Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

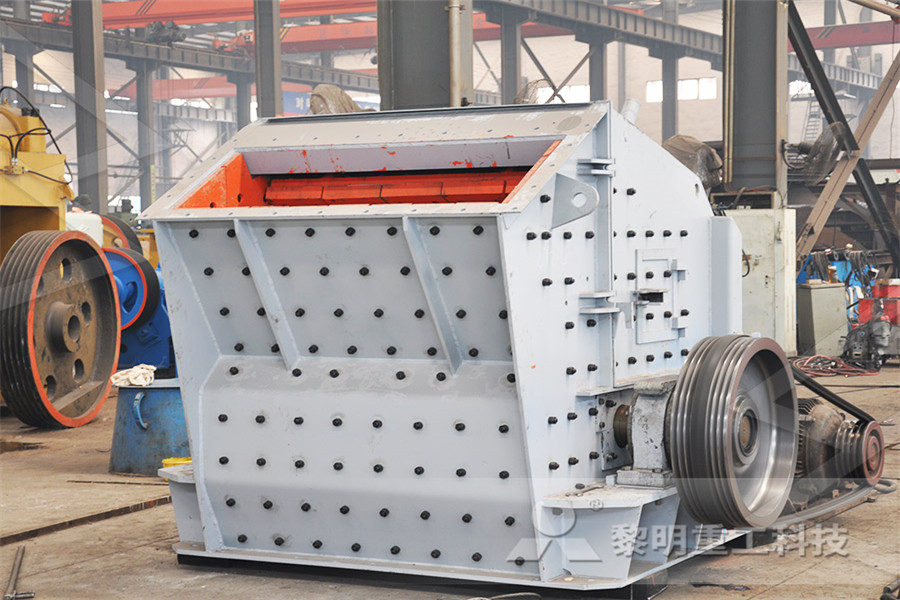

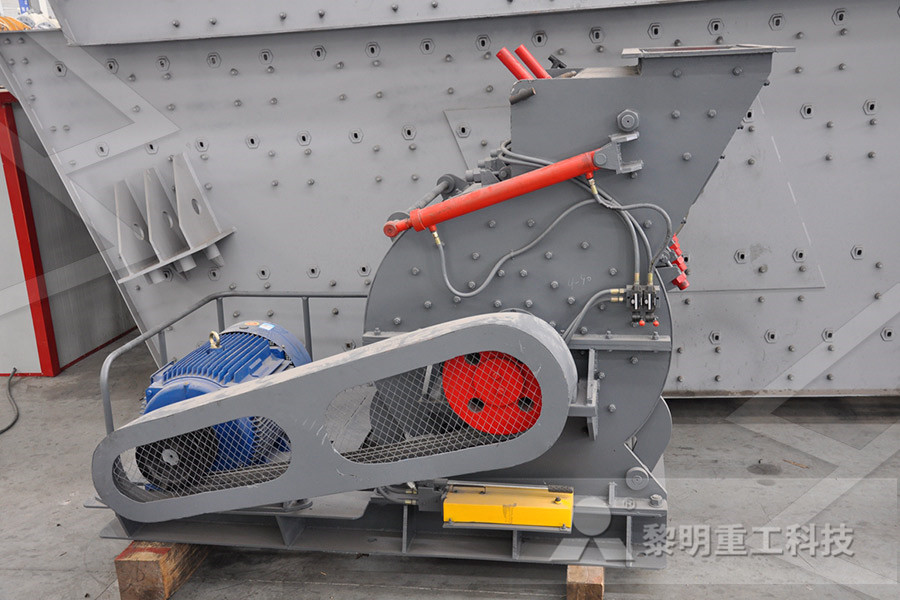

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Safety in Rolling Mills – IspatGuru

Worldwide, as the rolling speeds are increasing, greater emphasis is being placed on the aspects of safety while designing the mill equipment as well as during the finalization of the mill layouts Providing high importance to safety is in the best interest of the designers, manufacturers and the users of the rolling mills Safeguarding of the mill equipment is necessary for ensuring the safe working of the rolling mill Maximized safety The quickstop function of our Hägglunds direct drive systems provides the market’s fastest stopping time, and our rollback function automatically reverses your roll mill after an emergency stop That means maximum safety for your roll mill operatorsRoll Mills – Keep Your Rubber Processing Rolling roller mills consistently and safely grind wheat, corn, rye, barley, spelt and other grains We offer a wide range of roller mills and optional functionsRoller Mills Milling Group27081974 A safety device for rolling mills arranged to interrupt the transmission of motion from the motor to the rolling stands, in which the outlet guide for the rolled material of at least the last stand of the rolling mill is fixed to the housing of the respective stand by fixing means arranged to allow the guide to separate from the housing when said fixing means are subjected to a thrust greater than a SAFETY DEVICE FOR ROLLING MILLS PROPERZI I,ITTorrey Hills three roll mills are loaded with many safety features as standard to ensure maximized safety such as easily accessible emergency stop buttons, as well as an easily accessible on/off switch The emergency pullcord (T65 series) is located right on top of the machine for quick stopHow to safely operate a three roll mill?

Introduction to rubber processing and safety issues

Tworoll mills — Safety requirements provides details for the performance criteria for the Lunn bar and braking system This includes a requirement for automatic roll separation and reversal on operation of the Lunn bar Extrusion Introduction Keywords: cold rolling mills, risk assessment, analyze hazards, WRAC I INTRODUCTION A critical part of any safety and health program is the identification, assessment, elimination and/ or the control of hazards in the workplace It is impossible to eliminate all hazards, so the goalRisk Assessment and Control Measures for Cold Rolling Mill smallest mill will be up to 5,000 tonnes, 10,000 tonnes in the medium size mill and up to 20,000 tonnes in the largest model which considerably increases service intervals of the mill NEW TECHNOLOGY, NEW ADVANTAGES The SKIOLD disc mill® is the result of several years of product development and testing The object was to develop anSKIOLD DISC MILL® MLVSAs regards “abnormal” rolling conditions which are more or less very “normal” for rolling mills roll damage often occurs with consequences for the mill and the rolled product Evidently the reasons of roll failure have to be discussed and determined (or vice versa) to reduce the risk of repeated roll A BASIC UNDERSTANDING OF THE MECHANICS OF ROLLING 05112012 Informative video on mill safety for rubber products manufacturers The video, produced by the Rubber Manufacturers Association, covers mill safety at the pMill Safety YouTube

Introduction to rubber processing and safety issues

Tworoll mills — Safety requirements provides details for the performance criteria for the Lunn bar and braking system This includes a requirement for automatic roll separation and reversal on operation of the Lunn bar Extrusion Introduction Click Here to see video of new Safety Cage : Two Roll Rubber Mill sizes from 110 to 200 mm Models : LRMRS110, 150, 200 / Oil or Water Bench Top Two Roll Mill Type Model : LRMM100 The Micro Scientific Bench Top Two Roll Mills type LRMM100 is intended mainly for learning institutes and for laboratories where a smaller batch size is LabTech Two Roll Mills MidwestlabtechDisc mills are perfect for very fine comminution of soft, hard and brittle materials Reliable results guaranteed Read more about our disc millsDisc Mills from RETSCH fast and powerful 44 Mill Roll Heights Mill installations shall be installed so that the top of the operating rolls is at least 50 inches (127 cm) above the level on which the operator stands, irrespective of the size of the mill This distance shall apply to the actual working level, whether it be at the general floor level, in a pit, or on a platformSafety Specifications for Mills and Calenders in the • CT TwoRoll Mill with an advanced design • Suitable for rubber and plastic sheet preparation and compounding • Smooth running • Easy to control • Safety functions • Long service life • CT TwoRoll Mill consists of two rolls made of steel with hard chrome plating • Both rolls run at a fixed speed and a constant friction ratio •TwoRoll Mill CHAREON TUT

Buy Efficient, Authentic rubber mill safety

Mixing Mill / Open Mixing Mill Main techdnical spec : 1 type XK300 XK360 XK400 XK450 2 working diameter of rolls(mm) 300 360 400 450 3 working length of rolls(mm) 750mm 900mm 1000mm 1200mm 4 working linear speed of front roll(m/min) 151 1625 1865 245 5 friction ratio of front and rear roll 1:127 1:125 1:127 1:127 6 max gap(mm) 10 10 15 15 7 capacity Rotor Mills The rotor mill series includes Ultra Centrifugal Mills, Rotor Beater Mills and Cross Beater Mills Depending on the particular instrument they are suitable for the preliminary and fine size reduction of soft, fibrous and also hard materialsRotor Mills fast easy sample preparation Each roll is precision machined from select grades of high density steel After the machining process is completed, each roll is hardened to 65 HRC in strategic locations utilizing the latest in induction heat treating methods Pepetools is proud to be the only American manufacturer to produce, design, and build rolling mills in the USARolling Mills Pepetools" Yuwan Tech is a challenge without pause towards the dream Companies that seek the best value "유완테크As the originators of the Rupture Disk (Bursting Disc), BSB Safety Systems is best suited to finding the safest solution to your pressure problem We pride ourselves on catering for your needs with established products or custom made designs Safety Relief ValvesBSB Safety Systems

SAFETY GUIDELINES FOR IRON STEEL SECTOR

This safety guideline is applicable to High speed Automatic Rolling Mills Dept of an Integrated Steel Plant 3 PROCESS Rolling mills consists of different type of Mills based on the desired products namely: A Long Product Mill a) Light and Medium Merchant Mill/ Bar Mill b) Wire rod Mill c) Medium merchant structural mill/ Structural Mill• CT TwoRoll Mill with an advanced design • Suitable for rubber and plastic sheet preparation and compounding • Smooth running • Easy to control • Safety functions • Long service life • CT TwoRoll Mill consists of two rolls made of steel with hard chrome plating • Both rolls run at a fixed speed and a constant friction ratio •TwoRoll Mill CHAREON TUTDisc mills are perfect for very fine comminution of soft, hard and brittle materials Reliable results guaranteed Read more about our disc millsDisc Mills from RETSCH fast and powerful Health and Safety Executive ealh and Safe ecuie HS information sheet Engineering Information Sheet No 7 (Revision 1) Safe use of 3 roll bending machines Introduction This guidance is for employers and operators of manually loaded 3 roll bending machines It has been produced in order to assist with meeting legal dutiesSafe use of 3 roll bending machines EIS7RETSCH cutting mills provide highly efficient primary size reduction of heterogeneous material mixes but are also suitable for grinding soft, mediumhard, elastic or fibrous samples Cuttings mills offer a high level of operational safety and convenienceCutting Mills from RETSCH safe and convenient

Rotor Mills fast easy sample preparation

Rotor Mills The rotor mill series includes Ultra Centrifugal Mills, Rotor Beater Mills and Cross Beater Mills Depending on the particular instrument they are suitable for the preliminary and fine size reduction of soft, fibrous and also hard materialsSafety Tripod on a Rubber Mill] [Figure 21 Typical HandFeeding Tools] [Figure 22 Properly Guarded Foot Control] safety mats) on rollforming and rollbending machines The disc or wheel rating is marked on the disc or wheel in surface feet per minuteSafeguarding Equipment and Protecting University Health and Safety Risk assessments Code of Practice for Student Workshops Risk Assessment Milling Machine (Horizontal and Vertical) 17 February 2016 4 of 4 Ref; Health Safety Executive Engineering in Workshops If metalwork fluids are used they must be mixed and changed in accordance with the manufacturer’s instructionsMilling machine risk assessment Dyson자동등록방지를 위해 보안절차를 거치고 있습니다 Please prove that you are human자동등록방지를 위해 보안 daewhatechTHE PULP AND PAPER MILL Although there are several chemical and mechanical pulping methods used for delignifying wood (table 2l), separating fibers, and removing discoloration, all integrated pulp and paper mills involve the same general steps in the manufacture of pulp and paper These steps include: 1 ) raw materialThe Pulp and Paper Making Processes Princeton University