker grinding appropriate ideenausstahlchClinker grinding aids Gypsum is added to clinker primarily as an additive preventing the flash settings of the cement, but it is also very effective to facilitate the grinding of clinker by preventing agglomeration and coating of the powder at the surface of balls and mill wallCement clinker Wikipedia

Grinding aids for high performance cements

of view of clinker content and energy requirement for high fineness grinding) can be challenging and the use of suitable cement additives becomes mandatory Several types of products can be found on the market Whatever is the additive used (pure grinding aids, specifically designed toof the materials, controlled by the grinding equipment and on the duration of the grinding Grinding of cement is an important topic when it comes to energy consumption The clinker grinding is responsible for around 40% of the total energy usage during cement production [21]SINTEF REPORTAutomated computer control systems, for example, can be used to optimize the combustion process and conditions Improved process control will also help to improve the product quality – for example by fine tuning reactivity and hardness of produced clinker – which may lead to more efficient clinker grindingProcess Control and Optimization in Clinker Making Subject: Environmental Clearance for the proposed Clinker Grinding Unit of M/S Shree Cements Limited at Aurangabad Industrial Growth Center (Industrial Area), Tahsil District Aurangabad, Bihar Sir, This has reference to your application No SCL/Bihar/201112 dated 26/07/2011 and subsequent communications for Environmental ClearanceshreecementAutomated computer control systems, for example, can be used to optimize the combustion process and conditions Improved process control will also help to improve the product quality – for example by fine tuning reactivity and hardness of produced clinker – which may lead to more efficient clinker grindingProcess Control and Optimization in Clinker Making

Clinker Grinding Unit CHAENG

Clinker grinding processing: Clinker grinding is the stage in which the final product stage in cement production ,it is independent of each other In this stage, the cement clinker is added with an appropriate amount of the mixed material ,it is be ground to produce finished cementof view of clinker content and energy requirement for high fineness grinding) can be challenging and the use of suitable cement additives becomes mandatory Several types of products can be found on the market Whatever is the additive used (pure grinding aids, specifically designed toGrinding aids for high performance cementsCement Clinker Grinding Process Clinker grinding process in cement in uae CLINKER Clinker Supplier CTC Dubai is a leading international clinker trading and cement trading company known across the world In the 30 Years since CTC Dubai’s inception the company has supplied over 50 million tonnes of Clinker to various destinations from Arabian Gulf Far East Indian subcontinent Europe Africa Cement Clinker Grinding ProcessThere are six grinding systems available for the grinding of clinker Conventional closed circuit system consisting of ball mill, bucket elevator and high efficiency separator Pre grinding with aroller press and subsequent finish grinding in a ball mill operating in either open or close circuit Hybrid grinding in a roller press operating in closed circuit with separator and subsequent linker grinding process Miningof the materials, controlled by the grinding equipment and on the duration of the grinding Grinding of cement is an important topic when it comes to energy consumption The clinker grinding is responsible for around 40% of the total energy usage during cement production [21]SINTEF REPORT

Cement Clinker Efficient Raymond Millraymond Grinder

It is a new type of highfineness grinding mill with high efficiency and closed circulation, which can completely replace the cement ball mill This kind of machine is commonly used in cement plant for raw materials fine grinding Cement Clinker Raymond Mill Machine, Cement Clinker Alibaba offers 156 cement clinker raymond mill machine productsProcess Of Clinker Grinding Cement Clinker Grinding Process Sand Processing Cement Clinker Grinding Process Sand Processing Cement manufacturing is a complex process that begins with mining and then grinding raw materials that include limestone and clay, to a fine powder, called raw meal, which is then heated to a sintering temperature as high as 1450 c in a cement kilnIn this process, the Linker Grinding ProcessWHEN WORKING WITH PORTLAND CEMENT CLINKER DUST (WET OR DRY) ALWAYS WEAR PROTECTIVE IMPERVIOUS CLOTHING, WATERPROOF GLOVES AND, IF APPROPRIATE, WATERPROOF KNEEPADS AND BOOTS, MEETING APPLICABLE OSHA STANDARDS INHALATION • Avoid prolonged and repeated inhalation of Portland Cement Clinker DustsSafety Data Sheet Portland Cement ClinkerJaw crusher suitable for clinker crushing Lockmail powdered clinker not suitable for concrete coal mill is the main equipment of the rotary kiln cement clinker production system and at the same time, it is also suitable for powder grinding equipment system Get Price safety data sheet portland cement clinker jawpowdered clinker not suitable for concretegypsum content at the time of clinker grinding It is used mostly in under water construction where pumping is involved 6 Low Heat Cement – IS 12600: 1989 Formation of cracks in large body of concrete due to heat of hydration has focussed the attention of the concrete which produces less heat, at a low rate during the hydration processCement : Physical Properties and Types of Cement

(1)How to Improve the quality of cement kiln clinker?

Sep 21, 2017 Improve the quality of cement kiln clinker should control the five major aspects The fist major aspect: In order to ensure the implementation of the rotary cement kiln batching program and the uniformity of the raw material composition, improve the quality of clinker, in the production process quality control should pay attention to the mountain to improve the quality of rotary cement kiln Clinker grinding is the stage in which the final product stage in cement production ,it is independent of each other In this stage, the cement clinker is added with an appropriate amount of the mixed material ,it is be ground to produce finished cementClinker Grinding UnitCement clinker is the semifinished products based on limestone and clay, iron raw materials as the main raw material, formulated into raw materials according to the appropriate ratio, burning until part or all of the molten, and obtained after coolingCement Clinker Grinding Mills, Ultrafine Mills, Powder