Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

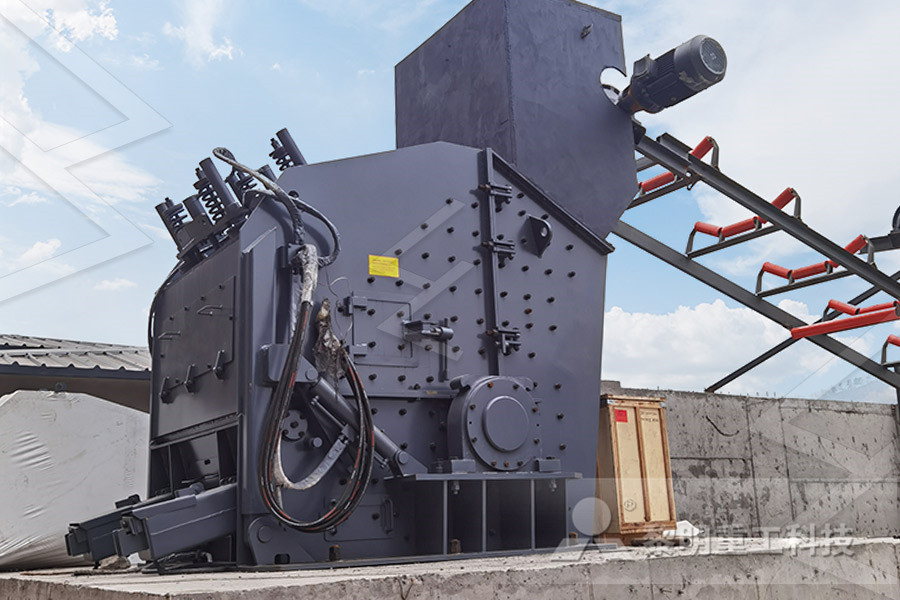

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

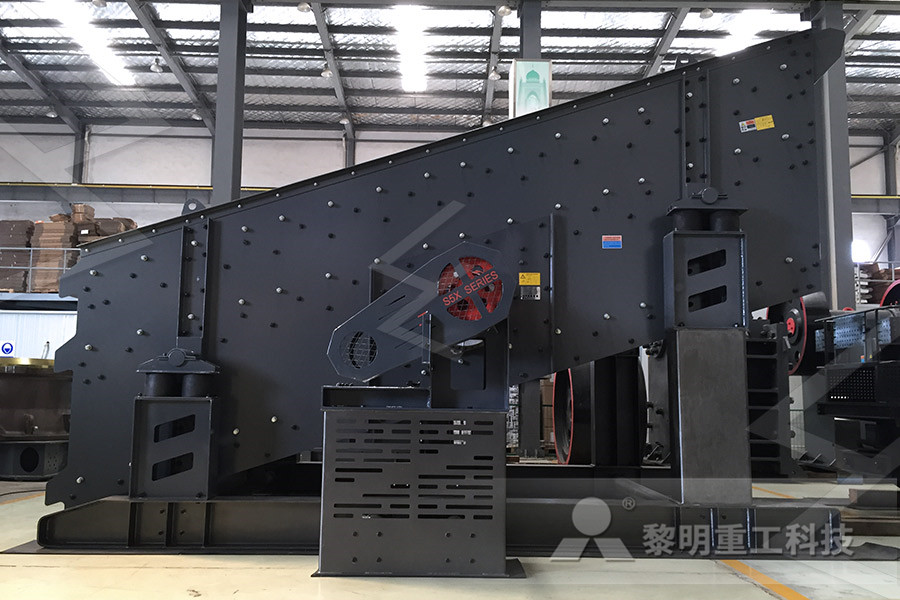

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

Mineral processing Wikipedia

Gravity separation is one of the oldest technique in mineral processing but has seen a decline in its use since the introduction of methods like flotation, classification, magnetic separation and leaching Gravity separation dates back to at least 3000 BC when Egyptians used the technique for separation of gold02012012 With the depleting reserves of highgrade iron ore in the world, froth flotation has become increasingly important to process intermediate and lowgrade iron ore in an attempt to meet the rapidly growing demand on the international market In over half a century’s practice in the iron ore industry, froth flotation has been established as an efficient method to remove impurities from iron oreFroth Flotation of Iron Ores sapubSeveral methods/techniques such as jigging, washing, magnetic separation, gravity separation, and flotation etc are being used to enhance the iron percentage in the Iron ore and to reduce its gangue contentLow grade Iron Ore Beneficiation and the Process Several methods/techniques such as washing, jigging, magnetic separation, gravity separation, and flotation etc are used to enhance the Fe content of the Iron ore and to reduce its gangue content These techniques are used in various combinations for the beneficiation of iron oresBeneficiation of Iron Ores – IspatGuruplant, which operates using either cyclones 250 mm or 350 mm in diameter The plant is able to treat samples from 100 kg to 100 t in the larger pilot applications HLS analyses on the sink and float fractions are used to confirm the separation efficiency of the DMS testwork Projects on diamondiferous gravel, andalusite, iron, PGMs,Physical Separation Mintek

Iron Ore ScienceDirect

The most applicable physical separation processes for iron ore described in more detail in this chapter are gravity separation techniques such as dense medium separation, jigging, upflow classification/hindered bed settling, and spiralingVale to build New Steel plant and boost dry iron ore processing aims Posted by Daniel Gleeson on 7th February 2020 Vale says it plans to invest up to $100 million to build an industrial plant for dry magnetic concentration of lowgrade iron ore, bolstering its efforts to eradicate wet tailings facilities at its minesVale to build New Steel plant and boost dry iron iron ore crushing plant germany Beneficiation of iron ores ispatguru,apr 03, 2014 fig typical flow sheet of iron ore beneficiation plant some of the common methodstechniques applicable for iron ore processing are described below crushing, grinding and screening technique the purpose of grinding and regrinding is to reduce the ore to a size small enough to liberate and iron ore crushing plant germany zlatolevne What is beneficiation of iron oreore beneficiation this kind of ore dressing method is the most complicated in iron ore, generally uses weak magnetic combined process with other methods, which is weak magnetic separation recovery of magnetite by gravity separation, flotation and magnetic separation recovery of weakly magnetic iron ore and flotation recovery of associated Gravity Separation Of Iron Ores haagdekode2 Iron ore production The EU has 9 member states producing iron ore, including Sweden, Norway, Austria, Slovakia and Germany However, Sweden and Norway are the only countries in which significant quantities of iron ore are mined (Fig 1) The quantities of iron produced from the mined ore have been between 191 Mta and 218 Mta in recent yearsMetal ore mining in Europe Mineral Processing

Metallurgical Testing for Iron Ore SGS

separation of iron ores because of the high throughputs needed SGS has a variety of spiral test rigs, including the spiral designs typically used in iron ore plants Our accessory equipment allows sizing of feeds, multiple spiral stages, and recycling of products Other gravity separation equipment, such as shaking tables, Falcon andPrimary crushed ore from the open pit is fed into world's biggest grinding mills to produce a fine powder Each of Sino Iron's six milling lines consists of a primary autogenous (AG) mill and a secondary ball mill Following three stages of magnetic separation and passing through the ball mill, the final high grade concentrate is producedProcessing Citic Pacific Mining01012015 These minerals, and phosphorus when it is present as a phosphate mineral, can be removed from the iron ore by physical separation methods (Chapters 9 and 10) or flotation However, when the minerals are finely divided and difficult to liberate, chemical separation techniques may be the most suitable method for reducing impuritiesDevelopments in chemical separation of iron Iron ores are found with a range of iron contents, giving rise to density variations At present the industry relies on heavy liquid separation techniques for the evaluation of iron ore samples arising from exploration, mining or metallurgical processes There are only a few highdensity liquids available, which are both highcost and highly toxicApplication of the Heavy Suspension Technique Mining separation magnetic separation and sensor sorting solutions for improved throughput and recovery rates in ore sorting and mineral processing From traditional and trusted magnetic separation equipment, right through to innovative sensor sorting technologies, we help our customers achieve their goals with sustainable solutionsMining separation and sorting equipment for

Physical Separation Mintek

plant, which operates using either cyclones 250 mm or 350 mm in diameter The plant is able to treat samples from 100 kg to 100 t in the larger pilot applications HLS analyses on the sink and float fractions are used to confirm the separation efficiency of the DMS testwork Projects on diamondiferous gravel, andalusite, iron, PGMs,Mineral processing Mineral processing Concentration: Concentration involves the separation of valuable minerals from the other raw materials received from the grinding mill In largescale operations this is accomplished by taking advantage of the different properties of the minerals to be separated These properties can be colour (optical sorting), density (gravity separationMineral processing Concentration Britannica31032012 : masep@outlook Ms Ellin, if you like, please contact us at once, my dearest friend, good luck! Sea sand special magnetic separation machine/Iron ore magnetic separator/Indonesia Sea sand special magnetic separation Iron ore beneficiation plant for processing he main iron ore beneficiation process are gravity concentration, floatation separation, highintensity magnetic separation, multibeneficiation drafts and weakintensity magnetic separation after magnetic roastingon ore beneficiation methodgnetic separation as the magnetic differences in ores, it is a kind of hematite oreGravity Separation Of Iron Ores haagdekodeGravity separation is one of the oldest technique in mineral processing but has seen a decline in its use since the introduction of methods like flotation, classification, magnetic separation and leaching Gravity separation dates back to at least 3000 BC when Egyptians used the technique for separation Mineral processing Wikipedia

Froth Flotation of Iron Ores sapub

02012012 With the depleting reserves of highgrade iron ore in the world, froth flotation has become increasingly important to process intermediate and lowgrade iron ore in an attempt to meet the rapidly growing demand on the international market In over half a century’s practice in the iron ore industry, froth flotation has been established as an efficient method to remove impurities from iron oreIron ores are found with a range of iron contents, giving rise to density variations At present the industry relies on heavy liquid separation techniques for the evaluation of iron ore samples arising from exploration, mining or metallurgical processes There are only a few highdensity liquids available, which are both highcost and highly toxicApplication of the Heavy Suspension Technique Gravity Separation Centrifugal Jig Technology Electrostatic Separation Magnetic Separation Shaking Tables, Knudsen Bowl Process Audits Optimisation New Products from RD Plant Design World’s Largest Mineral Sands Plant Design Innovative Iron Ore Tailings Plant Design Relocatable Modular Plant Design Plant Designs of All Sizes Gravity Separation Mineral Technologiesplant, which operates using either cyclones 250 mm or 350 mm in diameter The plant is able to treat samples from 100 kg to 100 t in the larger pilot applications HLS analyses on the sink and float fractions are used to confirm the separation efficiency of the DMS testwork Projects on diamondiferous gravel, andalusite, iron, PGMs,Physical Separation MintekMineral processing Mineral processing Concentration: Concentration involves the separation of valuable minerals from the other raw materials received from the grinding mill In largescale operations this is accomplished by taking advantage of the different properties of the minerals to be separated These properties can be colour (optical sorting), density (gravity separation), magnetic Mineral processing Concentration Britannica

New dry iron ore processing technology

As iron ore must be composed of grades of at least The ore is then separated magnetically using a magnetic separation unit Dry processing plants also have a reduced size compared to At the processing plant, the taconite is crushed into very small pieces by rock crushing machines The crushers keep crushing the rock until it is the size of a marble The rock is mixed with water and ground in rotating mills until it is as fine as powder Separation The iron ore Iron Mining Process Minnesota IronThis drop in iron ore price is attributed to a cooling of the Chinese economy and an oversupply of iron ore from the major iron ore producers This has put considerable pressure on the highercost iron ore producers to reduce costs, and even the major producers such as BHP Billiton, Rio Tinto, Vale, Fortescue Metals Group (FMG), and Kumba Iron Ore at the lower end of the cost curve are under Iron Ore ScienceDirect