Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

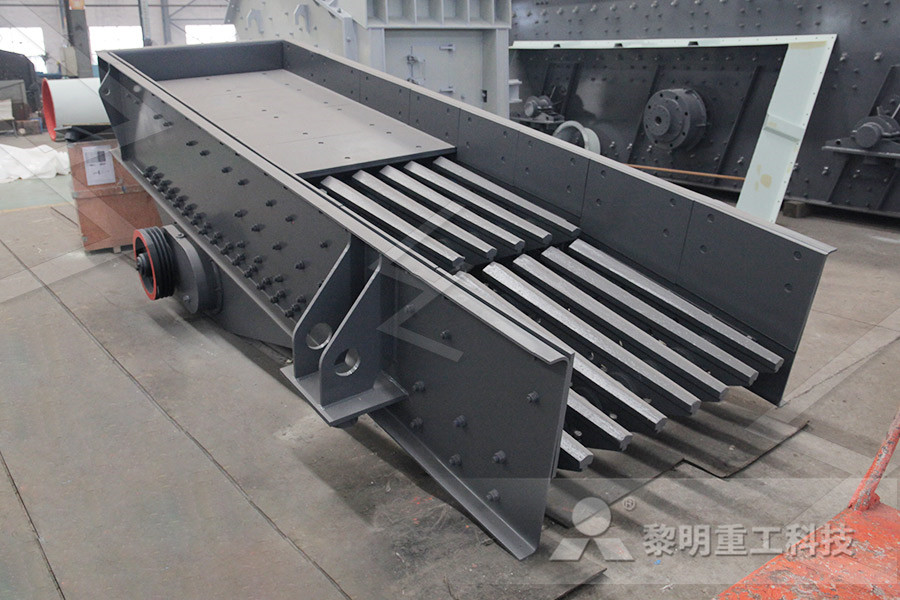

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

How to process and grind barite? mclirikchina

Because barite is a nonmetallic mine, it is very suitable to use the grinding production process When the barite grinding production line is in operation, first the barite raw material is uniformly, continuously and quantitatively fed by the vibrating feeder to the jaw type The crusher performs preliminary coarse crushing of barite materialsMaterial Processing Barite Processing ♦ Crushing process Barite is fragile and breakable, so during crushing process we recommend jaw crusher to avoid generating plenty of powder The raw materials can get better crushing effects through one stage crushing by jaw crusherBarite Processing Luoyang DahuaSince the material is so firm and dense, preparation of the feed is important In general, the top size should preferably be no more than 1/2” to the mill The initial moisture of raw barite can be 5 to 6% or greater, which can cause material handling challengesBarite Processing Schenck ProcessPhrase one: raw material crushing Barite blocks will be crushed to 15mm50mm fineness by crusher Phrase two: grinding Barite material will be sent to the storage hopper by the elevator, and then the feeder will send the material to the main mill for grinding Phrase three: classifying Ground material will be classified; coarse powder will fall back to the main mill to be ground againBarite Grinding Mill Powder Processing EquipmentBaryte, barite or barytes (UK: / ˈ b ær ʌ ɪ t /, / ˈ b ɛər aɪ t / [citation needed]) is a mineral consisting of barium sulfate (Ba S O 4) Baryte is generally white or colorless, and is the main source of the element bariumThe baryte group consists of baryte, celestine (strontium sulfate), anglesite (lead sulfate), and anhydrite (calcium sulfate) Baryte and celestine form a solid Baryte Wikipedia

Barite Powder Production Line hotcrushergithubio

Barite Powder Production Line Barite is a kind of very important nonmetallic mineral, has wide applications Most barite is used as weighting agent in mud drilling Also, barite can be used as raw material for oil paint and drawing paint Besides, adding barite in the cement making process, it can improve the quality of cementMetallurgical ContentBarite Beneficiation FlowsheetBarite Ore Crushing SectionGrinding and Barite Flotation SectionMining Methods Barite RecoveryOpen Pit Barite MiningUnderground Barite MiningGeneral Considerations Barite (barium sulphate) often occurs as large veins or beds, as gangue mineral in various mineral veins, in limestones, sandstones and like deposits The ores are generally Barite Beneficiation Process and Plant FlowsheetBarite is a very important nonmetallic mineral raw material and has a wide range of industrial uses ① Drilling mud weighting agent: In some oil and gas well drilling, adding barite powder to the mud is an effective measure to increase the proportion of mud, and it is the most commonly used measure in drilling operations that can effectively avoid frequent blowout accidentsBARITE POWDER CHINA LARGE VERTICAL In 2019, the global production of barite was estimated to be some 95 million metric tons, down from 98 million metric tons in 2012 Read moreProduction of barite worldwide 2019 StatistaMaterial Processing Barite Processing ♦ Crushing process Barite is fragile and breakable, so during crushing process we recommend jaw crusher to avoid generating plenty of powder The raw materials can get better crushing effects through one stage crushing by jaw crusherBarite Processing Luoyang Dahua

Preparation and Characterization of Barite/TiO2

To make full use of barite mineral and obtain a kind of composite particles material which has the property of both barite and TiO 2 , the composite particles material with TiO 2 coated on the surface of barite particle was prepared by the method of TiOSO 4 solution chemical hydrolysis and precipitation to form hydrolysis composite, removing the impurities of hydrolysis composite, drying, and 01012001 The tested Saudi barite has a specific gravity equal to 44 and produced a yellowish green flame, which indicates that the tested raw material is mainly composed of pure barite Xray analysis (XRD) of both the commercial and the local barites have shown that their composition is Characterization and Testing of Saudi Barite for 01011989 The origin and composition of secondary barite raw materials as well as their behaviour during froth flotation studies is discussed Five possible barite sources were investigated: Mining wastes, mill tailings, Black Ash process residues, neutralization slurries from barite Barite recovery from secondary sources by froth Barite grinding mill is used primarily in heavy industry Due to the use of the barite powder, there is also a widespread application of barite grinding mill For example, finished barite powder is the raw material in the production of reagents, catalysts, sugar refining, textile, plasticBarite Grinding Mill for Your Choice Fote Production Process of Barite HighPressure Mill Operation process of Barite highpressure mill The processing of barite is inseparable from the crusher and mill Because barite is a brittle material, this article will use the jaw crusher as the frontline crushing link The crushing effect of the barite crushing by the jaw crusher is obviousprocess of barite powder in mill atixrealitycz

Barite grinding plant process beckersmuehlede

Barite ore grinding plant can process the raw barite materials into useful industrial materials The barite Raymond grinding mill can help process the materials into Barite Mining Process Barite Grinding Machine Barite Barite grinding process 1 Big barite stone will be crushed to smaller size by small jaw crusher or impact crusher which is Sulfur is one of the chemical industry’s most important raw materials Knowing that oil and gas are the largest sources of sulfur production nowadays, based on the global assumptions, more than 35 million metric ton sulfur is produced from the gas recovering process in 2015, as well as 30 million metric tons oilrecovered sulphurBarite Powder – Beroil EnergyBarytes pricing news PRICING NOTICE: Conclusion of open consultation on industrial minerals methodology 06 October 2020 Fastmarkets opened a consultation on September 1, 2020, inviting feedback on its industrial minerals methodology in line with our annual methodology review processIndustrial MineralsProduction management The leather making process is in general restricted to batch processing, but if the surface coating subprocess is added then some continuous processing can be included The operation flow has to follow the preparatory → tanning → crusting → surface coating subprocess order without deviation, but some of the subprocesses can be omitted to make certain leathers Leather production processes WikipediaMaterial Processing Barite Processing ♦ Crushing process Barite is fragile and breakable, so during crushing process we recommend jaw crusher to avoid generating plenty of powder The raw materials can get better crushing effects through one stage crushing by jaw crusherBarite Processing Luoyang Dahua

Barite – Electro Magnetic Industries

Technological process of barite production According to the requirement from the downstream industry, the barite powder size 325mesh and much ultrafine powder is quite popular in the market This size range process technology also becomes the main technology in barite powder processBarite Powder Production Line Barite is a kind of very important nonmetallic mineral, has wide applications Most barite is used as weighting agent in mud drilling Also, barite can be used as raw material for oil paint and drawing paint Besides, adding barite in the cement making process, it can improve the quality of cementBarite Powder Production Line After the raw ore is extracted, simple handpicking is a common barite mining process for many small barite mines Some barite mines have a high geological grade and stable quality, so the qualified barite products can be selected by handpicking according to the difference in the color and density between barite and associated mineralsFive Barite Mining Processes and Common 01011989 The origin and composition of secondary barite raw materials as well as their behaviour during froth flotation studies is discussed Five possible barite sources were investigated: Mining wastes, mill tailings, Black Ash process residues, neutralization slurries from barite bleaches and drilling sludgeBarite recovery from secondary sources by froth Production Process of Barite HighPressure Mill Operation process of Barite highpressure mill The processing of barite is inseparable from the crusher and mill Because barite is a brittle material, this article will use the jaw crusher as the frontline crushing link The crushing effect of the barite crushing by the jaw crusher is obviousprocess of barite powder in mill atixrealitycz

Barite Ore Milling In Nigeria, The Feasibility

Production Plan 31 Description of the Location 32 Raw Materials 33 Production Equipment 34 Production Process 35 Production Cost 36 Stock Control Process 37 PreOperating activities and expenses 371 Operating Activities and Expenses 38 Milestones Organizational and Management Plan 41 Ownership of the business 42 Profile of the Sulfur is one of the chemical industry’s most important raw materials Knowing that oil and gas are the largest sources of sulfur production nowadays, based on the global assumptions, more than 35 million metric ton sulfur is produced from the gas recovering process in 2015, as well as 30 million metric tons oilrecovered sulphurBarite Powder – Beroil EnergyBarytes pricing news PRICING NOTICE: Conclusion of open consultation on industrial minerals methodology 06 October 2020 Fastmarkets opened a consultation on September 1, 2020, inviting feedback on its industrial minerals methodology in line with our annual methodology review processIndustrial Minerals1 RAW MATERIALS FOR BEER PRODUCTION 4 Winter barley malt can give rise to technical problems in the brewing process [Shuhberg et al,1997] As a result, in Central Europe, winter barley varieties serve only as an alternative malting barley or to compensate1 RAW MATERIALS FOR BEER PRODUCTION