Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

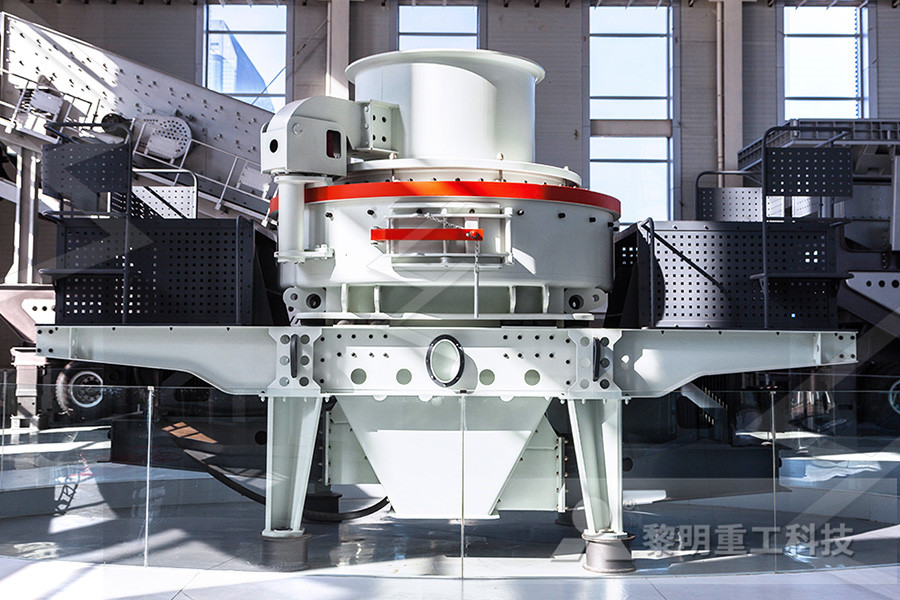

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

coal mill explosion control methods pochirajuco

coal mill explosion control methods 5 years after coal mine blast, explosion risks persist WTOP Apr 4, 2015 Five years after the blast that killed 29 West ia coal miners, In January, federal officials found excess methane and coal dust at Mill Branch Coal Corp ventilation and dust control standards since Upper Big BranchFeature: Coal Pulverization System: Explosion Prevention and Process Control 2 Explosion prevention and protection Principle of dust explosion prevention and protection has been introduced by Eckhoff [4] The main methods used in this system include atmospheric inerting, powder inerting (during stop and restart) and venting ProcessCoal Pulverization System: Explosion Prevention and a fire If the mill is restarted without first removing the hot coal, an explosion can occur when particles are suspended and exposed to the air Even when a mill is shut down routinely, there is a danger that any residual coal left within the mill will oxidise, which can explode as the mill is restarted To prevent a coal fire, the millsCOAL MILL Land Instruments InternationalConstructional explosion protection Explosion pressure shock resistant designs > Uses explosion vents and pressure shock resistant constructions to control the damage Explosion venting for riser duct and for coal mill bag house Explosion isolation Recommendations Coal Mill SafetyFeature: Coal Pulverization System: Explosion Prevention and Process Control 2 Explosion prevention and protection Principle of dust explosion prevention and protection has been introduced by Eckhoff [4] The main methods used in this system include atmospheric inerting, powder inerting (during stop and restart) and venting ProcessCoal Pulverization System: Explosion Prevention and

The prevention and control of fire and explosion in mines

3 Fires and explosions have the potential to kill many people This guidance tells you how to comply with the law; how to carry out fire and explosion risk assessments; and how to identify the measures necessary to avoid, control and mitigate those risks It will help mine owners and managers to prepare their fire and explosion protection Anatomy of a Float Coal Dust Explosion Coal combustion front Underlying rock dust dispersion lags behind the combustion front and unable to quench combustion front Surface coal dust disperses first Layered dust Float coal dust (024 mm or 001 in) Rock dust (254 mm or 10 in)Preventing Coal Dust Explosions in Underground Coal Minescoal dust explosions and to sunnnarize the preventive measures through which it may be possible to minimize the hazards of coal dust explo sions The properties of coal dust which have an important influence on its explosibility are: fineness, purity, percentage of volatileCoal dust explosions and their preventionFire Detection Methods for Coal Pulverizer Systems the risk of an explosion is low Vertical Spindle Mills The vertical spindle mill is a medium speed pulverizer and maintains a considerable amount of fuel in the mill system when operatingCoal Mill Explosion Study araczekplthe mill is restarted The Millwatch system is installed near the classifier and can detect the CO emitted from any hot inclusions within the residual coal With many baseload plants now being frequently dispatched, the risk of a catastrophic event mounts HIGH RISK AT MILL STARTUP AND SHUTDOWN Several methods are available to detect theCOAL HANDLING SAFETY AMETEK Land

Coal Mill an overview ScienceDirect Topics

To summarize the coal mill controls, they may be divided basically into two major categories: 1 To control the quality of coal being sent to the burners located on the furnace walls The word quality here means the temperature and fineness of the PFprimary explosion protection, i e the focussing of attention on the use of nonfl ammable substances that are not capable of forming an explosive atmosphere However, it is not always possible to exclude fl ammable substances such as methane or coal dust in mines, Basic concepts for explosion protection BARTECAll these steps have to be documented, put into an explosion protection document and shown to the authorities on demand Measures in case of an accident Especially the large fires and explosions in firms (eg explosions in a chemical company in Rotterdam in early 2011) indicate how important it is to have safe systems in placePrevention of fires and explosions OSHWikiInerting coal dust accumulations – stone dusting – the application of large quantities of finely crushed stone dust (limestone) to render fine coal dust incombustible Inerting airborne coal dust/roadway dust – passive explosion barriers storing a quantity of stone dust or water in a mine roadway in such a way that an explosion causes its dispersal to render the airborne dust cloud Methods of Control SkillPro Services Pty Ltd3 Fires and explosions have the potential to kill many people This guidance tells you how to comply with the law; how to carry out fire and explosion risk assessments; and how to identify the measures necessary to avoid, control and mitigate those risks It will help mine owners and managers to prepare their fire and explosion protection The prevention and control of fire and explosion in mines

CDC Mining Feature Coal Mine Explosion

Prevention of coal mine explosions requires a suite of control strategies, including sustaining a properly designed ventilation system, adequate sealing of abandoned areas, aggressive and frequent monitoring of methane, reduction of coal dust accumulations, and control of potential ignition sources through electrical safety and the use of permissible equipmentcoal dust explosions and to sunnnarize the preventive measures through which it may be possible to minimize the hazards of coal dust explo sions The properties of coal dust which have an important influence on its explosibility are: fineness, purity, percentage of volatileCoal dust explosions and their preventioncoal and the high temperature inside the mill lead to rapid oxidation of the coal This results in further heat buildup and the potential for a fire If the mill is restarted without first removing the hot coal, an explosion can occur when particles are COAL HANDLING SAFETY AMETEK LandMajor coal mine explosions in the United States, 1970–present 78 6–2 Gassiness of coal seams Subsequent chapters describe methane control methods for different kinds of mines and mining equipment, primarily for US coal minesHandbook for Methane Control in MiningBasics of Explosion Protection INTRODUCTION HAZARDOUS LOCATIONS INNOVATIVE EXPLOSION PROTECTION by R STAHL 18007824357 Class I, Locations Class I locations are those in which flammable "gases or vapors" are, or may be, present in the air in quantities sufficient to produce explosive or ignitible mixturesBasics of Explosion Protection INTRODUCTION

Basic concepts for explosion protection BARTEC

primary explosion protection, i e the focussing of attention on the use of nonfl ammable substances that are not capable of forming an explosive atmosphere However, it is not always possible to exclude fl ammable substances such as methane or coal dust in mines, or petrol and in future perhaps hydrogen in vehiclesAll these steps have to be documented, put into an explosion protection document and shown to the authorities on demand Measures in case of an accident Especially the large fires and explosions in firms (eg explosions in a chemical company in Rotterdam in early 2011) indicate how important it is to have safe systems in placePrevention of fires and explosions OSHWikiInerting coal dust accumulations – stone dusting – the application of large quantities of finely crushed stone dust (limestone) to render fine coal dust incombustible Inerting airborne coal dust/roadway dust – passive explosion barriers storing a quantity of stone dust or water in a mine roadway in such a way that an explosion causes its dispersal to render the airborne Methods of Control SkillPro Services Pty Ltd1 The explosion is believed to have been fueled by the everpresent sugar dust, an inherent aspect of the sugar refining process, which would coat surfaces and equipment in the facility A resulting investigation performed by the US Chemical Safety Board looking into the explosion concluded that the incident was "entirely preventable" and was the result of "inadequate Hazardous Area Classifications: What You