Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

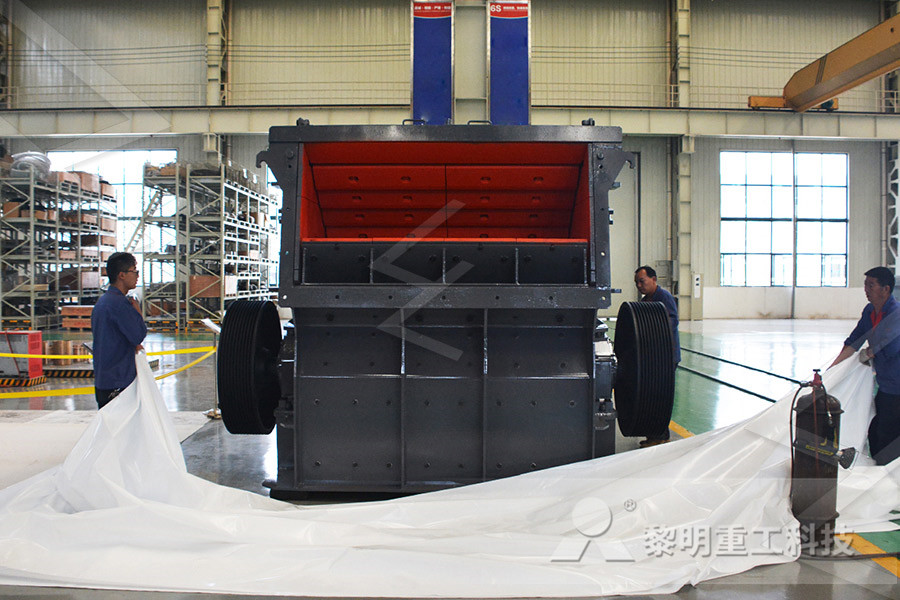

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

What is “In Situ” Mining? – Black Hills Clean Water Alliance

In situ leach mining (ISL) is a method of uranium mining where hundreds of wells are drilled in a “grid pattern” over an ore body that is located in a groundwater aquifer Water mixed with sodium bicarbonate concentrate is pumped down into the aquifer, Insitu is a Latin word that literally means “in the place” Unlike conventional mining methods, in situ recovery (ISR) removes the ore while leaving the rock “in the place” ISR utilizes a series of EPA Class III wells to inject native groundwater, fortified with oxygen and baking soda into the ore zoneInSitu Uranium Mining Process UrEnergyJun 25, 2019 Today’s infographic from Excelsior Mining Corp outlines a unique mining method, InSitu Recovery “ISR”, also known as InSitu Mining An Intro to InSitu Mining ISR is not a recent innovation in the mining sector In fact, ISR has been used for the past 50 years in uranium mining, and 48% of the world’s uranium gets mined this wayInfographic: Everything You Need to Know About InSitu MiningIn conjunction with this insitu solution mining, it is known in the art that various ores, for example, chalcopyrite and most other primary sulfide minerals, are not effectively dissolved by the leaching solution or the rate of solution is so slow that any such process is impracticalProcess for insitu mining KENNECOTT COPPER CORPORATIONby injecting steam deep underground and pumping the oil to surface (thermal insitu), or by mining the ore and physically separating the bitumen from the sand in a processing plant Suncor Energy has been mining the oil sands since the late 1960sMining versus insitu: A look at how energy companies are

Leaching Mining Fundamentals

Mar 05, 2014 The leaching process in mining is carried out either as heap leaching or insitu leaching Precious metals such as gold are extracted from their ores by a cyanide or ozone leaching process Radioactive metals, such as uranium are extracted by the process of acid leachingThis unit process includes insitu mining of uranium and associated processing activities, including milling and groundwater remediation Data are based primarily on US insitu leach (ISL) mines InSitu Leach Mining and Processing, Uranium (Technical Mar 09, 2016 Insitu copper leaching is a proven technology Insitu copper leaching is a proven technology For those unfamiliar with insitu leaching, it is the process of circulating solutionsInsitu copper leaching is a proven technology Insitu recovery (ISR, also referred to as insitu leaching or solution mining) may offer such a stepchange approach ISR refers to the recovery of valuable metals from ore deposits by the circulation of a fluid underground and the recovery of the valuable Insitu recovery—a move towards 'keyhole mining' Mining3In situ mining means a method of in‑place surface mining in which limited quantities of overburden are disturbed to install a conduit or well and the mineral is mined by injecting or recovering a liquid, solid, sludge or gas that causes the leaching, dissolution, gasification, liquefaction or extraction of the mineralIn situ mining does not include the primary or enhanced recovery of In situ mining legal definition of In situ mining by Law

In Situ Bitumen Extraction Oil Sands Magazine

Insitu facilities therefore have a much smaller footprint than surface mining operations Insitu plants require about 1/7th the land area of an equivalentsized mining facility More efficient water usage: Insitu operations use water for steam production, which is mostly recovered and recycled back into the process Dec 05, 2020 Insitu leaching is a process that is utilized in mining for the recovery of certain stated types of minerals that include uranium, gold and copperThe process requires that holes be drilled into the site where the deposit is located with the aim of creating portals through which certain liquid can be poured down to the deposit by the created portalWhat Is inSitu Leaching? (with picture)Insitu Leaching Insitu leaching is also known as insitu recovery, or solution mining This is especially used to extract copper and uranium In this process, holes are drilled into the ore deposit by explosive or hydraulic fracturing methods The leaching solution is then pumped through these channelsLeaching Mining FundamentalsThis unit process includes insitu mining of uranium and associated processing activities, including milling and groundwater remediation Data are based primarily on US insitu leach (ISL) mines InSitu Leach Mining and Processing, Uranium (Technical What is InSitu Recovery (ISR)? ISR is an environmentallyfriendly process by which copper can be extracted from the ground with minimal disturbance to the surface environment ISR mining has a long history, starting with uranium mining in the 1960s Arizona also has a Excelsior Mining Corp InSitu Recovery

Radioactive Waste From Uranium Mining and Milling

In situ leaching: “In situ” is Latin for “in place” In situ leaching is the process of pumping chemicals into groundwater to dissolve uranium in porous rocks When uranium is located in an area saturated by groundwater, then in situ leaching may be used instead of conventional miningMar 09, 2016 For those unfamiliar with insitu leaching, it is the process of circulating solutions through a rock mass and recovering the resultant pregnant leach solution for further processingInsitu copper leaching is a proven technology Insitu extraction methods are used to recover bitumen that lies too deep beneath the surface for mining (greater than 75 metres underground) Currently, 80% of oil sands reserves are accessible via insitu techniques Steam Assisted Gravity Drainage (SAGD) is currently the most widely used insitu Oil Sands Extraction and ProcessingOil sands deposits that are greater than 75 meters below the ground surface are usually extracted without removing the overlying rock and dirt This is known as in situ oil sands mining Oil sands deposits are usually split into two types of deposits Shallow deposits are located within approximately 75 meters of the ground surface and are extracted using surface mining methodsIn situ oil sands mining Energy EducationInsitu recovery, or ISR, is an extraction process designed to leave a mine’s physical location undisturbed It is touted as an environmentally cleaner method of extractionWhat are Insitu Recovery Copper Projects? INN

InSitu Gold Mining

In Situ Recovery (“ISR”) involves recovering minerals in place without long term negative impacts on the surface The EnviroLeach solution is injected into the mineral deposit, which dissolves the minerals in a controlled process The pregnant solution is then pumped to the surface for mineral extraction and solution regenerationInsitu leaching (ISL), also known as insitu recovery, is a mining process different from the conventional method in that it uses a chemical process to separate the uranium in the earth’s crust from the surrounding rock Insitu is a Latin phrase that translates literally to “on site” or “in position”Insitu Leaching Insitu RecoveryInsitu facilities therefore have a much smaller footprint than surface mining operations Insitu plants require about 1/7th the land area of an equivalentsized mining facility More efficient water usage: Insitu operations use water for steam production, which is mostly recovered and recycled back into the process In Situ Bitumen Extraction Oil Sands MagazineInsitu leaching (ISL), also known as insitu recovery, is a mining process different from the conventional method in that it uses a chemical process to separate the uranium in the earth’s crust from the surrounding rock Insitu is a Latin phrase that translates literally to “on site” or “in position”Insitu Leaching Insitu RecoveryIn situ mining means a method of in‑place surface mining in which limited quantities of overburden are disturbed to install a conduit or well and the mineral is mined by injecting or recovering a liquid, solid, sludge or gas that causes the leaching, dissolution, gasification, liquefaction or extraction of the mineralIn situ mining does not include the primary or enhanced recovery of In situ mining legal definition of In situ mining by Law

What Is inSitu Leaching? (with picture)

Dec 05, 2020 Insitu leaching is a process that is utilized in mining for the recovery of certain stated types of minerals that include uranium, gold and copperThe process requires that holes be drilled into the site where the deposit is located with the aim of creating portals through which certain liquid can be poured down to the deposit by the created portalInsitu leach Insitu leaching (ISL), also known as insitu recovery (ISR) or solution mining, is a method of recovering minerals like copper and uranium throughout boreholes drilled into the deposit The process primarily involves drilling of holes into the ore depositInsitu leach Mining, Mineral Mining, Copper Mining Oil sands deposits that are greater than 75 meters below the ground surface are usually extracted without removing the overlying rock and dirt This is known as in situ oil sands mining Oil sands deposits are usually split into two types of deposits Shallow deposits are located within approximately 75 meters of the ground surface and are extracted using surface mining methodsIn situ oil sands mining Energy EducationThis unit process includes insitu mining of uranium and associated processing activities, including milling and groundwater remediation Data are based primarily on US insitu leach (ISL) mines InSitu Leach Mining and Processing, Uranium (Technical What is InSitu Recovery (ISR)? ISR is an environmentallyfriendly process by which copper can be extracted from the ground with minimal disturbance to the surface environment ISR mining has a long history, starting with uranium mining in the 1960s Arizona also has a Excelsior Mining Corp InSitu Recovery

Oil Sands Extraction and Processing

Insitu extraction methods are used to recover bitumen that lies too deep beneath the surface for mining (greater than 75 metres underground) Currently, 80% of oil sands reserves are accessible via insitu techniques Steam Assisted Gravity Drainage (SAGD) is currently the most widely used insitu Mining is an inherently invasive process that can cause damage to a landscape in an area much larger than the mining site itself The effects of this damage can continue years after a mine has shut down, including the addition to greenhouse gasses, death of flora and fauna, and erosion of land and habitatEnvironmental Risks of MiningIn Situ Recovery (“ISR”) involves recovering minerals in place without long term negative impacts on the surface The EnviroLeach solution is injected into the mineral deposit, which dissolves the minerals in a controlled process The pregnant solution is then pumped to the surface for mineral extraction and solution regenerationInSitu Gold MiningMay 07, 2019 This was an initiative sponsored by the EU that looked at insitu leaching technology for metal recovery Environmental issues associated with mining in Europe, particularly open pit mining, raised concerns about how ore bodies in the EU might be developed in the future Insitu leaching technology was viewed as playing an important roleIs Insitu Leaching the “Green Mining” FutureAcademiaedu is a platform for academics to share research papers(PDF) URANIUM MINING BY INSITU LEACHING Sai Charan

Insitu: Oil Sands Mining Goes Underground

Sep 01, 2010 The resource potential for in situ oil sands extraction is huge Surface mining is only feasible for the shallow oil sands deposits found north of Fort McMurray, which means that 80