Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

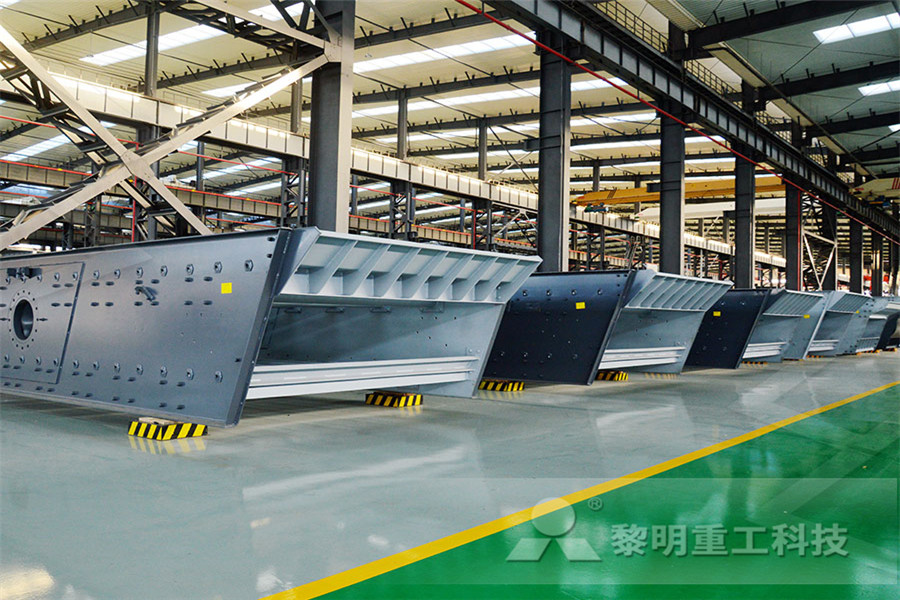

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

What to do if the temperature of the jaw crusher bearing

Jaw crusher is a commonly used crusher equipment For jaw crusher, bearing is one of the most important parts of the machine Once the bearing is damaged, it will cause the equipment to stop In the stone production process, the abnormal temperature rise of the bearing is one of the common failures Here are the reasons for the abnormal Therefore, during the working process of the jaw crusher, it is necessary to pay attention to whether the bearing is operating normally The common fault of jaw crusher bearings is that the temperature is too high What to do if the temperature is too high when the jaw crusher parts are running 1How to solve the phenomenon that the bearing temperature Jul 10, 2020 Jaw crusher bearingCauses and solutions of excessive temperature Bearing is the most important part of the jaw crusher It is easy to cause failure and damage the bearing under high temperature The following is the reason and solution of the high temperature of the jaw crusher bearing explained by Red Star Heavy Industry 1How to solve the high temperature of jaw crusher bearing?Therefore, during the working process of the jaw crusher, it is necessary to pay attention to whether the bearing is operating normally The common fault of jaw crusher bearings is that the temperature is too high What to do if the temperature is too high when the jaw crusher parts are running 1 The bearing of the jaw crusher is cut off orJaw Crusher Working Operation TemperatureIn the crushing industry, jaw crusher’s excellent performance saves the construction procedure greatlyHowever, in the working process, sometimes temperature rise phenomenon happensSolutions to the temperature rise of the jaw crusher

Jaw Crusher Handbook Stone Crusher PDF JXSC Mine

Jaw rock crusher must test run 2 hours when first startup It can be fed to work after the bolster temperature below 600 After that, a startup can work 3 Jaw crushers must be started with noload 4 Check that all the instruments are in good condition 5 Check the crushing cavity have or not Minerals and other noncrushing materialsJan 04, 2019 Jaw crushers A jaw crusher is a compressiontype of crusher Material is reduced by squeezing the feed material between a moving piece of steel and a stationary piece The setting or the space between those two pieces of steel controls the discharge size The tighter the setting, the smaller the output size and the lower the throughput capacityTips for maintaining efficiency in crushing circuits – Quarryjaw crusher running temperature GM stone crusher machine is designed to achieve maximum productivity and high reduction ratio From large primary jaw crusher and impact crusher to cone crusher and VSI series for secondary or tertiary stone crushing, GM can supply the right crusher as well as complete crushing plant to meet your material reduction requirementsjaw crusher running temperature parketcorneilliebevibrating feeder, jaw crusher, impact crusher or cone crusher, vibrating screen, belt conveyor and centrally electric controlling system, etc The designed capacity is from 40t/h to 600t/h To meet customer’s specific requirement for the stone crushing, we can also add other equipments such as cone crusher, dust catcher on the crushing plantCrushing PlantJaw CrusherIn the crushing industry, jaw crusher’s excellent performance saves the construction procedure greatlyHowever, in the working process, sometimes temperature rise phenomenon happensSolutions to the temperature rise of the jaw crusher

Jaw Crusher Working Operation Temperature

Therefore, during the working process of the jaw crusher, it is necessary to pay attention to whether the bearing is operating normally The common fault of jaw crusher bearings is that the temperature is too high What to do if the temperature is too high when the jaw crusher parts are running 1 The bearing of the jaw crusher is cut off orThe common fault of jaw crusher bearings is that the temperature is too high What to do if the temperature is too high when the jaw crusher parts are running 1 The bearing of the jaw crusher is cut off or injected too much oil Simple solution: just check the instructions carefully and fill in the oil regularly and quantitatively according How to solve the phenomenon that the bearing temperature What to inspect on Jaw Crusher bearings? Regularly check temperature of inner and outer swing stock bearings It should never exceed 60 degrees centigrade in normal applications Inspect labyrinth seals, they should always be lubricated to keep a dust sealGetting the most out of your Jaw Crusher Pilot CrushtecSep 10, 2019 In the use of the jaw crusher thin oil system, the temperature of the oil return should not exceed 60 degrees When the temperature is too high, we need to adjust the oil flow by adjusting the oil valve or use water cooling to reduce the temperature This will ensure the work of its productionJaw Crusher Lubrication Knowledge Analysis So when using the crusher must always pay attention to the internal temperature, if the device temperature is too high on the timely shutdown, such as when the temperature is reduced 4jaw crusher running, is strictly prohibited any cleanup work and install the removal of the belt; prohibit the hand or pry bar from the loading port to remove 5 place to be paid attention during the jaw crusher

jaw crusher running temperature parketcorneilliebe

jaw crusher running temperature GM stone crusher machine is designed to achieve maximum productivity and high reduction ratio From large primary jaw crusher and impact crusher to cone crusher and VSI series for secondary or tertiary stone crushing, GM can supply the right crusher as well as complete crushing plant to meet your material reduction requirementsvibrating feeder, jaw crusher, impact crusher or cone crusher, vibrating screen, belt conveyor and centrally electric controlling system, etc The designed capacity is from 40t/h to 600t/h To meet customer’s specific requirement for the stone crushing, we can also add other equipments such as cone crusher, dust catcher on the crushing plantCrushing PlantJaw Crusherstone crushers SS Engineers "suresh india Crushing 2002 – 48 x 10, 48 x 8, 42 x 32 New range of crusher manufactured and running Successfully 2003 – HIS VSI been designed and manufactured 2005 – First 150 – 200 TPH Trunkey with only Jaw Crusher Delivered at Harsol 2010 – First Indian Manufacturer to get Single toggle Auto Grease Type Jaw 2016 – Cone Crusher 100TPH,150TPH Jaw Crusher Running Temperature Rock Crusher India RockDescription A Laboratory Jaw Crusher engineered for precrushing of extremely hard up to brittle materials The 4″ x 5″ 911MPEJC100 Jaw Crusher is designed for batch and continuous crushing of middle hard, hard brittle and tough materials for the following fine grinding Principle of operation of this crusher The Model 100 mm X 130 mm 911MPEJC100 Jaw Crusher is used by laboratories and Laboratory Jaw Crusher 911MetallurgistDuring the fine crushing production of cone crusher, the problem of high lubricating oil temperature occurredEven when the fan cooler was running, the oil temperature was still higher than 50 the operating temperature was better kept within the range ofTemperature In Cement Crusher

AMIT 129: Lesson 12 Crusher and Mill Operation Safety

Crusher Blockage Clearing blocked jaw crushers can be very hazardous and many plant operators have been killed carrying out this task Blockage incidents can be greatly reduced by supplying rock that is properly sized to match the primary jaw opening Prevention of oversize in feed material starts at the face with good fragmentationA few helpful tips will keep not only your crusher, but also other heavy equipment running when the temperature drops Cold weather means the possibility of diesel fuel gelling Diesel that has gelled can cause the engine to not start at all or shut down midoperationKeeping your Equipment Running in Eagle Crusher CompanyHow to solve the temperature of jaw crusher is too high 10:17:05 The jaw crusher is composed of a movable jaw and a static jaw to form a crushing cavity, which simulates the movement of the animal's jaws to complete the material crushing operation Used in the crushing of various ores and bulk materials in mining smelting, building materials, highways, railways, water conservancy How to solve the temperature of jaw crusher is too high Therefore, during the working process of the jaw crusher, it is necessary to pay attention to whether the bearing is operating normally The common fault of jaw crusher bearings is that the temperature is too high What to do if the temperature is too high when the jaw crusher parts are running 1 The bearing of the jaw crusher is cut off orJaw Crusher Working Operation TemperatureA few helpful tips will keep not only your crusher, but also other heavy equipment running when the temperature drops Cold weather means the possibility of diesel fuel gelling Diesel that has gelled can cause the engine to not start at all or shut down midoperationKeeping your Equipment Running in Eagle Crusher Company

Jaw Crusher Lubrication Knowledge Analysis

Sep 10, 2019 There is also the temperature of the jaw crusher lubricant, we must also pay attention In the use of the jaw crusher thin oil system, the temperature of the oil return should not exceed 60 degrees When the temperature is too high, we need to adjust the oil flow by adjusting the oil valve or use water cooling to reduce the temperatureTherefore, mining or gravel aggregate producers need to do a good job in advance for jaw crusher bearing protection, so as not to cause unnecessary trouble in production Under normal circumstances, bearing’s temperature is around 30℃, and the maximum temperature should not exceed 70℃, otherwise, the bearing will deform because of the Beware of Jaw Crusher Bearings in High Summer Temperature 2 Trial run with load Do trial run with load after first successful trial run a No periodical or obvious impact sound in crusher b The biggest size of the feeding material must accord to specification c Constant running 8 hours for the first time, bearing temperature increase no more than 30°C 3 The checking before the startupHow to Operate the Jaw Crusher? Luoyang Dahuavibrating feeder, jaw crusher, impact crusher or cone crusher, vibrating screen, belt conveyor and centrally electric controlling system, etc The designed capacity is from 40t/h to 600t/h To meet customer’s specific requirement for the stone crushing, we can also add other equipments such as cone crusher, dust catcher on the crushing plantCrushing PlantJaw CrusherThe test run of impact crusher includes noload test run and load test run Through the test run, some faults and problems of the equipment can be found in advance Only by finding and solving these problems can the normal operation of the crusher be guaranteed Therefore, the test run of impact crusher is necessary and important Noload test Test Run of Impact CrusherCrusher Manufacturers Luoyang

EQUIPMENT AND MAINTENANCE

Keywords: Equipment, Maintenance, Crushers, Jaw crushers, Rock breakers, Refurbishing, Choking, Lubricating systems field from the late 1800s to the early 1900s In 1910 the largest gyratory cru shers built had 48inch openings However, about this time the jaw crusher came to The Hewitt Robins Jaw Crushers are known for durable construction, high productivity and a greater value for investment The rugged design provides the Reliability, quality, capacity, and ease of use you can expect with products from Hewitt Robins and the Jaw crushers Jaw Crushers by Hewitt Robins InternationalJan 13, 2014 Shanghai Veking Heavy Industries Co,Ltd is a professional manufacturer which mainly produces crushing and screening machines, including cone crusher, jaw crusher, sand making machine, impact running vibrating feeder, jaw crusher and belt conveyor Parts are easy to find, and maintenance is straightforward Carminex carries a full stock of jaw crusher parts to keep your machines up and running Performing simple maintenance will ensure that your jaw crushers provide longterm value Introducing the Cone Crusher Cone crushers take care of secondary and tertiary crushing applicationsJaw Crusher vs Cone Crusher: A ComparisonVertical Shaft Impact Crusher Routine Maintenance 1〉Check firmware every shift, fasten immediately if any flexible 2〉Stop the machine termly, open the checking door and check inside wear condition Replace and remove immediately if any wear, wearable block should be changed whole set if any wear to keep impeller balance in runningMaintenances Crusher Spare Parts For Sale

Temperature In Cement Crusher

During the fine crushing production of cone crusher, the problem of high lubricating oil temperature occurredEven when the fan cooler was running, the oil temperature was still higher than 50 the operating temperature was better kept within the range of