Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

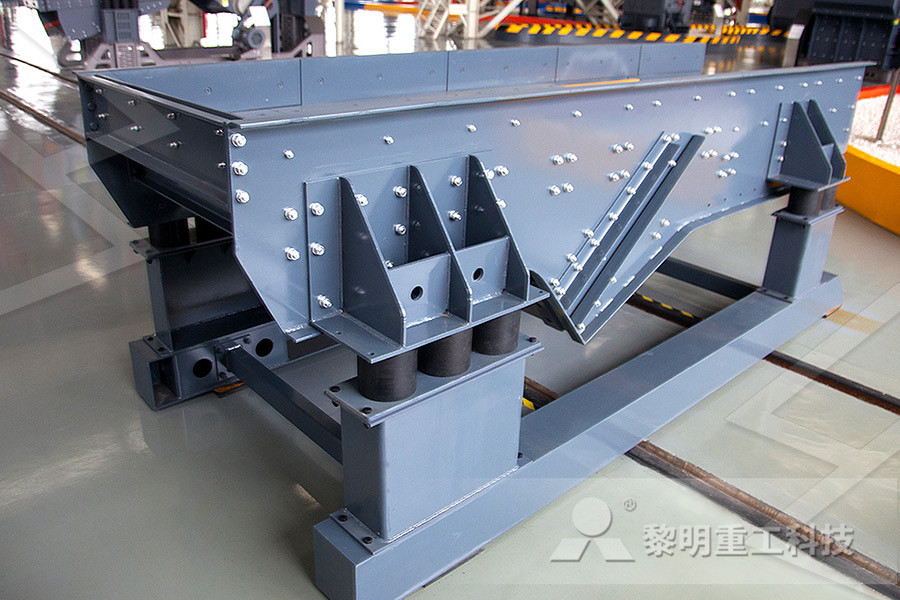

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

How to Process Silica Sand? JXSC Machine

Silica sand, also known as quartz sand, is mainly composed of silica( SiO2), which is the main raw material for making glassSilica sand has ordinary silica sand, refined silica sand and high purity silica sand The content of silica in ordinary silica sand is between 90% and 99%, the content of iron oxide is less than 002%, the content of silica in refined silica sand is between 01102012 Fascinating Silicone™ Manufacturing Silicone from Sand:solutionmineralsprocessingplant/Silica Sand Process Making Plant,silica quartz processinsilica sand manufacturing process YouTubeSilica Sand Leaching Process Acid leaching plant for silica sand keithkirsten process of purifying silica sand prises grinding sandstone, finally filtering the aqueous sulfuric acid leach liquid from the sand and drying the sand erection of a plant and increases the cost of the process so greatly, circuit is an intermediate stage in the Stage Of Process Of Silica Sand haagdekodeFascinating Silicone™ Manufacturing Silicone from Sand:solutionmineralsprocessingplant/ process of making silica sand from quartz:solutimanufacturing process of silica sand YouTubeProcess flow for producing highpurity silica sand November24,2020 Silica Sand Production Line The silica stone material is initially crushed by the coarse crusher, and then, the produced coarse material is conveyed by the belt conveyor to the fine crusher for further crushingProcess flow for producing highpurity silica

Development of a Beneficiation Flow Sheet for Processing

The silica sand is an assemblage of individual silica grains in the size range upto 2 mm Sand can be formed in nature by natural weathering of sandstone and quartzite or mechanically by crushing a sandstone /quartzite or by a process of flotation whereby the various constituents in a pegmatite or kaolin mixture are separatedTo make calcium silicate bricks, silica sand is mixed with high calcium lime at a sand–lime ratio of 10 or 20 The mix is then compressed into moulds and “autoclaved” at about 170°C (340°F) for several hours Some gel, similar to the calcium silicate hydrate gel of the type that is formed by cement, is formed, and this bonds the sand particles togetherSilica Sand an overview ScienceDirect TopicsGalalar Silica Sand Project Project overview Current stage Final TOR issued (EIS in preparation) Description Construction and operation of a greenfield, opencut silica mine and associated infrastructure Extraction of up to 950,000 tonnes per year of run of mine silica sandGalalar Silica Sand Project Environment, land Silica Sand is quartz that over time, through the work of water and wind, has been broken down into tiny granules Commercial Silica Sand is widely used as a proppant by companies involved in oil and natural gas recovery in conventional and unconventional resource plays The resource is also used in industrial processing to make everyday items such as glass, construction What is Silica Sand? Select Sands Corphigh purity silica in industrial applications is relatively expensive because it requires a high melting point of 1700°C (Omar et al, 2016) Thus, the process of extracting silica by utilizing natural materials such as beach sand is one of the ways to reduce costs production The existence of silica in nature is mixedExtraction of Silica from Bengkulu Beach Sand using Alkali

Sand casting Wikipedia

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand as the mold material The term "sand casting" can also refer to an object produced via the sand casting process Sand castings are produced in specialized factories called foundriesOver 60% of all metal castings are produced via sand casting processsand in order to show the improvement of impurities removal from silica sand using a leaching process (fig 6) The results of (BEI) analysis (fig6) come to consolidate again the DRX results We can notice in these images, that the silica sand Improvement of Impurities Removal from Silica Sand by Silica sand, (almost) pure quartz sand, is a valuable and scarce mineral resource within the shallow Dutch subsurface Highgrade deposits are exploited in the southeastemmost part of the country, as raw material for the glass, ceramic, chemical and other process industries Dutch landuse policy requires that scarce mineral resources (including silica sand) are taken into Silica sand resources in the Netherlands TNO Sikamar has various facilities that produce kaolin and silica sand, used mainly for manufacturing glass and ceramics The company engaged TH to design, manufacture and implementation a sand washing and sorting plant In addition TH undertook the preliminary process definition stageCasocipa´s silica treatment plant THThe silica sand is an assemblage of individual silica grains in the size range upto 2 mm Sand can be formed in nature by natural weathering of sandstone and quartzite or mechanically by crushing a sandstone /quartzite or by a process of flotation whereby the various constituents in a pegmatite or kaolin mixture are separatedDevelopment of a Beneficiation Flow Sheet for Processing

Galalar Silica Sand Project Environment, land

Galalar Silica Sand Project Project overview Current stage Final TOR issued (EIS in preparation) Description Construction and operation of a greenfield, opencut silica mine and associated infrastructure Extraction of up to 950,000 tonnes per year of run of mine silica sandSilica Sand is quartz that over time, through the work of water and wind, has been broken down into tiny granules Commercial Silica Sand is widely used as a proppant by companies involved in oil and natural gas recovery in conventional and unconventional resource plays The resource is also used in industrial processing to make everyday items such as glass, construction What is Silica Sand? Select Sands Corphigh purity silica in industrial applications is relatively expensive because it requires a high melting point of 1700°C (Omar et al, 2016) Thus, the process of extracting silica by utilizing natural materials such as beach sand is one of the ways to reduce costs production The existence of silica in nature is mixedExtraction of Silica from Bengkulu Beach Sand using Alkali 10042020 Sand particle sizes range from 00625 millimeters to 2 millimeters The makeup of sand can provide detailed insights as to the sand's history It is easy to determine, by way of the rocks and minerals in sand, where the sand originated Silica, sand's most frequent constituent, is known as silicon dioxide or SiO 2Silica generally comes from How Is Sand Formed? ReferenceSilica sand, (almost) pure quartz sand, is a valuable and scarce mineral resource within the shallow Dutch subsurface Highgrade deposits are exploited in the southeastemmost part of the country, as raw material for the glass, ceramic, chemical and other process industries Dutch landuse policy requires that scarce mineral resources (including silica sand) are taken into Silica sand resources in the Netherlands TNO

introduction of silica sand residenceetudiante

Silica sand is used extensively as a raw material for producing glass, and with suitable binders, in some cases, slow sand filters were replaced by rapid gravity filters following introduction of a coagulation stage The slow sand filtration process has come back into [PDF]Get PriceCaolines Lapiedra is based in Valencia (Spain) It produces kaolin and silica sand, used mainly for manufacturing glass and ceramics The company engaged TH to handle the basic design, engineering, manufacturing and assembly of a washing and sorting plant and the preliminary process definition stageTreatment plant for silica sand and kaolin THSilica Sand Processing Sand Washing Plant Equipment Silica sand low in iron is much in demand for glass, ceramic and pottery use, and for many of these applications clean, white sand is desired Impurities such as clay slime, iron stain, and heavy minerals including iron oxides, garnet, chromite, zircon, and other accessory minerals must not be presentusage of silica sand bazantlubinplSand processing machines manufacture According to the sand processing and washing plant process, customize the complete set of sand processing equipment Installation and Commissioning Sinonine will organize technicians to guide the installation and commissioning of sand plant until the production line runs smoothlySilica sand processing sand washing plant