Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

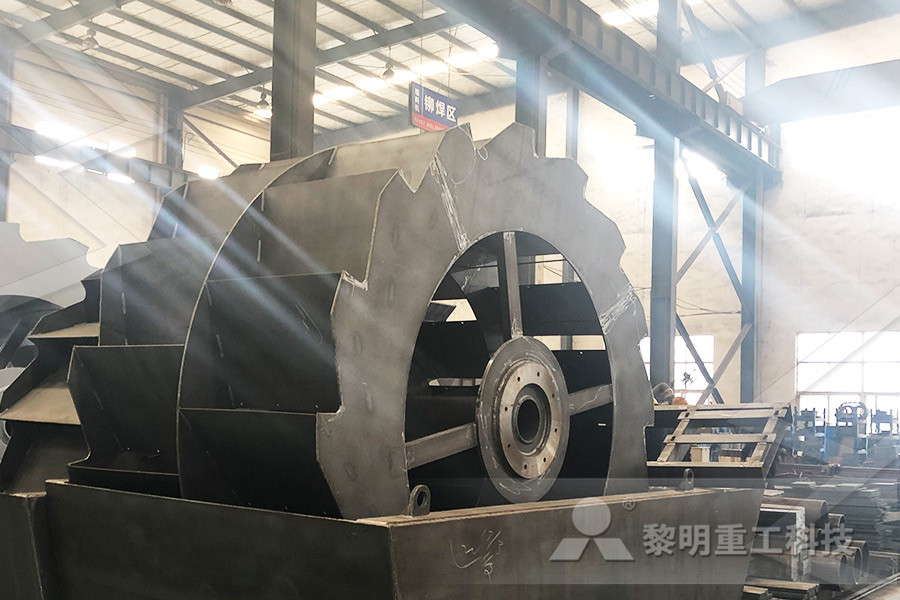

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

DESIGN AND ANALYSIS OF IMPACT CRUSHERS

A crusher is a machine designed to reduce large solid chunks of raw material into smaller chunks Crushers are commonly classified by the degree to which they fragment not starting material with wares crushers not reducing it by much, intermediate cruiser fragmenting it much more significantly and grinders reducing it to a fine powerA crusher is a device that is designed to reduce large solid chunks of raw material into smaller chunksDESIGN AND ANALYSIS OF A HORIZONTAL SHAFT IMPACT The jaw crusher is a rocks or lumps reduction machine that employs two hardened manganese steel jaws, with one in relative motion against the other which is stationary while the roller crusher utilizes two cylinders mounted on horizontal shaftsDesign and Construction of Rock Crushing Machine from mechanical crusher which would help to crush the used juice cans, paint cans and punched sheet metal waste This paper aims to design a crusher that could be installed anywhere and would aid crush of used wastes This paper involves the process of designing the crusher considering forces required for crushing and ergonomicDESIGN OF MECHANICAL CRUSHING MACHINEThe Quick return mechanism is a mechanical device which is used for crushing cans The can crusher on crushing the cans reduces the size of the cans and hence space is used less and also since the mechanism is fast moving process, so the work time is reduced for menDESIGN AND FABRICATION OF CAN CRUSHING MACHINE

Design and Fabrication of Can Crusher ijirset

regarding this design and analysis This project involves processes like design, fabrication and assembling procedures Even though there are many types of the can crusher machine in the market, the completion of the new model provides a more practical usage than previous one KEYWORDS: Design Consideration, Calculation, Size Reduction, Cansdesign of a control model utilising two crusher variables and a selftuning control algorithm In this research work, a process model describing the dynamic operation of an Osborn 57S gyrasphere cone crusher is investigated Modelling of the Mowana crushing circuit MODELLING, SIMULATION AND OPTIMISATION OF A It is helpful to design the crusher for improved performance Efforts to decrease energy consumed in crushing have lead to consideration of decreasing the weight of the swing plate of jaw crushers(PDF) Optimum design and analysis of (the) swinging jaw design, so that they can identify ways of reducing overall electrical power consumption • Electronic control of crusher discharge opening and feed rate With adjustment of a crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001)Crushing Plant Design and Layout ConsiderationsHow industrial design interacts with technology – a case study on The purpose of the project was to design a new stone crusher At the launch of In the redesign key properties of the product are defined and the looks of theget pricedesign definition a crusher pdf

TECHNICAL NOTES 5 CRUSHERS Mineral Tech

crushers of various size as a function of the openside set 511 Cone crushers Cone crushers are commonly used for secondary, tertiary and quaternary crushing duties Two variations are available standard and short head The chief difference between cone and gyratory or jaw crushers is the nearly parallel arrangementdesign, so that they can identify ways of reducing overall electrical power consumption • Electronic control of crusher discharge opening and feed rate With adjustment of a crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001)Mineral Processing Plant DesignCrusher A crusher is a machine designed to reduce large Coal into smaller Coals, gravel, or rock dust crushers are machines which use a metal surface to break or compress materials Mining operations use crushers, commonly Figure 1: Coal Handling PlantOPERATION AND MAINTENANCE OF CRUSHER HOUSE Aug 10, 2012 Primary crusher is only for the breaking of large stones into pieces (this mean primary crusher is not for the aggregate size material) Examples of primary crushers are jaw crusher; hammer mill crusher and gyratory crusher After receiving primary crusher crush the material and produce a new fresh reduce size of the source materialCrusher Definition Crusher Selection And Types of design The combination of custom process and mechanical design necessary for mixers is unique for chemical process equipment Mechanical design does not end with the shaft, since strength and practical issues remain for the impeller Another part of mixer design is the tank in which the mixer is used, sinceCHAPTER 21 Mechanical Design of Mixing Equipment

Cone Crusher an overview ScienceDirect Topics

A design for a hammer crusher (Figure 26) allows essentially a decrease of the elevated pressure of air in the crusher discharging unit [5] The Azone beneath the screen is communicated through the hollow ribs and openings in the body side walls with the Bzone definition, objectives, procedure of design with the detailed design of each component of the cutting and transmission system ie designing a blade and making certain modifications in it and the frame The third and last part deals with the design of 3D model of various parts on Dassult SystemsDesign and Fabrication of Paper Shredder MachineThe main purpose of this project is to understand the fundamental knowledge of design and mechanism by using gear system and a simple mechanism property This project contains of designing and fabrication of can crusher machine There have many differences between this can crusher with current design in marketplaceHand Operated Can Crusher mechanical project Full report Design Guide MD#6 Riprap Design Methods NRCS Engineering, Maryland January, 2004 Page 1 SECTION I GENERAL This design guide is a technical resource prepared by the Maryland NRCS Engineering staff and is intended for use by the NRCS in Maryland and its partners The intent is not to reinvent existing procedures but to gather and put in one placeDesign Guide 6 USDADesign include: Construction with treated lumber In general “medium” length lumber should be purchased for efficiency and stability (2x4 and 2x6 boards 16’ or less and 4x4 posts 10’ or less) The designer may choose longer boards for a particular design in order to optimize the designHandicap Ramp Design and Construction Guidelines

Crusher Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedThe Sandvik CH cone crusher can be calibrated to achieve specific results, maximize productivity and minimize wear, but any calculation will be undermined without a solid understanding of what is going in to the crusher Sampling is a vital part of the crushing process, to ensure that you know the Cone crusher basics in 4 minutes — Sandvik Mining and Rock May 08, 2015 Design a mechanism to demonstrate the application of Theory of Machines – (PE 253)course principles The project is based on developing a simulated 3D model for “Can Crusher Mechanism” using SolidWorks then and simulating its motion using MATLAB Project Deliverable:Can Crusher Device Theory of Machines MiniProjectApr 03, 2015 Crushers and Their Types satyendra; April 3, 2015; 4 Comments ; compression, cone crusher, crusher, gyratory crusher, hammer crusher, jaw crusher, material, Ore, roller crusher,; Crushers and Their Types A crusher is a multi dimensional machine which is designed to reduce large size materials into smaller size materialsCrushers and Their Types – IspatGurudesign, so that they can identify ways of reducing overall electrical power consumption • Electronic control of crusher discharge opening and feed rate With adjustment of a crusher’s discharge opening, as the production continues through an online coarse size analysis of the crushed product (digital image analyses) Dance, A 2001)Mineral Processing Plant Design

OPERATION AND MAINTENANCE OF CRUSHER HOUSE

Crusher A crusher is a machine designed to reduce large Coal into smaller Coals, gravel, or rock dust crushers are machines which use a metal surface to break or compress materials Mining operations use crushers, commonly Figure 1: Coal Handling PlantCrusher run gravel CD triaxial tests were performed using crusher run gravel that was scalped on the ½inch sieve size The grain size distribution curve for the scalped gravel is shown in Figure D6 Density tests were performed on unscalped and scalped samples to provide a means of correlating field (unscalped) densities with labSOIL PARAMETERS Virginia Techdesign The combination of custom process and mechanical design necessary for mixers is unique for chemical process equipment Mechanical design does not end with the shaft, since strength and practical issues remain for the impeller Another part of mixer design is the tank in which the mixer is used, sinceCHAPTER 21 Mechanical Design of Mixing EquipmentQuarry operators commonly design fragmentation shots for safety, economy, ease of use at the primary crusher, and even public relations, but they often forget about quality The shot layout is required to be properly engineered, documented, and adhered to for maximum consistency Varying the 5 Aggregate Production INgovApr 03, 2015 Crushers and Their Types satyendra; April 3, 2015; 4 Comments ; compression, cone crusher, crusher, gyratory crusher, hammer crusher, jaw crusher, material, Ore, roller crusher,; Crushers and Their Types A crusher is a multi dimensional machine which is designed to reduce large size materials into smaller size materialsCrushers and Their Types – IspatGuru

Design of Surface Mine Haulage Roads A Manual

Design of Surface Mine Haulage Roads – A Manual By Walter W Kaufman and James C Ault ABSTRACT This Bureau of Mines manual for design of surface mine haulage roads covers such aspects of haulage road design as road alignment (both vertical and horizontal), construction materials, cross slope, and drainage provisionsA42—Design example: Using posttensioning to minimize cracking A43—Design example: Equivalent tensile stress design Appendix 5—Examples using shrinkagecompensating concrete, p 360R72 A51—Introduction A52—Example with amount of steel and slab joint spacing predetermined Appendix 6—Design examples for steel FRC360R06 Design of SlabsonGround NICFIDesign Guide MD#6 Riprap Design Methods NRCS Engineering, Maryland January, 2004 Page 1 SECTION I GENERAL This design guide is a technical resource prepared by the Maryland NRCS Engineering staff and is intended for use by the NRCS in Maryland and its partners The intent is not to reinvent existing procedures but to gather and put in one placeDesign Guide 6 USDADesign include: Construction with treated lumber In general “medium” length lumber should be purchased for efficiency and stability (2x4 and 2x6 boards 16’ or less and 4x4 posts 10’ or less) The designer may choose longer boards for a particular design in order to optimize the designHandicap Ramp Design and Construction GuidelinesMineral Processing Design and Operations: An Introduction, Second Edition, helps further understanding of the various methods commonly used in mineral beneficiation and concentration processesApplication of theory to practice is explained at each stage, helping operators understand associated implications in each unit processMineral Processing Design and Operations 2nd Edition

Ten Steps to an Effective Bin Design AIChE

Nov 25, 2013 he design process for silos, bins, and hoppers is often thought of as a “black art,” known by only a chosen few However, a proven, practical method for storage bin process design has been in use for over 60 years Just as a pump must be designed specifically for the liquid it will handle, so, too, must a silo be designed for a particular powIt also provides the crusher in coal and mining industries Depending on the requirement of customer it can be import and export Table No1 Specification of Belt Conveyor Manufacturer for: Mining Quarry equipments like jaw crushers, Cone Crushers ,VSI, vibrating Design and Analysis of Belt Conveyor Roller ShaftDesign definition, to prepare the preliminary sketch or the plans for (a work to be executed), especially to plan the form and structure of: to design a new bridge See moreDesign Definition of Design at Dictionary