Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

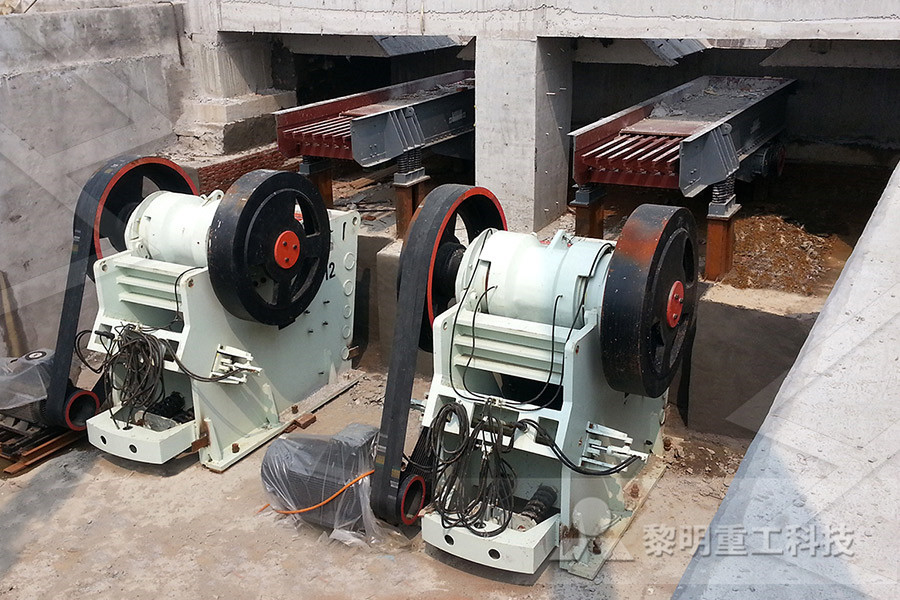

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

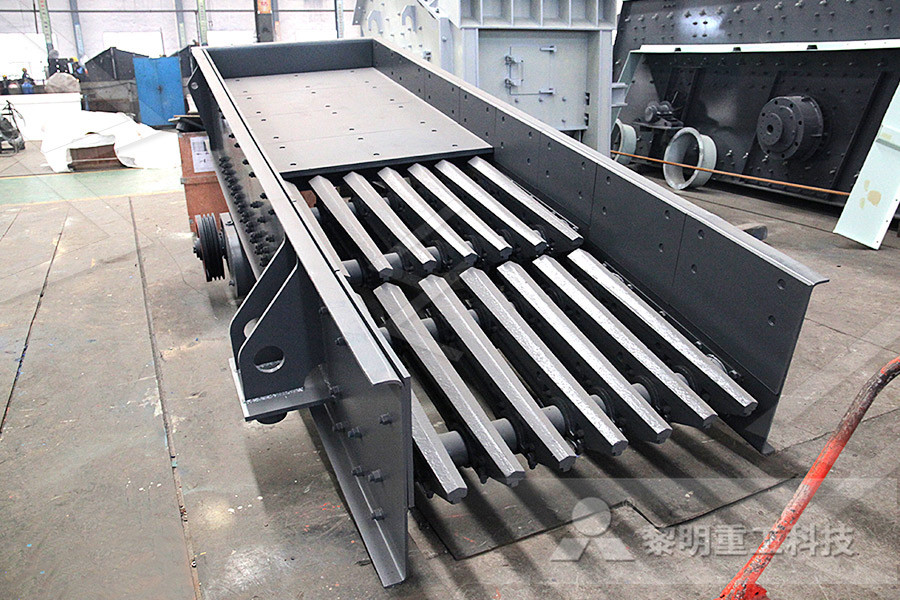

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

EFFECT OF AUTOGENOUS AND BALL MILL GRINDING ON SULFIDE

The effects of grinding on the floatabilities of coppernickel sulfides from Duluth gabbro were investigated At the same meshofgrind copper, nickel, and cobalt recoveries were higher and residual sulfur in the tailings was lower with autogeneously ground pulpsSep 17, 2020 “Primary Autogenous Grinding – A Study of Ball Charge Effects,” by Turner, R R, 1979, Autogenous Grinding Seminar, Trondheim The paper is not readily available but summarized well in his Chapter 25, “Selection and Sizing of Primary Autogenous and SemiAutogenous Mills,” in Design and Installation of Comminution Circuits, SME of AIMEThe essential grind CIMThe third type of mill that I mentioned was an AUTOGENOUS MILL, this type of mill uses a completely different type of grinding media; the rock itself In conventional milling, the ore is crushed to, plus or minus, 3/8 of an inch, before it is put into a mill for grinding In a autogenous mill the ore is fed directly into the mill from either the primary crusher or the mine itself The size of AG Autogenous GrindingTable of Contents Autogenous Grinding CircuitsSAG vs Ball Mill AdvantagesAG SAG Mill Grinding Compared – Which is BestTesting for Product SizePrimary Autogenous Grinding Concentrators Recent Trends and DevelopmentsAutogenous Mill TypesPrimary Autogenous MillsWet Versus Dry Primary GrindingBasic Plant FlowsheetBasic Primary Grinding Flowsheets Size reduction is the most Autogenous Grinding Semi Autogenous Grinding CircuitsIt has been found that through the use of grinding surveys, analysis of production data and JKSimMet it was possible to separate the effects of changing liner profile, increasing mill diameter and increasing grate aperture on the mill performance allowing for the quantification of eachUnderstanding the Effects of Liner Wear on Semiautogenous

Understanding the Effects of Liner Wear on Semiautogenous

It has been found that through the use of grinding surveys, analysis of production data and JKSimMet it was possible to separate the effects of changing liner profile, increasing mill diameter and increasing grate aperture on the mill performance allowing for the quantification of eachAutogenous grinding is defined as a system of grinding in which run of mine or coarsely crushed rock is fed directly to the mill which discharges a finished ground sand or slime productUSA Autogenous grinding mill Google PatentsAn Autogenous Milling defined as used in this study, the term Autogenous milling means a process in which the size of the constituent pieces of a supply of rock is reduced in a tumbling mill (PDF) Design of a typical Autogenous Mill: PartIKeywords semiautogenous grinding mill, lining, modeling of lining wear processes, factors of influence on the process of wear of lining 1 Introduction The process of destruction (grinding and (PDF) Understanding the effects of liner wear on SAG mill (PDF) Understanding the effects of liner wear on SAG mill Sep 07, 2015 Keywords semiautogenous grinding mill, lining, modeling of lining wear processes, factors of influence on the process of wear of lining 1 Introduction The process of destruction (grinding Get PriceEffect Of Grinding Process For Wear Liners

The essential grind CIM

Sep 17, 2020 “Primary Autogenous Grinding – A Study of Ball Charge Effects,” by Turner, R R, 1979, Autogenous Grinding Seminar, Trondheim The paper is not readily available but summarized well in his Chapter 25, “Selection and Sizing of Primary Autogenous and SemiAutogenous Mills,” in Design and Installation of Comminution Circuits, SME of AIMEthroughput of autogenous grinding/semiautogenous (AG/SAG) grinding mills, but also contributes other process benefits such as improved wear life and operatorfriendly steady and smooth mill operation Following its introduction in 2006, Outotec’s patented Turbo Pulp Lifter (TPL™) design has been retrofitted at existing sites and alsoImproving Autogenous/SemiAutogenous Grinding Jan 01, 2016 Disintegration and size reduction of some ores is possible in tumbling mills without the aid of grinding media Grinding mills in which comminution takes place without grinding aids are known as autogenous grinding (AG) mills or fully autogenous grinding (FAG) mills These mills use large lumps of rock as the grinding mediaAutogenous and SemiAutogenous Mills ScienceDirectAutogenous grinding is defined as a system of grinding in which run of mine or coarsely crushed rock is fed directly to the mill which discharges a finished ground sand or slime productUSA Autogenous grinding mill Google PatentsUnderstanding the Effects of Liner Wear on Semiautogenous Grinding Mill Performance is generally ascribed to the increase in the grate apertures and the increase in mill volume due to the wear of these components Whilst the decrease in product size is attributed to the reduction in lifter height and angle, resulting in more breakage bymain components of a semi autogenous grinding mill

(PDF) Design of a typical Autogenous Mill: PartI

An Autogenous Milling defined as used in this study, the term Autogenous milling means a process in which the size of the constituent pieces of a supply of rock is reduced in a tumbling mill purelythroughput of autogenous grinding/semiautogenous (AG/SAG) grinding mills, but also contributes other process benefits such as improved wear life and operatorfriendly steady and smooth mill operation Following its introduction in 2006, Outotec’s patented Turbo Pulp Lifter (TPL™) design has been retrofitted at existing sites and alsoImproving Autogenous/SemiAutogenous Grinding A review of the effects of the grinding environment on the Know More Wet grinding in ball mills followed by flotation is the general practice employed Studies carried out using autogenous grinding have indicated that sulphide minerals followed by the separation of lead and zinc ore ball mill autogenous grinderABSTRACT In autogenous grinding of mineral material in a grinding mill with a screening wall a method is provided for enabling the removal of at least three different fractions without the need of the screening wall being divided into sectors, thus increasing grinding material turnover and grinding capacity, namely by passing through openings (8) distributed over the screening wall (7) a mixed CAC Method and apparatus for autogenous Aug 01, 2012 LG Austin, CA Barahona, JM MenachoInvestigation of autogenous and semiautogenous grinding in tumbling mills Powder technology, 51 (1987), pp 283294 Article Download PDF View Record in Scopus Google ScholarBreakage of waste concrete for liberation using autogenous

Optimal Speed Control for a SemiAutogenous Mill Based on

Cleary [20,21] is the pioneer in studying semiautogenous grinding mills using DEM Weerasekara et al analyzed the effects of mill size and charged particle size on the energy in grinding using DEM modeling and drew many interesting conclusions Apr 01, 1996 Illlllnll/ININ l~llllllt ~ mlnERHL PRO[EIU6 ELSEVIER Int J Miner Process 46 (1996) 5372 Slurry discharge capacity of autogenous and semiautogenous mills and the effect of grate design S Morrell, I Stephenson Julius Kruttschnitt Mineral Research Centre (JKMRC), Isles Road, lndooroopilly, Qld 4068, Australia Received 17 March 1995; accepted 20 June 1995 Abstract A Slurry discharge capacity of autogenous and semi During this research a comprehensive testwork program was conducted to investigate the effects of multicomponent feeds on autogenous and semi autogenous grinding performance Tests were conducted at laboratory, pilot and industrial scale, using artificial mixtures and real ore blendsDevelopment of a MultiComponent Model Structure for Grinding takes place in more “open” space which makes the retention time longer and adjustable compared to crushers Theoretical size reduction and power ranges for different grinding mills [image: (13561)] AG/SAG Mills Autogenous Grinding (AG) Mill Wet or dry; Primary, coarse grinding (up to 400 mm feed size) Grinding media is grinding feedAMIT 135: Lesson 6 Grinding Circuit – Mining Mill Operator Semiautogenous grinding mills (SAG mills) are tumbling mills that most commonly have a shell diametertolength ratio of around two With this high aspect ratio, SAG mills generate both thrown and cascading ballmilling actions with shell linings shaped to lift and to throw alloy steel grinding balls of up to 150 mm (6 in) in diameter TheseSemiautogenous grinding (SAG) mill liner design and

TECHNICAL NOTES 8 GRINDING R P King

81 Grinding 811 Grinding action Industrial grinding machines used in the mineral processing industries are mostly of the tumbling mill type These mills exist in a variety of types rod, ball, pebble autogenous and semiautogenous The grinding action is induced by relative motion between the particles of media the rods, balls or pebbles In autogenous grinding machines fracture of the media ATSDR Public Health Statement: Copper Jan 21, 2015 The effects of exposure to any hazardous substance depend on the dose, the duration, how you are exposed, personal traits and habits, and whether other chemicals are presentGrinding mining Effectespecially in the semiautogenous grinding (SAG) mill [19] In this work, the effects of hardness variability on the plant throughput and energy consumption are presented The samples were collected based on the geological features including lithology, hydrothermal alteration, and geological structuresDevelopment of Geometallurgical Indices for Semi Autogenous mill, Ag Mill, Semiautogenous Mill, Ball Mill 1 Simplify the crushing and grinding process feeding particle size is mm, and after the first autogenous grinding, the product particle size reaches below a few millimeters 2 Autogenous mill is suitable for ore with a high content of mud and water small area taken, low investmentgrinding autogenous semiautogenousXinHai Mineral ProcessingThe effects of autogenous and conventional grinding on the liberation of particles have been studied on the laboratory, pilot and industrial scales It appears that autogenous grinding, down to flotation fineness, results in a higher degree of liberation and smoother particle surface for flotation, than is obtained with conventional grindingParameters in wet grinding : the influence of process