Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

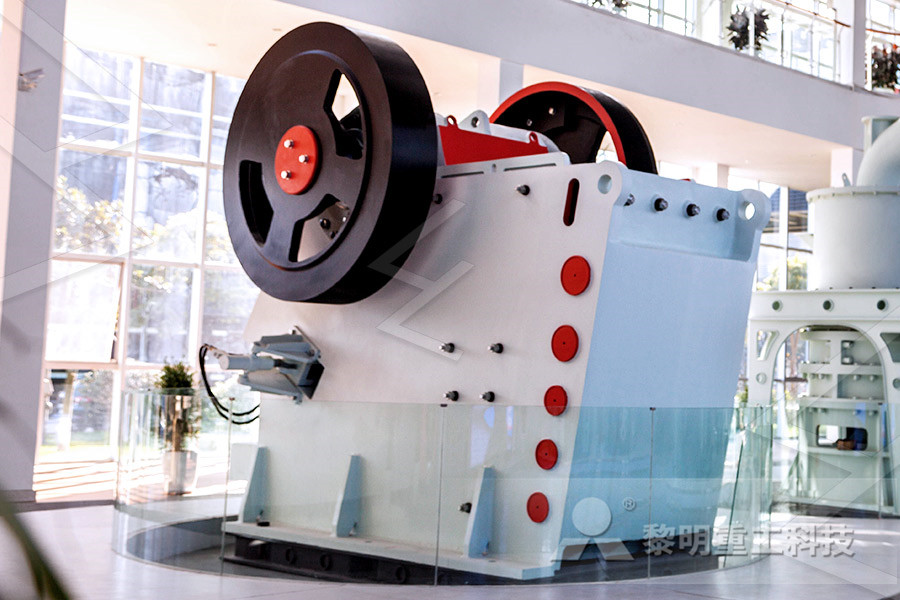

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Froth Flotation Process Detailed Explanation With

Apr 06, 2020 What is Froth Flotation Process? Froth flotation is one of the most popular operational processes for mineral beneficiation In ore/mineral beneficiation, froth flotation is a method by which commercially important minerals are separated from impurities and other minerals by collecting them on the surface of a froth layerFroth flotation is a physicochemical process that separates particles based on differences in surface wettability Flotation takes place by passing finely dispersed air bubbles through an aqueous suspension of particles (Fig 17) A chemical reagent, called a frother, is Flotation Froth an overview ScienceDirect TopicsDec 17, 2020 The mining uses of froth flotation include the separation of many different types of compounds including sulfides, silicates, phosphates, coal, and iron ore Reagents or surfactants are carefully chosen to produce exactly the separation effect desired for a What is Froth Flotation?The common gold extraction processes include gravity separation process, froth flotation process, cyanidation, etc Froth flotation process is the most widely used in gold extraction, but for different types of gold, we can choose flotation process combined processin order to improve the return on investment4 Types of Gold Ore Froth Flotation Combined ProcessFroth flotation is a highly versatile method for physically separating particles based on differences in the ability of air bubbles to selectively adhere to specific mineral surfaces in a mineral/water slurry1 Froth Flotation – Fundamental Principles

Frothers Quadra

In its simplest form, froth flotation is a method whereby minerals can be “skimmed” from the surface of “slurry” that is “foamed” with the assistance of specific chemicals, water and air bubbles In mineral processing, frothers are used to produce small persistent air bubblesFroth Flotation Froth flotation is one of the most versatile and flexible of all mineral separation processes Reasonable results are fairly easy to obtain but outstanding performance from a circuit requires constant attention and good understanding of the process and oreFroth Flotation Metallurgist Mineral Processing EngineerSep 14, 2011 Froth flotation is a three phase separation process for complex ores based on the manipulation of the difference in hydrophobicity of the solids Suspended, hydrophobic metalrich particles are contacted with, and subsequently combine to, air bubbles — whilst the more hydrophilic gangue particles sink and are recovered to the tails streamA review of froth flotation control ScienceDirectFigure 1: The flotation system includes many interrelated components, and changes in one area will produce compensating effects in other areas (Klimpel, 1995) Froth flotation is a good example of an engineering “system”, in that the various important parameters are highly interrelated, as 1 Froth Flotation – Fundamental PrinciplesSep 14, 2011 Examples include: entrainment of gangue into the froth phase, coalescence of bubbles, deattachment of valuable particles from bubbles as they impact the froth phase, etc (VenturaMedina, 2000) The feed composition and upstream grinding stages prior to flotation A review of froth flotation control ScienceDirect

Frothers Quadra Chemicals

Indorama produces the POLYFROTH® range of frothers for froth flotation This unique range of frothing properties and selectivity is what gives the different Indorama POLYFROTH® frothers their application and performance benefits in all mineral sectors of the mining industry, including base metal sulphides, precious metals (gold, silver, PGEs), industrial minerals, coal and various other non Our range of flotation solutions include frother and collector programs for coal, copper, molybdenum, phosphate, potash, and more All of our solutions address your process holistically, helping you optimize your flotation circuit to achieve greater selectivity, recovery, grade, and ultimately, cost performanceFlotation Solutions Maximizing Mineral Recovery EcolabFroth Flotation Froth flotation has been used to separate discrete mineral particles since the early 1900’s The key to effective separation of the minerals depends on differences in the surface chemistry of the minerals to be separated The process involves the McClelland Laboratories Inc Reno (775) 3561300 Mineral Outotec ACT simplifies froth speed control for the cameraequipped flotation machines, and can even help to build a comprehensive graderecovery system for the optimization of the entire flotation circuit Advantages include: Highquality digital network cameras; FrothSense Sensor System Outotecsize range for efficient froth flotation as a result of increased probabilities of particlebubble collision and attachment and reduced probability of detachment The major advantages of nanobubble enhanced flotation include lower collector and frother dosages since nanobubbles that are mostly smaller than 1 µm can be formedCAVITATION NANOBUBBLE ENHANCED FLOTATION

Mineral processing Wikipedia

Froth flotation is an important concentration process This process can be used to separate any two different particles and operated by the surface chemistry of the particles In flotation, bubbles are introduced into a pulp and the bubbles rise through the pulp In the process, hydrophobic particles become bound to the surface of the bubblesExamples of these applications include the use of such models in comminution [7][8][9][10], froth flotation systems [11] [12] [13][14][15][16], sensorbased ore sorting [17], and blast Purities prediction in a manufacturing froth flotation Froth flotation is the most widely used procedure for beneficiation of Accessory minerals present include beryl, columbitetantolite and apatite Traces of cassiterite, zircon, arsenopyrite, garnet, tourmaline, topaz, pyrite and chalcopyrite are also presentOptimisation of spodumene flotationThe froth flotation chemicals market is expected to register a CAGR of over 3%, during the forecast period The major factors driving the market studied include rising demand for froth flotation chemicals in AsiaPacific and increasing mining activities in Canada and MexicoFroth Flotation Chemicals Market 20202027 Industry The global froth flotation chemicals market is expected to grow at a CAGR of over 3% during the forecast period of 2019 – 2024 The major factors driving the market studied include rising demand for froth flotation chemicals in AsiaPacific and increasing mining activities in Canada and MexicoFroth Flotation Chemicals Market 2020 – Report Covers Key

Froth Flotation Hazen Research

Flotation techniques we have used in addition to the ordinary airfroth type include unusual procedures such as ion, precipitate, and agglomeration flotation using inert gas, air, or in situ gas generation We have applied dissolved air flotation to special situations and are familiar with various forms of "piggyback" flotation proceduresA froth flotation apparatus includes a gas bubbleparticle contact unit including a mixing means for breaking a gas into fine bubbles, such as a packed tower packing or mechanical agitation means, and a separate phase separation unit A conditioned aqueous pulp containing a mixture of hydrophobic and hydrophilic particles and a substantially Froth flotation Board of Control of Michigan Tech Flotation techniques we have used in addition to the ordinary airfroth type include unusual procedures such as ion, precipitate, and agglomeration flotation using inert gas, air, or in situ gas generation We have applied dissolved air flotation to special situations and are familiar with various forms of "piggyback" flotation Froth Flotation Hazen ResearchThe Handling Materials and Description of Froth Flotation: Froth Flotation is widely used for roughing, concentrating and recovering flotation of nonferrous metals that include copper, lead, zinc, nickel and molybdenum, ferrous metal, It can also be used for separating nonmetallic minerals like coal and fluorite The Advantages and Benefits of Froth Flotation:Froth Flotation machineOur range of flotation solutions include frother and collector programs for coal, copper, molybdenum, phosphate, potash, and more All of our solutions address your process holistically, helping you optimize your flotation circuit to achieve greater selectivity, recovery, grade, and ultimately, cost performanceFlotation Solutions Maximizing Mineral Recovery Ecolab

Surface Chemistry of Froth Flotation: Volume 1

th The technology of froth flotation, invented in the early 20 century was first used for the concentration of sulfide minerals Since then it has been applied for the processing of many nonsulfide ores as weIl, including oxides, carbonates, silicates, soluble minerals like halite and sylvite and energy minerals like coal and bitumenOutotec ACT simplifies froth speed control for the cameraequipped flotation machines, and can even help to build a comprehensive graderecovery system for the optimization of the entire flotation circuit Advantages include: Highquality digital network cameras; FrothSense Sensor System OutotecFroth flotation is an important concentration process This process can be used to separate any two different particles and operated by the surface chemistry of the particles In flotation, bubbles are introduced into a pulp and the bubbles rise through the pulp In the process, hydrophobic particles become bound to the surface of the bubblesMineral processing WikipediaExamples of these applications include the use of such models in comminution [7][8][9][10], froth flotation systems [11] [12] [13][14][15][16], sensorbased ore sorting [17], and blast Purities prediction in a manufacturing froth flotation Froth flotation is the most widely used procedure for beneficiation of Accessory minerals present include beryl, columbitetantolite and apatite Traces of cassiterite, zircon, arsenopyrite, garnet, tourmaline, topaz, pyrite and chalcopyrite are also presentOptimisation of spodumene flotation

Flotation Wear Components Multotec

Get all the wear components you need for your froth flotation plant from Multotec Highquality, hardwearing and available with short delivery times, wherever your plant is, we manufacture replaceable flotation wear components for all flotation cell types and sizesJan 30, 2015 Floatation Column Typical industrial column cell comprises a steel tank equipped with a feed inlet pipe near the top of the column, a system of internal and external launders to collect and remove froth and a slurry outlet near the bottom of the tank to remove nonfloating material Drain nozzle and a series of re pulping nozzles are also Floatation SlideShareA froth flotation apparatus includes a gas bubbleparticle contact unit including a mixing means for breaking a gas into fine bubbles, such as a packed tower packing or mechanical agitation means, and a separate phase separation unit A conditioned aqueous pulp containing a mixture of hydrophobic and hydrophilic particles and a substantially Froth flotation Board of Control of Michigan Tech In the frothflotation process, pine oil functions as a frothing agent or foaming agent Other frothing agents include eucalyptus oil, xanthates or fatty acids The frothing agent forms a foam (or frothIn froth flotation process, pine oil functions as a(an):More than 70% of potash is produced worldwide by froth flotation Flotation of potash was developed in the early 1930s Amines are widely used for flotation of sylvite (KCl) from halite (NaCl) and insoluble materials such as clays The unique features of potash flotation include solubility of sylvite in water, the size of particles floated An Overview Of Potash Flotation Hatch Ltd

Recovering Gold through the Froth Flotation Process

Feb 06, 2018 Later innovations include the MacArthurForrest Process and borax flux extraction However, one of the most interesting methods is froth flotation Froth flotation works by exploiting the hydrophobic properties of gold molecules First, ore is ground into an extremely fine powder The powdered ore is mixed with water to create a slurry, which