Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

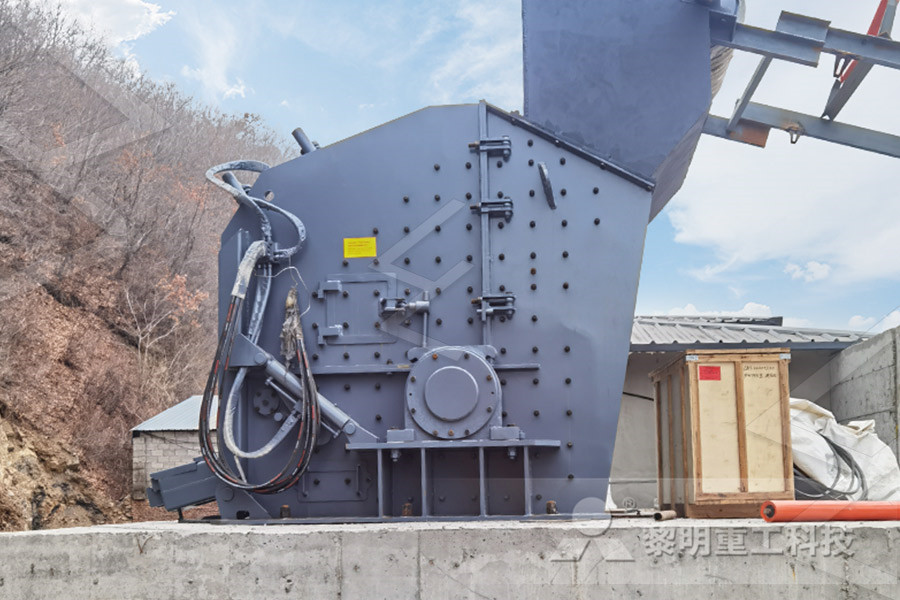

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Wet Grinding and Dispersing Equipment

Cutting edge technology The wet grinding and dispersing process defines your end product characteristics Our solutions include cuttingedge bead mills and threeroll mills, supported by unrivaled process and application expertise, to Cutting edge technology The wet grinding and dispersing process defines your end product characteristics Our solutions include cuttingedge bead mills and threeroll mills, supported by unrivaled process and application expertise, to Wet Grinding and Dispersing Equipment Innovative wet grinding and dispersing solutions We design and implement solutions tailored to your precise production requirements Working right across the globe, we focus on efficiency, robust design, ease of use and Wet Grinding and Dispersing Plant Engineering Wet grinding and dispersing Fundamental Considerations Carsten Schilde and Arno Kwade Institute for Particle Technology Technische Universität Braunschweig 03052019 Arno Kwade Fundamental Considerations Seite 2 Content 31 Description of grinding and dispersing results •Product quality •Productions capacityWet grinding and dispersing msmctwutwentenlPharma Cosmetics Pharma Cosmetics Dispersing Homogenizing Wet Grinding DeAerating Laboratory Machines NETZSCHBeads ® Laboratory Tests Seminars Webinars Biotechnology Cosmetics / Personal Hygiene Pharmaceuticals Extremely small batches for Active Pharmaceutical Substances – with the NETZSCH DeltaVita 1 it's now possible!Wet Grinding NETZSCH Grinding Dispersing

Grinding Dispersing WAB Group

Grinding Dispersing Controlled deagglomeration, dispersion and true grinding of solid particles in a liquid medium are the principal objectives of wetmilling technology Particle sizes below 100 nanometres can be achieved, which other grinding techniques can often only achieve with restrictionsWet Grinding Expert Vertical Stirred Bead Mill Without Sieve and Shaft Sealing Sanxing Feirong has developed a vertical bead mill without shaft seal and screen to address the problems faced by traditional horizontal grinding attritors, including the leakage and damage of mechanical seals, blockage of separating mesh, difficulty achieving nanometer particle size, nonuniform particle size, and low grinding Grinding Equipment Systems Grinding MediaPharma Cosmetics Pharma Cosmetics Dispersing Homogenizing Wet Grinding DeAerating Laboratory Machines NETZSCHBeads ® Laboratory Tests Seminars Webinars Biotechnology Cosmetics / Personal Hygiene Pharmaceuticals Extremely small batches for Active Pharmaceutical Substances – with the NETZSCH DeltaVita 1 it's now possible!netzschgrinding NETZSCH Grinding Our marketleading wet grinding and dispersing mills are packed with innovations designed to enhance your overall product quality They reduce production complexity, cut production times and Group Wet Grinding Dispersing LinkedInWet milling with IKA's inline machines is a safe and efficient alternative to dry grinding Dry grinding creates a lot of dust which causes the need for proper filtering systems This can be of particular importance during grinding of substances whose dust, when mixed with aerial oxygen, can result in explosive mixturesWet milling IKA

Wet grinding and dispersing msmctwutwentenl

Wet grinding and dispersing Fundamental Considerations Carsten Schilde and Arno Kwade Institute for Particle Technology Technische Universität Braunschweig 03052019 Arno Kwade Fundamental Considerations Seite 2 Content 31 Description of grinding and dispersing results •Product quality •Productions capacityInnovative wet grinding and dispersing solutions We design and implement solutions tailored to your precise production requirements Working right across the globe, we focus on efficiency, robust design, ease of use and maximum raw material yield to create flexible, economical and robust solutionsWet Grinding and Dispersing Plant Engineering Wet grinding dispersing With over 90 years of experience in wet grinding and dispersing, we have unrivaled expertise in plant and machine solutions across all industries, enabling you to create higher quality products with improved production processes at lower cost Battery solutionsManagement Change Grinding and Dispersing Learn about working at Group Wet Grinding Dispersing Join LinkedIn today for free See who you know at Group Wet Grinding Dispersing, leverage your professional network, and Group Wet Grinding Dispersing Group Wet Grinding Dispersing 871 followers on LinkedIn We offer comprehensive knowhow and deliver tailormade systems to wet grinding and dispersing industries Our marketleading wet grinding and dispersing mills are packed with innovations designed to enhance your overall product quality They reduce production complexity, cut production times and improve energy consumption Group Wet Grinding Dispersing LinkedIn

Wet Grinding Mill,Dry Milling,Inline Disperser

Founded in 2001, PUHLER is Your Specialist for Nano Grinding and Dispersing with an extensive knowhow in the field of dry and wet grinding processes The idea to build a wet grinding mill or a "wet grinding and dispersion processing unit", which do not just do everything but do it more simple wayThe wet grinding mills are suitable for grinding of the particle size range from 100 microns down to submicron (nanometer) Horizontal Disc Type Sand Mill Our JWS series horizontal disc type sand mills are applicable for supper fine wet grinding of powders or granules in liquids with zirconia beads (diameter 03 to 16mm)China Wet Grinding Equipment, Dispersing Wet grinding and dispersing With consumers demanding faster turnaround, personalization, and more ecological options, digital printing is a growing market Our revolutionary digital ink manufacturing solutions give you everything you need to create inks that meet the new printondemand requirements, while improving your productivityDigital Ink Manufacturing Equipment Grinding Wet milling with IKA's inline machines is a safe and efficient alternative to dry grinding Dry grinding creates a lot of dust which causes the need for proper filtering systems This can be of particular importance during grinding of substances whose dust, when mixed with aerial oxygen, can result in explosive mixturesWet milling IKAThis is where the DYNO ®MILL PHARMA wetmilling technology helps: By reducing the particle sizes during wet grinding, the available active ingredient surfaces increase overproportionately strongly and improve the bioavailability of the active ingredientPharmaceutical Industry WAB Group

Wet Grinding Dispersing Archives GAT

We are proud to representing ROOT Asia Co Ltd for their Wet Grinding Dispersing Product Solutions ROOT is the leading solution provider in the field of Wet Grinding, widely used in the fine chemical industrial as well as in research over 20 countries and is one of the largest manufacturers in the world With more than 10 years of providing the solution in wet grinding, Wet grinding and dispering – still a vivid topic! Wet grinding and dispering – still a vivid topic! Kwade, Arno 00:00:00 Editorial From Prof DrIng Arno Kwade, Institute for Particle Technology, Technische Universität Braunschweig Dear Reader, Grinding and dispersing are important unit operations of particle technology which have been practiced Wet grinding and dispering – still a vivid topic Wet grinding machines with nano particles sizes producing besides the direct synthesis of these materials by chemical methods wet grinding in stirred media mills is a suitable method for production of nano particl get a free quote effectively grinding an,Grinding And Dispersing grinding dispersing effectively vablnlUltrasonication is an efficient means for the wetmilling and microgrinding of particles Besides dispersing and deagglomerating, the wet milling is an important application of Hielscher ultrasonic devices In particular for the manufacturing of superfinesize slurries, ultrasound has many advantages, when compared with common size reduction equipment, such as: colloid Ultrasonic WetMilling and MicroGrinding Netzsch Grinding Dispersing was incorporated in the year 2005 as a Private Limited Company We are the manufacturer of Wet Grinding Mill, Dry Grinding Mill, Laboratory Homogenizer, Inline Disperser, Confectionery Machine and many moreWe are also providing Dispersing and Grinding Services All three business units of the NETZSCH zsch Grinding Dispersing Manufacturer

Wet milling IKA

Wet milling with IKA's inline machines is a safe and efficient alternative to dry grinding Dry grinding creates a lot of dust which causes the need for proper filtering systems This can be of particular importance during grinding of substances whose dust, when mixed with aerial oxygen, can result in explosive mixturesIn addition to the production and sale of grinding beads, we are also very intensively involved in process engineering in wet grinding In our production for ceramic beads and in our pilot plant we ourselves work with agitator bead mills and can therefore provide our customers with practical advice and optimise their production processes by means of suitable measuresGrinding/Milling/Dispersing Ceramic Beads NETZSCH Grinding Dispersing offers an extensive machine program for processengineering, providing solutions for wet and dry grinding, mixing, dispersing and deaeration For the formulation of plant protectants, fertilizers and seed treatments using the latest technology, NETZSCH offers sophisticated stateoftheart machines and processes for a variety of ALPHA® – the next Generation in Wet Grinding This is where the DYNO ®MILL PHARMA wetmilling technology helps: By reducing the particle sizes during wet grinding, the available active ingredient surfaces increase overproportionately strongly and improve the bioavailability of the active ingredientPharmaceutical Industry WAB GroupUS manufacturer of wet grinding and dispersing machinery Netzsch Fine Particle Technology said on Friday it has agreed to buy the Premier Mill unit of SPX Corporation (NYSE:SPW), a USbased global manufacturer of specialized engineered solutions, for an undisclosed sum, as a strategic addition to its portfolioWet grinding Article about wet grinding by