Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

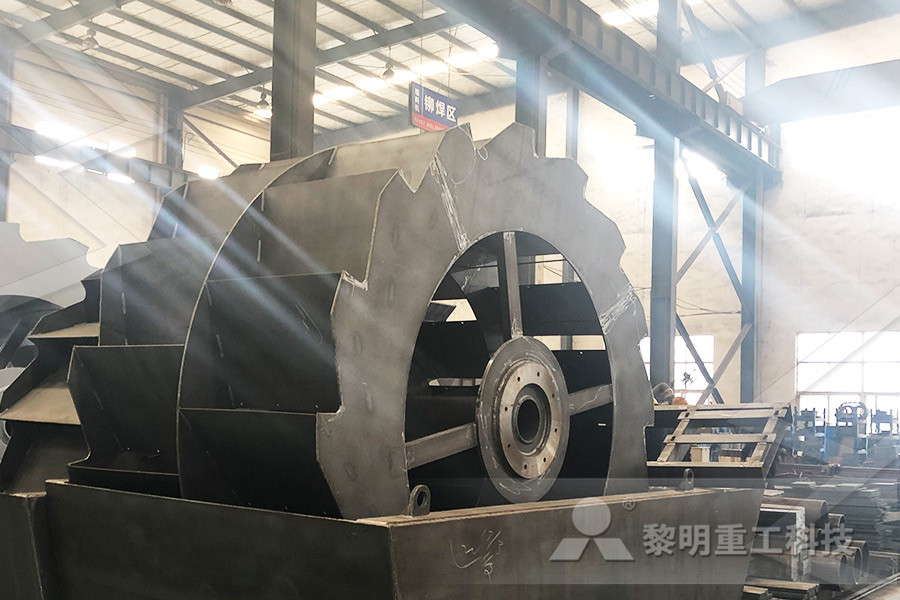

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

1210 Gray Iron Foundries US EPA

1210 Gray Iron Foundries 12101 General Iron foundries produce highstrength castings used in industrial machinery and heavy transportation equipment manufacturing Castings include crusher jaws, railroad car wheels, and automotive and truck assemblies Iron foundries cast 3 major types of iron: gray iron, ductile iron, and malleable iron The term cast iron is generally used to describe grey cast iron, but it can also describe a whole group of alloys too The surface color of the cast iron is often used to identify it Cast iron begins its life as pig iron, which is remelted and often combined with large amounts of scrap iron and sometimes with steelManufacturing Process of Cast Iron CastingsDuctile iron is made by the treatment of molten iron with nodulizing (spheroidizing) material During this treatment, graphite changes from flakes to nodules or spheres The treatment process is a key operation in the production of ductile iron that ensures a predetermined microstructure, and mechanical and engineering properties of castingsProcessing Techniques and Productions of Ductile Iron: A FOUNDRY 101 Stefan Drambarean Methods/Casting Design Eng Casting Process • Pattern • Mold • Molten Metal / Pouring • Cooling / Shakeout • Cleaning / HT • QC • Machining – Added value Pattern Making 1 Casting Design –PL, draft, FOUNDRY 101 Harrison Steel Castings CompanyGray iron, or grey cast iron, is a type of cast iron that has a graphitic microstructure It is named after the gray color of the fracture it forms, which is due to the presence of graphite It is the most common cast iron and the most widely used cast material based on weight It is used for housings where the stiffness of the component is more important than its tensile strength, such Gray iron Wikipedia

Foundry Sand Casting Process: Simple Step by

10072017 The sand casting process contains six basic steps While proper equipment and experience is required to produce a casting free of defects, the sand casting process itself is actually quite simple: 1 Create a Mold The first step is to create the mold for the casting14082020 Iron processing, use of a smelting process to turn the ore into a form from which products can be fashionedIncluded in this article also is a discussion of the mining of iron and of its preparation for smelting Iron (Fe) is a relatively dense metal with a silvery white appearance and distinctive magnetic properties It constitutes 5 percent by weight of the Earth’s crust, and Iron processing BritannicaA simplified schematic drawing of copper flotation flowsheet Runofmine open pit ore will be crushed in a gyratory crusher The crushed ore will be processed by means of semiautogenous and ball mill grinding followed by rougher flotation, regrind, cleaner flotation, and dewatering to produce copper concentrate The concentrate will be trucked via the existing road network in Copper Process Flowsheet Example1210 Gray Iron Foundries 12101 General Iron foundries produce highstrength castings used in industrial machinery and heavy transportation equipment manufacturing Castings include crusher jaws, railroad car wheels, and automotive and truck assemblies Iron foundries cast 3 major types of iron: gray iron, ductile iron, and malleable iron 1210 Gray Iron Foundries US EPAfinish Some of these processes are die casting process, investment casting process, vacuumsealed moulding process, and shell moulding process • Metal casting is a labour intensive process • Automation: a question NPTEL course on Manufacturing processes – I, Metal casting processes

A Production Planning Model for Maketo

The production process of foundry enterprise is various and complex, as well as various physical changes and chemical changes at the same time []Therefore, reasonable production planning is the key element of foundry enterprise; it is not only the main component to ensure the stable operation of production but also an effective guarantee to complete production targetSince the 20th century, for foundry industry, gray iron inoculation treatment and chemical hardening sand molding process have two new special significance These two inventions has broken the traditional methods for thousands of years, and has opened up new areas to improve the competitiveness of the castingMetal Casting Basic Knowledge Dandong Foundry10072017 The sand casting process contains six basic steps While proper equipment and experience is required to produce a casting free of defects, the sand casting process itself is actually quite simple: 1 Create a Mold The first step is to create the mold for the castingFoundry Sand Casting Process: Simple Step by Later, around 2000 BCE, iron was discovered But it was not until around 700 BCE that the first production of cast iron was developed in China Interestingly enough, the sand molding process of casting metals was also invented in China in 645 BCEThe Metal Casting Process Explained General Technological process: have used centrifugal casting processes to produce steel, iron and nonferrous carbon alloy castings Among them, the production of centrifugal cast iron tubes, There are no restrictions on the types of alloys and the production batches Such as gray cast iron engine box, high manganese steel elbow and so on10 Different Types of Casting Process

The Differences Between Ductile Iron and Gray

There are many grades of gray iron as per the ASTM A48 standard While gray iron does not have a measurable yield strength, the range for tensile strength is 20,000 psi – 60,000 psi Impact – Ductile iron has a greater resistance to impacts, and is able to resist a minimum of 7 foot pounds of impact (versus 2 pounds of impact for gray iron)The Manganese Mining Process More than 25 million tons of manganese are mined every year Most manganese mining occurs in open pits Although there are processes in place to mine manganese nodules in the ocean floor, they cannot complete with landbased mining productionManganese Mining and Processing: Everything A simplified schematic drawing of copper flotation flowsheet Runofmine open pit ore will be crushed in a gyratory crusher The crushed ore will be processed by means of semiautogenous and ball mill grinding followed by rougher flotation, regrind, cleaner flotation, and dewatering to produce copper concentrate The concentrate will be trucked via the existing road network in Copper Process Flowsheet Example1210 Gray Iron Foundries 12101 General Iron foundries produce highstrength castings used in industrial machinery and heavy transportation equipment manufacturing Castings include crusher jaws, railroad car wheels, and automotive and truck assemblies Iron foundries cast 3 major types of iron: gray iron, ductile iron, and malleable iron 1210 Gray Iron Foundries US EPA10072017 The sand casting process contains six basic steps While proper equipment and experience is required to produce a casting free of defects, the sand casting process itself is actually quite simple: 1 Create a Mold The first step is to create the mold for the castingFoundry Sand Casting Process: Simple Step by

The Metal Casting Process Explained General

Later, around 2000 BCE, iron was discovered But it was not until around 700 BCE that the first production of cast iron was developed in China Interestingly enough, the sand molding process of casting metals was also invented in China in 645 BCEThere are many grades of gray iron as per the ASTM A48 standard While gray iron does not have a measurable yield strength, the range for tensile strength is 20,000 psi – 60,000 psi Impact – Ductile iron has a greater resistance to impacts, and is able to resist a minimum of 7 foot pounds of impact (versus 2 pounds of impact for gray iron)The Differences Between Ductile Iron and Gray Technological process: have used centrifugal casting processes to produce steel, iron and nonferrous carbon alloy castings Among them, the production of centrifugal cast iron tubes, There are no restrictions on the types of alloys and the production batches Such as gray cast iron engine box, high manganese steel elbow and so on10 Different Types of Casting Process Iron castings, as objects of art, weapons of war, or in more utilitarian forms, have been produced for more than 2000 years As a commercial process, the production of iron castings probably has no equal for longevity, success or impact on our societyDUCTILE IRON DATA FOR ENGINEERS DIYTrade05112010 FoundryBasics 1 FoundryBasics By MrBRamesh, ME, (PhD), Research Scholar, CEG, Anna University, Chennai Associate Professor, Department of Mechanical FoundryBasics SlideShare

Production of iron and steel SlideShare

27042015 4/27/2015 11 Production of Pig – Iron process Scrap Change vessel converter Converter operation Furnace Pig Iron Ladle metallurgy 3 Steel production Engineering Materals II (MEng 2122) 12 4/27/2015 12 Production of Pig – Iron process Continuous casting plant 4 Products Slabs Rounds By Products Engineering Materals II (MEng 2122) 13The Manganese Mining Process More than 25 million tons of manganese are mined every year Most manganese mining occurs in open pits Although there are processes in place to mine manganese nodules in the ocean floor, they cannot complete with landbased mining productionManganese Mining and Processing: Everything A simplified schematic drawing of copper flotation flowsheet Runofmine open pit ore will be crushed in a gyratory crusher The crushed ore will be processed by means of semiautogenous and ball mill grinding followed by rougher flotation, regrind, cleaner flotation, and dewatering to produce copper concentrate The concentrate will be trucked via the existing road network in Copper Process Flowsheet Example