Solutions

Products

-

Primary mobile crushing plant

-

Independent operating combined mobile crushing station

-

Mobile secondary crushing plant

-

Fine crushing and screening mobile station

-

Fine crushing & washing mobile station

-

Three combinations mobile crushing plant

-

Four combinations mobile crushing plant

-

HGT gyratory crusher

-

C6X series jaw crusher

-

JC series jaw crusher

-

Jaw crusher

-

HJ series jaw crusher

-

CI5X series impact crusher

-

Primary impact crusher

-

Secondary impact crusher

-

Impact crusher

-

HPT series hydraulic cone crusher

-

HST hydraulic cone crusher

-

CS cone crusher

-

VSI6S vertical shaft impact crusher

-

Deep rotor vsi crusher

-

B series vsi crusher

-

Vertical grinding mill

-

Ultra fine vertical grinding mill

-

MTW european grinding mill

-

MB5X158 pendulum suspension grinding mill

-

Trapezium mill

-

T130X super-fine grinding mill

-

Micro powder mill

-

European hammer mill

-

Raymond mill

-

Ball mill

-

GF series feeder

-

FH heavy vibrating feeder

-

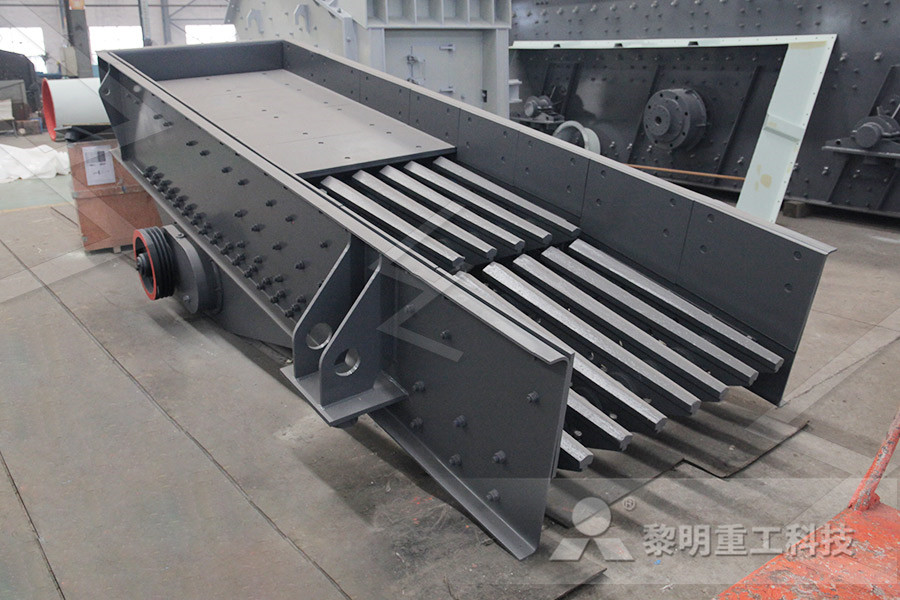

TSW series vibrating feeder

-

Vibrating feeder

-

Vibrating screen

-

S5X vibrating screen

-

Belt conveyor

-

Wheel sand washing machine

-

Screw sand washing machine

-

Rod mill

-

Dryer

-

Rotary kiln

-

Wet magnetic separator

-

High gradient magnetic separator

-

Dry magnetic separator

-

Flotation machine

-

Electromagnetic vibrating feeder

-

High frequency screen

The Kinetics of Calcination of High Calcium Limestone

R’T {(1/r *) 1 + (D/ kgro) Where D = diffusivity of lime layer cm2 sec1 Kg = mass transfer coefficient [PCO2]R = partial pressure of CO2 at reaction front atm [PCO2]G = partial pressure of CO2 in the bulk gas R’ = universal gas constant in mechanical terms cm2 atmgmole1k Equation (4) can be rearranged in the formA L Campbell, A R Job, and J F Robertson, Lime calcination: time and temperature of calcination expressed as a single variable and the effect of selected impurities on lime properties Zement Ralk Gips 9, 442(1988) Google ScholarLime Calcination SpringerLinkAfter calcination, pastes containing 50% calcium hydroxide and 50% burnt sludge were hydrated and the lime consumption investigated by differential thermal analysisLime Calcination Request PDF01042001 The most reactive quicklime is obtained by calcination of L S and for a calcination temperature of 900°C Traditional limekilns, using wood and charcoal as fuel, acquired this range of temperature (850–900°C) and it seems to be the primary reason of producing highquality limeThe effects of limestone characteristics and 10122019 Lime production represents the second largest contributor to industrial CO 2 emission in China, but it has not been well addressed Herein, an efficient and environmentfriendly Limestone Calcination Process with CO 2 Looping and Recovery (LCPCLR) is established to solve the associated environment issue CO 2 serves as heat carrier in the An environmentfriendly process for limestone

Novel Lime Calcination System for CO2 Capture

By assuming that the lime particles are spherical and the temperature from the surface to the center is linearly distributed (Iliuta et al pointed out that the temperature within the lime particle is slightly different from a linear distribution), then, according to the conservation of energy, T b satisfies the following formula where r is the radial coordinate and r 0 is the radius of the lime The most reliable factors for the estimation of lime reactivity are the specific surface area, porosity and hydration rate (T60) of the lime and the temperature during the calcination process The Effects of Limestone Characteristics and The process of calcination derives its name from the Latin calcinare (to burn lime) due to its most common application, the decomposition of calcium carbonate (limestone) to calcium oxide (lime) and carbon dioxide, in order to create cement The product of calcination is usually referred to in general as "calcine", regardless of the actual minerals undergoing thermal treatment Calcination is carried out in furnaces or reactors (sometimes referred to as kilnsor calciners) of various desigCalcination Wikipedia18102018 The Cimprogetti's TSR kilns utilizes the regenerative process for lime calcinationThe TSR kilns currently represent the best option for high and mediumreaRegenerative process for lime calcination (2012, 10122019 Lime production represents the second largest contributor to industrial CO 2 emission in China, but it has not been well addressed Herein, an efficient and environmentfriendly Limestone Calcination Process with CO 2 Looping and Recovery (LCPCLR) is established to solve the associated environment issue CO 2 serves as heat carrier in the An environmentfriendly process for limestone

Lime calcination Radarbolaget

Measure the calcination in burned lime online and on different places at a shaft furnace Measurement principle of calcination in limestone calcium oxide (burnt lime) has lower density than calcium carbonate (limestone), which makes radio waves to propagate faster through burnt lime:Experiments were made to define quantitatively the effects and interactions of the time of calcination, the temperature of calcination, and the particle size of a pure limestone upon the properties of the calcine that may affect the absorption of sulfur dioxide from flue gasesEffects of Calcination Conditions on the Review—calcination and carbonation of limestone during thermal cycling for CO 2 sequestration BR Stanmore, P Gilot* Laboratoire Gestion des Risques et Environnement, 25 rue de Chemnitz, 68200 Mulhouse, France Received 1 July 2004; accepted 1 January 2005 Abstract Some aspects of using lime from limestone to sequester CO 2 from combustion Review Review—calcination and carbonation of limestone EWC Code: 10 13 04 wastes from calcination and hydration of lime Type: Absolute Nonhazardous Waste Desc: Lime, Limestone, Calcium Oxide, Calcium Hydroxide, Quicklime , European Waste Catalogue Code, Waste Code, List of Waste Code10 13 04 – wastes from calcination and A lime kiln is a kiln used for the calcination of limestone (calcium carbonate) to produce the form of lime called quicklime (calcium oxide)The chemical equation for this reaction is CaCO 3 + heat → CaO + CO 2 This reaction takes place at 900 °C (1,650 °F) (at which temperature the partial pressure of CO 2 is 1 atmosphere), but a temperature around 1000 °C (1800 °F; at Lime kiln Wikipedia

Daswell Lime Calcination Plant Turnkey

Daswell Lime Processing Plant Supplier Henan Daswell machinery is a leading designer and manufacturer in mineral processing, such as calcium carbonate plant, quicklime plant, slaked lime plant and silica processing plantDaswell has professional workers and expertise, who are dedicated to providing tailored solutions for mineral processing plant and making quality Andrew R Firth, John F Garden, Interactions between Magnetite Oxidation and Flux Calcination during Iron Ore Pellet Induration, Metallurgical and Materials Transactions B, 101007/s1166300891626, 39, 4, (524533), (2008)Calcination kinetics and surface area of dispersed In a RD centre, both the clay and cement produced from it are subjected to a series of trials More than 30 different materials have been tested for initial feasibility and processing properties and activated in a muffle furnace, often followed by activation tests in a proprietary pilot (50 kg/hr) or semiindustrial (500 kg/hr) facilityIntroducing activated clays on an Cement 01072017 (26) d d t ∫ V ε s ρ g Y i d V = − ∮ A (ε s ρ g v → g Y i − ε s ρ g D i, e f f ∇ Y i) ⋅ n → d A + ∫ V S i, R d V S i,R is the net rate of production of species i by chemical reaction, i e relevant for CO 2 released by calcination (see Eq in section 334) The first term on the right hand side accounts for advection 3DDEMCFD simulation of heat and mass STP472: Effects of Calcination Conditions on the Properties of Lime Author Information: Mullins, R C Research chemists, Tennessee Valley Authority, Muscle Shoals, AlaEffects of Calcination Conditions on the

Effects of Calcination Conditions on the Properties

Experiments were made to define quantitatively the effects and interactions of the time of calcination, the temperature of calcination, and the particle size of a pure limestone upon the properties of the calcine that may affect the absorption of sulfur dioxide from flue gasesA lime kiln is a kiln used for the calcination of limestone (calcium carbonate) to produce the form of lime called quicklime (calcium oxide)The chemical equation for this reaction is CaCO 3 + heat → CaO + CO 2 This reaction takes place at 900 °C (1,650 °F) (at which temperature the partial pressure of CO 2 is 1 atmosphere), but a temperature around 1000 °C (1800 °F; at which Lime kiln WikipediaEWC Code: 10 13 04 wastes from calcination and hydration of lime Type: Absolute Nonhazardous Waste Desc: Lime, Limestone, Calcium Oxide, Calcium Hydroxide, Quicklime , European Waste Catalogue Code, Waste Code, List of Waste Code10 13 04 – wastes from calcination and Calcination refers to heating a solid to high temperatures in absence of air or oxygen, generally for the purpose of removing impurities or volatile substances However, calcination is also used to mean a thermal treatment process in the absence or limited supply of air or oxygen applied to ores and other solid materials to bring about a thermal decompositionCalcination WikipediaDaswell Lime Processing Plant Supplier Henan Daswell machinery is a leading designer and manufacturer in mineral processing, such as calcium carbonate plant, quicklime plant, slaked lime plant and silica processing plantDaswell has professional workers and expertise, who are dedicated to providing tailored solutions for mineral processing plant and making quality machineryDaswell Lime Calcination Plant Turnkey

Calcination kinetics and surface area of dispersed

Andrew R Firth, John F Garden, Interactions between Magnetite Oxidation and Flux Calcination during Iron Ore Pellet Induration, Metallurgical and Materials Transactions B, 101007/s1166300891626, 39, 4, (524533), (2008)A high correlation between the standard operational procedurefor the quality control of calcined kaolin and the Kx index was observed (r = 089), as well as with the 1900D parameter (r = 096) This study offers a new conceptual approach to the use of SWIR spectroscopy for the characterization the calcination of kaolin, withdrawing the need of using extensive laboratory techniquesTowards an Online Characterisation of Kaolin Trouver calcination de la chaux usine en Chine, calcination de la chaux Liste d'usine dont vous pouvez acheter des produits directement Nous vous offrons une grande liste de Chinois fiables calcination de la chaux usines / fabricants, fournisseurs, exportateurs ou calcination de la chaux Usine, Chine calcination Calcination rotary kiln china for sale There are forty years of manufacturing history with three major production bases over 160 senior R D engineers and 600+ large and medium sized digital processing equipment The first line technicians and professional after sales service personnel up to 2 300+ and 200+ respectively Introducing advanced technology and craftsmanship adopting internationalCalcination Lime Burning Equipment Kiln Supplier