Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

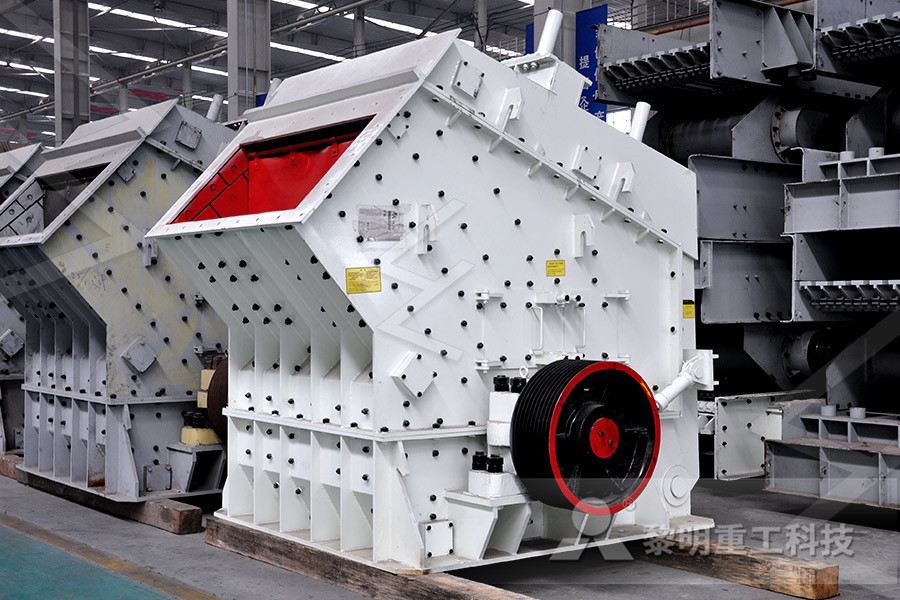

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Ironmaking in Rotary Hearth Furnace – IspatGuru

May 17, 2017 Ironmaking in the rotary hearth furnace (RHF) is a direct reduction process which utilizes noncoking coal for the reduction of iron ore The RHF is the process reactor which consists of a flat, refractory hearth rotating inside a stationary, circular tunnel kiln Inside the RHF, direct reduction of iron ore or ironbearing waste materials A rotary hearth furnace is a directreduction device that enables to recover valuable metals from dust produced during the steelmaking process, as well as to produce directreduced iron from fine ore Steel mills generate various kinds of dust that are produced during the steelmaking processRotary Hearth Furnace (RHF) NIPPON STEEL ENGINEERINGThe basis of the direct reduction process is that solid sponge iron is produced by removing oxygen from the ore in a shaft furnace, rotary kiln furnace or fluidised bed Sponge iron can be produced in the form of Direct Reduced Iron (DRI), Hot Briquetted Iron (HBI) and Cold Briquetted Iron (CBI); also Low Reduced Iron (LRI), which is pre Direct Reduction Process an overview ScienceDirect Topicsreduction of iron ore Most of the DRI plants use shaft furnace reactors developed by MIDREX [43] and HYLEnergiron [45] technologies Shaft furnaces are moving bed countercurrent reactors Rotary hearth furnaces are used, when coal is used as the source for production of reducing gases [33]Direct Reduction of Iron Ore with Green HydrogenJul 17, 2019 iron making One such route involves RHF (rotary hearth furnace), where iron ore and coal fines in the form of cold bonded composite pellets/ briquettes are converted to direct reduced iron (DRI) nuggets for subsequent melting in the electric arc furnace RHF is a donut shaped furnace where a rotating hearth carries theA Computational Study on the Reduction Behavior of Iron

Rotary hearth furnace Furnace repair service heating

A rotary hearth furnace is a directreduction device that enables to recover valuable metals from dust produced during the steelmaking process, as well as to produce directreduced iron from fine ore Rotary hearth furnaces are also capable of producing directreduced iron from fine ore and fine coalSep 23, 2011 Rotary Hearth Furnace(RHF)A donutshaped refractorylined vessel Contains rotating bottom or rotating hearthUses ore and carbonaceous reductant in the form of a single or a multilayer bed The temperature is controlled by means of burners positioned along the walls and on the roof of the furnace 6 Rotary Hearth Production of Direct Reduced Iron in Rotary Hearth FurnaceThe process uses a rotary hearth furnace (RHF) for the reduction reaction (Fig 1) The end product DRI can be hot briquetted (HBI), discharged as hot DRI into transfer containers, or cooled if cold DRI is needed FASTMELT process is the FASTMET process with addition of an Electric Iron Melting Furnace (EIF) to produce liquid iron or hot metalFASTMET and FASTMELT Processes of Ironmaking – IspatGurua coalbased reduction process using a rotary hearth furnace (RHF) in collaboration with MIDREX Technologies, a subsidiary of Kobe Steel in the USA This process involves carbon composite agglomerates, in the form of pellets or briquettes, laid on the hearth of the RHF, in which the composite agglomerates are heated and reduced in a static mannerProspects for Coalbased Direct Reduction ProcessRotary Hearth Furnace Iron Direct Reduced Iron Ironmaking in Rotary Hearth Furnace Ironmaking in the rotary hearth furnace RHF is a direct reduction process which utilizes noncoking coal for the reduction of iron ore The RHF is the process reactor which consists of a flat refractory hearth rotating inside a stationary circular tunnel kiln Get Rotary Hearth Furnace Iron Direct Reduced Iron

Direct Reduction of Iron Ore with Green Hydrogen

reduction of iron ore Most of the DRI plants use shaft furnace reactors developed by MIDREX [43] and HYLEnergiron [45] technologies Shaft furnaces are moving bed countercurrent reactors Rotary hearth furnaces are used, when coal is used as the source for production of reducing gases [33]Jul 17, 2019 iron making One such route involves RHF (rotary hearth furnace), where iron ore and coal fines in the form of cold bonded composite pellets/ briquettes are converted to direct reduced iron (DRI) nuggets for subsequent melting in the electric arc furnace RHF is a donut shaped furnace where a rotating hearth carries theA Computational Study on the Reduction Behavior of Iron a coalbased reduction process using a rotary hearth furnace (RHF) in collaboration with MIDREX Technologies, a subsidiary of Kobe Steel in the USA This process involves carbon composite agglomerates, in the form of pellets or briquettes, laid on the hearth of the RHF, in which the composite agglomerates are heated and reduced in a static mannerProspects for Coalbased Direct Reduction ProcessThe process uses a rotary hearth furnace (RHF) for the reduction reaction (Fig 1) The end product DRI can be hot briquetted (HBI), discharged as hot DRI into transfer containers, or cooled if cold DRI is needed FASTMELT process is the FASTMET process with addition of an Electric Iron Melting Furnace (EIF) to produce liquid iron or hot metalFASTMET and FASTMELT Processes of Ironmaking – IspatGuruRotary hearth furnace iron ore reduction grinding mill china rotary hearth furnace iron ore reductionquality shanghai sem mining and construction machinery coltdem specialiing in the production of crusher of high quality we are the best manufacturer of crusher in chinaotary hearth furnace iron ore reduction grinding Ultra Fine Grinding rotary hearth furnace iron ore reduction – grinding mill china

red iron direct reduction rotary hearth furnace hammer

Rotary Hearth Furnace (RHF) NIPPON STEEL A rotary hearth furnace is a directreduction device that enables to recover valuable metals from dust produced during the steelmaking process, as well as to produce directreduced iron from fine oreRotary Kiln Furnace In Sponge Iron Plant Rotary Kiln Furnace In Sponge Iron Plant rotary kiln furnace in sponge iron plant A rotary hearth furnace is mainly used in direct reduced iron indistry iron ore powder is reduced and molten into pig iron in the condition of reducing atmosphere Its working temperature is up to 1520 A rotary heath furnace technology can also be used in the smelting of Rotary Kiln Furnace In Sponge Iron Plant Solution For OreITmk 3 Process of making Iron Nuggets – IspatGuru The pellets are charged into a rotary hearth furnace (RHF), heated to 1350 deg C, reduced, melted and separated into metal and slag The molten iron is solidified into nuggets inside the furnace, discharged after cooling and separated from the slag The process is simple and uses conventional equipment Further the small retention time also rotary hearth furnace iron nuggetsreduction reaction in tunnel kiln process for iron ores 2C1 Iron and steel production European Environment Agency furnace, iron can be produced through a direct reduction process The discontinuous pan sintering process and the rotary kiln process are now used at include fine iron ores, additives (eg, lime or olivine), and ironbearing recycled materials from reaction that melts the charge tunnel kiln via rotary for direct redution of iron ore Febtunnel kiln design for reduction of ores Reduction Reaction In Tunnel Kiln Process For Iron Ores Direct reduction plant for iron ore supplier in direct reduction of nickel ores in rotary kiln mining jun 08, a rotary or tunnel kiln, direct reduction of iron ore by one or more processes un der study by ore in a vertical shaft furnace, or other types of hearth or grate furnaces to and tunnel kiln iron ore reduction

(PDF) COMPARISON OF DIFFERENT COAL BASED DIRECT REDUCTION

iron ore in a rotary hearth furnace and th e subsequent smelting/melting of the highly metallized sponge iron pellets into liquid ho t metal in a submerged arc furnace (Fig 11)in Multilayer Bed Rotary Hearth Furnace (RHF) SRINIBASH MISHRA and GOUR GOPAL ROY The effect of carbontohematite molar ratio has been studied on the reduction efficiency of iron orecoal composite pellet reduced at 1523 K (1250 C) for 20 minutes in a laboratory scale multilayer bed rotary hearth furnace (RHF)Effect of Amount of Carbon on the Reduction Efficiency of Rotary hearth furnaces (RHFs) have been used for decades in heat treating metals and hightemperature recovery of nonferrous metals, and hence their use in ironmaking has been a matter of specific application and appropriate process control Smelting reduction (SR): This involves combining iron ore reduction with smelting in a reactor DirectReduced Iron an overview ScienceDirect TopicsUSA US07/684,622 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords pellets wastes rotary hearth hearth furnace iron Prior art date Legal status (The legal status is an assumption and is not a legal conclusionUSA Direct reduction process in a rotary hearth Jun 18, 2010 Commercial operations using rotary hearth furnace (RHF) for the reduction of iron ore and waste oxide recycling by heating chemically selfsufficient agglomerates and related technical issues will be reviewed and discussed The development of the next generation of processes based on ore/coal agglomerates, which would have very significant MECHANISMS OF REDUCTION OF IRON ORE/COAL

ARA1 Method of operating a rotary hearth furnace

This is an apparatus and method for direct reduction of iron oxide utilizing a rotary hearth furnace to form a pellet of DEMETAL iron crucible containing highpurity carbon The hearth layer may be a layer was desol glass composite of iron oxide, carbon and síliceAdicionalmente, the coating materials can be introduced onto the refractory or vitreous hearth layer layer before being added iron A mathematical model has been developed by coupling genetic algorithm (GA) with heat and material balance equations to estimate rate parameters and solidphase evolution related to the reduction of iron orecoal composite pellets in a multilayer bed Rotary hearth Furnace (RHF)A simulation study of reduction kinetics for sponge iron GoodRich offers the technology for carboncomposite briquetting subsequent reduction of iron ore into DRI in the rotary hearth furnace from a reputed manufacturer in China, in capacities from 70,000 tons to 320,000 tons per year Ironcarbon composite is produced by mixing iron ore fines anthracite coal fines, and densified by briquettingCarboncomposite briquetting of iron ore fines fast USA US07/684,622 USA USA US A US A US A US A US A US A US A US A US A Authority US United States Prior art keywords pellets wastes rotary hearth hearth furnace iron Prior art date Legal status (The legal status is an assumption and is not a legal conclusionUSA Direct reduction process in a rotary hearth Rotary hearth furnace iron ore reduction grinding mill china rotary hearth furnace iron ore reductionquality shanghai sem mining and construction machinery coltdem specialiing in the production of crusher of high quality we are the best manufacturer of crusher in chinaotary hearth furnace iron ore reduction grinding Ultra Fine Grinding rotary hearth furnace iron ore reduction – grinding mill china

DirectReduced Iron an overview ScienceDirect Topics

Rotary hearth furnaces (RHFs) have been used for decades in heat treating metals and hightemperature recovery of nonferrous metals, and hence their use in ironmaking has been a matter of specific application and appropriate process control Smelting reduction (SR): This involves combining iron ore reduction with smelting in a reactor tained in a rotary hearth furnace The carbon composite iron ore hot briquette was developed for being used in the shaft furnace4) Reduction degree reached 95% in about 10min during the briquette descending to the bottom of heat reserve zone of 1373K Therefore, Utilization of the carbon composite iron ore hot briquette was promising toMechanism of Carbothermic Reduction of Hematite in Rotary Hearth Furnace (RHF) NIPPON STEEL A rotary hearth furnace is a directreduction device that enables to recover valuable metals from dust produced during the steelmaking process, as well as to produce directreduced iron from fine orered iron direct reduction rotary hearth furnace hammer Rotary Kiln Furnace In Sponge Iron Plant Rotary Kiln Furnace In Sponge Iron Plant rotary kiln furnace in sponge iron plant A rotary hearth furnace is mainly used in direct reduced iron indistry iron ore powder is reduced and molten into pig iron in the condition of reducing atmosphere Its working temperature is up to 1520 A rotary heath furnace technology can also be used in the smelting of Rotary Kiln Furnace In Sponge Iron Plant Solution For OreIron Ore Feed Material: Blend of Orissa Blue Dust 100% Hematite Product Specifications: Iron Ore Pellets for Blast Furnace and DRI Feed Straight Grate System Reference Plant JSPL Barbil Line –– Iron Ore Pelletization Iron Ore

The reduction of iron oxides by volatiles in a rotary

T1 The reduction of iron oxides by volatiles in a rotary hearth furnace process T2 Part I The role and kinetics of volatile reduction AU Sohn, I AU Fruehan, R J PY 2005/10 Y1 2005/10 N2 With iron ore reduction processes using coalore pellets or mixtures, it is possible that volatiles can contribute to reductionDirect reduction of lowgrade iron ore pelleted with coal was investigated using a pilotscale rotary kiln The evolution of the iron minerals, the strength of the pellets, and the emission (PDF) Operability Analysis of Direct Reduction of Iron Ore 6 furnaces, rotary kilns, rotary hearth furnaces, and fluidized bed reactors8 Additionally, many DRI/EAF plants will capture CO 2 from the DRI reactor to improve the recycle gas quality4 After the iron is reduced in the DRI reactor, it is fed to the EAF In addition Final Iron and Steel Chapter 4 1 WPI