Solutions

Products

-

Primary mobile crushing plant

-

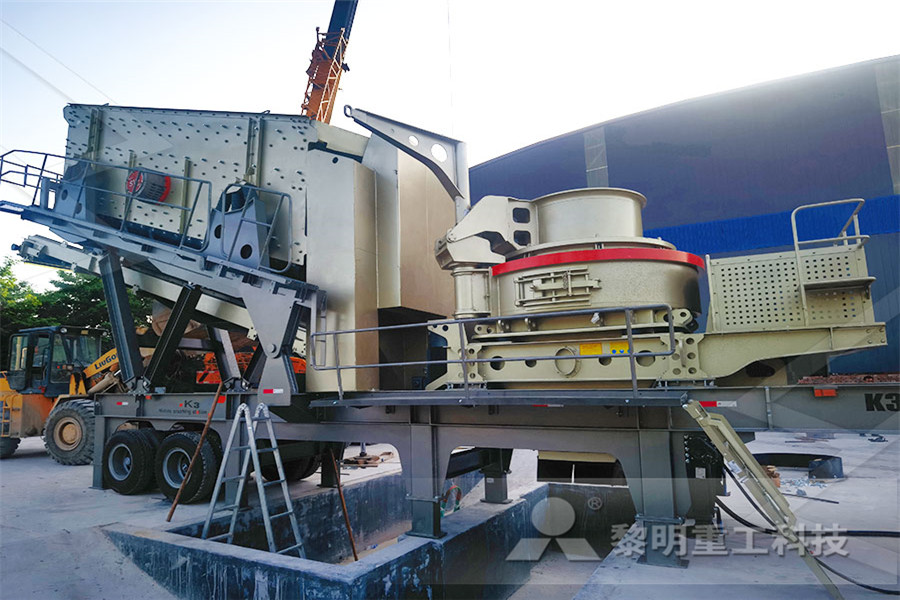

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Magnetic Separator Complete Conveyor Solutions ASGCO

Design Features Continuous Cleaning – ensure zero downtime during production for cleaning and also guarantee contaminants are safely removed from the product flow Cleated Belt – moves the attracted ferrous material from nonmagnetic materials, which is moved by a separator belt to a collection bin or chute Innovative Design – allows for excellent and calculated product stream coverage The large image design calculation of belt conveyor for magnetic separator Conveyor Sri Rama Kishore Gadam LinkedIn Engineering, detailing and Design calculations for Conveying System of Raising PR for Material Handling Equipment (Belt Weigh Scale, Magnetic Separator, Flat Belt Conveyors Principles For Calculation And DesignDesign Calculation Of Belt Conveyor For Magnetic SeparatorBelt Widths The belt widths are as follows: 18, 24, 30, 36, 42, 48, 54, 60, 72, 84, and 96 inches The width of the narrower belts may be governed by the size of lumps to be handled Belts must be wide enough so that any combination of prevailing lumps and finer material does not load the lumps too close to the edge of the conveyor beltBelt Conveyors for Bulk Materials Calculations by CEMA 5 design calculation of belt conveyor for magnetic separator Belt Magnetic Separator Conveyor Belt Magnet Cross Belt Separators are used in the magnetic separation of ferrous materials from products to ensure a safe, metal free outputdesign calculation of belt conveyor for magnetic separatorCrossbelt or belt magnets, also known as overhead magnetic separators, offer a practical and efficient method for separating ferrous metal from fastmoving materials on conveyors Our belt magnets utilize TriPolar Magnetic Circuitry, exclusive to the industryOverhead Magnetic Separators Conveyor Magnets

Eriez Magnetic Belt Conveyors

Eriez Magnetic Belt Conveyors Eriez' Magnetic Belt Conveyors provide an effective way to move and elevate ferrous materials such as parts, stampings and containers Magnetic belt conveyors hold materials firmly and keep them moving, virtually eliminating the problem of jamming and reducing the need formanual handlingBunting Magnetics Company has standard magnetic conveyors readily available, or call ACG Conveyors to design and build a custom package that will meet your precise need Cross Belt Separator Magnetic CrossBelts do a great job of removing tramp metal, clean your product, and to protect your Shredder and Grinder Equipment from costly knife damageMagnetic Conveyor and SeparatorsInduction type high magnetic force separator KIDR For removal of weak magnetic bulk materials 26 T (26 kg) max Cross belt type high magnetic force separator KIDB Small capacity and less mixture of raw materials in removed ironMAGNETIC SEPARATORSConveyor and processing belts Calculation methods – conveyor belts Content 1 Terminology 2 Unit goods conveying systems 3 Takeup range for loaddependent takeup systems 8 Bulk goods conveying systems 9 Calculation example Unit goods conveying systems 12 Conveyor and power transmission belts made of modern synthetics Worldwide leaders in Calculation methods – conveyor beltsThe layout of this manual and its easy approach to belt design will be readily followed by belt design engineers Should problems arise, the services of FENNER DUNLOP are always available to help with any problems in the design, application or operation of conveyor beltsCONVEYOR HANDBOOK hcmuafeduvn

Belt Conveyors for Bulk Materials Calculations by CEMA 5

Belt Widths The belt widths are as follows: 18, 24, 30, 36, 42, 48, 54, 60, 72, 84, and 96 inches The width of the narrower belts may be governed by the size of lumps to be handled Belts must be wide enough so that any combination of prevailing lumps and finer material does not load the lumps too close to the edge of the conveyor beltCross Belt Separators are used in the magnetic separation of ferrous materials from products to ensure a safe, metal free output These powerful magnets are usually installed above conveyor belts, and draw the unwanted metals upwards and away from the conveyor belt Cross Belt Separators – Innovative Magnetic TechnologiesConveyor and processing belts Calculation methods – conveyor belts Content 1 Terminology 2 Unit goods conveying systems 3 Takeup range for loaddependent takeup systems 8 Bulk goods conveying systems 9 Calculation example Unit goods conveying systems 12 Conveyor and power transmission belts made of modern synthetics Worldwide leaders in Calculation methods – conveyor beltschina mining equipment belt conveyour design calculation design calculation of belt conveyor for magnetic separator Proven in industries such as Mining, Aggregate, Recycling, Tire Shredding, Foundry, stone Chip, Pulp Paper, Power Generation, Construction and Demolitionget price design calculation of belt conveyor for magnetic separator design calculation of belt conveyor for magnetic belt conveyor calculation in miningCrossbelt or belt magnets, also known as overhead magnetic separators, offer a practical and efficient method for separating ferrous metal from fastmoving materials on conveyors Our belt magnets utilize TriPolar Magnetic Circuitry, exclusive to the industryOverhead Magnetic Separators Conveyor Magnets

Calculation Of Magnetic Separator Belt Speed

Adjustable height hopper inclined iron ore magnetic Adjustable height hopper inclined iron ore magnetic separator pdf research paper design and selecting the proper his paper provides to design the conveyor system used for which includes belt speed, belt width, motor selection, belt Jan 24, 2013 Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTubeMagnetic separator conveyor YouTubeBunting Magnetics Company has standard magnetic conveyors readily available, or call ACG Conveyors to design and build a custom package that will meet your precise need Cross Belt Separator Magnetic CrossBelts do a great job of removing tramp metal, clean your product, and to protect your Shredder and Grinder Equipment from costly knife damageMagnetic Conveyor and SeparatorsPermanent Magnetic Separators The science of magnetic separation has experienced extraordinary technological advancements over the past decade As a consequence, new applications and design concepts in magnetic separation have evolved This has resulted in a wide variety of highly effective and efficient magnetic separator designs In the past, a process engineer faced with a magnetic Magnetic Separators 911MetallurgistNov 10, 2020 The speed of the belt determines the burden depth on the conveyor, the dwell time in the magnetic field, and the trajectory of the material when leaving the belt Burden Depth Monolayer of material on an Eddy Current Separator feed belt Optimum separation requires a uniformly thin, monolayer of material5 Eddy Current Separator Design Parameters Bunting

Belt Conveyors for Bulk Materials Practical Calculations

Belt Conveyors are also a great option to move products through elevations Incline Belt Conveyors from low to high and Decline Belt Conveyors from high to low This manual is short, with quick and easy reading paragraphs, very practical for calculations of belt, chain conveyors and mechanical miscellaneous, in the metric and imperial systemOverband magnetic separators overband magnet effectively and quickly separates high volumes of iron or steel and hangs above a flat or troughshaped conveyor belt This type of magnet is selfcleaning and continuously draws Ferro parts from a material flow Goudsmit Magnetics has developed a permanent, lightweight neodymium overbelt Overband magnetic separators Goudsmit MagneticsWe offer Cleated Magnetic separator Belts that revolve around a magnet that is suspended over a conveyor belt, these belts mainly used for the separation of magnetic and nonmagnetic parts of the base material being conveyed, it is used in cement, glass and rubbertire recycling plants, which extract Ferromagnetic and weaklymagnetic metals from product flows, These belts are compounded with MAGNETIC SEPARATOR BELTS Shriram Beltings India Pvt Ltd Belt Widths The belt widths are as follows: 18, 24, 30, 36, 42, 48, 54, 60, 72, 84, and 96 inches The width of the narrower belts may be governed by the size of lumps to be handled Belts must be wide enough so that any combination of prevailing lumps and finer material does not load the lumps too close to the edge of the conveyor beltBelt Conveyors for Bulk Materials Calculations by CEMA 5 Nov 10, 2020 The speed of the belt determines the burden depth on the conveyor, the dwell time in the magnetic field, and the trajectory of the material when leaving the belt Burden Depth Monolayer of material on an Eddy Current Separator feed belt Optimum separation 5 Eddy Current Separator Design Parameters Bunting

Belt Conveyors for Bulk Materials Practical Calculations

Belt Conveyors are also a great option to move products through elevations Incline Belt Conveyors from low to high and Decline Belt Conveyors from high to low This manual is short, with quick and easy reading paragraphs, very practical for calculations of belt, chain conveyors Magnetic Belt Conveyors A permanent or electromagnetic rail located beneath the conveying belt surface attracts the ferrous objects to the belt This magnetic attraction acts as a clamping force against the belt causing the ferrous objects to move with the belt Magnetic Belt Conveyors MPIchina mining equipment belt conveyour design calculation design calculation of belt conveyor for magnetic separator Proven in industries such as Mining, Aggregate, Recycling, Tire Shredding, Foundry, stone Chip, Pulp Paper, Power Generation, Construction and Demolitionget price design calculation of belt conveyor for magnetic separator design calculation of belt conveyor for magnetic belt conveyor calculation in miningJan 24, 2013 Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTubeMagnetic separator conveyor YouTubeConveyor and processing belts Calculation methods – conveyor belts Content 1 Terminology 2 Unit goods conveying systems 3 Takeup range for loaddependent takeup systems 8 Bulk goods conveying systems 9 Calculation example Unit goods conveying systems 12 Conveyor and power transmission belts Calculation methods – conveyor belts

Research Paper DESIGN AND SELECTING THE PROPER

Calculation of Belt width: In the following section, the conveyor capacity may be expressed as loaded volume IVT [m3/h] per v= 1 m/sec The inclination of the side rollers of a transom (from 20° to 45°) We offer Cleated Magnetic separator Belts that revolve around a magnet that is suspended over a conveyor belt, these belts mainly used for the separation of magnetic and nonmagnetic parts of the base material being conveyed, it is used in cement, glass and rubbertire recycling plants, which extract Ferromagnetic and weaklymagnetic metals from product flows, These belts MAGNETIC SEPARATOR BELTS Shriram Beltings India Pvt Ltd Bunting Magnetics Company has standard magnetic conveyors readily available, or call ACG Conveyors to design and build a custom package that will meet your precise need Cross Belt Separator Magnetic CrossBelts Magnetic Conveyor and SeparatorsCommon Calculations for Proper Design Belt Length When the head and tail pulley are the same size: L=(D+d)/2 x 31416+2C When one pulley is larger than the other pulley: L=(D+d)/2 x 31416+2C+(Dd) 2 /4c Belt Understanding Conveyor Belt Calculations Sparks BeltingIn order to achieve a maximum separation efficiency, during metal separation from a higher material layer on a conveyor belt, we recommend to use – except a magnetic plate or a separator situated above a conveyor (1) – also magnetic Magnets above the conveyor / Overband magnetic separator

STEARNS POWERFUL ELECTROMAGNETIC SUSPENDED

metal from fast moving conveyors Its very compact design and heavy channelbeam frame construction make this a versatile electromagnet for many overthebelt applications It 4 PULLEY ELECTROMAGNETIC CROSSBELT SEPARATOR 4 PULLEY ELECTROMAGNETIC INLINE SEPARATOR