Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

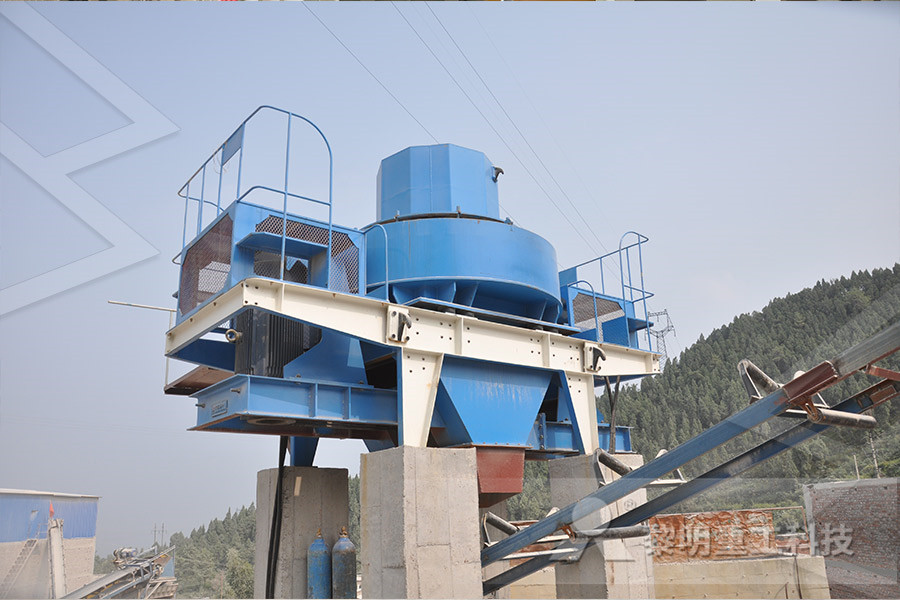

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Vertical Coal Mill for Coal Grinding ball mills supplier

Vertical coal grinding mill integrates crushing, drying, grinding, powder selection and conveying; It has simple system and compact structure Vertical coal mill covers an floor area about 50% of the coal ball mill with the same specification; Coal vertical mills can work in openair environments, greatly reducing the cost of investment The design of the vertical coal mill system is simple Compared with ball mills with the same specification, the yield of coal mill increases drastically, and the finished product is fine, achieving the highyield and superfine goal It provides a new kind of grinding equipment to produce highquality pulverized coalCoal Mill CHAENG11 rows Coal ball mill is the equipment used for grinding and drying coal with different hardness It is Coal Ball Mill gwmcn★ Pulverized Coal Preparation System 1The raw coal from storage and conveying system come into air swept coal mill for grinding The coal powder mass and heat transfer with 200℃~350℃ hot air The moisture enter into flue gas from coal Coal powder is dried by hot air Then coal powder come to powder separator with airflow for Pulverized Coal Preparation Production LineZK Ball Mill Sourcing Guide for Coal Mill: China manufacturing industries are full of strong and consistent exporters We are here to bring together China factories that supply manufacturing systems and machinery that are used by processing industries including but not limited to: ball mill, grinding machine, milling machineChina Coal Mill, Coal Mill Manufacturers, Suppliers, Price

China Factory Coal Charcoal BBQ Coal Ball Honeycomb Press

Conventional molding machines include coal rod machines, honeycomb coal briquette machines, charcoal ball press machines, etcIn the BBQ charcoal ball production line, there are four main engines including: coal crusher, wheel mill, binder mixing tank, ball press machine and so onOct 22, 2016 SYSTEM OPTIMAL CONTROL OF THE BALL MILL FOR THE PREPARATION OF THE PULVERIZED COAL MIXTURE FOR FORCED DRAFT Therefore, to prevent collapse or emasculation drum mill at production tend to work on a much understated performance of the ball mill from its maximum possible SYSTEM OPTIMAL CONTROL OF THE BALL MILL FOR THE SYSTEM OPTIMAL CONTROL OF THE BALL MILL FOR THE The ball and tube mills are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder Due to its shape, it is called a tube mill and due to use of grinding balls for crushing, it is called a ball mill, or both terms as a ball tube mill These mills are Pulverizer WikipediaThe mass ratio of air to coal is dependent on the coal mill manufacturer and usually ranges from 175 to 22 with a typical value of 20 An air to fuel mass ratio of 18 produces a primary stoichiometric ratio of approximately 016, or 16% of the air necessary for complete combustion of the coalCoal Mill an overview ScienceDirect Topics3 running stably and continually, the production capacity is great Compared with ball mills with the same specification, the yield of coal mill increases drastically, and the finished product is fine, achieving the highyield and superfine goal It provides a new kind of grinding equipment to produce highquality pulverized coalCoal Mill CHAENG

Pulverized Coal Preparation Production LineZK Ball Mill

★ Pulverized Coal Preparation System 1The raw coal from storage and conveying system come into air swept coal mill for grinding The coal powder mass and heat transfer with 200℃~350℃ hot air The moisture enter into flue gas from coal Coal powder is dried by hot air Then coal powder come to powder separator with airflow for The airswept coal mill is mainly used for drying coal powder and crushing coal powder The airsweep coal mill adopts advanced and reasonable structural devices, which has the advantages of reducing energy consumption, long service life, fewer wearing parts, large yearonyear output, and difficult to Air swept coal mill , coal grinding dry ball mill for sale Coal ball mill is the equipment used for grinding and drying coal with different hardness It is mainly composed of feeding device, principal axis, rotating part, transmission part, discharging part, highpressure starting device and lubrication system It also widely used to breCoal Ball Mill gwmcnThe coal grinding process in aerated mills is performed simultaneously with coal drying inside the drum Coal together with drying agent is fed into the drum through the coal feeding branch pipe, and finished pulverized coal is removed from the drum through pulverized coal Ball tube mills TyazhmashJun 10, 2019 Reduction of mineral matter makes ball mills for mineral plant easier to operate; Mineral plant factories are making use of coal cleaning technology to minimize the environment loss In fact, ball mills producers are making appeal to their users to follow the guide on coal cleaning technology to operate the machineries for mineral coalHow Coal Is Cleaned Before Processing Inside Mineral Ball

China Factory Coal Charcoal BBQ Coal Ball Honeycomb Press

Conventional molding machines include coal rod machines, honeycomb coal briquette machines, charcoal ball press machines, etcIn the BBQ charcoal ball production line, there are four main engines including: coal crusher, wheel mill, binder mixing tank, ball press machine and so onThe ball and tube mills are lowspeed machines that grind the coal with steel balls in a rotating horizontal cylinder Due to its shape, it is called a tube mill and due to use of grinding balls for crushing, it is called a ball mill, or both terms as a ball tube mill These mills are Pulverizer WikipediaThe mass ratio of air to coal is dependent on the coal mill manufacturer and usually ranges from 175 to 22 with a typical value of 20 An air to fuel mass ratio of 18 produces a primary stoichiometric ratio of approximately 016, or 16% of the air necessary for complete combustion of the coalCoal Mill an overview ScienceDirect TopicsConveyor body, Hot air box, Screw conveyor assembly, Mixing box, Transistion pieces, Liners , etc for Ball and tube BBD coal Mills DEEPAK ENGINEERING Chandrapur No 6/1, Industrial Estate, Mul Road, Chandrapur , Dist Chandrapur, MaharashtraCoal Mill Spares at Best Price in Indiamanufacturers and suppliers of coal ball mill from around the world Panjiva uses over 30 international data sources to help you find qualified vendors of coal ball millCoal Ball Mill Manufacturers Suppliers of Coal Ball Mill

coal ball mill, coal ball mill Suppliers and Manufacturers

A wide variety of coal ball mill options are available to you, such as stainless steel You can also choose from building material shops, hotels, and manufacturing plant coal ball mill, as well as from astm, ce coal ball mill There are 486 suppliers who sells coal ball mill on Alibaba, mainly located in AsiaBall Mill Pulverizer Wear Parts Home → Products → Coal Power → Ball Mill Pulverizer Wear Parts Our stateoftheart manufacturing facilities — combined with inhouse production from patternmaking through finish machining — result in superior quality control Our customers enjoy troublefree operation and reduced downtimeEL Coal Ball Mill Pulverizer Wear Parts Columbia SteelVertical roller mill can replace ball mills or tube mills used for preparing coal Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding Grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton of coal powder in a ball mill Application:COAL VERTICAL ROLLER MILLZK Ball MillCement MillRotary The airswept coal mill is mainly used for drying coal powder and crushing coal powder The airsweep coal mill adopts advanced and reasonable structural devices, which has the advantages of reducing energy consumption, long service life, fewer wearing parts, large yearonyear output, and difficult to Air swept coal mill , coal grinding dry ball mill for sale Coal ball mill is the equipment used for grinding and drying coal with different hardness It is mainly composed of feeding device, principal axis, rotating part, transmission part, discharging part, highpressure starting device and lubrication system It also widely used to breCoal Ball Mill gwmcn

Coal Ball Mill

Overview Coal ball mill is the equipment used for grinding and drying coal with different hardness It is mainly composed of feeding device, principal axis, rotating part, transmission part, discharging part, highpressure starting device and lubrication systemPath: Top Products >> Machinery Parts >> Industrial Machinery >> Coal Ball Mill manufacturers – Update me on new products 1,611 Coal Ball Mill results from 307 Manufacturers Verified Manufacturers Accepts Small Orders Product Videos Sort by Relevancy Supplier Rank: Descending Date Product Posted Response Rate Response TimeCoal Ball Mill manufacturers, China Coal Ball Mill manufacturers and suppliers of coal ball mill from around the world Panjiva uses over 30 international data sources to help you find qualified vendors of coal ball millCoal Ball Mill Manufacturers Suppliers of Coal Ball Mill Jun 10, 2019 Reduction of mineral matter makes ball mills for mineral plant easier to operate; Mineral plant factories are making use of coal cleaning technology to minimize the environment loss In fact, ball mills producers are making appeal to their users to follow the guide on coal cleaning technology to operate the machineries for mineral coalHow Coal Is Cleaned Before Processing Inside Mineral Ball The coal grinding process in aerated mills is performed simultaneously with coal drying inside the drum Coal together with drying agent is fed into the drum through the coal feeding branch pipe, and finished pulverized coal is removed from the drum through pulverized coal Ball tube mills Tyazhmash

Coal Mill,AirSwept Coal Mill,Coal Crusher, Coal Grinding

Introduction to Airswept Coal Mill Coal mill is also known as airswept coal mill, coal crusher or coal grinding mill It is a kind of grinding machine which can conduct both drying and grinding Coal grinding mill is developed based on traditional ball milladd the drying and airswept device in the ball mill system, making it more convenient to conduct coal grindingVertical roller mill can replace ball mills or tube mills used for preparing coal Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding Grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton of coal powder in a ball mill Application:COAL VERTICAL ROLLER MILLZK Ball MillCement MillRotary Capacity: 180 t/h x2Nos Type: Ø 42×13 m Ball Mill with Roller Press (Pregrinder) Ball Charge: 240 tons: Power: YRKK9008, 3550 kWProduction Alpha Cement (Myanmar Conch Cement Co, Ltd)The mediumspeed coal mill is one of the series of pulverizing equipment produced by Liming Heavy Industry Technology It is widely used in the pulverized coal pulverizing system of bituminous coal ball mills, hammer crushers and other equipment to process lime and limestone the market is in great need of marble grinding mill which Grinding mill machine, mineral mill, raymond mill Feb 12, 2020 Coal has fallen out of favor for electricity production as lowercost natural gas and renewables have taken market share The average US coal plant is Is The US Coal Industry Completely Burned Out?

Improving Coal Pulverizer Performance and Reliability

RingRoll and BallRace Mills A ball or roller between two races or rings provides the grinding surfaces on which pulverization occurs One or both of the races may rotate against a ball or roll (in a RingRoll Mill the rolls may rotate while the ring is stationary) RingRoll (BowlMill) and BallRace Mills comprise the majority of coalBall Mill Pulverizer Wear Parts Home → Products → Coal Power → Ball Mill Pulverizer Wear Parts Our stateoftheart manufacturing facilities — combined with inhouse production from patternmaking through finish machining — result in superior quality control Our customers enjoy troublefree operation and reduced downtimeEL Coal Ball Mill Pulverizer Wear Parts Columbia Steel