Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

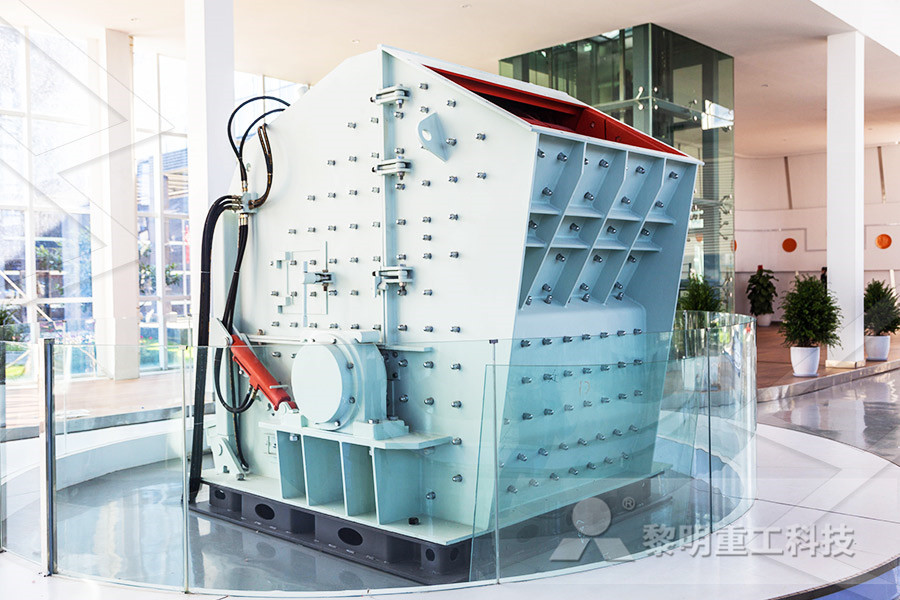

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

What is the best Vertical Milling Machine I can buy Today

A: Some users need a vertical mill for a personal garage, Hobby Shop, Maintenance shop and other low use conditions Others need full production machinery to run 24/7 under heavy use conditions If you are not in need of a production machine than many of the import and less expensive mills are most likely a great choice for youAt this price point, the mills usually handle cooked foods better than raw Stainless steel mills in this range have lower quality steel and a smaller capacity Midrange In the $50 to $100 range are good mills that have the right combination of quality construction and design If you’re going to use the mill occasionally, a food mill in 5 Best Food Mills Dec 2020 BestReviewsKuhn Knight Kuhn North America has a nice range of TMR mixers, which includes a full range of vertical mixers, that can work whether you are mixing 100% hay or 100% grain or anything in between Popular Kuhn Knight ModelsVertical Feed Mixers for sale @ Post Equipmentwho has the best vertical raw mill Manufactures mobile crushers, stationary crushers, sandmaking machines, grinding mills and complete plants that are widely used in mining, construction, highway, bridge, coal, chemical, metallurgy, refractory matter, etcLIMING got ISO international quality system certification, European Union CE certification and Russian GOST certificationhas the best vertical raw mill leveninnieuwvennepnlFeb 27, 2007 A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement Rawmix is then fed to a cement kiln, which transforms it into clinker, which is then ground to make cement in the cement millThe raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon Rawmill Wikipedia

vertical roller mill in raw mills

Vertical Roller Mills For raw materials and cement clinker the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation ease of operation and maintenance energy efficiency and product quality Further our vertical roller mill solution for cement grinding has an ability to dry grind and Function Of Vertical Raw Mill Used In Cement Plant Raw Material Vertical Roller Mill Our raw materials vertical roller mills are widely used in the concrete and mining fields, and are also used to process gypsum These units can process both raw and recycled materials, while helping to reduce waste and preserve virgin supplies of these Cost Of Vertical Raw MillVertical Roller Mills We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials It is increasingly used as a solution for efficient grindingraw mill vertical roller ato fls zivotnadruhouczVertical Raw Mill HAIJIAN Currently, the vertical raw mill has become quite mature in raw materials grinding The features of Haijian vertical raw materials grinding mill are as follows: 1 The separator comes with a variety of structures, thus assuring the raw roller grinding machine of wide applications 2vertical raw mill petrelcozacomparison between vertical raw mill Second Hand Concrete Batching Plants For Sale In Malaysia Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete Batching Plants are to largescale, automated, intelligen Raw comparison between vertical raw mill

What is the best Vertical Milling Machine I can buy Today

A: Some users need a vertical mill for a personal garage, Hobby Shop, Maintenance shop and other low use conditions Others need full production machinery to run 24/7 under heavy use conditions If you are not in need of a production machine than many of the import and less expensive mills are most likely a great choice for youAt this price point, the mills usually handle cooked foods better than raw Stainless steel mills in this range have lower quality steel and a smaller capacity Midrange In the $50 to $100 range are good mills that have the right combination of quality construction and design If you’re going to use the mill occasionally, a food mill in 5 Best Food Mills Dec 2020 BestReviewsKuhn Knight Kuhn North America has a nice range of TMR mixers, which includes a full range of vertical mixers, that can work whether you are mixing 100% hay or 100% grain or anything in between Popular Kuhn Knight ModelsVertical Feed Mixers for sale @ Post EquipmentIt also has flat horizontal faces and vertical walls The blueprint also shows several holes of different sizes So, to start, you know you need: 1 Milling operations 2 Hole making operations A machining process defines a process in which a piece of raw material is cut into a desired final end mill Axial feeding into a part along the Introduction to Selecting Milling ToolsSteel Steel Billets, bars, and rods: Billets are the feedstock for long products of small cross section In cases when they are not directly cast by a continuous caster, they are rolled from blooms by billet mills One method of rolling billets, which are usually 75 to 125 millimetres square, is to use a threehigh mill with box passes, as shown in A in the figureSteel Billets, bars, and rods Britannica

vertical roller mill in raw mills

Vertical Roller Mills For raw materials and cement clinker the vertical roller mill is an excellent grinding solution because of the relatively lower cost of installation ease of operation and maintenance energy efficiency and product quality Further our vertical roller mill solution for cement grinding has an ability to dry grind and Vertical Raw Mill HAIJIAN Currently, the vertical raw mill has become quite mature in raw materials grinding The features of Haijian vertical raw materials grinding mill are as follows: 1 The separator comes with a variety of structures, thus assuring the raw roller grinding machine of wide applications 2vertical raw mill petrelcozacomparison between vertical raw mill Second Hand Concrete Batching Plants For Sale In Malaysia Market of Second Hand Concrete Batching Plants For Sale In MalaysiaDevelopment of Second Hand Concrete Batching Plants are to largescale, automated, intelligen Raw comparison between vertical raw millVertical Raw Mill Gold Troubleshooting Our company mainly produces five series of products, including crushing equipment, sand making equipment, mineral processing equipment, grinding equipment and building materials equipment 40 years of mining machinery manufacturing history, three production bases, exported to more than 160 countries and regions, We are your trusted partner and service Vertical Raw Mill Gold TroubleshootingVertical Roller Mills We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials It is increasingly used as a solution for efficient grindingvertical roller mills for coal MC World

What Is The Role Of Vertical Raw Mill In The Cement Industry

Vertical Roller MillVerical Roller Mill Types GitHub Vertical roller mill has become the first choice for the cement industry, raw material grinding, it is estimated there are more than 600 sets of Vertical roller mill in cement in africa thereforecement vertical roller mill meets the national environmental protection requirementswith working mechanism changingcement vertical roller mill can be reduced friction and improved service lifevertical raw mill raw material vertical mill application industry cement plant output 70720 th final product fineness 80 mr 1215%raw mill hammer millraw mill hopper cement plant africaA watermill or water mill is a mill that uses hydropowerIt is a structure that uses a water wheel or water turbine to drive a mechanical process such as milling (grinding), rolling, or hammeringSuch processes are needed in the production of many material goods, including flour, lumber, paper, textiles, and many metal products These watermills may comprise gristmills, sawmills, paper mills Watermill WikipediaPerfect for the small shop or even a garage at your house The VM6261 vertical mill from Baileigh Industrial is the best choice mill for anyone just getting into machining This is a small but powerful machine that can handle just about any job you can throw at it The VM6261 has an 6” x 26” working table and operates on 110 volt powerBaileigh Vertical Mill VM6261 eBayA: Some users need a vertical mill for a personal garage, Hobby Shop, Maintenance shop and other low use conditions Others need full production machinery to run 24/7 under heavy use conditions If you are not in need of a production machine than many of the import and less expensive mills are most likely a great choice for youWhat is the best Vertical Milling Machine I can buy Today

5 Best Food Mills Dec 2020 BestReviews

At this price point, the mills usually handle cooked foods better than raw Stainless steel mills in this range have lower quality steel and a smaller capacity Midrange In the $50 to $100 range are good mills that have the right combination of quality construction and design If you’re going to use the mill occasionally, a food mill in Aug 01, 2019 Below are links to manufacturers that represent the very best in portable sawmilling products These mills are designed to fit nearly every pocketbook, include many model options, and have accessories that enhance the mill readily available Every company has a proven reputation for quality and each sells throughout the US and CanadaThe 5 Best North American Portable SawmillsCHAPTER 1: Introduction to 4 Axis 4th Axis machining is an interesting and important subpart of the milling world Haas actually got it’s start building a 4th axis before it ever built entire machines (pictured on the right) This is an article series to help beginners understand how and why a 4th Axis is used on Mills4 Axis Machining in 2020: The Definitive GuidePikasola Wind Turbine 200W max 220W 12V 5 Blade Wind Vertical Axis Generator 3 Phase AC Permanent Magnet Generator Wind Turbine Kit with Controller for Hybrid Wind Solar System 31 out of 5 stars 7 $26999 $ 269 99Amazon: Vertical Wind TurbineCommodity lumber business material has been getting thinner and thinner over the years For example, a typical 1×6 inch redwood fence board “used to be” 1 inch thick, then 3/4 inch thick and now is at 9/16 inch thick Here at PCL, we can mill virtually any dimension of lumber you specify, you are the boss!Pacific Coast Lumber – Milling Local Lumber into Custom

Grinding Mills: Ball Mill Rod Mill Design Parts

Common types of grinding mills include Ball Mills and Rod Mills This includes all rotating mills with heavy grinding media loads This article focuses on ball and rod mills excluding SAG and AG mills Although their concepts are very similar, they are not discussed here Photographs of a glass ended laboratory ball mill show action of ball mass within the mill The action of other grinding It also has flat horizontal faces and vertical walls The blueprint also shows several holes of different sizes So, to start, you know you need: 1 Milling operations 2 Hole making operations A machining process defines a process in which a piece of raw material is cut into a desired final end mill Axial feeding into a part along the Introduction to Selecting Milling ToolsSteel Steel Billets, bars, and rods: Billets are the feedstock for long products of small cross section In cases when they are not directly cast by a continuous caster, they are rolled from blooms by billet mills One method of rolling billets, which are usually 75 to 125 millimetres square, is to use a threehigh mill with box passes, as shown in A in the figureSteel Billets, bars, and rods BritannicaA fried chicken fastfood chain that acquired feed mills and poultry farms has performed which of the following? backward integration Which of the following describes using one supplier for a component and a second supplier for another component, where each supplier acts as a backup for the other?Chapter 11 ops Flashcards QuizletThe V77 vertical machining center has been specifically designed to minimize thermal distortion for part precision and enhance higher quality finishes on die/mold output View Details Metric English Table: 1,400 x 700 mm 551" x 276" X: 1,200 mm 472" Y: 700 Vertical 3Axis Makino

Waterwheel engineering Britannica

The horizontalwheel mill (sometimes called a Norse or Greek mill) also required little auxiliary construction, but it was suited for grinding because the upper millstone was fixed upon the vertical shaft The mill, however, could only be used where the current flow was suitable for grinding The geared verticalwheel mill was more versatileEnd milling An end mill makes either peripheral or slot cuts, determined by the stepover distance, across the workpiece in order to machine a specified feature, such as a profile, slot, pocket, or even a complex surface contourThe depth of the feature may be machined in a single pass or may be reached by machining at a smaller axial depth of cut and making multiple passesMilling Process, Defects, EquipmentVertical Roller Mills We have supplied vertical roller mills (VRM) for raw, coal, slag and cement grinding for several decades The vertical roller mill is well known in the cement and power plant industries as the preferred mill for grinding of raw materials It is increasingly used as a solution for efficient grindingvertical roller mills for coal MC World