Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

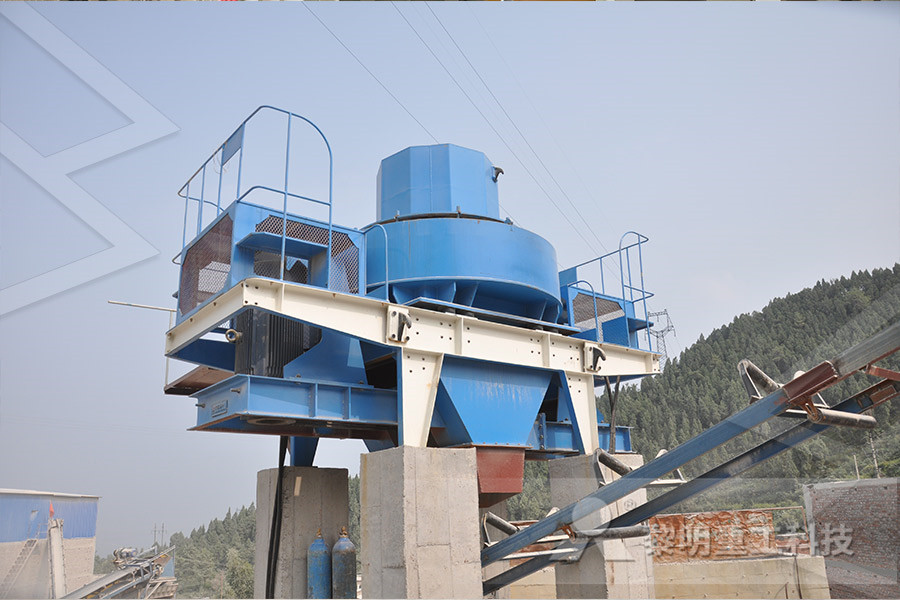

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Andersen Cascade Impactor (ACI)

8111 Stand (incl Base Plate, Boss Head and Clamp) 5212 ‘Quick Clamp’ for Andersen Cascade Impactor 5401 ACI Carrying/Wash Rack 5441 ACI Collection Plate Rack Spare Parts 8307 Complete Set of 13 ACI Silicone Rubber ORings 8314 Set of 8 Stainless Steel Collection Plates (283 L/min)Cascade impactors operate on the principle of curvilinear motion of particles in the aerosol stream Figure 910 a is a schematic representation of the principle of operation of an Andersen cascade impactor (ACI) A single jet per impactor stage is shown Impactors with multiple jets in each stage function in the same mannerCascade Impactor an overview ScienceDirect TopicsAndersen Cascade Impactor 8 Stage MDI Metered Dose Inhalers; DPI Dry Powder Inhaler Aerodynamic particle sizing The design concept of the Andersen Cascade Impactor evolves from the following information: The human respiratory system tract is an aerodynamic classifying system for airborne particlesAndersen Cascade Impactor 8 Stage TCR TecoraThe design concept of the Andersen Cascade Impactor evolves from the following Cascade ImpactorsImpaction surfaces Cascade impactors are multijet, multistage devices operating at constant flowrates steel plates are used in DPI and MDI applications to test inhalation suspensions and spray Glassfiber filters are commonly used for ANDERSEN CASCADE IMPACTOR OUTDOOR AIR QUALITYThe instrument of choice for measuring the APSD of DPI products to meet both regulatory and pharmacopoeial requirements alike is the cascade impactor There are five different cascade impactors/impingers suitable for the assessment of APSD, however, only the Andersen Cascade Impactor (ACI), the Next Generation Impactor (NGI) and the MultiStage Andersen Cascade Impactor (ACI) Copley Scientific

Andersen Cascade ImpactorACI Westech Scientific Instruments

The 8stage Andersen Cascade Impactor (ACI) is the most frequently used instrument for the testing of inhaler products within the Pharmaceutical Sector Westech ACIs are specifically designed to meet the highest criteria laid down in the various Pharmacopoeias for characterising aerosol clouds emitted by Jet to plate spacer Tie bolt— Pressure tap Filter Impaction plate Figure 1 Schematic cutaway view of high volume cascade impactor Design There are four basic approaches to the design of a cascade impactor: (1) single jet, (2) multiple jet, (3) single slit, and (4) multiple slit In this study, multiple arrangements wereDesign and Calibration of A High Volume Cascade ImpactorThe instrument of choice for measuring the APSD of MDI or BAI products to meet both regulatory and pharmacopoeial requirements alike is the cascade impactor There are five different cascade impactors/impingers suitable for the assessment of APSD, however, only the Andersen Cascade Impactor (ACI), the Next Generation Impactor (NGI) and the Andersen Cascade Impactor (ACI) Copley ScientificA3G – AUTOMATED ANDERSEN CASCADE IMPACTOR A3G CONFIGURATIONS pMDI CONFIGURATION NASAL CONFIGURATION DPI CONFIGURATION DUSA CONFIGURATION Advantages of A3G Versatile machine Can be user configured for Oral or Nasal APSD test, and for 30/60/90 LPM in a matter of minutes Can Dose in ACI Column or in DUSA Tube In the the Nasal Andersen Cascade Impactor (ACI) — Lab Automate TechnologiesThe 1980’s saw an influx of new impactors, but using the sieve method as seen in the Andersen cascade sampler The SAS sampler is in essence a single stage sieve, or multi point impaction sampler, but due to the technology a more compact solution to slittoagar Pharma’s need for portable instruments to take to multiple sampling locations A brief history of the impaction sampler

Andersen Cascade Impactor (ACI) Copley Scientific

The instrument of choice for measuring the APSD of MDI or BAI products to meet both regulatory and pharmacopoeial requirements alike is the cascade impactor There are five different cascade impactors/impingers suitable for the assessment of APSD, however, only the Andersen Cascade Impactor (ACI), the Next Generation Impactor (NGI) and the The design concept of the Andersen Cascade Impactor evolves from the following Cascade ImpactorsImpaction surfaces Cascade impactors are multijet, multistage devices operating at constant flowrates steel plates are used in DPI and MDI applications to test inhalation suspensions and spray Glassfiber filters are commonly used for ANDERSEN CASCADE IMPACTOR OUTDOOR AIR QUALITYUnit 10, Rectory Farm Business Park Upper Stondon, Bedfordshire, SG16 6LJ, UK Tel: +44(0)1462 Fax: +44(0)1462 : sales@westechinstrumentshome ACI Anderson Cascade ImpactorAndersen Cascade Impactor ACI Andersen Cascade Impactor ACI Cascade impactors operate on the principle of inertial impaction Each stage of the impactor comprises a series of nozzles or jets through which the sample laden air is drawn directing any airborne particles towards the surface of the collection plate for that particular stageimpaction plates for andersen cascade impactorThe Andersen Cascade Impactors (ACI) are uniquely defi ned as a primary standard classifi cation device thanks to performance verifi cation through well established fundamental physical principles With over 40 years of published performance, our multistage Andersen Cascade Impactor is the best instrument for determiningThermo Scientific N6 Single Stage Andersen Cascade

How Does a Cascade Impactor Work? YouTube

Feb 05, 2020 Cascade impaction is the primary method for determination of the aerodynamic particle size distribution (APSD) of orally inhaled drug products (OIDPs), due tThe 8stage Andersen Cascade Impactor (ACI) is the most frequently used instrument for the testing of inhaler products within the Pharmaceutical Sector Westech ACIs are specifically designed to meet the highest criteria laid down in the various Pharmacopoeias for characterising aerosol clouds emitted by Andersen Cascade ImpactorACI Westech Scientific InstrumentsJet to plate spacer Tie bolt— Pressure tap Filter Impaction plate Figure 1 Schematic cutaway view of high volume cascade impactor Design There are four basic approaches to the design of a cascade impactor: (1) single jet, (2) multiple jet, (3) single slit, and (4) multiple slit In this study, multiple arrangements wereDesign and Calibration of A High Volume Cascade ImpactorSIXSTAGE VIABLE CASCADE IMPACTOR The SixStage ACI is a multiorifice, cascade impactor which is normally used to measure the concentration and particle size distribution of aerobic bacteria and fungi in the intramural or ambient air This instrument has been widely used as a standard for enumerating the viable particles in a microbial aerosolSixStage and TwoStage Viable Andersen Cascade Impactor Feb 27, 2013 As a bioaerosol sampling standard, Andersen type impactor is widely used since its invention in 1950s, including the investigation of the anthrax attacks in the United States in 2001 However, its related problems such as impaction and desiccation stress as well as particle bounce have not been solved Here, we improved its biological collection efficiencies by plating a mineral oil layer Enhancing Bioaerosol Sampling by Andersen Impactors Using

Cascade Impactor an overview ScienceDirect Topics

An advanced cascade impactor, such as a lowpressure impactor, consists of several such impaction plates with nozzles of gradually decreasing diameters This equipment classifies inert particles by size, with diameters ranging from 30 nm to 10 μm The sampling flow rate With cascade impaction analysis bounce effects can negatively influence stage collection efficiency, especially with increasing impactor loads Cascade Impactors, where plates were either left (PDF) PRACTICES OF COATING COLLECTION SURFACES OF CASCADE A cascade impactor measures the reach range of a particulate substance as it moves through an opening with the use of aerosolCascade impactors are strictly measurementrelated devices In addition to measuring the range of substances moved through an opening by aerosol, the impactor can also be used to determine the particle size of the distributed substanceCascade impactor Wikipedia405 Minimizing V ariability of Cascade Impaction Measurements surement ” [eg, detection and assay of the active pharma ceu t ica l ingr edien t (API ), such as HPLC anal ys is] , a nd(PDF) Minimizing Variability of Cascade Impaction The instrument of choice for measuring the APSD of MDI or BAI products to meet both regulatory and pharmacopoeial requirements alike is the cascade impactor There are five different cascade impactors/impingers suitable for the assessment of APSD, however, only the Andersen Cascade Impactor (ACI), the Next Generation Impactor (NGI) and the Andersen Cascade Impactor (ACI) Copley Scientific

home ACI Anderson Cascade Impactor

Unit 10, Rectory Farm Business Park Upper Stondon, Bedfordshire, SG16 6LJ, UK Tel: +44(0)1462 Fax: +44(0)1462 : sales@westechinstrumentsJet to plate spacer Tie bolt— Pressure tap Filter Impaction plate Figure 1 Schematic cutaway view of high volume cascade impactor Design There are four basic approaches to the design of a cascade impactor: (1) single jet, (2) multiple jet, (3) single slit, and (4) multiple slit In this study, multiple arrangements wereDesign and Calibration of A High Volume Cascade ImpactorAndersen Cascade Impactor ACI Andersen Cascade Impactor ACI Cascade impactors operate on the principle of inertial impaction Each stage of the impactor comprises a series of nozzles or jets through which the sample laden air is drawn directing any airborne particles towards the surface of the collection plate for that particular stageimpaction plates for andersen cascade impactorAndersen Cascade Impactor is the best instrument for determining or “cascade” of jet stages and impaction surfaces The Andersen Cascade Impactor Visual Inspection System, or ACIVIS, is a highly accurate, digital video scanning system for the Calibration standard plates Research results with an impactThe BioStage singlestage cascade impactor operates on the principle of inertial impaction and meets NIOSH and ACGIH recommendations for sampling indoor and outdoor air for mold and bacteria Made of precisiontooled aluminum, the sampler contains a jet classification stage and base plate precisionthreaded together for a positive seal and an BioStage Standard Impactor Order HighQuality BioStage

(PDF) PRACTICES OF COATING COLLECTION SURFACES OF CASCADE

With cascade impaction analysis bounce effects can negatively influence stage collection efficiency, especially with increasing impactor loads Cascade Impactors, where plates were either left Feb 27, 2013 As a bioaerosol sampling standard, Andersen type impactor is widely used since its invention in 1950s, including the investigation of the anthrax attacks in the United States in 2001 However, its related problems such as impaction and desiccation stress as well as particle bounce have not been solved Here, we improved its biological collection efficiencies by plating a mineral oil layer Enhancing Bioaerosol Sampling by Andersen Impactors Using cascade impactors (Andersen, Berner, Davis, MOUDI etc) to measure the activity size distribution of the radon progeny in the environment (4,5,11,12) In spite of their careful use, their nonideal behavior is not adequately known (13,14) The stage cut off points of cascade impactor are generally obtained from theoretical calculation using inertialResponses of Low Pressure Andersen Sampler for Collecting The Andersen impactor is a six stage multiple slot impactor which operates at a flow rates of up to 1000l/min, so collecting large quantities of material in a relatively short space of time This makes it ideal for use with analysis techniques which require large quantities of material, or where high time resolution information is neededImpactors and Filters (Centre for Atmospheric Science diameter than the collection plate, allowing unimpacted particles to go around the plate and into the next stage (Figure 3) Figure 3: Schematic cross section of the nonviable impactor stages Progressively smaller orifices increase the orifice velocity in eight successive stages causing impaction OPERATING MANUAL Model 900 Environmental Instruments

how to use Andersen 6state cascade impactor (instruction

Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTubeA typical impaction plate will have a pressure drop directly proportional to the square of the flow rate For example, Stage 5 of a UW MIII Impactor has a flow resistance which follows the relationship: AP (cm WC) = 02 (Qs)2 (B5) B46 PARTICLE PENETRATION B461 Select Dilution Air Flow Rate Select the dilution air flow rate necessary Procedures for Cascade Impactor Calibration and Operation Dec 10, 2019 Attempts to avoid this problem by the use of adhesive layers or fibrous filters on the impaction plates create other, unanticipated complications [51,57,7073] Sampling Sampling practices play an important role in particle size characterization using cascade impactors Shortduration sampling may result in unrepresentative size estimates [74]Cascade Impactors Drug Delivery ALPF Medical Research