Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

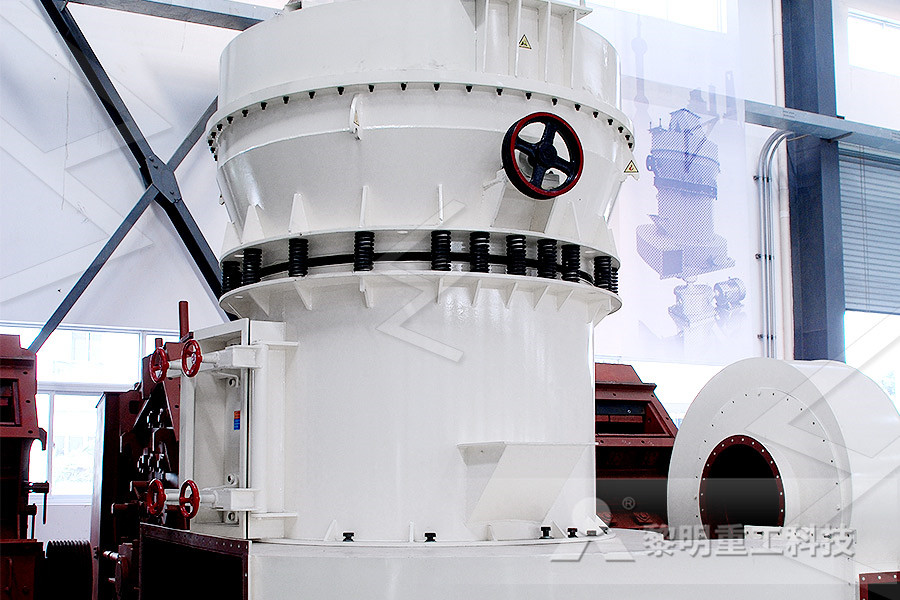

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Key Components Design of Vertical Shaft Impact

This paper introduced the structure and working principle of the vertical sharft impact crusher The determation of its main parameters is investigated in the first placeDesign program and practical application of its key components is then described in detailOn the basis of above work,3D digital model of this crusher is also built up by using Siemens NX 70, which improves the design Vertical Shaft Impactor (VSI) Working principle of vertical shaft impactor is totally different than horizontal shaft impactor It has a high speed rotor with wearing resistant tips and main chamber (crushing chamber) is designed in such a way so that speed rotor throw Read the rest > Impact Crusher, Quarry Crusher Manufacturer SHUNKYImpactcrusherModeling and Optimization of a Vertical Shaft Impactor for Modeling and Optimization of a Vertical Shaft Impactor for Production of Artificial Sand Master of Science Thesis , Vertical Shaft Impact crushers have been used for a long time to reduce the size of , Design to represent the crusher and rotor geometries in the system The modelled VSI isvertical shaft crusher design referencesVertical shaft impact VSI crushers Barmac vertical shaft impact VSI crushers were the first vertical shaft impactors in the world The original Barmac VSI crusher was developed in New Zealand over 40 years ago after which the VSI crushers have spread to thousands of crushing sites around the globe Read Morevertical shaft impact crusher design pdf azdocnlThe vertical spindle is free to rotate around its own axis The crusher illustrated is a shortshaft suspended spindle type, meaning that the main shaft is suspended at the top and that the eccentric is mounted above the gear The shortshaft design has superseded the longshaft design in which the eccentric is mounted below the gearCrusher Wikipedia

(PDF) Design and performance evaluation of

Design and performance evaluation of vertical shafts: rational shaft design method and verification of design method January 2011 Canadian Geotechnical Journal 25(2):320337TYPES OF SHAFT:Transmission shaft: These shafts transmit power between the source and machines absorbing power The counter shafts, line shafts, overhead shafts all shafts are transmission shafts Machine shafts: These shafts from an integral part of the machine itself DESIGN OF SHAFTS The shaft may be designed on the basis of 1 Strength 2Shaft Design Material , Types , How to Design ShaftShaft design based on strengthShaft design based on strength Ai l t ( ti )Axial stress (continue): 1 αλ==≤,( /)L r 115 2,( /) 5 1 00044 yc 115 s λ λ αλ − => 2, π nE n = 10 for hinged end; n = 225 for fixed end n = 16 for ends ppy , g,artly restrained, as in bearing , L = shaft length syc = yypield stress in compression Lecture1 ME 343: Mechanical Design3 University of Babylon1250 MECHANICAL DESIGN OF MIXING EQUIPMENT Figure 211 Directdrive portable mixer (Courtesy of Lightnin) mixers are mounted on the vertical centerline of a tank with baffles, but may be offcenter or offcenter, angle mountedCHAPTER 21 Mechanical Design of Mixing EquipmentShaft mining or shaft sinking is excavating a vertical or nearvertical tunnel from the top down, where there is initially no access to the bottom Shallow shafts, typically sunk for civil engineering projects, differ greatly in execution method from deep shafts, typically sunk for mining projectsWhen the top of the excavation is the ground surface, it is referred to as a shaft; when the top Shaft sinking Wikipedia

Key Components Design of Vertical Shaft

This paper introduced the structure and working principle of the vertical sharft impact crusher The determation of its main parameters is investigated in the first placeDesign program and practical application of its key components is then described in detailOn the basis of above work,3D digital model of this crusher is also built up by using Siemens NX 70, which improves the design Modeling and Optimization of a Vertical Shaft Impactor for Modeling and Optimization of a Vertical Shaft Impactor for Production of Artificial Sand Master of Science Thesis , Vertical Shaft Impact crushers have been used for a long time to reduce the size of , Design to represent the crusher and rotor geometries in the system The modelled VSI isvertical shaft crusher design referencesVertical shaft impact VSI crushers Barmac vertical shaft impact VSI crushers were the first vertical shaft impactors in the world The original Barmac VSI crusher was developed in New Zealand over 40 years ago after which the VSI crushers have spread to thousands of crushing sites around the globe Read Morevertical shaft impact crusher design pdf azdocnlDesign and performance evaluation of vertical shafts: rational shaft design method and verification of design method January 2011 Canadian Geotechnical Journal 25(2):320337(PDF) Design and performance evaluation of Vertical shaft impact vsi crushers vertical shaft impact vsi crushers were the first vertical shaft impactors in the world the original barm address no 169 scientific avenue, national hightech industrial development zone, zhengzhou Impact crusher vertical dwgVertical Shaft Impact Crushers Manufacturer In

ME 343: Mechanical Design3 University of Babylon

Shaft design based on strengthShaft design based on strength Ai l t ( ti )Axial stress (continue): 1 αλ==≤,( /)L r 115 2,( /) 5 1 00044 yc 115 s λ λ αλ − => 2, π nE n = 10 for hinged end; n = 225 for fixed end n = 16 for ends ppy , g,artly restrained, as in bearing , L = shaft length syc = yypield stress in compression Lecture1 Vertical shaft furnace design and operation have their roots deep in antiquity There is substantial evidence to indicate that iron was reduced from its oxides to serve mankind’s needs long before recorded civilization actually prior to 3500 BC For at least 5500 years man has been matching wits with Nature to find better methods of extracting this most common, yet essential, Vertical Shaft Furnace Design1250 MECHANICAL DESIGN OF MIXING EQUIPMENT Figure 211 Directdrive portable mixer (Courtesy of Lightnin) mixers are mounted on the vertical centerline of a tank with baffles, but may be offcenter or offcenter, angle mountedCHAPTER 21 Mechanical Design of Mixing EquipmentShaft mining or shaft sinking is excavating a vertical or nearvertical tunnel from the top down, where there is initially no access to the bottom Shallow shafts, typically sunk for civil engineering projects, differ greatly in execution method from deep shafts, typically sunk for mining projectsWhen the top of the excavation is the ground surface, it is referred to as a shaft; Shaft sinking WikipediaMechanical Motion Systems; Making the Right Shaft Connections Securing a belt pulley to a drive shaft often seems like such a routine task, that engineers and mechanics can easily overlook some Making the Right Shaft Connections Machine

Key Components Design of Vertical Shaft

This paper introduced the structure and working principle of the vertical sharft impact crusher The determation of its main parameters is investigated in the first placeDesign program and practical application of its key components is then described in detailOn the basis of above work,3D digital model of this crusher is also built up by using Siemens NX 70, which improves the design 132 Vertical Shaft Impact Crusher 4 14 Advantages of Impact crushers 5 15 Principle of Operation 5 Chapter 2: Design and Calculation 21 Design of VBelt drive 7 22 Design of Shaft 10 23 Design DESIGN AND ANALYSIS OF IMPACT CRUSHERSModeling and Optimization of a Vertical Shaft Impactor for Modeling and Optimization of a Vertical Shaft Impactor for Production of Artificial Sand Master of Science Thesis , Vertical Shaft Impact crushers have been used for a long time to reduce the size of , Design to represent the crusher and rotor geometries in the system The modelled VSI isvertical shaft crusher design referencesVertical shaft impact VSI crushers Barmac vertical shaft impact VSI crushers were the first vertical shaft impactors in the world The original Barmac VSI crusher was developed in New Zealand over 40 years ago after which the VSI crushers have spread to thousands of crushing sites around the globe Read Morevertical shaft impact crusher design pdf azdocnlVertical shaft impact vsi crushers vertical shaft impact vsi crushers were the first vertical shaft impactors in the world the original barm address no 169 scientific avenue, national hightech industrial development zone, zhengzhou Impact crusher vertical dwgVertical Shaft Impact Crushers Manufacturer In

ME 343: Mechanical Design3 University of Babylon

Shaft design based on strengthShaft design based on strength Ai l t ( ti )Axial stress (continue): 1 αλ==≤,( /)L r 115 2,( /) 5 1 00044 yc 115 s λ λ αλ − => 2, π nE n = 10 for hinged end; n = 225 for fixed end n = 16 for ends ppy , g,artly restrained, as in bearing , L = shaft length syc = yypield stress in compression Lecture1 Vertical shaft furnace design and operation have their roots deep in antiquity There is substantial evidence to indicate that iron was reduced from its oxides to serve mankind’s needs long before recorded civilization actually prior to 3500 BC For at least 5500 years man has been matching wits with Nature to find better methods of extracting this most common, yet essential, metal from her Vertical Shaft Furnace DesignInnovative Vertical Axis Wind Turbine designs you can take inspiration from While most of us would be satisfied with above DIY designs, there are a few who would surely like to take things to the next level And if you are one of those few, you would surely like to know what else can you do with a vertical DIY Vertical Axis wind turbine designs and much Shaft mining or shaft sinking is excavating a vertical or nearvertical tunnel from the top down, where there is initially no access to the bottom Shallow shafts, typically sunk for civil engineering projects, differ greatly in execution method from deep shafts, typically sunk for mining projectsWhen the top of the excavation is the ground surface, it is referred to as a shaft; when the top Shaft sinking WikipediaMechanical Motion Systems; Making the Right Shaft Connections Securing a belt pulley to a drive shaft often seems like such a routine task, that engineers and mechanics can easily overlook some Making the Right Shaft Connections Machine