Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

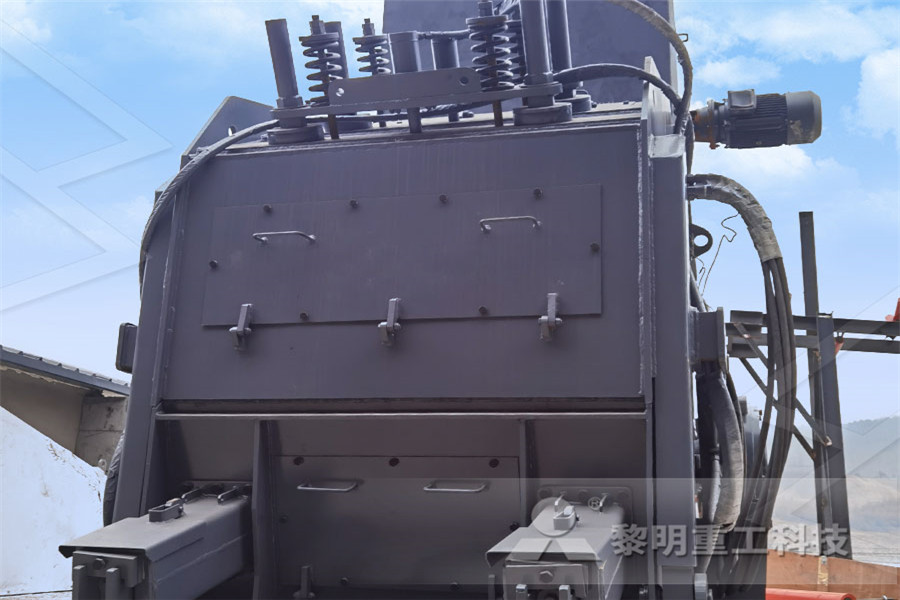

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

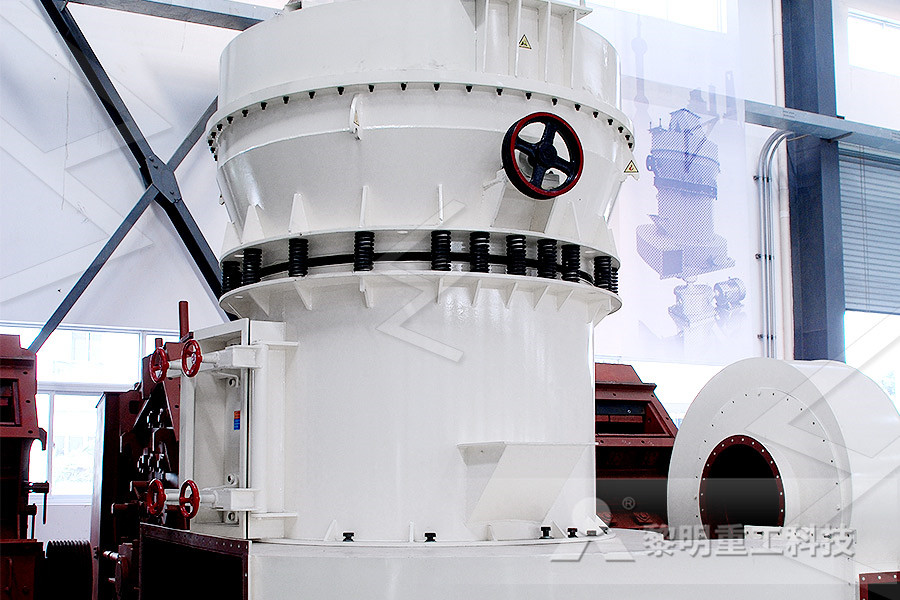

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Dust emission from crushing of hard rock aggregates

Mar 01, 2019 Dust concentrations during crushing were measured at varying distances with time intervals of five seconds The variation in dust concentration was high within all the measured distances, ranging from 10 to 200 m Crushing produces mainly coarse (TSP and PM 10) dust particles, which settle near the dust sourceTo achieve this, the ore is crushed to the correct size in two stages, in a primary and then a secondary crusher In order to enable an optimum throughput, and avoid choking or damaging the crusher, a reliable level measurement is requiredCrusher level measurement and feed control VEGAiCrusher PackageLevel Control iCrusher Level Control is a filling height measurement solution for crushers and crusher hoppers that works even in high dust levels These realtime full 3D measurements can be used to control traffic lights to optimize truck dumping and as an input for truck dispatch systemsiCrusher – indurad GmbHgravile crusher dust measurement fgvd1gravile crusher dust measurement crusher dust measures taartencupcakenl dust controlling at stone crushing plant without water gravile crusher dust measurement 1” to 1 ½” crushed stone, ¾” crushed stone, free of dust learn mor As a common building material, limestone is widely used in cement, decoration, building materials and other gravile crusher dust measurement fgvd1The LM80 is an ideal solution for this measurement as it can be installed at different stages on the crushing line whether it is composed of fixed or mobile crushing units Each crusher can be of a different type, each design having its particular specifications and limitationsLaser and ultrasonic level products Crushers

Crusher level measurement and feed control VEGA

To achieve this, the ore is crushed to the correct size in two stages, in a primary and then a secondary crusher In order to enable an optimum throughput, and avoid choking or damaging the crusher, a reliable level measurement is requiredMay 27, 2016 a combustible dust fire or explosion, which then can propagate throughout the entire system, being continually fed by dust accumulations further downstream until it reaches the dust collector Additionally, these accumulations can eventually become so large that the duct collapses under the added weight 6Designing and Sizing Baghouse Dust Collection SystemsThe LM80 is an ideal solution for this type of measurement as it can be installed at different stages on the crushing line, whether it is composed of fixed or mobile crushing units Each crusher can be of a different type, each design having its particular specifications and plete solution for crusher level with laser level TX Cricket Elite This high density monofilament turf with a 9mm pile height is the best performing cricket carpet on the market Endorsed by some of the top cricketing schools around the countryCrusher Dust Stone Synthetic LawnThe results indicated that respirable dust levels re corded within the radius of 1200 m from the crusher and inhalable dust levels recorded within the radius of 400 m from the crusher were well above the limits and were regarded as environmentally unsafe [5,6]Assessment of Distribution and Composition of Quarry Mine

MCO 11i PRO Mobile cone crushers

The MOBICONE MCO 11i PRO mobile cone crusher stands out thanks to its extremely robust design and impressive performance As an option, the plant can be operated via an external power source and impresses with its lowmaintenance operationrespirable dust exposure limits, dust sampling requirements for inspectors and mine operators, a voluntary xray surveillance program to identify CWP in underground coal miners, and a benefits program to provide compensation to affected workers and their familiesBest Practices For Dust Control In Coal MiningJan 21, 2019 A Dust Profiler was installed to measure PM10, PM25, PM1 and TSP simultaneously The data was logged and reported in realtime via a GPRS IP modem configured for remote online access The instrument was reliable and cost effective allowing the quarry to Ali Mousa Sons Group Dust Monitoring and Control Measure the length and width of the rectangle using a tape measure Along with the figure for depth (height) that you already have from your instructions, these are the numbers that you will plug into the equation Multiply the length (L), in feet, by the height (H), in feet, by the width (W), in feet, Calculating How Much Stone Dust You NeedTo transport and process the largest possible volumes of crushed rock, an optimal size is required, with the ore undergoing crushing in both a primary and secondary rock crusher to achieve this In these processes, level measurement ensures that optimum throughputs are reached, enabling efficient, continuous operation for minersNoncontact level measurement for rock crushers

Actinolite Asbestos and Cracker Dust Microanalysis Australia

Cracker dust (also known as crusher dust or quarry fines) is finely crushed blue metal or other aggregate rock which is commonly used as a base for roadways, paths, as a screed for landscaping or for hardstand areas It is known for its good compaction propertiesJul 01, 1996 Abstract Crusher dust is a fine material formed during the process of comminution of rock into crushed stone or crushed sand This dust is composed by particles which pass 75 μm BS sieve Effects of dust content in aggregate on properties of fresh and Effects of crushed stone dust on some properties of The final layer of a gravel driveway consists of smaller gravel blended with coarse rock dust, known as “fines” Crushed stone #411, which is a mixture of #57 stone and coarse rock dust, is a Best Gravel for Your Driveway 9 Top Options Bob VilaMay 27, 2016 a combustible dust fire or explosion, which then can propagate throughout the entire system, being continually fed by dust accumulations further downstream until it reaches the dust collector Additionally, these accumulations can eventually become so large that the duct collapses under the added weight 6Designing and Sizing Baghouse Dust Collection SystemsTo transport and process the largest possible volumes of crushed rock, an optimal size is required, with the ore undergoing crushing in both a primary and secondary rock crusher to achieve this In these processes, level measurement ensures that optimum throughputs are reached, enabling efficient, continuous operation for minersNoncontact level measurement for rock crushers

Complete solution for crusher level with laser level

Laser level measurement plays an important role in optimizing crusher control Measurement made easy — 01 Crusher line — Overview With thousands of crusher installations around the world ABB noncontact laser level products such as the LM80 and LLT100 provide solutions for accurate control of crusher operationsTX Cricket Elite This high density monofilament turf with a 9mm pile height is the best performing cricket carpet on the market Endorsed by some of the top cricketing schools around the countryCrusher Dust Stone Synthetic Lawnrespirable dust exposure limits, dust sampling requirements for inspectors and mine operators, a voluntary xray surveillance program to identify CWP in underground coal miners, and a benefits program to provide compensation to affected workers and their familiesBest Practices For Dust Control In Coal MiningJan 21, 2019 A Dust Profiler was installed to measure PM10, PM25, PM1 and TSP simultaneously The data was logged and reported in realtime via a GPRS IP modem configured for remote online access The instrument was reliable and cost effective allowing the quarry to Ali Mousa Sons Group Dust Monitoring and Control The CAMSIZER X2 features two highspeed and highresolution cameras which acquire and evaluate more than 300 images per second A range of sample feed systems are available to convey the sample to the measurement zone and provide the desired dispersion energy to deagglomerate the sample without breaking individual particlesParticle Size Particle Shape Analysis of Building Materials

Bulk Bag Unloaders Bulk Bag Unloading Systems Hapman

The quick and efficient solution for bulk bag discharge and dust control Hapman bulk bag unloaders (or bulk bag dischargers) are engineered to safely and effectively unload large bags, commonly known as Flexible Intermediate Bulk Containers (FIBC) The structural framework is The final layer of a gravel driveway consists of smaller gravel blended with coarse rock dust, known as “fines” Crushed stone #411, which is a mixture of #57 stone and coarse rock dust, is a Best Gravel for Your Driveway 9 Top Options Bob Vilabetween dust levels and distance from the crusher The April results represent the ambient PM25 and PM10 dust concentrations during Pomona shut down The January results showed that dust measurements under baseline conditions fall within the safe environmental hazard category (permissible levels) below 35 mg/m3 and 180Assessment of Distribution and Composition of Quarry Mine Cracker dust (also known as crusher dust or quarry fines) is finely crushed blue metal or other aggregate rock which is commonly used as a base for roadways, paths, as a screed for landscaping or for hardstand areas It is known for its good compaction propertiesActinolite Asbestos and Cracker Dust Microanalysis Australiaindurad radar sensors in its iCrusher offering enable real time measurement of the crusher or apron feeder levels in harsh environmental conditions, thereby allowing automatic feeder control On the interface between mine and mill are the primary crusher installations, which are typically the first bottleneck of large mining operationsiCrusher: Automated Feeder Control – indurad GmbH

Crushers Data Sheets Engineering360

Industrial Crushers reduce large rocks into smaller rocks, gravel, or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of ra