Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

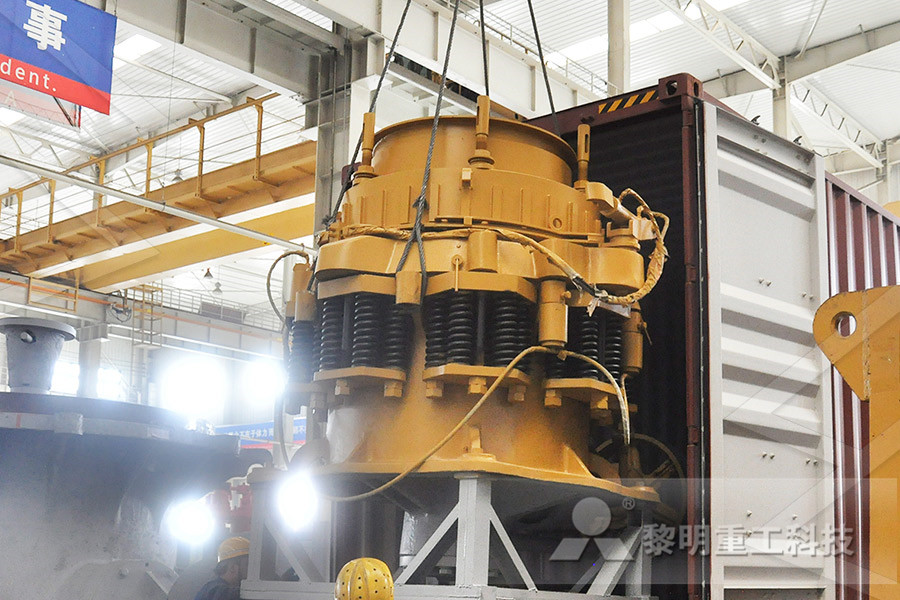

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Recycled Aggregate Concrete: Applications,

Recycled aggregate concrete (RAC) is produced in three major steps: Evaluation of Source concrete: The first step in production of RAC is to determine the quality of the source concrete Properties and records of source concrete like strength, durability and composition are looked into for deciding the proper source concreteA research investigated the e ects of recycled concrete aggregate (RCA) on workability of concrete using water cement ratios: 050, 060 and 065 and their test results revealed that RCA signi Properties of HighWorkability Concrete with 07072015 The second study examines how the workability and compressive strength characteristics of concrete mixes are affected when varying amount of recycled concrete fines are used as cement replacement Experimental procedures for both studies involved the breaking and crushing of cast concrete blocks to produce recycled materialsSustainable Construction: Use of Recycled RCA The recycled aggregate concrete is made by mixing 60% of recycled aggregates with 40% of crushed stone chips The aggregates used for concrete batching are maintained at saturated surface dry condition The workability of the recycled aggregate concrete is slightly lower than that of the conventional concrete TheA STUDY ON RECYCLED CONCRETE AGGREGATESthat workability decreases as the percentage replacement increases and workability increases with increase in W/C ratio Thus the use of recycled aggregates in concrete reduces the workability of the concrete Table41: Compaction factor results for NAC and RAC % replacemen t 0% 30% 35 % 40% 45% 50% Compactio n factor (027 w/c) 088 3Optimization of Recycled Aggregate Concrete

Recycled Concrete Aggregate an overview

Recycled concrete aggregate (RCA) are aggregates obtained by recycling clean concrete waste where content of other building waste must be very low – below few per cent For instance, British standard BS 85002 ( BSI, 2006 ) defines RCA as recycled aggregate with maximum masonry/fines content of 5%, maximum lightweight material/asphalt content of 05% and maximum other foreign 27 RECYCLED AGGREGATE CONCRETE: A SUSTAINABLE BUILT ENVIRONMENT In the present study the influence of recycled coarse aggregate (RCA) obtained from three different sources having different ages of structures are on the properties of recycled aggregate concrete (RAC) are investigated RAC mixes are prepared with each source of RCA separatelyMechanical Properties Of Recycled Aggregates 01052018 1 Introduction Recycled aggregate (RA) derived from construction and demolition waste is suitable for partial or entire replacement for virgin aggregate when making new concrete Using waste concrete as RA could save about 60% of limestone resources and reduce CO2 emissions by Durability of recycled aggregate concrete – A RA mixed with fresh water TWW mixed with normal aggregates Workability Slump values of recycled aggregate concrete (RAC) decrease with increasing percentage replacement of RA Durability of recycled aggregate concrete Request Recycled aggregate concrete RAC is concrete made from recycled aggregate It was found that the workability of fresh RAC decreases with an increase in recycled aggregate due to water absorption of mortar adhered to recycled aggregate 6 The strength of RAC is reported to be less by about 10 compared to normal concrete 8 9workability of recycled concrete aggregate

Workability and Rheology of Fresh Recycled

The higher heterogeneity in terms of experimental slump measure occurs indeed when recycled aggregate concrete is tested In this chapter, a review of the existing experimental methods for the evaluation of fresh concrete workability is givenrecycled aggregate concrete (RCA) as a substitute for virgin coarse aggregate in the compressive strength of `plain concrete workability of concrete with natural and recycled aggregate is almost the same if ―water saturated—surface dry recycled aggregate is usedA Review Paper on use of Recycled Aggregates in ConcretePhysical and mechanical characteristics of recycled concrete aggregate (RCA) acquired from concrete waste are thoroughly examined Though the RCA exhibited relatively lesser performance compared with the natural coarse aggregate (NCA), it reveals the same properties as of normalweight aggregates in several instancesSuitability Investigation of Recycled Concrete 07072015 The second study examines how the workability and compressive strength characteristics of concrete mixes are affected when varying amount of recycled concrete fines are used as cement replacement Experimental procedures for both studies involved the breaking and crushing of cast concrete blocks to produce recycled materialsSustainable Construction: Use of Recycled that workability decreases as the percentage replacement increases and workability increases with increase in W/C ratio Thus the use of recycled aggregates in concrete reduces the workability of the concrete Table41: Compaction factor results for NAC and RAC % replacemen t 0% 30% 35 % 40% 45% 50% Compactio n factor (027 w/c) 088 3Optimization of Recycled Aggregate Concrete

PROPERTIES OF RECYCLED AGGREGATE CONCRETE

concrete Keywords: recycled aggregate concrete, construction and demolition waste, concrete properties, research 1 INTRODUCTION Recent floods, that struck our our country and the region, have caused widespread damage, among which damage to building structures is dominant Society is not only faced with the problems of fin27 RECYCLED AGGREGATE CONCRETE: A SUSTAINABLE BUILT ENVIRONMENT In the present study the influence of recycled coarse aggregate (RCA) obtained from three different sources having different ages of structures are on the properties of recycled aggregate concrete (RAC) are investigated RAC mixes are prepared with each source of RCA separatelyMechanical Properties Of Recycled Aggregates recycled aggregate concrete have been reported by many researchers, but higher grade activities are seldom reported, because of its personal property on workability, strength and durability The scope of this project is to decide and to examine the high Experimental Study on High Strength Concrete with Recycled Recycled aggregate concrete RAC is concrete made from recycled aggregate It was found that the workability of fresh RAC decreases with an increase in recycled aggregate due to water absorption of mortar adhered to recycled aggregate 6 The strength of RAC is reported to be less by about 10 compared to normal concrete 8 9workability of recycled concrete aggregatethe demolished concrete aggregate 10%, 20%, 30% by weight of the conventional coarse aggregate and the concrete cubes were casted by that demolished concrete aggregate then further tests conducted such as workability , compressive strength for that DAC and the result obtained are found to be comparable with the conventional concretePartial Replacement of Coarse Aggregate with Demolished

Sustainable Construction: Use of Recycled

07072015 The second study examines how the workability and compressive strength characteristics of concrete mixes are affected when varying amount of recycled concrete fines are used as cement replacement Experimental procedures for both studies involved the breaking and crushing of cast concrete blocks to produce recycled materialsrecycled aggregate concrete (RCA) as a substitute for virgin coarse aggregate in the compressive strength of `plain concrete workability of concrete with natural and recycled aggregate is almost the same if ―water saturated—surface dry recycled aggregate is usedA Review Paper on use of Recycled Aggregates in ConcreteThis study presents the effects of recycled concrete aggregate (RCA) on the key fresh and hardened properties of concrete RCA was used to produce highworkability concrete substituting 0100% natural coarse aggregate (NCA) by weight The slump andProperties of highworkability concrete with that workability decreases as the percentage replacement increases and workability increases with increase in W/C ratio Thus the use of recycled aggregates in concrete reduces the workability of the concrete Table41: Compaction factor results for NAC and RAC % replacemen t 0% 30% 35 % 40% 45% 50% Compactio n factor (027 w/c) 088 3Optimization of Recycled Aggregate ConcreteRecycled concrete aggregate (RCA) is generally produced by twostage crushing of demolished concrete, and screening and removal of contaminants such as reinforcement, paper, wood, plastics and gypsum Concrete made with such recycled concrete aggregate is called recycled aggregate concrete (RAC) The main purpose of this work is to determineRecycled Concrete as Aggregate for Structural Concrete

Workability and Compressive Strength of

Concrete waste from construction site such as pile waste and tested concrete cubes waste is quite a problem for the contractor to dispose of This waste is currently being buried or dumped illegally at a certain area, which lead to environmental pollution issue and waste of construction materials In this study, concrete cubes waste from a concrete testing laboratory is crushed and recycled Because recycled aggregate contains mortar from the original concrete, it is more porous and absorptive than many natural aggregates Recycled aggregate had water absorption of 96% The workability of concrete, as the amount of recycled aggregate was increased, the concrete required more water to maintain adequateThe Use of Recycled Concrete Aggregates (RCA) for Concrete mix with 30% recycled aggregate had the lowest chloride penetration after 2 weeks of saturation and performed better than a concrete mix with 100% natural aggregate Owing to the lower density and higher water absorption of recycled aggregates, chloride ion diffusion increased with increasing recycled aggregate content beyond 2#x2009;weeksEffects of Recycled Aggregate on Concrete Mix Recycled aggregate concrete RAC is concrete made from recycled aggregate It was found that the workability of fresh RAC decreases with an increase in recycled aggregate due to water absorption of mortar adhered to recycled aggregate 6 The strength of RAC is reported to be less by about 10 compared to normal concrete 8 9workability of recycled concrete aggregatethe demolished concrete aggregate 10%, 20%, 30% by weight of the conventional coarse aggregate and the concrete cubes were casted by that demolished concrete aggregate then further tests conducted such as workability , compressive strength for that DAC and the result obtained are found to be comparable with the conventional concretePartial Replacement of Coarse Aggregate with Demolished