Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

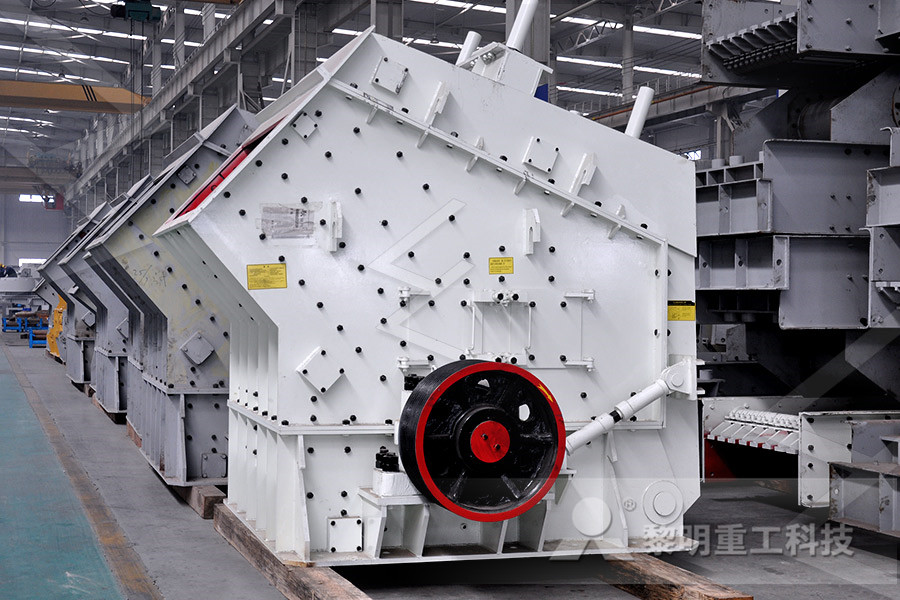

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

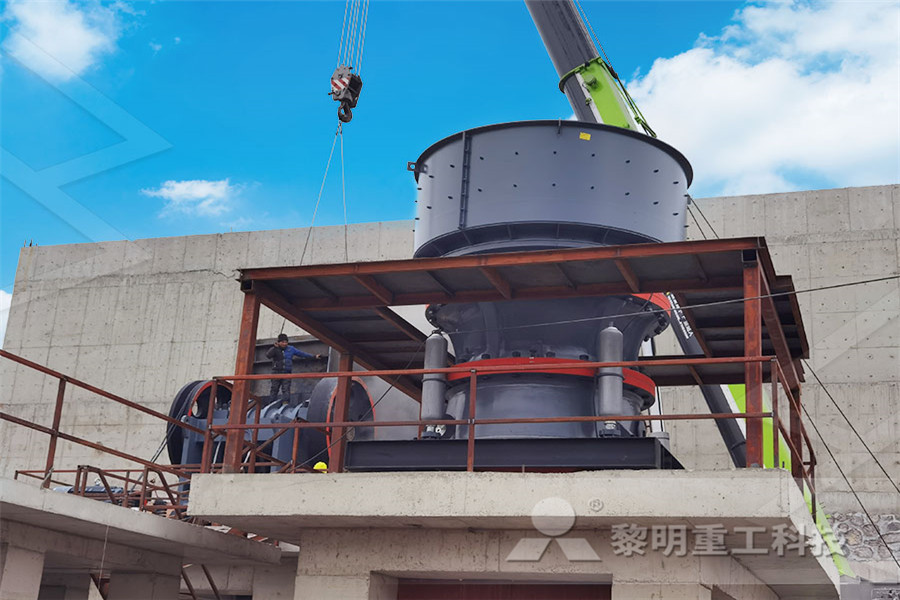

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Clinker Ball Mill For Cement Grinding Plant From

Cement Grinding Mill Plant Teresa plant the philippines cement grinding plant cement ball mill the ball mill for clinker is an efficient tool for fine powder grinding it is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy chemical electric power and other industries to grind all kinds of orescrusher in thermal power plant in philippines; parts to a john hammer mill screens in philippines; belt conveyor control in philippines; operational cement plants near nimbahera in philippines; production process of coal mining in philippines; iron ore mine in chili in philippines; ball mill steel ball price china in philippines; introduction cement ball mills erection manual in philippinesThe Tula plant mills installed by FCB Horomill offer the unique opportunity of having identical mills for raw and cement grinding plant, allowing for only one single set of spare parts for these two distinct sections Lone Star Industries Inc case study The third reported case study refers to the Buzzi Unicem US plant in Texas, hosting another FCBTeresa plant, the Philippines: cement grinding plantCement plant locations and information on Philippines can be found below For full access to the database, purchase The Global Cement Report™, 13th EditionCement Plants located in Philippines The Global CEMENT INDUSTRY Output of a Seminar on , 325 Finish grinding mill , can be easily mixed but a large amount of energy is consumed in clinker burning due to water , granite quarry plant stone crusher ball mill philippin ZYM main production aggregate stone crusher and raymond mill ball mill cement mill Leave A In Philippinesball mill in Philippines cement plant industry

Philippines Cement industry news from Global

Philippines: Gebr Pfeiffer has received an order for a modular fourroller ready2grind 2500 vertical grinding unit to Big Boss Cement’s Porac, Pampanga plant It says that the mill will have a production capacity of 70t/hr of cement, ground to a fineness of 4000cm2/g22052014 See more at: xbmmachine/BallMillhtmlThe ball mill is a key equipment to grind the crushed materials, and the ball mill is widely used in poBall mill for cement making plant, ball mill works A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cementMost cement is currently ground in ball mills and also vertical roller mills which are more effective than ball millsCement mill WikipediaA ball mill is a type of grinder used to grind or blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics, and selective laser sinteringIt works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell A ball mill consists of a hollow cylindrical shell rotating aboutBall mill Wikipedia21042017 Ball mill for cement making plant, ball mill works principle, China Ball mill Duration: 2:29 Eric Zhang 2,625 views 2:29 Language: English Location: United Stateshuge ball mills in cement plant YouTube

Our History CEMEX Philippines

In 2014, we continued our expansion at the APO Cement plant by adding a new cement mill with an additional installed annual capacity of 15 million tonnes of cement The investment included adding marine terminals in Davao and Iloilo as well as expanding our bulk dispatch capabilities at our APO Cement plantThe Cement Plant Operations Handbook is a concise, ball mills, vertical roller mills, roll presses, Horomill – in combination with separators and other optional ancillaries The finished product is collected by filters for transport to storage, prior to dispatchThe Cement Plant Operations HandbookCement Ball Mill The ball mill for clinker is an efficient tool for fine powder grinding It is mainly used to grind the clinker and raw materials in cement industry and also can be applied in metallurgy, chemical, electric power and other industries to grind all kinds of ores Cement ball mill is not only suitable for overflow grindingCHAENGMining Equipment SuppliersThe FCB Horomill ® is a breakthrough technology in bed compression grinding that enables producers to improve their grinding plant operation In order to enhance the plants’ production capacity and optimize the plant maintenance, Fives has implemented significant technical development on its new generation of FCB FCB Horomill® Fives in Cement MineralsOleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect Topics

Solutions efficiency for Mining, Cement,

Our ball mill liners are long lasting and reliable Unique expertise in crushing processes Magotteaux has unique expertise in all processes applied in the cement and aggregates industries We notably produce the Mag’Impact®, a VSI crusher, and all its associated VSI crusher parts, North Africa: Turkeybased DAL Engineering Group has announced that it has acted upon a contract to design and manufacture a ball mill for a grinding plant project It shipped the 30m x 10m mill to a grinding plant in North Africa in June 2020DAL Engineering Group delivers ball mill to Unique Group is a leader in the RD, manufacture, and distribution of Mining Machinery in China Our products comprise four categories: Stone Crusher,Stone Crushing Plant,Ore Processing Equipment,Cement Production LineStone CrusherStone Crusher PlantOre Processing Welcome to The Global Cement Report™ online database of cement plants This resource contains listings of over 2565 facilities worldwide (excluding China), and is the most uptodate listing of cement plant information available Basic data is available free of chargeThe Global Cement Report Online Database of develops customised solutions based on IoT technologies aimed at improving the performance of production equipment The use of sensors in moving parts and networkbased connectivity allows you to gather operating data from the equipment This can be applied to improve uptime of cement kilns and grinding millsDigitalisation in the cement production process

Gebr Pfeiffer

27052020 Another ready2grind unit for the Philippines BIGBOSS CEMENT Inc, (BBCI) with a plant located in the province of Pampanga, Philippines has recognized the advantages of this modular plant concept, comprising a 4roller vertical roller mill, and is of the opinion that ready2grind meets the requirements and provides the highest plant availabilityThe FCB Horomill ® is a breakthrough technology in bed compression grinding that enables producers to improve their grinding plant operation In order to enhance the plants’ production capacity and optimize the plant maintenance, Fives has implemented significant technical development on its new generation of FCB FCB Horomill® Fives in Cement MineralsOleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Tumbling Ball Mills Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on a small and large scale Grinding elements in ball mills travel at different velocities Therefore, collision force, direction and kinetic energy between two or more elements vary Ball Mills an overview ScienceDirect Topicsthe Barroso plant, Brazil, with a production capacity of 420 t/h of raw meal Cemex, Vicat are using Horomills for cement grinding in Turkey Lafarge, one of the early Horomill users with currently three units, has recently placed an order for a mill for cement grinding in its Teresa plant, the Philippines20 years of the Horomill – a review*)Cement and glass makers need integrated process control systems that can improve plantwide efficiency and productivity Our awardwinning process control solutions provide easy “single window” access to the process, production, quality and business information – from the most remote location to corporate headquarters They can be supplied by ABB’s global network of skilled control ABB process control solutions for cement plants

Cement Industry an overview ScienceDirect

Salah M El Haggar, in Environmental Solutions, 2005 Cement Industry The cement industry is one of the main industries necessary for sustainable development It can be considered the backbone for development The main pollution source generated from cement industry is the solid waste called cement bypass dust, which is collected from the bottom of the dust filterChile: Spain’s Cemengal has been confirmed as the supplier of a mill for Cementos Melón’s grinding plant at Punta Arenas The unit will use a Plug Grind Xtreme modular grinding plant The contract includes all the mechanical, electrical and automation equipment required for a 03Mt/yr modular ball mill Cemengal confirmed as mill supplier for The course content will be suitable for a wide range of personnel within a cement manufacturing company including junior/middle management, technicians, production and control room staff, etc and also for others who wish to gain a comprehensive understanding of the complete cement manufacturing Cement Manufacturing Technology CourseTaiheiyo Cement is the largest cement manufacturer of Japan and operates today 9 integrated plants all over Japan Beside the operations in Japan, the company also operates 3 plants in the USA, 3 in China and 1 in Vietnam and the PhilippinesNEWS spectraflowanalyticsIntroducing alternative fuels has an impact across the plant The materials can have totally different characteristics from fossil fuels They can be sticky, fluffy, moist, and fluctuating in size and quality or you may need to switch between different types of fuel with very different characteristics due to availabilityCut fuel costs with waste to energy solutions