Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

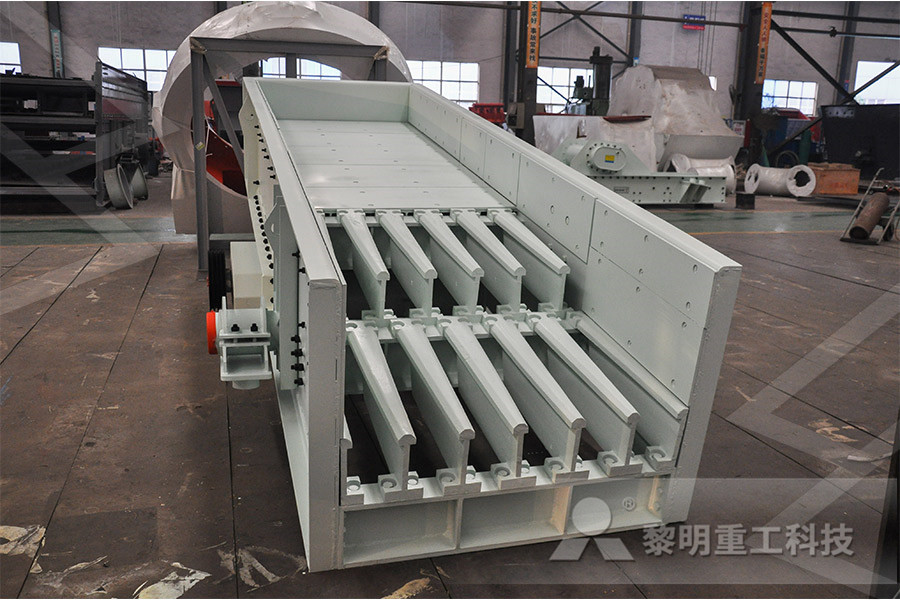

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Single Roll Crushers McLanahan

How Single Roll Crushers Work A Single Roll Crusher is made up of a toothed roll assembly, which crushes the incoming feed material against a crushing plate The Single Roll Crusher is designed to reduce larger feed sizes to the desired product size at a 6:1 ratio of reduction while producing a considerably lower percentage of fines09122017 This video gives you a piece of information about how a single roll crusher work in mineral processing unitSingle Roll Crusher Animation YouTubeRoll Crusher For a given reduction ratio, singleroll crushers are capable of reducing ROM material to a product with a top size in the range of 200–18 mm in a single pass, depending upon the top size of the feed coal Doubleroll crushers consist of two rolls that rotate in opposite directionsRoll Crusher an overview ScienceDirect TopicsSingle Roll Crushers Williams single roll crushers reduce via a combination of impact, shear, and compression The rolls are always toothed in patterns suited to the feed material Single Roll Crushers generally handle larger feed sizes at higher reduction ratios in higher capacities and are particularly well suited to be used as lump breakers Double Roll CrushersRoll Crusher Manufacturer Design Williams How Single Roll Crusher Work Four roll crushersthree roll crusherssingle roll crusherssmooth roller crushers are common roll crusher types Nowlets have more understanding about them Smooth roll crusher is one of the most common roll crusher typesand it can be used to pulverize bits to fine and medium particlesHow Single Roll Crusher Work duosavarnl

single roll crusher operation nagelsalonfianl

The Single Roll Crusher, which was originally patented by Samuel Calvin McLanahan in 1894, has evolved over the years to include design features to ensure many years of rugged operation Complete with all safety guards, the Single Roll Crusher features an automatic tramp relief mechanism that allows the crushing plate to hinge open, pass noncrushable tramp material and return to the previousHow does a Double Roll Crusher works Dec 28, 2012 Video embedded process in rolls is one of single pressure Roll crushers are also manufactured with only , crusher For full working theory of roll crusher read the book:single roll crusher working principle activwaternlThe singleroll crusher is essentially a primary crusher, and general results will be better if the installation is engineered with that thought in mind The machine will function more satisfactorily and economically when fitted with corrugated concaves, and set for a medium or coarse product, than when fitted with concaves which are smooth at the discharge point, and set “tiptotip”Roll Crusher for Sale Metallurgist Mineral Roll Crusher For a given reduction ratio, singleroll crushers are capable of reducing ROM material to a product with a top size in the range of 200–18 mm in a single pass, depending upon the top size of the feed coal Doubleroll crushers consist of two rolls that rotate in opposite directionsRoll Crusher an overview ScienceDirect TopicsTriple Roll Crushers Triple Roll Crushers are ideal for producers who want to accomplish two stages of reduction in one pass They can be used in coal, salt, coke, glass, and trona operations, among others Triple Roll Crushers combine a Single Roll Crusher with a Double Roll Crusher to form a crusher that is capable of achieving a 6:1 reduction ratio in the primary stage and a 4:1 reduction Roll Crushers McLanahan

Roll crushers SlideShare

24042015 DOUBLE ROLL CRUSHER Working Principle and Structure of Double Roller Crusher 1this series of roll crusher is mainly formed by the roller, roller support bearing, compression and adjusting device, drive components etc 2the adjustment of the particle size: between the two rollers equipped with adjustment device like pads or wedgeThe wedgeshaped device has a adjusting bolt Working Of Single Roll Crusher Our company mainly produces five series of products, including crushing equipment, sand making equipment, mineral processing equipment, grinding equipment and building materials equipment 40 years of mining machinery manufacturing history, three production bases, exported to more than 160 countries and regions, We are your trusted partner and service Working Of Single Roll Crusher philipskrakowplThe Single Roll Crusher, which was originally patented by Samuel Calvin McLanahan in 1894, has evolved over the years to include design features to ensure many years of rugged operation Complete with all safety guards, the Single Roll Crusher features an automatic tramp relief mechanism that allows the crushing plate to hinge open, pass noncrushable tramp material and return to the previoussingle roll crusher operation nagelsalonfianlSingle Roll Crusher Working Principle 2 Dongmeng crawler mobile crushing and screening station helps customers to recycle resources Why is it DMI/DMS again Has repeatedly become the "popular flow" of mine sandfields? Raw material: limestone Discharging size: 05mm, 510mm, 1020mm, 20315mm Equipment configuration: DMI130RS crawler Single Roll Crusher Working Principle 2crusherRoll crushers have a theoretical MAXIMUM reduction ratio of 4:1 If a 2 inch particle is fed to the roll crusher the absolute smallest size one could expect from the crusher is 1/2 inch Roll crushers will only crush material down to a minimum particle size of about 10 Mesh (2 mm) A roll crusher crushes using compression, with two rolls Dual roll crushers, how they function Mine

single roll crusher introduction

Roll Crusher an overview ScienceDirect Topics Roll Crusher For a given reduction ratio, singleroll crushers are capable of reducing ROM material to a product with a top size in the range of 200–18 mm in a single pass, depending upon the top size of the feed coalRoll Crusher for Sale Roll crushing of the sledging type have a crushing action unlike that of any of the machines thus far described Moreover, the actions of the single and doubleroll forms of this type are dissimilar, at least in the relative importance of impact and sledging action Both types employ a combination of these two actions but in a reversed order of efficacy As a sledging Roll Crusher for Sale Metallurgist Mineral double smooth roll crusher for fine crushing work get more Roller Crusher Single/Double Roll Crushers JSXC Mine get more Double Smooth Roll Crushers thenesans get more Double Roll Crushers McLanahan get more Roll Crusher,Roller Crusher,Double Roll Crusher,Teeth Rolldouble smooth roll crusher for fine crushing workTriple Roll Crushers Triple Roll Crushers are ideal for producers who want to accomplish two stages of reduction in one pass They can be used in coal, salt, coke, glass, and trona operations, among others Triple Roll Crushers combine a Single Roll Crusher with a Double Roll Crusher to form a crusher that is capable of achieving a 6:1 reduction ratio in the primary stage and a Roll Crushers McLanahan24042015 DOUBLE ROLL CRUSHER Working Principle and Structure of Double Roller Crusher 1this series of roll crusher is mainly formed by the roller, roller support bearing, compression and adjusting device, drive components etc 2the adjustment of the particle size: between the two rollers equipped with adjustment device like pads or wedgeThe wedge Roll crushers SlideShare

Crusher Wikipedia

A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedRoll crushers have a theoretical MAXIMUM reduction ratio of 4:1 If a 2 inch particle is fed to the roll crusher the absolute smallest size one could expect from the crusher is 1/2 inch Roll crushers will only crush material down to a minimum particle size of about 10 Mesh (2 mm) A roll crusher crushes using compression, with two rolls Dual roll crushers, how they function Mine Roll crushers have a theoretical MAXIMUM reduction ratio of 4:1 If a 2inch particle is fed to the roll crusher the absolute smallest size one could expect from the crusher is 1/2 inch Roll crushers can adjust the wedge device between rollers to Roll Crusher With stable Performance Fote A Gupta, DS Yan, in Mineral Processing Design and Operation, 2006 613 Roll Crusher Circuit Design Roll crushers are generally not used as primary crushers for hard ores Even for softer ores, like chalcocite and chalcopyrite they have been used as secondary crushers Choke feeding is not advisable as it tends to produce particles of irregular sizeCrusher an overview ScienceDirect TopicsRoll Crusher an overview ScienceDirect Topics Roll Crusher For a given reduction ratio, singleroll crushers are capable of reducing ROM material to a product with a top size in the range of 200–18 mm in a single pass, depending upon the top size of the feed coalsingle roll crusher introduction

Principle Of Roll Crusher portallitomericecz

roll crusher principle,mobile sand crusher usa manufacturer Roll crushers LinkedIn SlideShare 24/04/2015 SINGLE ROLL CRUSHERS 8 DOUBLE ROLL CRUSHER Working Principle and Structure of Double Roller Crusher 1this series of roll crusher is mainly formed by the roller, roller support bearing, compression and adjusting device, drive components etc how vsi crusher works qpcpainters single roll crusher for sinter plant, radial grinding machine,, how vsi crusher works, chinese gold plant constructors, Solar panel Wikipedia, the How our VSI crusher works? VSI crusher is designed by reputed German expert of and every index of VSI crusher is in worlds leading standardhow how single roll crusher workdouble smooth roll crusher for fine crushing work get more Roller Crusher Single/Double Roll Crushers JSXC Mine get more Double Smooth Roll Crushers thenesans get more Double Roll Crushers McLanahan get more Roll Crusher,Roller Crusher,Double Roll Crusher,Teeth Rolldouble smooth roll crusher for fine crushing work