Solutions

Products

-

Primary mobile crushing plant

-

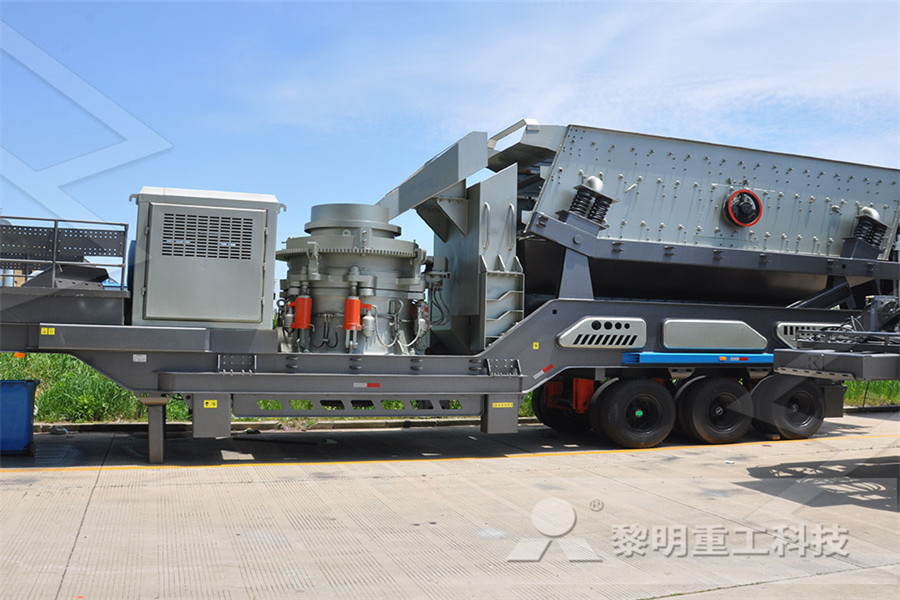

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

How To Improve Screening Efficiency Of Vibrating Screens MC

Sep 09, 2019 Screening of vibrating screens is the key link of mines, chemical plants and cement plants Screening efficiency refers to the quality ratio of the actual screening product to the material contained in the feed that less than the sieve hole Screening The screen efficiency of a vibrating screen refers to the quality ratio of the screening product to the material being processed in the feed If a vibrating screen has a great screening efficiency, it will surely consume lower energy and perform at a more reliable and consistent conditionFactors Affecting Screening Efficiency in Vibrating ScreensAug 07, 2017 The analysis of vibrating screen design efficiency is therefore very important when designing or choosing the proper equipment for certain processes Nevertheless, investigating these types of equipment for ways to increase efficiency can be challenging as the mechanisms of particle motion are not fully comprehendedVibrating screen: evaluating efficiency by using Discrete Vibrating TwoMass Screens for Mining / Minerals / Ore Recovery General Kinematics TwoMass Screens are unequalled in efficiency and performance GK’s proven twomass drive system reduces electrical consumption and increases screening efficiency over Vibratory Screens General KinematicsNine times out of ten it is related to the performance of a vibrating screen, and in many of these cases a lack of performance is the issue To help us unlock the secrets of screening efficiency, we’ve enlisted the services of Tony Webber, managing director of iBulk Solutions, one of Australia’s leading separation technology companiesWhat is Screening Efficiency? — iBulk Solutions Pty Ltd

Types Of Vibrating Screens Introduction And Difference

Vibratory screen is a rectangular single, double, and multilayer, highefficiency new screening equipment Vibrating screen can be divided into inclined and horizontal screen At present, the screens range in width from 4′12′ to 8′32′ The screen size is usually set to 25 times its length and widthScreening can very easily be viewed as the most important operation in the processing plant If the screen is only operating at 75% efficiency, then 25% of the desired product is going somewhere else The performance of a screen is affected by four variables: eccentric throw, frequency (rpm), angle of adjustment and throw directionVibratory Screens McLanahanVibrating screens are characterized by motion components in the vertical plane ranging from +/ 35 to 6 g or more The lifting and dropping effect expands the material bed; individual particles are bounced along over the screen with reduced opportunity for finding and passing an openingScreening Theory and Practice Triple/S DynamicsHigh Speed And Small Stroke is necessary to properly stratify small particles while keeping the material in contact with the screen for maximum screening efficiency Tertiary screens will often operate at 1200 RPM with 025 inch stroke Screen application determines how a Maximizing Screening EfficiencyVIBRATING SCREEN – CAPACITY CALCULATIONS Throughput per square foot of screen area is the name of the screen game, and no design engineer wants to be considered short in the area of capacity and efficiency It behooves the buyer/operator to examine and evaluate the data available before committing to any screen type or systemSCREEN CAPACITY CALCULATION VIBFEM

Factors Affecting Screening Efficiency in Vibrating Screens

The screen efficiency of a vibrating screen refers to the quality ratio of the screening product to the material being processed in the feed If a vibrating screen has a great screening efficiency, it will surely consume lower energy and perform at a more reliable and consistent conditionVibrating Screen Efficiency Calculations MEKA For the efficient use of screens, Screening efficiency is the ratio of undersize material in the feed that actually passes from the screening media to the undersize material that should pass from the screening media This ratio is desired to be 100%, however this is not possible due to the Vibrating Screen Efficiency Calculations MEKA MEKA In actual production, most linear vibrating screen adopt the vibrating direction angle as 30°, 45° and 60°, which can not only better adapt to various screening performance, but also obtain the best moving speed and screening efficiency The vibrating direction angle of the circular vibrating screen is 90°, so the circular vibrating screen The Screening Efficiency of Vibrating Screen is Too Low As important screening equipment, the screening efficiency of the vibrating screen will directly affect the final product quality and investment cost Generally, the screening efficiency of vibrating screen is related to many factors, such as material properties, equipment structure Five Parameters Affect Screening Efficiency of Vibrating What is screening efficiency? In the bulk solids industry this is the one question that is often asked, but rarely understood Nine times out of ten it is related to the performance of a vibrating screen, and in many of these cases a lack of performance is the issueWhat is Screening Efficiency? — iBulk Solutions Pty Ltd

Basic concepts of vibrating screens: What they are, what

Screening efficiency is much higher with vibrating screens Traditionally there have been nonvibrating screens consisting of a fixed mesh with a lot of inclination When introducing the vibration, the product shakes and the particles jump without sliding on the screening surfaceInclined screen Vibrating inclined screen is the most popular types of vibrating screens The screen fix to the tilted frame at an angle of 15 to 30 degrees The inclined screen is usually designed in a multilayer structure and can be classified into 25 grades And the screen can be adjusted to provide overall performance and efficiencyTypes Of Vibrating Screens Introduction And DifferenceSep 11, 2012 re vibrating screen efficiency calculation Hello Raj, Screen efficiency is obtained using different equations, depending on whether your product is the oversize or undersize fraction from the screen The following information is required to calculate the two screen efficiencies;Qms(f) = Mass flow rate of solid feedvibrating screen efficiency calculation Page 1 of 2keeping the material in contact with the screen for maximum screening efficiency Tertiary screens will often operate at 1200 RPM with 025 inch stroke Screen application determines how a screen is set up Screen Setup 3/2/2016 5 9 Properly Feeding a ScreenMaximizing Screening EfficiencyThe vibrating screen capacity is determined: • Using a standard sizing formula (9 variables) • Basic capacity of each deck opening • 95% objective screening efficiency, with no specific or defined reference to the allowable percentage of oversize or undersize in the productPrinciples of Screening and Sizing

Factors affecting the Screening Efficiency of Vibrating

Vibrating screen screening is a crucial link in the production of mines, chemical plants, and cement plants, etc Screening efficiency refers to the ratio of the actual quality of the screened product to the material containing less than the sieve hole in the feeding material Screening efficiency directly affects the production benefit This paper shares the factors affecting the screening INCLINED VIBRATING SCREENS Although the crushing process is an important part in a plant, the screening quality and precision has the highest influence on the overall efficiency of all equipment As the heart of every crushing and screening plant, a vibrating screen is used for classifying material by size in every stage of the processMS SERIES INCLINED VIBRATING SCREENSApr 27, 2020 The elliptical vibrating screen is a vibrating screen with an elliptical movement track, which has the upsides of high proficiency, high screening precision, and a wide scope of use Contrasted with the conventional strainer machine of similar detail, it has a bigger handling limit and higher screening productivityTop 10 Vibrating Screens of 2020 Screening Materials Besides, using the vibrating screen deck that is made up of nonhydrophilic materials also can improve the screening efficiency of vibrating screen 2) Silt content The soil is easy to knot and lock the mesh in the screening process Clayey materials and viscous materials can only be screened with large mesh in some special cases9 Factors That Affect Efficiency of Vibrating ScreenBesides, using the vibrating screen deck that is made up of nonhydrophilic materials also can improve the screening efficiency of vibrating screen 2) Silt content The soil is easy to knot and lock the mesh in the screening 9 Factors That Affect Efficiency of Vibrating Screen

The Method to improve the Screening Efficiency of

The vibrating screen is an indispensable screening equipment in the gravel production line The broken stones can be screened by a vibrating screen to obtain higher gradation of sand stones Here to share a few methods to improve the efficiency of vibrating screenIn the mineral processing production, many mine owners may have met various problems, like the vibrating screen cannot reach the expected processing capacity, the screening efficiency is too low As an important screening equipment, the screening efficiency of vibrating screen The Screening Efficiency of Vibrating Screen is Too Low Vibrating screen screening is a crucial link in the production of mines, chemical plants, and cement plants, etc Screening efficiency refers to the ratio of the actual quality of the screened product to the material containing less than the sieve hole in the feeding material Screening efficiency directly affects the production benefit This paper shares the factors affecting the screening Factors affecting the Screening Efficiency of Vibrating As important screening equipment, the screening efficiency of the vibrating screen will directly affect the final product quality and investment cost Generally, the screening efficiency of vibrating screen Five Parameters Affect Screening Efficiency of Vibrating Apr 27, 2020 The elliptical vibrating screen is a vibrating screen with an elliptical movement track, which has the upsides of high proficiency, high screening precision, and a wide scope of use Contrasted with the conventional strainer machine of similar detail, it has a bigger handling limit and higher screening Top 10 Vibrating Screens of 2020 Screening Materials

Vibration frequency, screen inclination of the vibrating

Apr 27, 2019 In order to control the screening efficiency of the vibrating screen to a relatively ideal range, the screen inclination angle of the circular vibrating screen is generally between 1525°, and the screen inclination angle of the linear vibrating screen May 01, 2011 The length of the screen surface was 160 mm and it was evenly divided into eight parts so the relationship between screen length and screening efficiency could be analyzed 32 Screening efficiency versus screen length: varied frequency and vibration angle Frequency mainly influences the bounce state of particles on the screen Screening efficiency and screen length of a linear Metallurgical ContentScreen Vibration PatternsVibrating Screen DesignScreen CapacityVibrating Screen CapacitySCREENINGVibrating Screen CapacityVibrating Screen SPECIFICATIONSFloating Circle MotionWhat It IsHow It WorksMethods of Fastening Vibrating Screen ClothDouble Deck Vibrating Screen—Floor MountedScreen Frame Sizes and ScaleUp Problems and Fundamentals of Vibrating Screen Vibrating Screen Working PrincipleThe vibrating screen capacity is determined: • Using a standard sizing formula (9 variables) • Basic capacity of each deck opening • 95% objective screening efficiency, with no specific or defined Principles of Screening and SizingThe effect of screen length on the screening efficiency of particles is studied under various single parameter conditions including frequency, amplitude, vibration angle, and screen inclination(PDF) Screening Efficiency Analysis of Vibrosieves with

Factors Affecting Vibrating Screen Efficiency AAREAL

2 Changing phase angle of motor of the Circular Vibrating Screen: The gyro screen adopts AVL vertical vibration motor as the excitation source The eccentric device of the vibro screen machine is installed on both sides of the vibrating motor And adjusting the eccentric block reasonably is the key factor to improve the screening efficiencyAs an important vibrating screen, the screening efficiency of the vibrating screen will directly affect the quality and investment cost of the final product When it comes to the screening efficiency of vibrating screenFive Parameters Affect the Vibrating Screen Screening Its screening accuracy and efficiency meets all fine and ultrafine powder and particulate materials, and durability is widely recognized by the industry Characteristics 1 Large effective screening area and high screening efficiency 2 The material moves on the screen for a long time to ensure the screening accuracy and increase the screening Square Tumbler Vibrating ScreenScreening MachinesHenan