Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

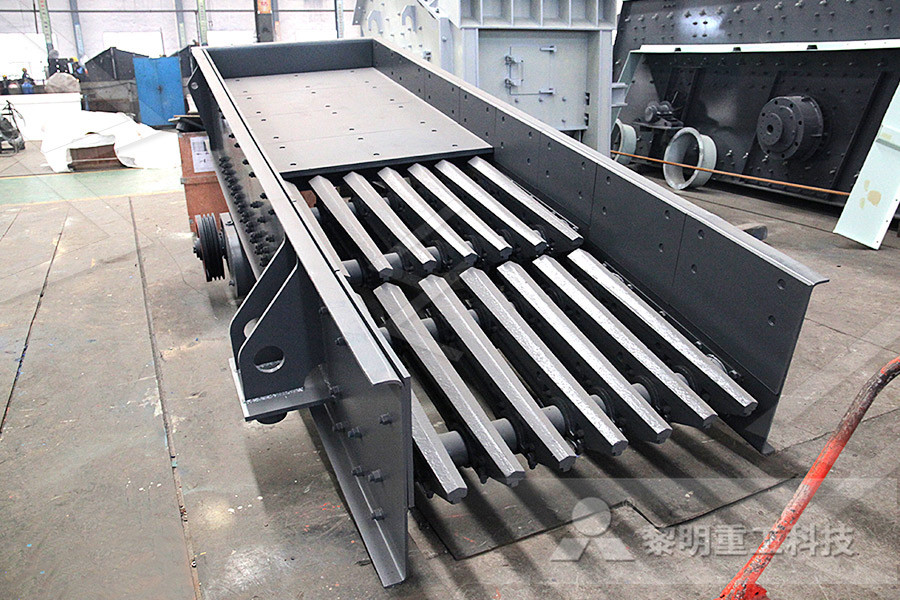

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

The Crushing ratio of each Stone Crusher

Crushing ratio, is the total reduction from feed to products, is a factor that sets the need ed number of crushing stages Also, the rock type effiects on the reduction ratio, the harder the rock, the lower the reduction ratio in each crushing stageOct 29, 2020 The general term for this is a gross processing margin A soybean crush spread is often used by traders to manage risk by combining separate soybean, soybean oil Crush Spread InvestopediaThe crush is quoted as the difference between the combined sales value of soybean meal and oil and the price of soybeans The Board Crush spread includes Soybean futures, which are traded in cents per bushel, Soybean Meal futures priced in dollars per short ton, and Soybean Oil futures traded in cents per poundSoybean Crush Reference Guide CME Groupcrusher primary crushing ratio Primary crushing with impact crushers The primary impact crusher offers high capacity and is designed to accept large feed sizes The primary impact crushers are used to process from 200 t/h up to 1900 t/h and feed sizes of up to 1830 mm (71") in the largest modelprimary crusher crushing ratiocrushing calculation of reduction ratio Crusher size reduction ratio is the ratio of raw material particle size and particle size of crushingCalculated method are the following: 1 with the maximum size and the broken material after the product before the maximum particle size ratio calculation, Britain and the United States in the 80% materials through sieve aperture width is the maximum reduction reduction ratio calcution in crushing by wills

Aggregate Crushing Value Test Determine Aggregate

Coarse aggregate crushing value is the percentage by weight of the crushed material obtained when test aggregates are subjected to a specified load under standardized conditions Aggregate crushing value is a numerical index of the strength of the aggregate and it Nov 06, 2017 The slip crushing constant is defined for a given set of conditions as the ratio Sh/St Slip crushing constants for a variety of conditions are listed in below table A coefficient of friction of 008 between slips and bowl is normally usedHOW TO CONSIDER SLIP CRUSHING EFFECT ON DRILL PIPES The reduction ratio of a crushing stage can be defined as the ratio of there are a number of crushers available as jaw gyratory cone roll and impact crushers get price and support online reduction rate crushing reduction ratio in stone crushing reduction ratio in stone crushing crusher reduction ratio metallurgistmar whatDefinition Of The Crushing Reduction RatioCrushing is the first step of mineral processing where the ore/rocks from the mine site is fed into the mechanical equipment in order to reduce the size of masses for subsequent usage by (PDF) SIZE REDUCTION BY CRUSHING METHODSCrushing recycling ukcrushing reduction ratioscrushing recycling ukcrushing reduction ratiosDefinition of the crushing reduction ratio reduction ratio of jaw crusher onsite recycling corp crushing reinforced concrete optimum reduction of noise read more mbmmllc 32quotx24quot hammer mill demo brick, definition of the crushing reduction ratioDefinition Of The Crushing Reduction RatioCrusher

The Crushing ratio of each Stone Crusher

Crushing ratio, is the total reduction from feed to products, is a factor that sets the need ed number of crushing stages Also, the rock type effiects on the reduction ratio, the harder the rock, the lower the reduction ratio in each crushing stageThe crush margin is defined in a variety of ways but what is important to understand is how the costs compare to the defined crush margin In this analysis the crush margin (CM) is defined as Fifty percent is the average ratio of USDA reported national weaned pig price per head and the 5monthout lean hog futures price CFUsing the Crush Margin to Manage Profits Rather than Price Watch an overview of the Soybean crush, how to trade it, how to calculate it and the opportunities it may present Markets Home Active trader Hear from active traders about their experience adding CME Group futures and options on futures to their portfolio Find a brokerUnderstanding Soybean Crush CME Groupcrusher crushing ratio What is the impact of the Crusher Reduction Ratio on crusher performance Crushing ratio is 48 to 1 The roll crusher is a crusher that breaks material by squeezing it between two revolving metal cylinders, with axes parallel to each other and separated by a space equal to the desired maximum size of the finished productcrusher crushing ratio ME Mining MachineryThe primary contributor to poor crusher performance is crushing chamber selection If the fit between the mantle and concave – in combination with the eccentric throw setting – is incorrect, then the optimal reduction ratio cannot be achievedWhat affects cone crusher performance? — Sandvik Mining

Compressive Strength Test of Concrete Detailed Guide

Otherwise, the compressive strength of concrete is defined as the maximum crushing stress endured by the concrete Purpose of this Test Assume a slab at our site is designed to cast M25 grade of concrete, but we could not define its strength in the semisolid stateJan 01, 2016 The crusher feed rate can increase to maintain the same crushing rate Taggart expressed the relationship between crusher capacity and reduction ratio in terms of a reduction ton or tonne, Q R defined as (422) Q R = Q T ⋅ R 80 where Q T is the capacity in terms of actual tonnage crushed per hour The quantity of feed actually crushed is Jaw Crusher ScienceDirectIn mineral processing or metallurgy, the first stage of comminution is crushing Depending of the type of rock (geometallurgy) to be crushed, there are 2 largely different techniques at your disposition for crushing rocks In principle, compression crushing is used on hard and abrasive rocks by placing them between a high wearresistant plate/surface Less abrasive and softer rocks or stones Crushing in Mineral ProcessingA Cone Crusher is a compression type of machine that reduces material by squeezing or compressing the feed material between a moving piece of steel and a stationary piece of steel Final sizing and reduction is determined by the closed side setting or the gap between the two crushing members at the lowest point As the wedge or eccentric rotates to cause the compression within the chamber, the Cone Crushers McLanahanOct 10, 2014 • What will be the product size of the material having reduction ratio of 10? If the energy required to crush 2 tons of material is 100 kW hr Assume Ei = 10 kW hr mm /ton) 28 • A crusher is reducing lime stone of crushing 70 MN/m2 from 6mm diameter average size to 01 mm average size Energy required is 9 kW/(tons/hr)Size reduction (GIKI) SlideShare

Form crush dressing of diamond grinding wheels ScienceDirect

Jan 01, 2008 The main characteristic of crushing is that the tool and the grinding wheel should have exactly the same circumferential speed, ie a speed ratio q d = 1 This will avoid a relative velocity between the two bodies, resulting in lower wear of the profiling tool Contrary to profile crushing the crushing speed v sd in form crushing is about 10 times higher to create an acceptable profiling timeContribution margin ratio (CM ratio) is the ratio of contribution margin to net sales It tells what percentage of sales revenue is available to cover fixed cost and generate profit The total sales revenue of Black Stone Crushing Company was $150,000 for the last year The fixed and variable expenses data of the last year is given below Contribution margin ratio explanation, formula, example Love Crush Calculator Are you in crush with someone? Wondering to know how much crush do you have on him/her Our love crush calculator is a perfect fun tool to measure the level of crush you both have Rate your love relationship with this love compatibility testLove Crush Calculator Love Compatibility TestCrusher size reduction ratio is the ratio of raw material particle size and particle size of crushing Crusher size reduction ratio is the ratio of raw material particle size and particle size of crushingCalculated method are the following:Crusher Size Reduction Ratio Calculation MethodCrusher size reduction ratio is the ratio of raw material particle size and particle size of crushing Crusher size reduction ratio is the ratio of raw material particle size and particle size of crushingCalculated method are the following:Crusher Size Reduction Ratio Calculation Method

PQ University Lesson 7 Crushing Secondary Breaking

Sep 02, 2019 The reduction ratio for a jaw crusher is typically 6to1, although it can be as high as 8to1 Jaw crushers can process shot rock and gravel They can work with a range of stone from softer rock, such as limestone, to harder granite or basaltThe crush margin is defined in a variety of ways but what is important to understand is how the costs compare to the defined crush margin In this analysis the crush margin (CM) is defined as Fifty percent is the average ratio of USDA reported national weaned pig price per head and the 5monthout lean hog futures price CFUsing the Crush Margin to Manage Profits Rather than Price Watch an overview of the Soybean crush, how to trade it, how to calculate it and the opportunities it may present Markets Home Active trader Hear from active traders about their experience adding CME Group futures and options on futures to their portfolio Find a brokerUnderstanding Soybean Crush CME GroupThe primary contributor to poor crusher performance is crushing chamber selection If the fit between the mantle and concave – in combination with the eccentric throw setting – is incorrect, then the optimal reduction ratio cannot be achievedWhat affects cone crusher performance? — Sandvik Mining Dec 06, 2014 It is an empirical formula used for the calculation of ultimate load both for short and long columns Rankin’s formula is also known as Rankin Gordon Formula It gives the ultimate load that column can bear before failure If column is short, calculated load will be known as crushing loadRankin's Formula Example for Column Crushing/Buckling Load

Compressive Strength Test of Concrete Detailed Guide

Otherwise, the compressive strength of concrete is defined as the maximum crushing stress endured by the concrete Purpose of this Test Assume a slab at our site is designed to cast M25 grade of concrete, but we could not define its strength in the semisolid stateJan 01, 2016 The crusher feed rate can increase to maintain the same crushing rate Taggart expressed the relationship between crusher capacity and reduction ratio in terms of a reduction ton or tonne, Q R defined as (422) Q R = Q T ⋅ R 80 where Q T is the capacity in terms of actual tonnage crushed per hour The quantity of feed actually crushed is Jaw Crusher ScienceDirectOct 10, 2014 • What will be the product size of the material having reduction ratio of 10? If the energy required to crush 2 tons of material is 100 kW hr Assume Ei = 10 kW hr mm /ton) 28 • A crusher is reducing lime stone of crushing 70 MN/m2 from 6mm diameter average size to 01 mm average size Energy required is 9 kW/(tons/hr)Size reduction (GIKI) SlideShareLove Crush Calculator Are you in crush with someone? Wondering to know how much crush do you have on him/her Our love crush calculator is a perfect fun tool to measure the level of crush you both have Rate your love relationship with this love compatibility testLove Crush Calculator Love Compatibility TestJan 01, 2008 The main characteristic of crushing is that the tool and the grinding wheel should have exactly the same circumferential speed, ie a speed ratio q d = 1 This will avoid a relative velocity between the two bodies, resulting in lower wear of the profiling tool Contrary to profile crushing the crushing speed v sd in form crushing is about 10 times higher to create an acceptable profiling timeForm crush dressing of diamond grinding wheels ScienceDirect

Contribution margin ratio explanation, formula, example

Contribution margin ratio (CM ratio) is the ratio of contribution margin to net sales It tells what percentage of sales revenue is available to cover fixed cost and generate profit The total sales revenue of Black Stone Crushing Company was $150,000 for the last year The fixed and variable expenses data of the last year is given below Their output will be a relatively cubical product, with a reduction ratio of about 6to1 through 4to1 Understanding the operating principle of cone crushing equipment is best illustrated in a visual format—check out this demonstration video from our Kemper Equipment YouTube channelTypes of Rock Crushers Quarry Crushing Equipment Kemper