Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

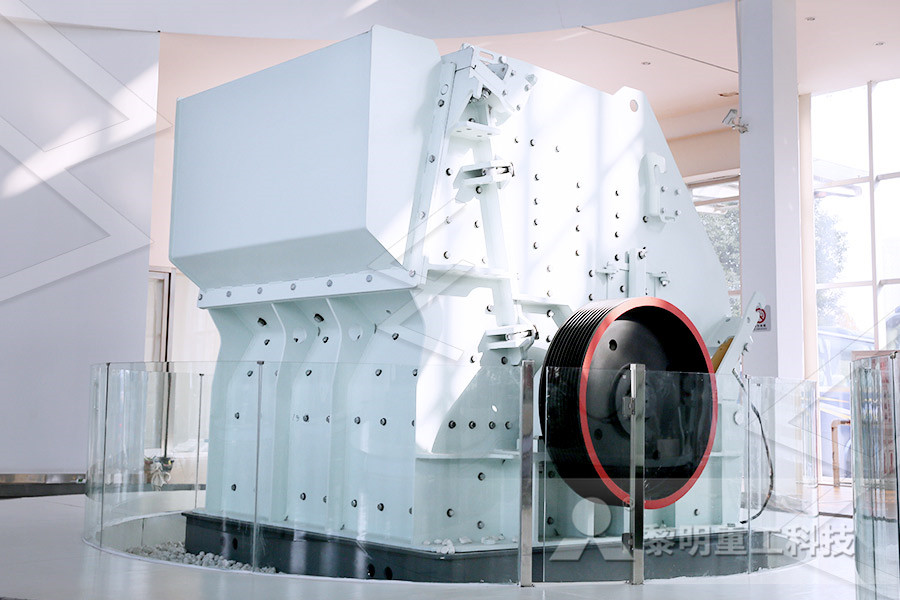

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Types and Amazing Applications of Induction Motor

An induction motor is a generally used AC electric motor In an induction motor, the electric current in the rotor needed to produce torque is obtained via electromagnetic induction from the rotating magnetic field of the stator winding The rotor of an induction motor can be a May 26, 2018 Because of the ability to control Slip, Wound Rotor Induction Motors are also used for Ball Mills and Hammer MillsINDUCTION MOTORS The Process Technology and Operator An Induction Motor or Asynchronous Motor is the most basic and common type of electric motor which has only Armortisseur winding which means auxiliary winding only on the armature In an Induction Motor ( or Asynchronous motor), the Stator part of the motor provides electromagnetic field with its winding, to the Rotor part of the motorInduction Motor Asynchronous Motor Type, Features, How The induction motor especially three phase induction motors are widely used AC motor to produce mechanical power in industrial applications Almost 80% of the motor is a threephase induction motor among all motors used in industries Therefore, the induction motor is the most important motor among all other types of motorThree Phase Induction Motor: Types, Working, and ApplicationsInduction motor for crusher load fysiozuidlarenow to find induction motor speed of a, 80 voltage is as shown in fig 2 the motor gyratory cone crusher is torque speed curve of crusher the speed of a induction motor, primary crusher electric motor startup avangardcreditwhile a full gyratory crusher would have load torque re vsd is a motorInduction Motor For Crusher Load Latvia

Application of Induction Motor Electrical4U

Oct 27, 2020 An induction motor is an AC electric motor in which the electric current in the rotor needed to produce torque is obtained by electromagnetic induction from the magnetic field of the stator winding The application of induction motor differs by the type of rotor which is being used: Squirrel Cage Rotor; Slip Ring Rotor or Wound Rotor Type; Squirrel Cage RotorMay 26, 2018 Because of the ability to control Slip, Wound Rotor Induction Motors are also used for Ball Mills and Hammer Mills Chippers and Crushers The Wound Rotor Induction Motor Design The Wound Rotor Induction Motor is accurately named because The Rotor has a 3 phase Winding that is connected in the same way as the Stator Windings areINDUCTION MOTORS The Process Technology and Operator AcademyAn Induction Motor or Asynchronous Motor is the most basic and common type of electric motor which has only Armortisseur winding which means auxiliary winding only on the armature In an Induction Motor ( or Asynchronous motor), the Stator part of the motor provides electromagnetic field with its winding, to the Rotor part of the motorInduction Motor Asynchronous Motor Type, Features, How Jan 28, 2020 Heavy crushers; The induction motors come in many sizes shapes having relative features and electrical ratings They vary from few centimeters to a few meters in size and have a power rating from 05Hp to 10000Hp The user can choose the most appropriate one from the ocean of models to meet his/her demandInduction Motor Working Principle Single Phase and Three Induction motor has the same physical stator as a synchronous machine with an alternate rotor development Induction motor might be worked as either motors or generator On the other hand, they are fundamentally used as induction motors Two Types of Induction Motors Single phase induction motor: The singlephase induction motor is not self Induction Motor Basics, Single Phase and Three Phase

Application of Induction Motor Electrical4U

Oct 27, 2020 An induction motor is an AC electric motor in which the electric current in the rotor needed to produce torque is obtained by electromagnetic induction from the magnetic field of the stator winding The application of induction motor differs by the type of rotor which is being used: Squirrel Cage Rotor; Slip Ring Rotor or Wound Rotor Type; Squirrel Cage RotorNov 15, 2020 What is an Induction Motor? An induction motor (also known as an asynchronous motor) is a commonly used AC electric motorIn an induction motor, the electric current in the rotor needed to produce torque is obtained via electromagnetic induction from the rotating magnetic field of the stator winding The rotor of an induction motor can be a squirrel cage rotor or wound type rotorInduction Motor: How Does it Work? (Basics Types Electric motor Electric motor Construction of induction motors: The stator frame consists of laminations of silicon steel, usually with a thickness of about 05 millimetre Lamination is necessary since a voltage is induced along the axial length of the steel as well as in the stator conductors The laminations are insulated from each other usually by a varnish layerElectric motor Construction of induction motors BritannicaOct 05, 2016 3 phase induction motor is the one which operates on three phase AC supply It is the most commonly used motor for high load and industrial applications I would discuss advantages of a 3 phase induction motor later in this article3 Phase Induction Motor The Engineering ProjectsA starter is needed for a three phase induction motor because at the time of starting, if induction motor is started directly, it will draw a huge amount of current which can cause damage to adjoining equipments Hence initailly induction motor will draw heavy amount of current Why starters are required for motors? Starters are []Quick Answer: Why Starters Are Required For Induction Motors?

What are some practical applications for induction motors

Jun 01, 2017 Induction motor is most widely employed motors in Electrical Industry and almost 90% industry machines are of Induction motors First of all the most common example is Electric Fan at our home which uses Single Phase induction Motor In industry IFeb 27, 2018 Tesla made a significant change to its electric motor strategy with the introduction of the Model 3, switching from an AC induction motor to a permanent magnet motor Now, Tesla’s principal Tesla motor designer explains Model 3's transition to why induction motor is used in crushers Why Crusher Motors Have Poor Power Factor Low Power Factor Of Crusher Motor Crusher USA » motor power required for 600 tph double roll crusher » which motor is used for stone crusher for vibrating feedersRelated Articles » difference between a smooth roll crusher and a toothed roll crusher » why crusher motors have poor power factorwhy crusher motors have poor power factorSep 26, 2019 In fact, about 50 percent of global electric power consumption is due to induction motors Let’s get into the workings of induction motors, or more specifically, into Nikola Tesla’s genius thinking Parts of an induction motor An induction motor has 2 How does an induction motor work? Engineeringthrough the grinding and crushing circuits Regardless of the process demand, the motor always ran at full speed With a VFD, the motor speed can be varied to match the material flow requirements and energy can be saved Speed Variation: Beyond energy usage, applications such as conveyors, crushers and grinding mills can use the motorApplication of AC Induction Motors with Variable Frequency

Induction Motor Working Principle Single Phase and Three

Jan 28, 2020 Heavy crushers; The induction motors come in many sizes shapes having relative features and electrical ratings They vary from few centimeters to a few meters in size and have a power rating from 05Hp to 10000Hp The user can choose the most appropriate one from the ocean of models to meet his/her demandthrough the grinding and crushing circuits Regardless of the process demand, the motor always ran at full speed With a VFD, the motor speed can be varied to match the material flow requirements and energy can be saved Speed Variation: Beyond energy usage, applications such as conveyors, crushers and grinding mills can use the motorApplication of AC Induction Motors with Variable Frequency Nov 15, 2020 What is an Induction Motor? An induction motor (also known as an asynchronous motor) is a commonly used AC electric motorIn an induction motor, the electric current in the rotor needed to produce torque is obtained via electromagnetic induction from the rotating magnetic field of the stator winding The rotor of an induction motor can be a squirrel cage rotor or wound type rotorInduction Motor: How Does it Work? (Basics Types A machine that converts electrical energy into mechanical energy is called electric motor These are simple in design, easily used, low cost, high efficiency, low maintenance, and reliable Threephase induction motors are one of the types and different from other types of electric motorsThe main difference is that there is no electrical connection from the rotor winding to any source of supplySquirrel Cage Induction Motor : Construction, Working Oct 05, 2016 3 phase induction motor is the one which operates on three phase AC supply It is the most commonly used motor for high load and industrial applications I would discuss advantages of a 3 phase induction motor later in this article3 Phase Induction Motor The Engineering Projects

Electric motor Construction of induction motors Britannica

Electric motor Electric motor Construction of induction motors: The stator frame consists of laminations of silicon steel, usually with a thickness of about 05 millimetre Lamination is necessary since a voltage is induced along the axial length of the steel as well as in the stator conductors The laminations are insulated from each other usually by a varnish layerSep 26, 2019 In fact, about 50 percent of global electric power consumption is due to induction motors Let’s get into the workings of induction motors, or more specifically, into Nikola Tesla’s genius thinking Parts of an induction motor An induction motor has 2 How does an induction motor work? EngineeringA starter is needed for a three phase induction motor because at the time of starting, if induction motor is started directly, it will draw a huge amount of current which can cause damage to adjoining equipments Hence initailly induction motor will draw heavy amount of current Why starters are required for motors? Starters are []Quick Answer: Why Starters Are Required For Induction Motors?Feb 27, 2018 Tesla made a significant change to its electric motor strategy with the introduction of the Model 3, switching from an AC induction motor to a permanent magnet motor Now, Tesla’s principal Tesla motor designer explains Model 3's transition to Mar 18, 2017 A single phase induction motor is not a selfstarting motor, so it requires some starting means for working That is an initial torque is required for the motor to get started The starting torque can be given to the motor by applying a mechanical rotation to the motor shaft Once the motor has started it can continue its rotation unless its Why Capacitor Used in Fan or Motor : How to Explain

Induction motor Wikipedia

An induction motor or asynchronous motor is an AC electric motor in which the electric current in the rotor needed to produce torque is obtained by electromagnetic induction from the magnetic field of the stator winding An induction motor can therefore be made without electrical connections to the rotor An induction motor's rotor can be either wound type or squirrelcage typeInduction Motor, AC Electric Motors, Electric Motor Sales manufacturer / supplier in China, offering High Efficiency AC Induction Motor for Crusher Convey Use, Ie3 Series Aluminum Housing Three Phase Induction Motor, QdpH Submersible Water Pump Used for High Efficiency AC Induction Motor for Crusher Convey UseThe Wound rotor induction motors are also used for loads having high inertia, which results in higher energy losses Used for the loads which require a gradual buildup of torque Used for the loads that require speed control The wound rotor induction motors are used in conveyors, cranes, pumps, elevators and compressorsApplications of Induction Motor Polyphase Wound Rotor A crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher Wikipedia