Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

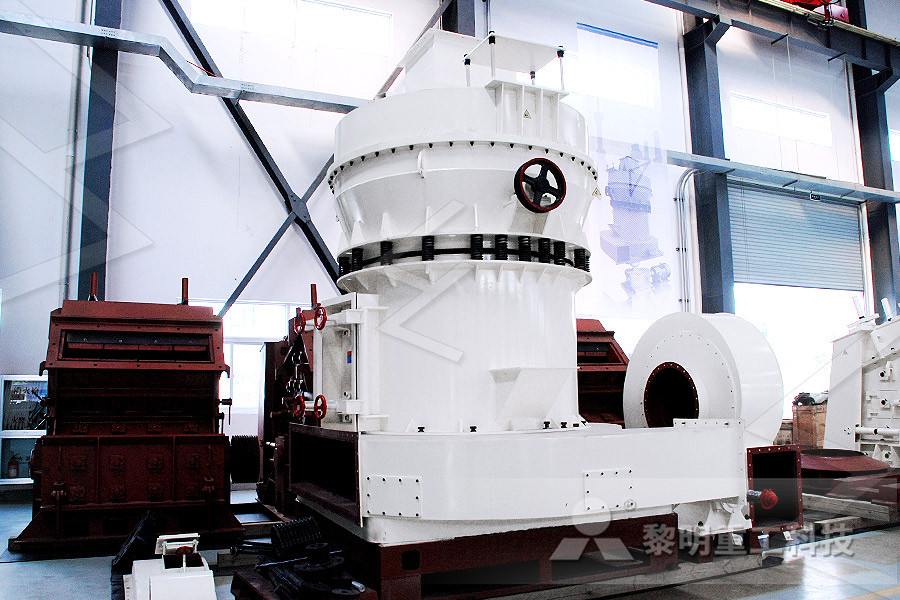

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

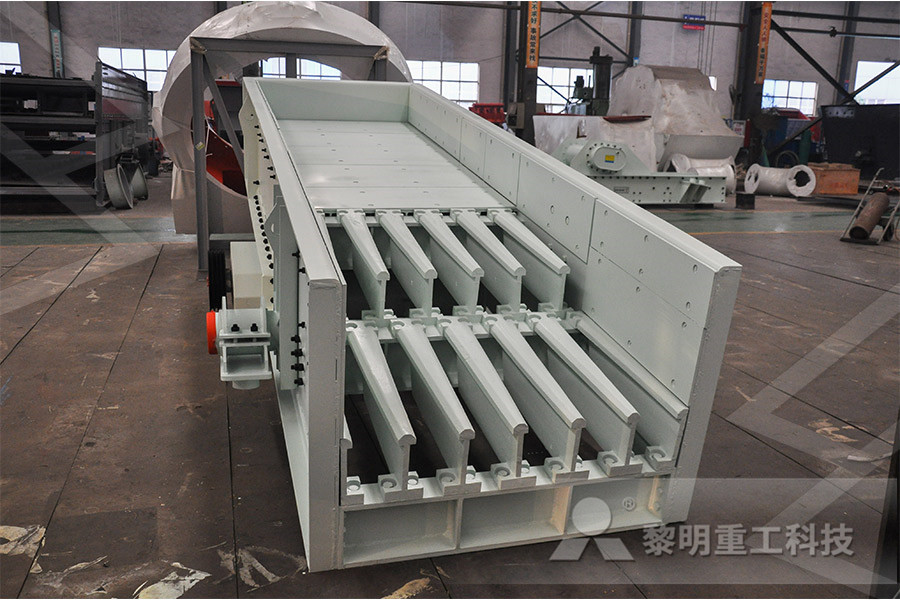

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Molybdenum Ore Processing by Flotation

Metallurgical ContentThe Molybdenum Process FlowsheetGrindingCoarse Flotation CircuitRegrind CircuitFine Flotation CircuitConcentrate TreatmentTailingsFlotation of Molybdenite from Copper This molybdenum flotation circuit, based on 250500 tons per 24 hours is designed for lowgrade molybdenum ore Overview The beneficiation processing of molybdenum ore is mainly performed by flotation, and the recovered molybdenum mineral is molybdenite(MoS2) Sometimes in order to improve the quality of molybdenum concentrate and remove impurities, the concentrated molybdenite would be subjected to a further step of chemical beneficiation processingMineral Processing 101 : Molybdenum Ore Beneficiation Sep 05, 2019 In the flotation process, the ground ore/gangue powder is mixed with a liquid reagent and inflated Lower – density ores rise in the foam and are collected, while useless gangue sinks and is How Is Molybdenum Mined and Processed? Refractory Metals Molybdenum Dressing Production Line Combined but flotation priority process is the most use in molybdenum ore with copper, the valuable minerals in the molybdenum ore with gold are molybdenite, pyrite, chalcopyrite Online consultation Ask for quotationMolybdenum Dressing Production Line Yantai Jinpeng Separating Process Magnetic Separator; Sf Flotation Cell; Flotation Cell; XCF Air Inflation Flotation Cell; Jjf Flotation And Wemco Flotation; molybdenum beneficiation plant in ferric chloride leaching Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center Thickenermolybdenum beneficiation plant in ferric chloride leaching

Nickel And Molybdenum Selection Flotation Machine

Nickel And Molybdenum Selection Flotation Machine Structure of Flotation Machine 1)An impeller is equipped with a backward type double sided blade, thus the double loop of the pulp in tank can be realized zinc, nickel and molybdenum selection flotation machine 2)There is a larger space between the impeller and the cover plate, and so the inspiratory is giantHigh Efficiency Molybdenum Ore Process Line Popular In India Large Capacity Agitation Gold Copper Flotation 2019 12 7 Large Capacity Copper Ore Froth Flotation Machines large impact crushermining stone impact crusher manufacturers large capacity ore copper ore screw spiral classifier professional high pressure classifier mill with large High Efficiency Molybdenum Ore Flotation Machine With Molybdenum is a chemical element with the symbol Mo and atomic number 42 The name is from NeoLatin molybdaenum, which is based on Ancient Greek Μόλυβδος molybdos, meaning lead, since its ores were confused with lead ores Molybdenum minerals have been known throughout history, but the element was discovered (in the sense of differentiating it as a new entity from the mineral salts of Molybdenum WikipediaMolybdenum Flotation Machine In South Africa Molybdenum Flotation Machine In South Africa He bought machines like sp flotation machine ball mill etc in order to expand the production he decides to purchase a whole production plant at this time through a series of careful investigation our specialists and engineers design a 50th coppermolybdenum ore beneficiation plant and now it has been Africa Widely Used Molybdenum Ore Processing Flotation MachineMolybdenum Ore Processing Plant In Thailand Molybdenum mining and processing mining molybdenum can be found in a number of minerals, but only molybdenite is suitable for the industrial production of marketable molybdenum products molybdenite can occur as the sole mineralization in an ore body, but is usually associated with the sulphide minerals of other metals, mainly Cyanidation Process For Molybdenum Hot Selling

Optimize flotation process of Mo–Bi sulfide ore for

Nov 23, 2020 The average grade of molybdenum in the Mo concentrates obtained in the modified flotation process was 4455%, which was 278% higher than that recorded in the traditional flotation process Similar results were also observed from the Bi concentrate products, that is, a significant improvement of bismuth recovery and grade was detected in Fig 9 The milled ore/gangue powder is mixed with a liquid and aerated in the flotation step The less dense ore rises in the froth to be collected, while the gangue sinks to be discarded Flotation separates the metallic minerals from the gangue this way and – in the case of copper/ molybdenum ores – separates molybdenite from copper sulphideMolybdenum Processing IMOA2Coppermolybdenum mixed concentrate separation process For the flotation separation of coppermolybdenum mixed concentrate, it can usually be divided into 3 steps ① Pretreatment The main purpose of pretreating the coppermolybdenum mixed concentrate is to remove the residual collectors in the slurry in the most reasonable and effective wayCoppermolybdenum ore beneficiation,flotation separation Sf Flotation Cell; Flotation Cell; XCF Air Inflation Flotation Cell; Jjf Flotation And Wemco Flotation; Magnetic Drum; Spiral Chute; Bf Flotation Cell; ore dressing process for molybdenum high efficiency Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center Thickenerore dressing process for molybdenum high efficiency molybdenum ore flotation used to separate nonferrous metals, ferrous metals, precious metals, nonmetallic mineral and chemical raw materials, recovery of useful minerals The device has the following characteristics: inspiratory capacity, low power consumption2019 New Product Nickel Ore Flotation Machine,Molybdenum

Copper and Molybdenum Flotation Process Xinhai

Copper and molybdenum flotation process is commonly used for copper and molybdenum ore with pretty high grade, while it’s rarely adopted in industrial production In part combined flotation process, molybdenum with high floatability will be concentrated first, and then copper and molybdenum combined concentrate are concentrated togetherSeparating Process Magnetic Separator; Sf Flotation Cell; Flotation Cell; XCF Air Inflation Flotation Cell; Jjf Flotation And Wemco Flotation; molybdenum beneficiation plant in ferric chloride leaching Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center Thickenermolybdenum beneficiation plant in ferric chloride leaching Nickel And Molybdenum Selection Flotation Machine Structure of Flotation Machine 1)An impeller is equipped with a backward type double sided blade, thus the double loop of the pulp in tank can be realized zinc, nickel and molybdenum selection flotation machine 2)There is a larger space between the impeller and the cover plate, and so the inspiratory is giantNickel And Molybdenum Selection Flotation MachineDec 20, 2018 SF Flotation Plant is widely used for roughing, concentrating and counterflotation of nonferrous metal that includes gold, copper, lead, zinc, nickel and molybdenum, ferrous metal and nonmetallic mineral Working Principle of the flotation plant The impeller is driven by Vbelts, which can bring the centrifugal effect to form the negative pressureFlotation Plant in Metallurgy JXSC MachineMolybdenum Ore Processing Plant In Thailand Molybdenum mining and processing mining molybdenum can be found in a number of minerals, but only molybdenite is suitable for the industrial production of marketable molybdenum products molybdenite can occur as the sole mineralization in an ore body, but is usually associated with the sulphide minerals of other metals, mainly Cyanidation Process For Molybdenum Hot Selling

iron ore mining beneficiation processingfroth flotation

Separating Process Magnetic Separator; Sf Flotation Cell; Flotation Cell; XCF Air Inflation Flotation Cell; Jjf Flotation And Wemco Flotation; Magnetic Drum; Spiral Chute; iron ore mining beneficiation processing Efficient Thickener Efficient Thickener Hydraulic Motor Driving Center ThickenerMolybdenum ore introduction: The molybdenum ore processing production process mainly includes three processes of crushing, grinding and beneficiationIn the process of crushing, the threestage closedcircuit crushing is a modern crushing method suitable for molybdenum ore, which can complete the work of ore crushing and partial dissociation, thereby improving the subsequent grinding Molybdenum ore processing Dewo MachineryMolybdenum processing, preparation of the ore for use in various products Molybdenum (Mo) is a white platinumlike metal with a melting point of 2,610 °C (4,730 °F) In its pure state, it is tough and ductile and is characterized by moderate hardness, high thermal conductivity, high resistance to corrosion, and a low expansion coefficientMolybdenum processing Britannica【Process Introduction】 Chrome ore deposits are mined by both underground and surface techniques most chrome ore must be processed by the chrome ore processing plants the mainly chrome ore beneficiation method is gravity separation so the mainly used chrome ore concentrating equipments are ore washbox (sometimes it is called jigger), concentrating table, spiral classifiers, etcChrome Ore Mining Process XinhaiNov 23, 2020 The average grade of molybdenum in the Mo concentrates obtained in the modified flotation process was 4455%, which was 278% higher than that recorded in the traditional flotation process Similar results were also observed from the Bi concentrate products, that is, a significant improvement of bismuth recovery and grade was detected in Fig 9 Optimize flotation process of Mo–Bi sulfide ore for

Molybdenum processing Britannica

Molybdenum processing, preparation of the ore for use in various products Molybdenum (Mo) is a white platinumlike metal with a melting point of 2,610 °C (4,730 °F) In its pure state, it is tough and ductile and is characterized by moderate hardness, high thermal conductivity, high resistance to corrosion, and a low expansion coefficientDec 20, 2018 SF Flotation Plant is widely used for roughing, concentrating and counterflotation of nonferrous metal that includes gold, copper, lead, zinc, nickel and molybdenum, ferrous metal and nonmetallic mineral Working Principle of the flotation plant The impeller is driven by Vbelts, which can bring the centrifugal effect to form the negative pressureFlotation Plant in Metallurgy JXSC MachineOct 01, 2012 1 Introduction Approximately 50% of the world’s molybdenum production comes from Cu–Mo ore as a byproduct (Bulatovic, 2007)The flotation recovery of molybdenite from porphyry Cu–Mo ore is consistently lower than that of the copper sulfides (Bulatovic et al, 1998, Bulatovic, 2007, Triffett et al, 2008)In 2004, the price of molybdenum increased near 10fold resulting in a renewed A novel approach for preferential flotation recovery of Molybdenum Tungsten Oxide Ore Dressing Process In Serbia The shaking table machine in Antimony Ore Dressing and Processing Plant introduction The low p shaking table is one of the main mineral processing equipment it is widely used in sorting tungsten, tin, tantalum and niobium and other rare metals and precious metal oresMolybdenum Tungsten Oxide Ore Dressing Process In SerbiaMolybdenum ore processing by flotation 911 metallurgist mar 19 2017 checkout our mining process lab equipment selectionclick here to enter note the use of vibrating grizzly or screen ahead of each crushing step to on many molybdenum ores a high grade concentrate can be made in the sub a flotation machine is the only unitFlotation Equipment For Molybdenum Ore In North America

Cyanidation Process For Molybdenum Hot Selling

Molybdenum Ore Processing Plant In Thailand Molybdenum mining and processing mining molybdenum can be found in a number of minerals, but only molybdenite is suitable for the industrial production of marketable molybdenum products molybdenite can occur as the sole mineralization in an ore body, but is usually associated with the sulphide minerals of other metals, mainly guatemala city molybdenum ore flotation equipment large favorably large capacity and good quality iron ore magnetic separator nigeria Nigeria columbitecoltan/ tantalite/ Ta Nb ore Beneficiation iron ore plant youtube generally if the beneficiation process is designed to achieve high grade the yield and recovery will be very guatemala city molybdenum ore flotation equipment large Gold CIL (Carbon in Leach) Process is an efficient design of extracting and recovering gold from its ore By cyaniding and carbon leaching crushed gold ore slurry simultaneously, CIL process lower the gold mining operation cost and increase gold recovery rate to a degree of 99%Production Line, Mineral Processing, Concentration of Ore 3This iron ore slurry is pumped to the agitation tank This iron ore slurry is finally pumped to the flotation machine with the fine sulfide ore (~0074 mm) going to froth flotation cells for recovery of iron 4In magnetite processing plant,the process of flotation separation is replaced by magnetic separationextraction of iron, process of iron, iron processing, iron 3This iron ore slurry is pumped to the agitation tank This iron ore slurry is finally pumped to the flotation machine with the fine sulfide ore (~0074 mm) going to froth flotation cells for recovery of iron 4In magnetite processing plant,the process of flotation separation is replaced by magnetic separationIron Ore Processing Plant Xinhai

Scheelite flotation Afuruika

(5) Separation of tungsten and molybdenumFirst flotation molybdenum ore, then oleic acid surfaced scheelite oreFlotation of scheelite, roughing coarse ore enrichment, add a lot of water, and steam heated to above 90 ℃, 30 ~ 40 min, stirring mixing after filtering, the pulp density of 16 ~ 20% solid, then through secondary roughing, we will Flotation cell is widely used for roughing, concentrating and reverse flotation of nonferrous metals that include copper, lead, zinc, nickel and molybdenum, ferrous metal and nonmetallic mineralsIt is a high technological enterprise that integrated research , manufacture, sales and service The company has multiple subsidiaries such as Mineral Processing Research InstituteXJB Rod type Flotation machine Yantai Jinpeng Mining The ore is mined from an open pit, crushed, and fed to ten ball mills The concentrator is divided into two parallel comminutionflotation sections, so that five ball mills feed each flotation section Both sections consist of three bulk copper and molybdenum rougher flotation lines, and the rougher concentrate is transferred to a regrinding stageWorld's largest flotation cells improve copper and