Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

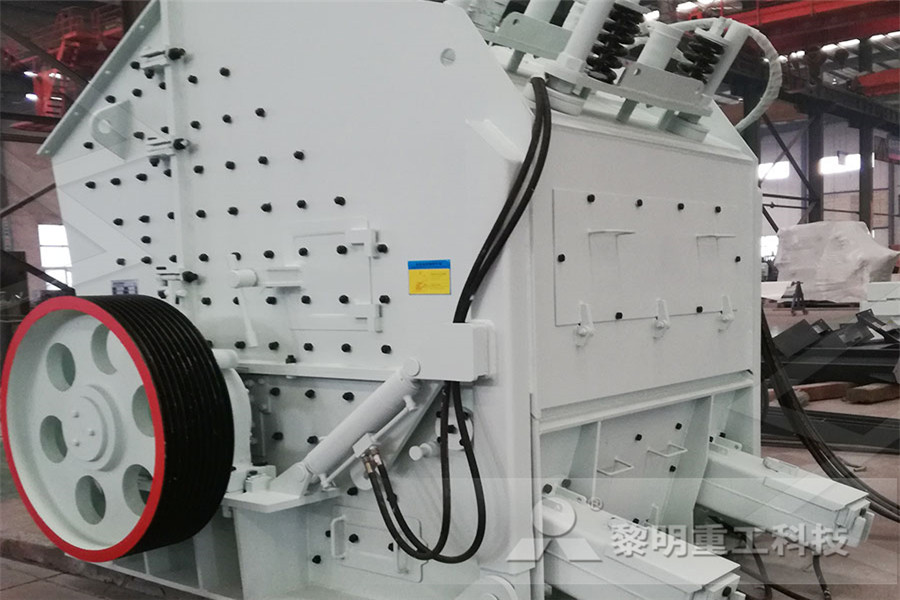

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

how a jaw crusher works and what it is used for

A Jaw Crusher is one of the main types of primary crushers in a mine or ore processing plant The size of a jaw crusher is designated by the rectangular or square opening at the top of the jaws (feed opening) For instance, a 24 x 36 jaw crusher has a opening of 24" by 36", a 56 x 56 jaw crusher Jaw crushers are often designated by the size of the top opening where material enters The openings tend to be either rectangular or square and are referenced in inches For example, a 3244 or 32×44 jaw crusher has a 32” by 44” opening, 32” being the gap at the top between the jaw What is a Jaw Crusher? TelsmithThe gyratory crusher can, just like a jaw crusher, accept boulder sizes close to 15 m (for the largest equipment) – This crusher can handle products with a Mohs hardness that is not necessarily less than 5 – As is the case for jaw crushers, there is not any mutual sliding on grinding surfaces, but simply rolling of the nut on concavesJaw Crusher an overview ScienceDirect TopicsJaw crushers are often designated by the size of the top opening where material enters The openings tend to be either rectangular or square and are referenced in inches For example, a 3244 or 32×44 jaw crusher has a 32” by 44” opening, 32” being the gap at the top between the jaw dies and 44” being the width between the side platesWhat is a Jaw Crusher? TelsmithThe gyratory crusher can, just like a jaw crusher, accept boulder sizes close to 15 m (for the largest equipment) – This crusher can handle products with a Mohs hardness that is not necessarily less than 5 – As is the case for jaw crushers, there is not any mutual sliding on grinding surfaces, but simply rolling of the nut on concavesJaw Crusher an overview ScienceDirect Topics

jaw crusher utilizes introonlinecz

TST jaw crusher Jaw crushers 2 ’s history with the design and manufacture of jaw crushers dates back more than 100 years with the utilizes in each crusher model The bearings are supported by a large diameter forged alloy steel, generous radii and no threads to ensure that allThe Bison 280 a compact and aggressive track mobile jaw crusher featuring the proven ‘900mm x 600mm’ single toggle jaw crusher This machine utilizes an extremely fuel efficient and powerful ‘Direct Drive’ system to power the crusher which provides excellent performance in recycling, contracting and quarrying industriesBison Jaw Crusher Crushing Machine EvoQuipJaw crushers are one of the most commonly preferred crushers due to their ability to crush all kinds of materials of any hardness, as well as their lowcost operation and easy maintenance SUCCESS IN EVERY HARDNESS Wide range of crushing for soft to very hard materialsJaw Crushers MEKA Crushing Screening Plants01042008 china This jaw crusher machine uses motor as its power Through the motor's wheels, the eccentric shaft is driven by the triangle belt andThe Working Principle of Jaw Crusher YouTubeA crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher Wikipedia

Jaw Crusher Handbook Stone Crusher PDF

This jaw crusher handbook that we hope can help you to learn more about the stone crusher jaw crusher working principle When the jaw stone crusher working, the motor drives the belt and Pulley, moves the movable jaw up and down through the eccentric shaft The angle between the bracing plate and movable jaw gets bigger when the jaw rising Jaw crushers process medium to hard quarry rock or other materials by compressing it between the fixed jaw and the swing jaw The swing jaw being the moving part is attached to a rotating eccentric shaft The fixed jaw is an integral part of the crusher frame Both jaws are fitted with manganese jaw liners that can be replaced or reversed when Jaw Crushers, Jaw Crusher, Hard Rock Processing, Crusher range Overview Our range of jaw, cone and impact crushers provide unbeatable performance and mobility across a wide range of applications Key benefits Jaw B Series Product information Impact R Series Performance through innovation Unrivalled performing crushing chamberCrushers KeestrackJaw crushers are often designated by the size of the top opening where material enters The openings tend to be either rectangular or square and are referenced in inches For example, a 3244 or 32×44 jaw crusher has a 32” by 44” opening, 32” being the gap at the top between the jaw What is a Jaw Crusher? TelsmithJXSC Jaw Crushers Advantages Features 40 years of manufacturing and engineering experience keep us innovative and knowledge in the rock break machines and its applications, which thus provide reliable industry rocks crushers and solutions for every customer using jaw crusher manufacturers JXSC machines to meet their production goalsThe jaw crusher Jaw Crusher Primary Crusher in Mining

Jaw crushers, Stationary Jaw crusher series —

Sandvik jaw crushers are of the singletoggle type with advanced features for optimized performance, easy maintenance, long life and a low cost per ton These crushers feature a deep, symmetrical crushing chamber, easy settings adjustment, a large feed opening for its size, and an ideal nip angle that offers smooth material flow and high reduction efficiencyLokotrack ® LT130E™ mobile jaw c rusher is a primary crusher for largescale quarry operations Despite its massive size, Lokotrack® LT130E™ is easily transportable between sites It can be used as a primary crusher in a multistage crushing process or as a Lokotrack® LT130E™ mobile jaw crusher H2238 Jaw Crushers View More TelsmithHydraJawCrushers Hydraulic Chamber Clearing system with push button controls allows the crusher to start up in as little as 15 minutes Toggle tensioning system eliminates the need to adjust springs when changing the settingJaw Crushers TelsmithJaw crushers are typically used as primary crushers because they can take large and variable sized feed material, so the original feed won’t have to be blasted down to a fine size jaws are designed to be significantly more reliable and have lower wear rates, maximizing production and minimizing wear partsJaw Crusher Premiertrak 600 Jaw crushers process medium to hard quarry rock or other materials by compressing it between the fixed jaw and the swing jaw The swing jaw being the moving part is attached to a rotating eccentric shaft The fixed jaw is an integral part of the crusher frame Both jaws are fitted with manganese jaw liners that can be replaced or reversed when Jaw Crushers, Jaw Crusher, Hard Rock

Jaw Crusher Premiertrak 400X R400X

Jaw crushers are typically used as primary crushers because they can take large and variable sized feed material, so the original feed won’t have to be blasted down to a fine size jaws are designed to be significantly more reliable and have lower wear rates, maximizing production and minimizing wear partsThe Bison 160 Hybrid hooklift jaw crusher represents a new milestone for EvoQuip It is an ideal crusher for waste contractors who can utilize existing hooklift vehicles to either bring material to depot for processing or alternatively bring the crusher to the waste on site – turning waste into profit whilst providing excellent productivity and fuel efficiencyBison 160 Hook Lift Jaw Crusher EvoQuipA crusher is a machine designed to reduce large rocks into smaller rocks, gravel, sand or rock dust Crushers may be used to reduce the size, or change the form, of waste materials so they can be more easily disposed of or recycled, or to reduce the size of a solid mix of raw materials (as in rock ore), so that pieces of different composition can be differentiatedCrusher Wikipedia